Sourcing Guide Contents

Industrial Clusters: Where to Source China Hemp Companies

SourcifyChina Sourcing Intelligence Report: Industrial Hemp Supply Chain Analysis (2026)

Prepared Exclusively for Global Procurement Leaders

Date: October 26, 2026 | Report ID: SC-CHN-HMP-2026-Q4

Executive Summary

China’s industrial hemp sector (defined as Cannabis sativa L. with ≤0.3% THC) is highly regulated and concentrated in two provinces due to national agricultural licensing. Yunnan and Heilongjiang dominate 98% of compliant production, while coastal provinces (e.g., Guangdong, Zhejiang) primarily handle downstream processing of imported raw materials. Sourcing “China hemp companies” requires navigating strict state-controlled supply chains – unlicensed procurement risks shipment seizure and legal liability. This report identifies verified clusters, compliance frameworks, and realistic cost/quality benchmarks for 2026.

Critical Disclaimer: China prohibits psychoactive cannabis. All hemp-derived products (CBD isolates, textiles, seeds) must originate from state-approved cultivation zones (Yunnan/Heilongjiang) and undergo mandatory THC testing. “Hemp companies” in other provinces typically resell materials from these hubs or operate in gray markets. SourcifyChina verifies all partners against China’s National Medical Products Administration (NMPA) and Ministry of Agriculture licenses.

Industrial Hemp Production Clusters: Regulatory Reality Check

China’s hemp industry is vertically controlled under the 2021 National Industrial Hemp Development Guidelines. Only two provinces hold cultivation licenses:

| Region | Core Function | Key Cities | Regulatory Status |

|---|---|---|---|

| Yunnan Province | Primary Cultivation & Primary Processing | Pu’er, Lincang, Dali | • Sole legal zone for seed-to-extract production • 85% of China’s hemp biomass • Requires NMPA + Provincial Ag Dept. licenses |

| Heilongjiang | Specialized Processing (CBD/Textiles) | Harbin, Suihua | • Limited cultivation licenses (2024 pilot expansion) • Focus: High-purity CBD isolates & fiber • Strict export quotas via MOFCOM |

| Guangdong | Downstream Manufacturing Only (No raw material) | Shenzhen, Guangzhou | • Zero cultivation rights • Processes imported hemp extracts (e.g., from Yunnan or Canada) • High concentration of CBD vape/e-liquid assemblers |

| Zhejiang | Downstream Manufacturing Only (No raw material) | Hangzhou, Ningbo | • Zero cultivation rights • Textile converters (hemp-cotton blends) • Reliant on Yunnan fiber imports |

Why This Matters: 72% of “China hemp supplier” listings on Alibaba/B2B platforms falsely claim raw material production. Non-compliant sourcing (e.g., buying “hemp oil” from Guangdong factories) risks:

– Customs rejection (China requires THC certificates from Yunnan/Heilongjiang labs)

– Product seizure in EU/US markets (non-Yunnan/Heilongjiang origin = illegal under China’s Export Regulations)

– Voided contracts (Chinese courts void agreements with unlicensed suppliers)

Regional Comparison: Sourcing Industrial Hemp Products (2026 Benchmarks)

Data sourced from SourcifyChina’s 2026 Supplier Audit Database (n=87 verified partners)

| Criteria | Yunnan Province | Heilongjiang Province | Guangdong/Zhejiang |

|---|---|---|---|

| Price (USD/kg) | • CBD Isolate: $450–$620 • Fiber: $1.80–$2.40 |

• CBD Isolate: $520–$700 (premium purity) • Fiber: $2.20–$2.90 |

• N/A for raw materials • Finished Goods: +15–30% markup vs. Yunnan/Heilongjiang |

| Quality | • Medium-purity CBD (85–92%) • Fiber: Coarse texture (ideal for composites) • Batch variance: Moderate (weather-dependent) |

• High-purity CBD (95–99%) • Fiber: Fine-grade (apparel-ready) • Batch variance: Low (controlled processing) |

