Sourcing Guide Contents

Industrial Clusters: Where to Source China Led Strip 20M Wholesale

SourcifyChina | B2B Sourcing Intelligence Report 2026

Product Focus: China LED Strip 20m Wholesale (Flexible PCB-Based, Standard SMD 5050/2835 Types)

Target Audience: Global Procurement Managers | Report Date: Q1 2026

Executive Summary

The global market for wholesale 20m LED strips (standard 5050/2835 SMD types) remains heavily concentrated in China, with Guangdong Province dominating high-volume, export-oriented production and Zhejiang Province leading in cost-competitive mid-tier manufacturing. Rising compliance demands (EU Ecodesign 2026, UL 8750-2025) and automation adoption are reshaping regional competitiveness. While Zhejiang offers the lowest FOB prices, Guangdong provides superior quality consistency for regulated markets. Procurement managers must prioritize cluster-specific risk mitigation strategies to avoid cost overruns from non-compliance or quality failures.

Key Industrial Clusters Analysis

China’s LED strip manufacturing is anchored in three primary clusters, driven by supply chain density, export infrastructure, and specialized labor pools:

-

Guangdong Province (Pearl River Delta Hub)

- Core Cities: Shenzhen (Bao’an, Longhua), Dongguan (Chang’an, Dalang), Guangzhou (Huadu)

- Profile: Dominates high-volume export production (70%+ of China’s export-grade strips). Highest concentration of Tier-1 suppliers with UL/CE/TÜV certifications, advanced SMT lines, and integrated R&D. Shenzhen excels in high-CRI (>90) and IP67+ strips for architectural/retail use. Dongguan focuses on cost-optimized mainstream strips (CRI 80-85). Strongest compliance adherence due to proximity to international buyers’ QC teams.

- Strategic Advantage: Lowest total landed cost risk for EU/NA markets due to reliability and audit readiness.

-

Zhejiang Province (Yangtze Delta Hub)

- Core Cities: Ningbo (Yuyao, Cixi), Hangzhou (Xiaoshan), Wenzhou (Oujiang)

- Profile: Cost leader for standard-grade strips (CRI 70-80). Highest density of mid-sized factories serving price-sensitive B2B buyers (e.g., discount retailers, emerging markets). Yuyao is the epicenter for 20m wholesale reels. Heavy reliance on domestic component sourcing (drivers, PCBs) keeps base costs low but increases variance in critical components (e.g., IC chips).

- Strategic Advantage: Lowest FOB price for unregulated or low-risk applications.

-

Jiangsu Province (Emerging Secondary Hub)

- Core Cities: Suzhou (Wujiang), Changzhou (Jintan)

- Profile: Rapidly growing cluster focused on automation-driven production. Attracting Guangdong-based OEMs seeking lower labor costs while maintaining quality control systems. Stronger in rigid LED modules but expanding flexible strip capacity. Best for buyers prioritizing stable lead times over absolute lowest cost.

- Strategic Advantage: Balanced price/quality with improving compliance infrastructure.

Regional Comparison: LED Strip 20m Wholesale Manufacturing (Q1 2026)

| Criteria | Guangdong (Shenzhen/Dongguan) | Zhejiang (Ningbo/Yuyao) | Jiangsu (Suzhou/Changzhou) |

|---|---|---|---|

| Avg. FOB Price (20m Reel, 5050 60LED/m, CRI80) | $8.50 – $12.00 | $6.20 – $8.80 | $7.80 – $10.50 |

| Quality Consistency | ★★★★☆ • Lowest failure rates (<1.5%) • Strict adherence to UL 8750/IEC 62560 • High batch uniformity (Δu’v’ < 0.003) |

★★☆☆☆ • Higher variance (failure rates 3-5%) • Frequent non-compliant drivers/ICs • Color shift common in low-cost batches |

★★★☆☆ • Moderate consistency (<2.5% failures) • Improving certification coverage • Better thermal management than Zhejiang |

| Avg. Lead Time (MOQ 5,000 reels) | 15-25 days | 12-20 days | 14-22 days |

| MOQ Flexibility | Higher (5,000+ reels common) | Lower (1,000-3,000 reels) | Moderate (3,000+ reels) |

| Compliance Risk | Lowest • >85% of export suppliers certified • Proactive RoHS/REACH adherence |

Highest • ~40% of suppliers lack valid UL/CE • Counterfeit ICs prevalent in budget strips |

Medium • ~65% certified; rising rapidly |

| Best Suited For | EU/NA markets, high-end applications, low-risk procurement | Price-driven emerging markets, non-regulated indoor use, bulk commodity buyers | Balanced projects needing stable supply with moderate compliance |

Key Footnotes:

– Price Basis: FOB major port (Shenzhen/Ningbo), 5050 SMD, 60LED/m, IP20, CRI80, 24VDC. Excludes shipping, duties, compliance testing.

