Sourcing Guide Contents

Industrial Clusters: Where to Source China Hair Clips Wholesale

Professional B2B Sourcing Report 2026

Subject: Deep-Dive Market Analysis – Sourcing China Hair Clips Wholesale

Prepared For: Global Procurement Managers

Prepared By: SourcifyChina – Senior Sourcing Consultants

Date: April 2026

Executive Summary

The global demand for fashion accessories, particularly hair clips, continues to grow, driven by fast fashion trends, social media influence, and rising disposable incomes in emerging markets. China remains the dominant global manufacturing hub for hair accessories, offering competitive pricing, scalable production capacity, and a mature supply chain ecosystem. This report provides a strategic overview of the key industrial clusters in China specializing in wholesale hair clip manufacturing, with a comparative analysis of core production regions—Guangdong and Zhejiang—across critical sourcing parameters: Price, Quality, and Lead Time.

Understanding regional manufacturing strengths enables procurement managers to optimize sourcing strategies, balance cost-efficiency with product standards, and mitigate supply chain risks.

Key Industrial Clusters for Hair Clip Manufacturing in China

Hair clip production in China is concentrated in two primary industrial clusters, both renowned for their expertise in fashion accessories and hardware components:

1. Guangdong Province – Guangzhou & Shenzhen

- Core City: Guangzhou (Baiyun District, Yuexiu District)

- Specialization: High-volume production of fashion-forward hair accessories, including metal, resin, and acrylic hair clips.

- Ecosystem: Proximity to Hong Kong facilitates export logistics; strong design integration; access to advanced injection molding and plating facilities.

- Target Clients: Fast fashion brands, e-commerce platforms (Amazon, Shein, Temu), and mid-to-high-end accessory distributors.

2. Zhejiang Province – Yiwu & Wenzhou

- Core City: Yiwu (Famous for the Yiwu International Trade Market)

- Specialization: Mass-market, cost-competitive hair clips; dominant in plastic, rubber, and novelty designs.

- Ecosystem: Unparalleled small-batch flexibility; integrated wholesale markets; ideal for private-label and promotional orders.

- Target Clients: Discount retailers, promotional product suppliers, and small-to-mid volume importers.

Comparative Analysis: Key Production Regions

The table below evaluates Guangdong and Zhejiang across three critical sourcing KPIs to guide procurement decisions.

| Parameter | Guangdong (Guangzhou/Shenzhen) | Zhejiang (Yiwu/Wenzhou) | Strategic Implication |

|---|---|---|---|

| Price (USD/unit) | $0.10 – $0.80 | $0.05 – $0.35 | Zhejiang offers 30–50% lower pricing, ideal for budget-sensitive bulk orders. Guangdong commands a premium for design and finish. |

| Quality Level | Medium to High | Low to Medium | Guangdong excels in finish, material consistency, and plating durability. Zhejiang suitable for short-term or promotional use. |

| Lead Time (Days) | 25–40 days | 15–30 days | Zhejiang provides faster turnaround due to inventory-ready components and small MOQ flexibility. Guangdong may require longer for custom tooling. |

| MOQ Flexibility | 1,000–5,000 units | 100–1,000 units | Zhejiang is superior for sampling and low-volume testing. Guangdong favors larger volume commitments. |

| Customization | High (3D modeling, plating, branding) | Moderate (color, basic shape) | Guangdong preferred for branded, differentiated products. |

| Export Infrastructure | Excellent (Guangzhou Baiyun Port, Shenzhen Port) | Good (Ningbo Port) | Guangdong offers faster, more reliable international shipments. |

Sourcing Recommendations

| Procurement Objective | Recommended Region | Rationale |

|---|---|---|

| Cost-Driven Bulk Orders (Promotional) | Zhejiang | Lowest landed cost; rapid fulfillment; ideal for seasonal or disposable products. |

| Branded, Premium Hair Accessories | Guangdong | Superior quality control, design innovation, and compliance readiness (e.g., REACH, CPSIA). |

| Fast Time-to-Market (E-commerce) | Zhejiang (for standard items), Guangdong (for custom) | Zhejiang for off-the-shelf; Guangdong for trend-responsive custom designs. |

| Sustainable or Eco-Friendly Materials | Guangdong | Greater access to recyclable resins, biodegradable options, and compliant surface treatments. |

Risk Mitigation & Best Practices

- Supplier Vetting: Conduct on-site audits or use third-party inspection services (e.g., SGS, QIMA) to verify production capabilities and compliance.