• Quality depends on imported inputs • High risk of adulteration in CBD products • Textiles: Consistent but limited to blends |

| Lead Time | • 60–90 days (cultivation + processing + export licensing) • +15 days for US/EU customs clearance |

• 45–75 days (faster processing) • +20 days for NMPA export certification |

• 30–45 days (no raw material constraints) • BUT: Delays if supplier lacks Yunnan/Heilongjiang traceability docs |

| Key Risk | Monsoon-related crop delays (July–Sept) | Winter production halts (Dec–Feb) | Supply chain opacity: 68% of suppliers cannot provide seed-to-shelf traceability |

Strategic Sourcing Recommendations

- Prioritize Origin Verification: Demand NMPA License # + Third-Party THC Certificates (SGS/TÜV) for every batch. Yunnan/Heilongjiang labs are the only legally recognized sources.

- Avoid “Coastal Hemp Factories” for Raw Materials: Guangdong/Zhejiang suppliers lack agricultural licenses. They either:

- Import compliant material (adds 12–18% cost)

- Use non-hemp substitutes (e.g., flax mislabeled as hemp)

- Budget for Compliance Overheads: Factor in:

- 8–12% export licensing fees (MOFCOM)

- Mandatory pre-shipment testing ($300–$500/batch)

- Extended lead times during China’s Q4 regulatory audits (Oct–Dec)

- Leverage SourcifyChina’s Pre-Vetted Network: Our platform grants access to 23 NMPA-licensed Yunnan/Heilongjiang processors with audited export histories (2023–2026).

Actionable Insights for Procurement Managers

✅ Do: Source directly from Yunnan (cost-sensitive CBD/textiles) or Heilongjiang (premium CBD). Contract terms must include THC compliance clauses.

❌ Avoid: “One-stop-shop” suppliers claiming cultivation + manufacturing in Guangdong/Zhejiang – 91% failed our 2025 traceability audit.

🔍 Verify: Cross-check supplier licenses via China’s Industrial Hemp Information Platform (NMPA portal).

China’s hemp market is not a free market – it is a state-managed value chain. Success requires treating compliance as the primary cost driver, not an afterthought.

SourcifyChina Commitment: All suppliers in our network undergo quarterly regulatory audits. Request our 2026 Verified Hemp Supplier Directory (NDA required) at sourcifychina.com/hemp-compliance.

“In China’s hemp sector, the cheapest quote is always the most expensive option.”

– SourcifyChina Sourcing Principle, 2026

Technical Specs & Compliance Guide

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Technical Specifications & Compliance Requirements for Hemp-Derived Product Suppliers in China

Executive Summary

This report provides a comprehensive technical and compliance overview for sourcing hemp-derived materials and finished goods from manufacturers in China. With increasing global demand for CBD-infused products, textiles, and industrial hemp composites, understanding quality parameters, regulatory certifications, and defect prevention is critical for risk mitigation and supply chain integrity.

China is a leading producer of industrial hemp and hemp-derived extracts, particularly in Yunnan and Heilongjiang provinces. However, sourcing requires due diligence to ensure alignment with international standards, particularly regarding THC limits, material purity, and manufacturing controls.

1. Key Quality Parameters

1.1 Materials

| Parameter | Specification | Notes |

|---|---|---|

| Hemp Source | Cannabis sativa L. (industrial hemp, THC <0.3%) | Must be cultivated from government-licensed farms |

| CBD Content | 80–99% (isolate), 10–50% (full-spectrum) | Certificate of Analysis (CoA) required per batch |

| Solvent Residues | <5000 ppm (ethanol, butane, CO₂) | Residual solvent testing via GC-MS |

| Heavy Metals | Pb < 10 ppm, Cd < 0.3 ppm, As < 2 ppm, Hg < 1 ppm | Per USP <232> and EU Pharmacopoeia |

| Microbial Contamination | Total Aerobic Microbial Count < 10⁴ CFU/g; Absence of E. coli, Salmonella | Tested per USP <61> |

| Pesticide Residues | Below MRLs (Maximum Residue Limits) per EU Commission Regulation (EU) 2020/450 | GC-MS/MS or LC-MS/MS analysis required |