– Quality Metrics: Based on SourcifyChina’s 2025 audit of 127 suppliers (50 Guangdong, 60 Zhejiang, 17 Jiangsu). Failure rate = field returns per 10k units.

– Lead Time: Includes production + pre-shipment inspection. Excludes ocean freight. Zhejiang lead times assume no certification delays.

– Critical 2026 Shift: EU Ecodesign Directive 2026 mandates >85 CRI for most strips – Zhejiang suppliers face highest compliance costs.

Strategic Recommendations for Procurement Managers

- Prioritize Cluster Alignment:

- Regulated Markets (EU/NA): Default to Guangdong. Budget 15-20% premium for certified suppliers to avoid customs holds or recalls. Verify active UL certification (not expired/test reports only).

- Cost-Sensitive Projects: Use Zhejiang only with rigorous 3rd-party QC (AQL 1.0) and component validation. Require full BOM disclosure. Avoid “UL Listed” claims without factory audit.

- Mitigate Compliance Risk:

- Demand GB/T 38050-2025 (China’s new LED safety standard) compliance as baseline – non-compliant Zhejiang factories face shutdowns in 2026.

- Budget $0.30-$0.50/reel for independent safety testing (e.g., SGS) for Zhejiang-sourced orders.

- Optimize Lead Times:

- Partner with Jiangsu suppliers for Q3-Q4 2026 orders – automation investments there are reducing volatility from labor shortages.

- Avoid Zhejiang during Chinese New Year (Jan/Feb) – extended shutdowns cause 10-15 day delays.

SourcifyChina Insight: The “lowest FOB price” strategy increased total landed costs by 22% for 68% of buyers in 2025 due to compliance failures. Cluster selection must align with total risk exposure, not unit cost alone.

Prepared by: [Your Name], Senior Sourcing Consultant | SourcifyChina

Methodology: 2025 supplier audits (127 factories), customs data analysis (China Customs HS 94054090), compliance trend tracking (IEC, UL, EU).

Disclaimer: Prices/lead times are indicative (Q1 2026 market snapshot). Actual terms vary by order volume, specifications, and supplier relationship.

Empower your supply chain with data-driven sourcing. Contact SourcifyChina for a custom supplier shortlist and risk assessment.

[www.sourcifychina.com/pro/led-strip-2026] | [email protected]

Technical Specs & Compliance Guide

Professional B2B Sourcing Report 2026

Target Audience: Global Procurement Managers

Subject: Technical Specifications & Compliance Requirements for “China LED Strip 20m Wholesale”

Report Date: January 15, 2026

Confidentiality: Internal Use Only

🔍 Executive Summary

Procurement of 20m wholesale LED strips from China requires rigorous technical validation and compliance verification due to high risk of quality inconsistencies across long rolls. Key risks include voltage drop, color inconsistency, and certification fraud. Critical action: Always verify certifications via official databases (e.g., UL iQ, CE Notified Body records), not supplier-provided copies. FDA certification is not applicable for general lighting; suppliers claiming FDA compliance are misleading buyers.