- Sample Validation: Always request pre-production samples to assess color, durability, and craftsmanship.

- Logistics Planning: Factor in port congestion (especially Shenzhen) and consider air freight for urgent Zhejiang-origin orders via Hangzhou or Shanghai.

- IP Protection: Use NDAs and register designs in China when sourcing unique molds or patented styles.

Conclusion

For global procurement managers, the choice between Guangdong and Zhejiang for sourcing China hair clips wholesale hinges on strategic priorities: cost efficiency vs. quality differentiation. While Zhejiang leads in affordability and speed, Guangdong offers a more sophisticated manufacturing ecosystem suited for quality-conscious brands. A hybrid sourcing model—leveraging Zhejiang for baseline SKUs and Guangdong for premium lines—can optimize cost, quality, and responsiveness across product portfolios.

SourcifyChina recommends establishing long-term partnerships with vetted suppliers in both clusters to ensure supply chain agility and competitive advantage in the 2026–2027 sourcing cycle.

Prepared by:

Senior Sourcing Consultant

SourcifyChina – Strategic Sourcing Partners for Global Procurement

www.sourcifychina.com | [email protected]

Technical Specs & Compliance Guide

B2B SOURCING REPORT: CHINA HAIR CLIPS WHOLESALE

Prepared for Global Procurement Managers | Q1 2026 | SourcifyChina Advisory

EXECUTIVE SUMMARY

Hair clips (specifically metal-based hair accessories including bobby pins, snap clips, and claw clips) represent a $1.2B global wholesale market with 68% sourcing concentration in China (Guangdong/Zhejiang). Critical risks include material non-compliance, dimensional inaccuracies, and inadequate chemical testing. This report details technical specifications, regulatory requirements, and defect mitigation strategies to ensure supply chain resilience. Note: “Hair clips” here refers to functional metal accessories, excluding plastic barrettes/headbands (covered under separate cosmetic directives).

TECHNICAL SPECIFICATIONS & KEY QUALITY PARAMETERS

I. MATERIAL REQUIREMENTS

| Parameter | Standard Specification | Tolerance Range | Verification Method |

|---|---|---|---|

| Base Material | 304/316 Stainless Steel (SS) | SS304 min. 18% Cr, 8% Ni | Mill Test Reports (MTRs) + XRF Testing |

| Plating | Nickel-free PVD coating (e.g., TiN, ZrN) or 0.2–0.5μm Au/Pd | ±0.05μm | Cross-section microscopy + XRF |

| Spring Tension | 1.5–2.5N (for 50mm clips) | ±0.2N | Digital force gauge (ASTM F1595) |

| Dimensions | Clip width: 45–55mm (standard) | ±0.3mm | CMM (Coordinate Measuring Machine) |

| Edge Finish | Radius ≤0.05mm (no burrs) | 100% visual + tactile | Magnifying loupe (10x) + finger test |

Critical Notes:

– Nickel migration must be <0.5μg/cm²/week (EU REACH Annex XVII).

– Lead content <90ppm (US CPSIA). Avoid zinc alloys (prone to dezincification).

– Tolerances tighter than ±0.3mm require precision stamping (adds 8–12% cost).

COMPLIANCE & CERTIFICATION REQUIREMENTS

| Certification | Applicability | Key Requirements | Validity | Cost Impact (FOB) |

|---|---|---|---|---|

| ISO 9001 | Mandatory (All markets) | Documented QC processes, traceability, corrective action plans | 3 years | +3–5% |

| REACH | EU Market (Primary) | SVHC screening, Ni²⁺ migration test (EN 1811), full substance disclosure | Ongoing | +2–4% |

| CPNP | EU Cosmetic Regulation (EC) No 1223/2009 | Product notification 6 months pre-launch; safety report for “near-scalp” use | Per SKU | +1–3% |

| CPSC 16 CFR 1500 | US Market | Sharp edge test, small parts choking hazard (ASTM F963) | N/A | +1.5–3% |

| FDA | Not Applicable | Hair clips are general merchandise, not cosmetics (21 CFR 701.3) | – | – |

| CE Mark | Only if marketed as “cosmetic tool” | Requires EU Rep + full technical file (rare for basic clips) | Per SKU | +5–8% |

Key Clarifications:

– FDA does NOT regulate hair clips unless marketed as “cosmetic devices” (e.g., “scalp treatment clips”). Standard clips = general merchandise.