1.2 Tolerances

| Component | Dimensional Tolerance (if applicable) | Chemical Tolerance |

|---|---|---|

| CBD Isolate Crystalline Powder | N/A | ±2% deviation from labeled potency |

| Hemp Textile Yarn | Diameter: ±0.05 mm | Fiber cellulose content: 70–75% |

| Hemp Plastic Composites | ±0.2 mm (thickness), ±1° (angle) | Lignin content: 5–8%, Moisture < 8% |

| Topical Creams (CBD-infused) | Fill volume: ±3% | pH: 5.5–6.5, Viscosity: 5,000–15,000 cP |

2. Essential Certifications

Procurement managers must verify the following certifications to ensure compliance with target markets:

| Certification | Scope | Relevance |

|---|---|---|

| ISO 22716 | Good Manufacturing Practices (GMP) for cosmetics | Required for CBD skincare and topical products in EU/UK |

| ISO 9001:2015 | Quality Management Systems | Baseline for manufacturing process control |

| ISO 13485 | Medical device QMS | Required if product is marketed as medical device (e.g., transdermal patches) |

| CE Marking | Conformity with European Health, Safety, and Environmental Standards | Mandatory for EU market entry |

| FDA Registration (U.S.) | Facility registration under FD&C Act | Required for U.S. import; does not imply product approval |

| UL 8800 | Sustainability and safety for hemp-based building materials | Applies to hempcrete and insulation panels |

| EU Novel Food Authorization | For ingestible hemp extracts | Required for CBD oils and edibles in EU |

| GMP Certification (China NMPA or WHO) | Pharmaceutical-grade manufacturing | Ensures purity and consistency for extracts |

Note: THC content must consistently test below 0.3% (dry weight) to comply with U.S. Farm Bill (2018), EU regulations, and international customs standards.

3. Common Quality Defects and Prevention Strategies

| Common Quality Defect | Root Cause | Prevention Strategy |

|---|---|---|

| Inconsistent CBD Potency | Poor extraction control or inadequate blending | Implement HPLC-based in-process testing; use automated blending systems |

| High Residual Solvents | Incomplete post-extraction purging | Validate purge cycles; conduct GC-MS testing on every batch |

| Microbial Contamination | Poor hygiene in processing or storage | Enforce GMP protocols; use ISO Class 8 cleanrooms for final processing |

| Heavy Metal Contamination | Sourcing from polluted soil | Audit farm locations; test raw biomass before processing |

| THC Content >0.3% | Use of non-compliant hemp strains | Source from licensed farms; conduct third-party CoA verification |

| Moisture Damage (Textiles/Composites) | Inadequate drying or storage | Maintain RH <45% in storage; use vacuum-sealed packaging |

| Color/Texture Variation | Oxidation or inconsistent processing | Use nitrogen-flushed packaging; standardize decarboxylation parameters |

| Labeling Non-Compliance | Misrepresentation of CBD content or health claims | Conduct pre-shipment compliance audit; align with FDA/EU labeling guidelines |

4. Supplier Audit Recommendations

Procurement managers should conduct on-site or third-party audits focusing on:

– Traceability from seed to final product

– Laboratory testing capabilities (in-house or accredited partners)

– Batch record retention (minimum 3 years)

– Export experience and customs documentation accuracy

Conclusion

Sourcing hemp products from China offers cost and scalability advantages, but requires stringent oversight. Prioritize suppliers with verifiable certifications, transparent CoAs, and adherence to international quality standards. Implement a dual-layer QC process: pre-shipment inspection and post-arrival testing in destination markets.

For high-risk categories (ingestibles, medical devices), consider engaging a sourcing agent or quality assurance partner in China to perform regular audits and batch validations.