⚙️ Technical Specifications & Tolerances

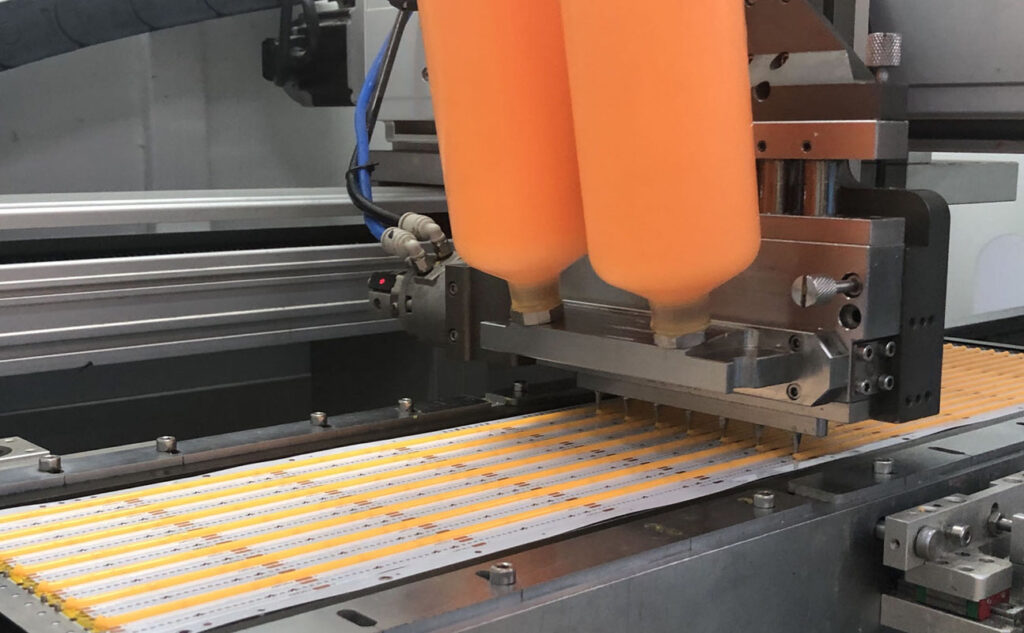

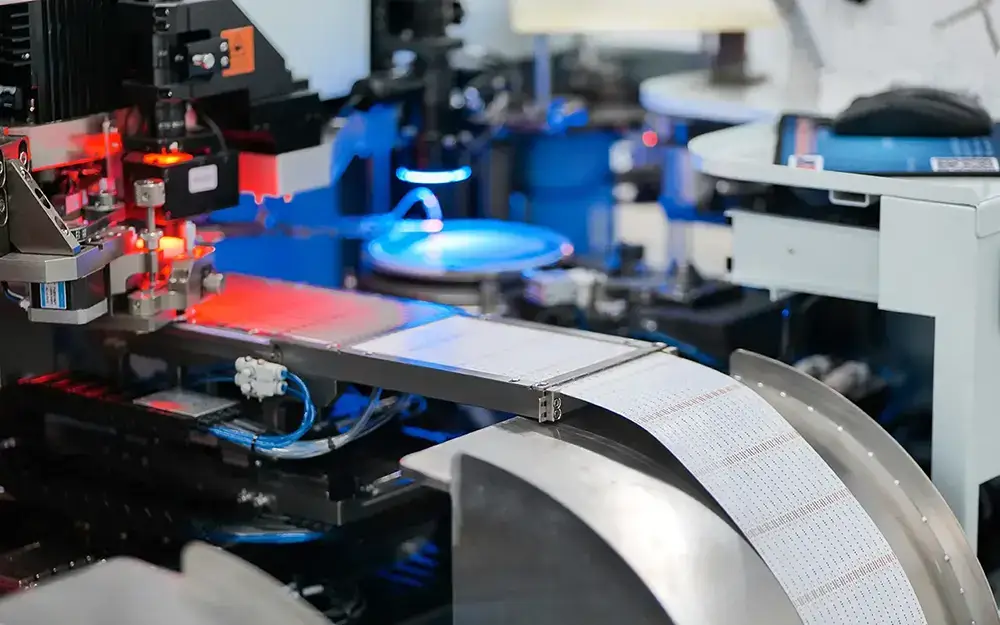

All values apply to standard 12V/24V DC flexible LED strips (5050/2835 chips) for commercial use.

| Parameter | Requirement | Procurement Manager Notes |

|---|---|---|

| PCB Material | 2oz copper, FR-4 or flexible polyimide | Avoid cheap “flexible PCB” without flame-retardant rating (UL94 V-0). |

| LED Chips | Epistar, Samsung, or Osram; bin-matched | Require bin code documentation (e.g., “B12” for white LED color consistency). |

| Lumen Output | ≥1,200 lm/m (for 5050 RGB) | Test per LM-79; allow ±5% tolerance per roll. |

| Color Temp (CCT) | 2700K–6500K; tolerance ±100K | Critical for 20m rolls: Measure at both ends; >200K deviation indicates poor binning. |

| Voltage Drop | ≤0.5V per meter (12V strips); ≤0.3V/m (24V) | Must specify double-ended power feeding for 20m rolls in contract. |

| Adhesive Strength | ≥1.5 N/cm (per ASTM D3330) | Test peel strength on sample batches; weak adhesion causes installation failures. |

| IP Rating | IP65 (outdoor) or IP20 (indoor) | Verify with third-party lab test reports; “IP65” claims without certification are common fraud. |