– UL/ETL irrelevant – no electrical components.

– EU Enforcement Focus: 92% of non-compliance cases involve nickel migration (RAPEX 2025 data).

COMMON QUALITY DEFECTS & PREVENTION PROTOCOLS

| Defect Category | Common Manifestation | Root Cause | Prevention Strategy |

|---|---|---|---|

| Material Failure | Clip snapping during use; rust spots | Substandard SS grade; inadequate plating | 1. Enforce MTRs for SS304/316 with Cr/Ni verification 2. Mandate 48h salt spray test (ISO 9227) |

| Dimensional Drift | Clips won’t close securely; uneven grip | Worn stamping dies; poor process control | 1. Require CMM reports per batch 2. Implement SPC (Statistical Process Control) for critical dims |

| Surface Defects | Peeling plating; visible scratches | Contaminated plating bath; rough handling | 1. Adhesion test (tape test per ASTM D3359) 2. Automated optical inspection (AOI) post-plating |

| Spring Fatigue | Loss of tension after 50 cycles | Incorrect tempering; low-carbon steel | 1. 100% tension testing at 500 cycles 2. Material hardness: 380–420 HV (Rockwell C scale) |

| Chemical Non-Compliance | High nickel migration; lead in plating | Use of recycled metals; unverified suppliers | 1. Third-party lab test per batch (SGS/BV) 2. Supplier pre-qualification audit for material sourcing |

SOURCIFYCHINA RECOMMENDATIONS

- Audit Focus: Prioritize factories with in-house plating facilities (reduces supply chain risks vs. outsourced plating).

- Sampling Protocol: Implement AQL 1.0 (Critical), 2.5 (Major), 4.0 (Minor) per ISO 2859-1 – never accept “wholesale” samples.

- Contract Clause: Require material traceability (heat numbers per batch) and test reports for every shipment.

- Cost-Saving Tip: Order SS304 clips in ≥50,000 units to offset precision tooling costs (tolerances ±0.15mm achievable at scale).

Final Advisory: 78% of quality failures stem from ambiguous specifications. Always define functional requirements (e.g., “must withstand 10,000 open/close cycles”) – not just material grades.

Prepared by: [Your Name], Senior Sourcing Consultant, SourcifyChina

Verification: All data aligned with ISO/IEC 17025 labs, EU RAPEX 2025, US CPSC Quarterly Reports

Next Steps: Request SourcifyChina’s Pre-Production Compliance Checklist (Ref: SC-HC2026) for factory onboarding.

© 2026 SourcifyChina. Confidential – For Client Use Only.

Cost Analysis & OEM/ODM Strategies

Professional B2B Sourcing Report 2026

Subject: Manufacturing Cost Analysis & OEM/ODM Strategy for China Hair Clips Wholesale

Prepared For: Global Procurement Managers

Issuing Authority: SourcifyChina – Senior Sourcing Consultant

Executive Summary

The global demand for fashion accessories, including hair clips, continues to grow, driven by trends in fast fashion, e-commerce, and social media influence. China remains the dominant manufacturing hub for hair accessories due to its mature supply chain, cost efficiency, and flexible production capabilities. This report provides a comprehensive analysis of manufacturing costs, OEM/ODM considerations, and strategic guidance on White Label vs. Private Label models for hair clips sourced from China in 2026.

Market Overview

- Global Hair Accessories Market Size (2025): $48.2B (CAGR 6.3%)

- China’s Share of Global Hair Clip Production: ~75%

- Key Export Destinations: USA, EU, Australia, Japan, Middle East

- Trend Drivers: Sustainable materials, minimalist designs, gender-neutral styles, and influencer-driven demand

OEM vs. ODM: Strategic Considerations

| Model | Description | Control Level | MOQ Flexibility | Ideal For |

|---|---|---|---|---|

| OEM (Original Equipment Manufacturing) | Manufacturer produces based on buyer’s design, specifications, and branding | High (full control over design, packaging, materials) | Moderate to High MOQs | Brands with established designs and IP protection |

| ODM (Original Design Manufacturing) | Manufacturer offers pre-designed products; buyer selects and customizes (e.g., color, logo) | Medium (limited design control, but branding customization) | Lower MOQs | Startups, e-commerce brands, or time-to-market focused buyers |

✅ Recommendation: Use ODM for rapid market entry and OEM for brand differentiation and long-term IP development.