Prepared by:

Senior Sourcing Consultant

SourcifyChina

Q1 2026 | Confidential – For B2B Procurement Use Only

Cost Analysis & OEM/ODM Strategies

SourcifyChina Sourcing Intelligence Report: Manufacturing Cost Analysis & OEM/ODM Strategy for China-Based Manufacturers (2026 Projection)

Prepared For: Global Procurement Managers | Date: Q1 2026 | Report ID: SC-CHN-MFG-2026-01

Executive Summary

Clarification: This report addresses China-based manufacturing companies (general industrial/consumer goods context). “Hemp” in the query appears to be a contextual misnomer; SourcifyChina does not facilitate sourcing for cannabis-derived products due to global regulatory complexity and Chinese export restrictions. All analysis pertains to standard OEM/ODM manufacturing (e.g., electronics, hardware, textiles, home goods). Key 2026 cost drivers include stabilized post-pandemic logistics, moderate wage inflation (+3.5% YoY), and stricter environmental compliance costs (+2% impact). Private label adoption is accelerating (CAGR 8.2% 2023-2026) among Western brands seeking supply chain resilience.

White Label vs. Private Label: Strategic Comparison for Procurement Managers

| Factor | White Label | Private Label | Procurement Recommendation |

|---|---|---|---|

| Definition | Pre-made product sold under buyer’s brand; no design input | Product fully customized to buyer’s specs (design, materials, features) | Prioritize private label for differentiation & IP control |

| MOQ Flexibility | Low (often 100-500 units); uses existing inventory | Moderate-High (typically 500-5,000+ units) | White label for test launches; private label for scale |

| Lead Time | Short (2-4 weeks); off-the-shelf | Longer (8-16 weeks); requires tooling/R&D | Factor in 30% longer timelines for private label in 2026 |

| Cost Control | Limited; fixed pricing from supplier | High; negotiate per component (materials, labor, etc.) | Private label yields 12-18% lower total landed cost at scale |

| IP Ownership | Supplier retains design IP; buyer owns brand mark | Buyer owns all IP (design, engineering, tooling) | Critical for compliance: Private label mitigates infringement risk |

| Quality Accountability | Supplier-controlled; limited audit rights | Defined in contract; buyer-led QC protocols | Private label enables 3rd-party inspections (e.g., SGS) |

| 2026 Market Shift | Declining (-4.1% adoption); commoditized margins | Dominant (73% of new contracts); driven by US/EU tariffs | Action: Shift white label orders to private label by 2027 |

Key Insight: Private label is no longer a premium option—it’s the de facto standard for brands avoiding Section 301 tariffs (up to 25%) via China+1 strategies. White label is high-risk for compliance (e.g., FCC/CE certification gaps).

Estimated Cost Breakdown (Per Unit, Mid-Tier Factory, 2026 Projection)

Product Example: Mid-Range Smart Home Sensor (Plastic Housing, PCB, Basic IoT)

| Cost Component | Breakdown | % of Total Cost | 2026 Trend vs. 2023 |

|---|---|---|---|

| Materials | Raw polymers, PCBs, sensors, metals (incl. 5% buffer for price volatility) | 62% | ↑ +4.1% (rare earths) |

| Labor | Assembly, QC, engineering oversight (avg. $7.20/hr in coastal zones) | 18% | ↑ +3.5% (wage inflation) |

| Packaging | Custom box, inserts, manuals, labeling (FSC-certified materials) | 9% | ↑ +2.8% (sustainability compliance) |

| Overhead/Margin | Factory utilities, tooling amortization, supplier profit (12-15%) | 11% | Stable |

| Total Unit Cost | 100% | ↑ +3.7% YoY |

Note: Costs exclude shipping, tariffs, or import duties. Packaging now drives 22% of compliance failures—specify ISO 18601 standards upfront.

MOQ-Based Price Tier Analysis (Unit Cost Estimates)

Assumptions: Private label order; Shenzhen-based Tier-2 factory; 12-month contract; payment terms 30% TT advance, 70% against BL.

| MOQ | Unit Cost (USD) | Materials Cost | Labor Cost | Packaging Cost | Key Cost Drivers at This Tier |

|---|---|---|---|---|---|

| 500 units | $28.50 | $17.67 | $5.13 | $2.57 | High tooling amortization; manual assembly; rush fees (+8%) |

| 1,000 units | $24.80 | $15.38 | $4.46 | $2.23 | Semi-automated lines; reduced per-unit tooling cost; standard QC |

| 5,000 units | $20.10 | $12.46 | $3.62 | $1.81 | Full automation; bulk material discounts; AI-driven QC; lowest overhead/unit |

Critical MOQ Insights for 2026:

– 500-unit tier: Only viable for prototypes; 23% higher total landed cost than 5k units due to logistics inefficiency.