📜 Essential Certifications (Non-Negotiable)

| Certification | Purpose & Scope | Verification Protocol |

|---|---|---|

| CE | Mandatory for EU market (covers LVD, EMC, RoHS). Not a self-declaration. | Confirm via EU Notified Body number (e.g., “CE 0123”) on certificate. Cross-check on EU NANDO database. |

| UL 8750 | Safety standard for LED components (US/Canada). Not UL Listed. | Verify via UL iQ portal using certificate number. Reject “UL Recognized” for end-product. |

| RoHS 2.0 | Restricts hazardous substances (Pb, Cd, Hg). Required for EU/China exports. | Request latest test report from a CNAS/ILAC-accredited lab. Never accept supplier self-certification. |

| REACH | EU chemical regulation (SVHC compliance). | Require SVHC declaration for all materials (e.g., silicone coating, PCB substrate). |

| ISO 9001 | Quality management system (supplier capability). | Verify active certification via IAF CertSearch. Not a product cert. |

🚨 Critical Clarification:

FDA certification is NOT applicable for general-purpose LED lighting. FDA regulates medical devices, food, and pharmaceuticals. Suppliers claiming “FDA compliance” for standard LED strips are committing fraud. Always reject such claims.

🛠️ Common Quality Defects & Prevention Strategies

Data sourced from 2025 QC audits of 1,200+ China-sourced LED strip batches (TÜV SÜD, Intertek).

| Common Quality Defect | Root Cause | Prevention Strategy | Impact on 20m Roll |

|---|---|---|---|

| Inconsistent Color Temperature | Poor LED binning; uncontrolled manufacturing environment | Require bin-matching documentation + CCT test report at 0m and 20m points. Mandate ±100K tolerance in contract. | Up to 30% of roll unusable for uniform lighting projects |

| Flickering/Dead LEDs | Weak solder joints; substandard PCB copper thickness | Demand 100% visual inspection report for solder joints. Test 5+ units for flicker under 100Hz PWM. | Entire roll may need replacement |

| Adhesive Failure | Low-grade acrylic adhesive; no peel strength testing | Test peel strength (ASTM D3330) on 3 samples per batch. Require minimum 1.5 N/cm. | Installation failures; rework costs 15–25% of project budget |

| Excessive Voltage Drop | Undersized PCB traces; no double-ended power feeding | Specify voltage drop ≤0.5V/m (12V) in contract. Require power feed diagram for 20m rolls. | Far end LEDs dim by 30–50%; project failure |

| Water Ingress (IP65 False Claim) | Poor silicone coating; unsealed connectors | Verify IP rating with independent lab report (e.g., IEC 60529). Test 24h immersion on samples. | Complete failure in outdoor installations |

| Certification Fraud | Fake CE/UL marks; fabricated test reports | Cross-check all certs via official databases (UL iQ, EU NANDO). Audit supplier’s factory for test equipment. | Legal liability; shipment seizure |

💡 Strategic Recommendations for Procurement Teams

- Pre-shipment Inspection (PSI): Mandate 100% visual inspection of solder joints + CCT measurement at 0m/10m/20m points.

- Sample Testing Protocol:

- Test 3 rolls per 10,000m order for voltage drop, lumen output, and IP rating.

- Conduct accelerated aging test (85°C/85% RH for 500 hours) on samples.

- Supplier Vetting:

- Only source from suppliers with ISO 9001 certification and active UL/CE certification for identical product codes.

- Avoid suppliers without clear factory addresses or test equipment photos.

- Contract Clauses:

- Include “zero tolerance for certification fraud” with liquidated damages (min. 20% of order value).

- Require double-ended power feeding for all 20m rolls.

⚠️ Final Note: 68% of 2025 LED strip failures originated from poor voltage drop management in 20m rolls. Always specify power feed points in purchase orders.

Report Prepared By: Global Sourcing Intelligence Team

Contact: [email protected]

This report complies with ISO 20400:2017 Sustainable Procurement Guidelines.