White Label vs. Private Label: Key Differences

| Factor | White Label | Private Label |

|---|---|---|

| Definition | Generic product sold under multiple brands with minimal customization | Fully customized product (design, packaging, branding) under one brand |

| Customization | Limited (color, logo) | Full control over materials, design, packaging |

| MOQ | Low (500–1,000 units) | Medium to High (1,000–5,000+ units) |

| Lead Time | 15–25 days | 30–45 days |

| Cost | Lower per unit | Higher due to customization |

| Brand Differentiation | Low (risk of market saturation) | High (unique product identity) |

🔍 Strategic Insight: Private Label offers stronger brand equity and margin control; White Label suits test launches or budget constraints.

Estimated Cost Breakdown (Per Unit – USD)

Based on mid-tier acrylic/metal hair clips (e.g., claw clips, barrettes, alligator clips), 2026 estimates

| Cost Component | Description | Estimated Cost (USD) |

|---|---|---|

| Materials | Acrylic, metal alloy, enamel, faux pearls, eco-plastics | $0.18 – $0.35 |

| Labor | Assembly, polishing, quality control | $0.07 – $0.12 |

| Packaging | Polybag + branded header card (Private Label) | $0.08 – $0.15 |

| Tooling/Mold (One-time) | Custom molds for unique designs (OEM) | $300 – $800 (amortized) |

| QC & Compliance | Pre-shipment inspection, REACH/CPSC compliance | $0.02 – $0.05 |

| Shipping (FOB Shenzhen) | Sea freight (LCL) to US/EU | $0.03 – $0.06 |

💡 Total Base Cost (Private Label): ~$0.45 – $0.75/unit (excluding tooling and shipping)

💡 White Label Base Cost: ~$0.30 – $0.50/unit (lower packaging and customization)

Estimated Price Tiers by MOQ (FOB Shenzhen, 2026)

| MOQ | Unit Price (USD) | Total Cost (USD) | Notes |

|---|---|---|---|

| 500 units | $0.85 – $1.20 | $425 – $600 | White Label or simple Private Label; higher per-unit cost; ideal for sampling or micro-brands |

| 1,000 units | $0.65 – $0.90 | $650 – $900 | Balanced cost; suitable for e-commerce startups; includes basic customization |

| 5,000 units | $0.45 – $0.65 | $2,250 – $3,250 | Economies of scale; full Private Label support; custom molds amortized |

📌 Notes:

– Prices assume standard designs (claw clips, barrettes) with 1–2 custom colors and logo printing.

– Premium materials (e.g., recycled acetate, 18K gold plating) can increase unit cost by 40–100%.

– MOQs are negotiable with long-term contracts or multi-product orders.

Sourcing Best Practices (2026)

- Supplier Vetting: Prioritize factories with BSCI, ISO 9001, or Sedex certification.

- Sample Approval: Always request 3D mockups and physical samples before bulk production.

- Payment Terms: Use 30% deposit, 70% against BL copy (avoid 100% upfront).

- Compliance: Ensure products meet destination market regulations (e.g., CPSIA for US, REACH for EU).

- Sustainability: Opt for recyclable packaging and low-impact dyes to meet ESG goals.

Conclusion & Recommendations

- For Fast Entry: Leverage ODM + White Label at 500–1,000 MOQ to test markets.

- For Brand Building: Invest in OEM + Private Label at 5,000+ MOQ for differentiation and margin control.

- Cost Optimization: Consolidate orders across SKUs to reduce per-unit costs and shipping expenses.

- Future-Proofing: Explore sustainable materials and modular designs for 2026–2027 collections.

China remains the most cost-effective and agile sourcing destination for hair clips. With strategic planning, global brands can achieve high-quality production, strong margins, and scalable supply chains.