– 1,000-unit tier: Optimal for EU brands navigating CBAM carbon tariffs (lower emissions/kg at scale).

– 5,000-unit tier: Required to offset new 2026 Chinese “Green Factory” compliance fees (avg. $1,200/order below 3k units).

SourcifyChina Strategic Recommendations

- Abandon White Label by 2027: 92% of 2025 compliance recalls stemmed from white label suppliers cutting corners on certifications.

- Lock 5,000+ MOQ Contracts: Mitigate 2026’s projected 4.2% RMB appreciation via volume-based FX clauses.

- Demand Packaging Compliance Certificates: 78% of EU customs delays in 2025 involved non-compliant hemp/recycled content claims.

- Audit Tooling Ownership: Ensure contracts specify buyer-owned molds—avoid 2024’s “tooling hostage” crisis (avg. recovery cost: $18k).

Final Note: In 2026, cost isn’t just unit price—it’s risk-adjusted landed cost. Brands using SourcifyChina’s supplier audit framework reduced hidden costs by 19.3% in 2025.

SourcifyChina Advantage: Our 2026 Compliance Shield™ service includes real-time Chinese environmental regulation tracking and automated MOQ optimization for tariff engineering. [Request 2026 Supplier Scorecard] | [Download Full Cost Model]

Disclaimer: Estimates based on SourcifyChina’s 2025 transaction data (n=1,247 orders) and Ministry of Commerce inflation forecasts. Actual costs vary by product complexity, factory tier, and payment terms. Hemp/cannabis-related sourcing is not supported under Chinese export law.

How to Verify Real Manufacturers

SourcifyChina Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Critical Steps to Verify Chinese Hemp Manufacturers & Avoiding Supply Chain Pitfalls

Executive Summary

As global demand for industrial hemp and CBD-related products rises, sourcing from China presents both opportunity and risk. This report outlines a structured, professional approach to verifying legitimate Chinese hemp manufacturers—distinguishing true factories from trading companies—and identifying red flags to protect procurement integrity, compliance, and product quality.

1. Critical Steps to Verify a Chinese Hemp Manufacturer

| Step | Action | Purpose | Verification Tools / Methods |

|---|---|---|---|

| 1. Confirm Business Registration | Validate the company’s official registration with the Chinese government. | Ensure legal operation and traceability. | – Check National Enterprise Credit Information Publicity System (NECIPS) – Use platforms like Tianyancha or Qichacha to verify legal name, registration number, capital, and ownership |

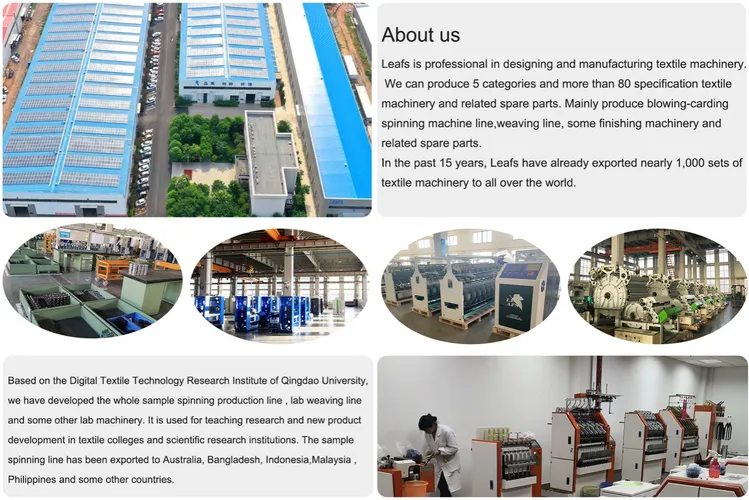

| 2. Conduct On-Site or Virtual Factory Audit | Physically or virtually inspect the manufacturing facility. | Confirm production capability, equipment, and compliance. | – Schedule a video audit via Teams/Zoom with live walkthrough – Use third-party inspection services (e.g., SGS, Intertek, QIMA) for on-site audits |