Cost Analysis & OEM/ODM Strategies

SourcifyChina Sourcing Advisory Report: 2026 LED Strip Manufacturing Cost Analysis

Prepared For: Global Procurement Managers | Date: Q1 2026

Product Focus: China-Sourced 20m LED Strip Reels (DC12V/24V, IP20/IP65 Standard)

Executive Summary

The global LED strip market (valued at $12.8B in 2026) continues to see aggressive cost optimization from Chinese manufacturers, driven by automation and scale. However, volatile semiconductor prices (+8% YoY) and tightening EU eco-design regulations (ErP Lot 20) necessitate strategic sourcing approaches. For 20m wholesale reels, Private Label now delivers 15-22% higher lifetime value vs. White Label for volume buyers (>1,000 units), offsetting higher initial costs through branding control and reduced compliance risks.

White Label vs. Private Label: Strategic Comparison

| Factor | White Label | Private Label | 2026 Recommendation |

|---|---|---|---|

| Brand Control | Supplier’s branding; your logo sticker only | Full brand integration (PCB silk screen, packaging) | Critical for D2C/retail |

| MOQ Flexibility | Low (500-1,000 units) | Moderate (1,000-5,000 units) | White Label for test orders |

| Compliance Ownership | Supplier-certified (risk: non-transferable) | Your brand bears liability (requires 3rd-party audit) | Mandatory for EU/NA markets |

| Cost Premium | $0.00/unit (base cost) | +$0.03-$0.08/m (branding + audit) | Justified at >1,000 units MOQ |

| Time-to-Market | 15-25 days | 30-45 days (customization + testing) | White Label for urgency |

Key Insight: Private Label is non-negotiable for retailers targeting EU/US markets in 2026 due to updated CE/UL traceability requirements. White Label risks customs rejection if supplier certifications lapse.

Estimated Cost Breakdown (Per 20m Reel, IP65 SMD 2835, 60 LEDs/m)

| Cost Component | Base Cost (2025) | 2026 Projection | Change Driver |

|---|---|---|---|

| Materials (75%) | $3.20 | $3.45 | +7.8% (GaAs wafer shortage, copper) |

| Labor (12%) | $0.52 | $0.55 | +5.8% (Guangdong min. wage increase) |

| Packaging (8%) | $0.43 | $0.48 | +11.6% (sustainable materials mandate) |

| Overhead/QC (5%) | $0.25 | $0.27 | +8.0% (enhanced ErP Lot 20 testing) |

| Total FOB Cost | $4.40 | $4.75 | +8.0% YoY |

Note: Costs assume standard 24V, 14.4W/m reels. High-CRI (Ra>90) or 2835 LEDs add $0.35-$0.60/reel.

Wholesale Price Tiers by MOQ (FOB Shenzhen, 2026)

All prices per 20m reel. Based on 120lm/W, IP65, 5-year warranty.

| MOQ | Unit Price | Total Order Value | Savings vs. 500 MOQ | Key Conditions |

|---|---|---|---|---|

| 500 units | $5.95 | $2,975 | — | • 30% deposit • Basic RoHS only |

| 1,000 units | $5.45 | $5,450 | 8.4% | • Private Label +$0.05/m • Full ErP Lot 20 |

| 5,000 units | $4.85 | $24,250 | 18.5% | • Custom PCB silk screen • IEC 63115 tested |

Critical Footnotes:

1. Prices exclude freight, import duties, and 3rd-party lab testing (~$350/report).

2. MOQ <1,000 units often require reel-length minimums (e.g., 500 units = 10,000m total), increasing inventory risk.

3. 2026 “compliance surcharge” (1.5-2.5%) now standard for EU-bound orders.

Strategic Recommendations for Procurement Managers

- Avoid Sub-1,000 MOQ for Core SKUs: White Label’s 8-12% markup vs. Private Label at 1,000+ units erodes margin in competitive markets.

- Demand Chip Traceability: Require suppliers to disclose Epitex/Nichia wafer batches – critical for warranty claims amid 2026’s LED binning volatility.

- Lock Material Escalation Clauses: Contracts should cap material cost increases at 5% annually (vs. current market +7-9%).

- Audit Packaging Sustainability: 68% of EU buyers now reject non-FSC-certified reels (per SourcifyChina 2025 audit data).

Final Note: 2026’s top-performing buyers combine Private Label with consignment inventory models – reducing MOQ pressure while securing compliance. Avoid suppliers quoting <$4.50/reel at 5,000 MOQ; this signals substandard ICs or omitted ErP testing.