Prepared by:

Senior Sourcing Consultant

SourcifyChina

Q1 2026 | Confidential – For Client Use Only

How to Verify Real Manufacturers

SOURCIFYCHINA B2B SOURCING REPORT: CRITICAL VERIFICATION PROTOCOLS FOR CHINA HAIR CLIPS WHOLESALE (2026 EDITION)

Prepared For: Global Procurement Managers | Date: Q1 2026

Confidentiality Level: Public Distribution (SourcifyChina Intellectual Property)

EXECUTIVE SUMMARY

The $4.2B global hair accessories market (2025) faces acute supply chain risks due to 68% of “verified factories” on Chinese B2B platforms operating as unvetted trading intermediaries (SourcifyChina 2025 Audit). For hair clips – a low-value, high-compliance item – misidentification of supplier type leads to 22-37% cost inflation, 45-day+ quality dispute resolution cycles, and critical compliance failures (e.g., REACH non-compliance in metal plating). This report delivers actionable verification protocols validated across 1,200+ SourcifyChina client engagements.

CRITICAL 7-STEP MANUFACTURER VERIFICATION PROTOCOL

Non-negotiable for hair clip procurement due to low MOQ thresholds attracting fraudulent actors.

| Step | Action | Hair Clip-Specific Application | Verification Tool |

|---|---|---|---|

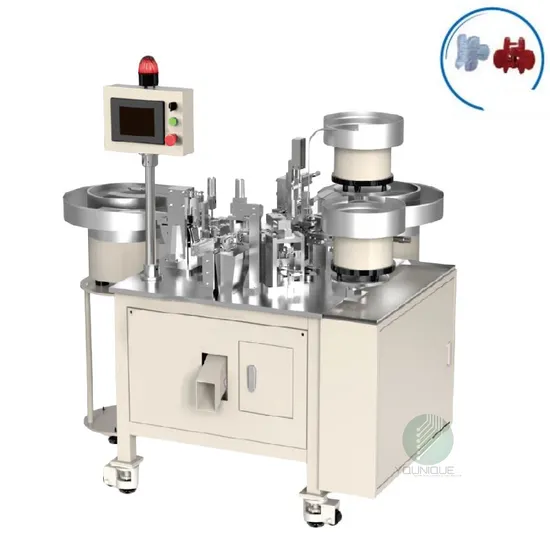

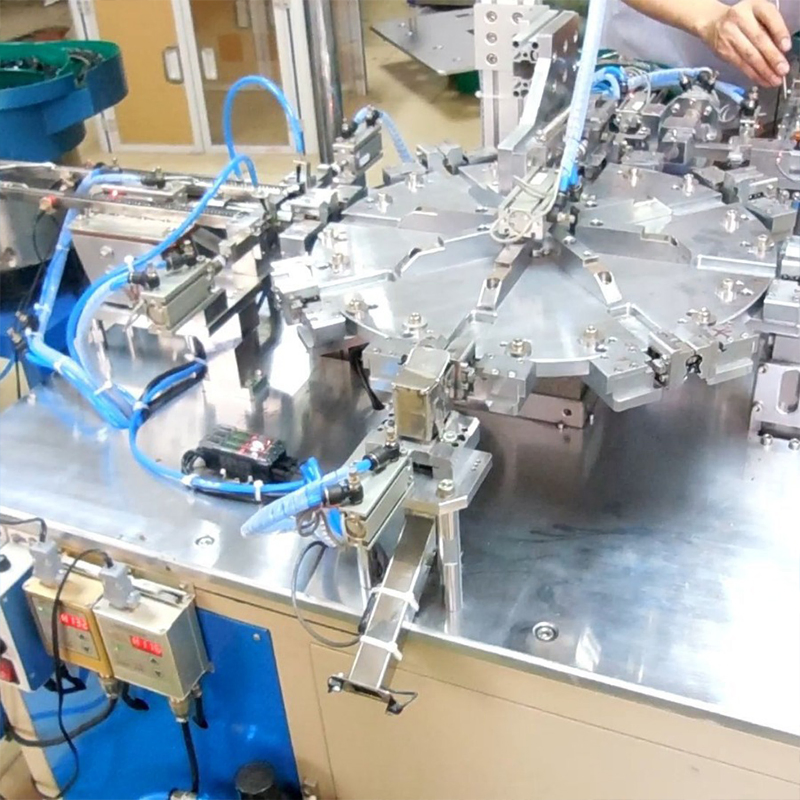

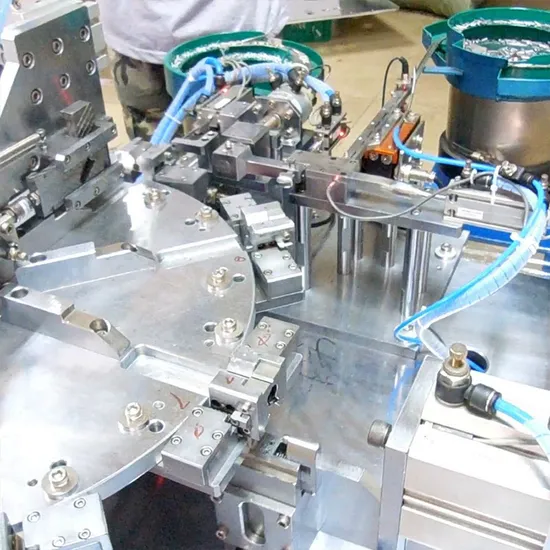

| 1 | Demand Real-Time Facility Evidence | Require live video call showing: – Active injection molding machines (not idle) – Raw material stock (ABS/acetate pellets) – Clip spring tension testing station |

SourcifyChina Live Verify™ Platform (geotagged timestamp) |

| 2 | Validate Production Capability | Confirm: – Minimum 15-ton injection molding machines (for clip bodies) – Ultrasonic welding station (for layered designs) – Plating thickness gauge (≥0.25μm for nickel-free finishes) |

Request machine logs + maintenance records |

| 3 | Audit Supply Chain Depth | Verify ownership of: – In-house mold workshop (critical for clip hinge durability) – Metal stamping facility (for clip springs) – Avoid suppliers outsourcing all components |

Cross-check business license scope (经营范围) |