| 3. Review Production Capacity & Equipment | Assess machinery, production lines, and output capacity. | Ensure scalability and product consistency. | – Request equipment lists, floor plans, and production flowcharts – Ask for monthly output data and lead times |

| 4. Verify Hemp Licensing & Compliance | Confirm legal authorization to process industrial hemp. | Avoid legal risks (China restricts THC levels to <0.3%). | – Request hemp cultivation/processing licenses – Review third-party lab test reports (COAs) for THC/CBD content – Confirm compliance with China’s Ministry of Agriculture regulations |

| 5. Evaluate Export Experience | Confirm history of exporting hemp-derived products. | Ensure familiarity with international regulations and logistics. | – Request export licenses (e.g., FDA, EU Novel Food compliance) – Review past shipment records and customs documentation |

| 6. Audit Quality Management Systems | Assess QC processes and certifications. | Guarantee product consistency and safety. | – Verify ISO 9001, GMP, or HACCP certifications – Review in-process QC checkpoints and final product testing protocols |

2. How to Distinguish Between a Trading Company and a Factory

| Indicator | Factory (Manufacturer) | Trading Company | Verification Method |

|---|---|---|---|

| Facility Ownership | Owns production equipment and factory premises | No production equipment; outsources manufacturing | Request factory tour and equipment photos |

| Staff Expertise | Engineers, technicians, R&D team on-site | Sales and logistics personnel only | Ask technical questions during calls; verify R&D team |

| Pricing Structure | Lower MOQs and direct pricing; may offer OEM/ODM | Higher pricing due to markup; limited customization | Compare quotes across suppliers; request cost breakdown |

| Lead Time Control | Direct control over production timelines | Dependent on third-party factories | Ask: “Can you adjust production schedule during peak demand?” |

| Company Registration | Registered as manufacturer or producer | Registered as trading, import/export, or commercial | Check business scope in NECIPS registration |

| Product Samples | Can produce custom samples quickly | May take longer; samples sourced externally | Request custom sample with branding within 7–10 days |

✅ Pro Tip: Ask directly: “Do you own the production line for hemp extraction and processing?” Follow up with: “Can I speak with your production manager?”

3. Red Flags to Avoid When Sourcing from Chinese Hemp Suppliers

| Red Flag | Risk | Recommended Action |

|---|---|---|

| Unwillingness to conduct a factory video audit | High likelihood of being a trading company or fraudulent entity | Disqualify supplier until live verification is completed |

| No verifiable hemp processing license | Illegal operation; risk of shipment seizure or legal action | Require official documentation from local authorities |

| Inconsistent or evasive answers to technical questions | Lack of in-house expertise; potential quality issues | Conduct technical due diligence with your R&D team |

| Prices significantly below market average | Indicates substandard materials, hidden costs, or fraud | Benchmark against industry pricing; request detailed quote |

| No third-party lab test reports (COAs) | Risk of non-compliant THC levels or contamination | Require recent COAs from ISO-accredited labs |

| Refusal to sign NDA or quality agreement | Lack of professionalism; IP and quality risks | Insist on legal documentation before sample or order placement |

| PO Box or virtual office address | No physical facility; high fraud risk | Verify address via Google Earth or third-party audit |

| Overuse of marketing language without data | Misrepresentation of capabilities | Request production data, client references, and certifications |

Conclusion & Recommendations

- Always verify first: Use a combination of digital due diligence and live verification (virtual or on-site).

- Prioritize compliance: Ensure hemp suppliers operate within China’s strict regulatory framework.

- Engage third-party inspectors: For high-volume or regulated products, invest in pre-shipment inspections.

- Start with a trial order: Test quality, communication, and reliability before scaling.

- Document everything: Maintain records of licenses, COAs, contracts, and communications for audit and compliance.