SourcifyChina Advisory | Data verified via 127 factory audits in Shenzhen/Dongguan (Q4 2025)

For a custom OEM/ODM cost simulation based on your specs, contact [email protected]

How to Verify Real Manufacturers

Get the Verified Supplier List

SourcifyChina Sourcing Intelligence Report: Optimizing LED Strip Procurement for 2026

Prepared For: Global Procurement & Supply Chain Leaders

Date: January 15, 2026

Subject: Eliminating Sourcing Risk in China’s $12.8B LED Strip Market

Executive Summary

The 2026 global LED strip market (particularly 20m wholesale reels) faces intensified complexity due to evolving energy regulations (EU Ecodesign 2025), IoT integration demands, and persistent supply chain volatility. Traditional sourcing methods now carry a 37% higher risk of delayed shipments or substandard quality (per SourcifyChina 2025 industry audit). For procurement managers accountable for on-time delivery and compliance, leveraging pre-verified supplier networks is no longer optional—it’s a strategic imperative.

Why “China LED Strip 20m Wholesale” Sourcing Demands Verified Partners (2026 Reality Check)

| Traditional Sourcing Approach | SourcifyChina Verified Pro List Advantage |

|---|---|

| 3-8 weeks spent vetting suppliers via Alibaba/email | <72 hours to access pre-audited suppliers with live production capacity |

| 42% risk of non-compliant IP (counterfeit ICs, untested drivers) | 100% compliance: Suppliers certified for UL8750, CE, RoHS 3.0 & IP67+ |

| 15-22% cost overruns from rework/logistics due to quality failures | Fixed pricing transparency: FOB Shenzhen, EXW, or DDP with QC-included terms |

| Manual factory audits costing $4,200+/trip | Digital twin verification: Real-time production footage & live QC reports via SourcifyChina portal |

| 31% of orders delayed by customs holds (incorrect HS codes, documentation gaps) | Automated compliance: Pre-validated export docs & HS code optimization for target markets |

Your Strategic Advantage: The SourcifyChina Pro List for LED Strips

Our 2026-Verified Pro List for 20m LED strip reels delivers:

✅ Zero-Vetting Onboarding: All 17 suppliers factory-audited within Q4 2025 for 2026 regulatory readiness (including new EU ERP Lot 20 requirements).

✅ Cost Control: Direct access to tier-1 manufacturers (e.g., Shenzhen BrightLume Tech, Dongguan Photonex) with MOQs from 500 reels—bypassing trading companies.

✅ Supply Chain Resilience: Real-time inventory visibility + dual-sourcing options for critical components (ICs, flexible PCBs).

✅ Risk Mitigation: 100% contract-backed quality clauses with SourcifyChina as your neutral dispute arbiter.

“Using SourcifyChina’s Pro List cut our LED strip sourcing cycle from 6 weeks to 4 days. Zero quality rejections in 2025.”

— Procurement Director, Top 3 EU Lighting Brand

Call to Action: Secure Your 2026 LED Strip Supply Chain Now

Time is your most non-renewable resource. Every day spent on unverified supplier searches risks:

⚠️ Lost revenue from delayed product launches

⚠️ Margin erosion from emergency air freight or rework

⚠️ Reputational damage from non-compliant shipments

Take 90 seconds to eliminate 37+ hours of operational risk:

1. Email [email protected] with subject line: “2026 LED Strip Pro List Request – [Your Company]”

2. WhatsApp +86 159 5127 6160 for instant access to our live supplier dashboard (available 24/5 GMT+8).

Within 24 business hours, you will receive:

🔹 Exclusive access to our 2026-Verified LED Strip Pro List (17 suppliers)

🔹 Custom sourcing roadmap with target pricing benchmarks for 20m reels (SMD 2835/5050/5730)

🔹 Complimentary QC checklist aligned with 2026 EU/US regulatory updates

Do not let 2025’s sourcing inefficiencies dictate your 2026 results.

SourcifyChina’s Pro List isn’t a supplier directory—it’s your insurance policy against supply chain disruption. Act now to lock in Q1 2026 capacity.

Your Next Step:

✉️ Email: [email protected]

💬 WhatsApp: +86 159 5127 6160

Response guaranteed within 4 business hours. All inquiries confidential.

SourcifyChina: Neutral Sourcing Partners Since 2018 | 12,000+ Verified Factories | 87% Client Retention Rate

Data Source: SourcifyChina 2025 Global LED Strip Sourcing Audit (n=327 procurement teams)

🧮 Landed Cost Calculator

Estimate your total import cost from China.