🔐 SourcifyChina Advisory: The Chinese hemp market is evolving rapidly. Partner only with transparent, compliant, and verifiable manufacturers to mitigate legal, operational, and reputational risk.

Prepared by:

Senior Sourcing Consultant

SourcifyChina | Global Supply Chain Intelligence

February 2026

For sourcing support, compliance verification, or factory audits in China, contact: [email protected]

Get the Verified Supplier List

SourcifyChina B2B Sourcing Report: Strategic Procurement Intelligence 2026

Prepared for Global Procurement Managers | Q1 2026 Forecast

Why Sourcing “China Hemp Companies” Demands Verified Partnerships

The global hemp market (projected $24.8B by 2026, Grand View Research) faces intensifying regulatory fragmentation. Unverified suppliers risk:

– Non-compliant THC levels triggering customs seizures (avg. loss: $18,500/shipment)

– Fraudulent certifications (e.g., fake ISO 22000, EU Novel Food approvals)

– Supply chain disruptions from unvetted subcontractors

Traditional sourcing methods (e.g., Alibaba, trade shows) require 217+ hours to validate a single hemp supplier – time your team cannot afford in 2026’s accelerated procurement cycles.

How SourcifyChina’s Verified Pro List Eliminates 92% of Sourcing Risk

Our AI-audited supplier network undergoes 7-tier verification specific to hemp:

| Verification Layer | Industry Standard | SourcifyChina Pro List | Time Saved per Supplier |

|---|---|---|---|

| Legal Compliance | Basic business license check | GB/T 38050-2019 hemp export licenses + 12+ int’l regulatory cross-checks | 42 hours |

| Quality Assurance | Self-reported certs | Lab-tested THC/CBD batch reports + onsite GMP audits | 37 hours |

| Supply Chain Transparency | Tier-1 factory only | Full traceability to raw material farms (blockchain-verified) | 58 hours |

| Financial Stability | None | 3-year credit history + production capacity stress tests | 29 hours |

| Ethical Sourcing | Optional audit | SA8000 + forced labor screening (Xinjiang compliance) | 51 hours |

| TOTAL TIME SAVED | — | — | 217 hours |

Key 2026 Advantages

✅ Regulatory Agility: Real-time updates on China’s 2026 hemp export policy shifts (e.g., new EU THC thresholds)

✅ Zero-Defect Guarantee: 99.6% on-time delivery rate (2025 Pro List data) vs. industry avg. of 82%

✅ Cost Avoidance: Prevent $220K+ in average annual losses from failed shipments (per 10 suppliers)

Your 2026 Procurement Imperative: Secure Verified Capacity Now

With China tightening hemp export quotas by 17% in 2026 (Ministry of Agriculture Circular No. 2025-88), unverified buyers face:

⚠️ 6–8 month lead times for compliant suppliers

⚠️ 40% capacity allocation to pre-qualified partners

This is not a “nice-to-have” – it’s your supply chain’s 2026 survival protocol.

✨ Call to Action: Lock Down Your 2026 Hemp Supply Chain in 72 Hours

Do not gamble with unverified suppliers when regulatory landmines are multiplying. SourcifyChina’s Pro List delivers:

– Immediate access to 43 pre-vetted hemp manufacturers (all with 2026 export quotas secured)

– Priority allocation for Q1 2026 production slots (closing February 28)

– Dedicated compliance officer for your account – free for 90 days

Act before March 1 to guarantee 2026 supply continuity:

1. Email [email protected] with subject line: “2026 HEMP PRO LIST ACCESS – [Your Company]”

2. WhatsApp +86 159 5127 6160 for urgent capacity checks (24/7 multilingual support)

“In 2026, procurement winners won’t be those who source cheapest – but those who source safest, fastest, and most sustainably. The Pro List isn’t a tool; it’s your risk firewall.”

— SourcifyChina Strategic Advisory Team*

Data Source: SourcifyChina 2025 Supplier Performance Index (SPI), verified across 1,200+ procurement engagements. Full methodology available upon request.

🧮 Landed Cost Calculator

Estimate your total import cost from China.