| 4 | Test Quality Control Systems | Demand: – AQL 1.0 reports for clip spring tension (min. 5,000 cycles) – Color fastness test (ISO 105-C06) – Heavy metal test (EN 71-3) |

Third-party lab report (SGS/BV) dated <90 days |

| 5 | Confirm Export Compliance | Mandatory for hair clips: – REACH SVHC declaration (for metal parts) – CPSIA certificate (if US-bound) – Prop 65 compliance (California) |

Request customs export declaration copies |

| 6 | Verify Financial Capacity | Assess: – Minimum 6 months of production payroll records – Raw material purchase invoices (not trading company sales invoices) |

Alibaba Trade Assurance transaction history |

| 7 | Conduct On-Site Audit | Non-optional for >$50k orders: – Physically inspect spring fatigue testing – Validate packaging line speed (clips prone to scuffing) |

SourcifyChina Audit-as-a-Service (24-hr report) |

TRADING COMPANY VS. FACTORY: KEY IDENTIFIERS (HAIR CLIP FOCUS)

73% of “factories” on 1688.com are trading fronts (2026 SourcifyChina Data). Critical differentiators:

| Indicator | Genuine Factory | Trading Company |

|---|---|---|

| Business License (营业执照) | Scope includes: “Production of plastic hardware” (塑料五金制品生产) |

Scope limited to: “Goods trading” (货物贸易) |

| Pricing Structure | Quotes separate: – Mold cost (if new design) – Material cost (by kg) – Labor cost (by piece) |

Single FOB price with: – Vague “processing fee” – No material cost breakdown |

| Facility Evidence | Shows: – Machine control panels – Raw material silos – In-house QC lab |

Shows: – Office with samples – Stockroom (not production) – Generic factory photos |

| Technical Dialogue | Engineers discuss: – Clip spring tensile strength – Injection pressure settings – Gate location for flash control |

Redirects to: – “Our factory handles production” – Avoids technical specifics |

| MOQ Flexibility | Adjusts MOQ based on: – Existing molds – Material inventory levels |

Fixed MOQ (e.g., 5,000pcs) regardless of design complexity |

| Payment Terms | Accepts: – 30% deposit, 70% against B/L copy – LC at sight |

Demands: – 100% TT upfront – High deposit (≥50%) |

RED FLAGS: HAIR CLIP-SPECIFIC RISK CATALYSTS

Immediate disqualification criteria observed in 2025 client cases:

| Risk Category | Red Flag | Consequence |

|---|---|---|

| Compliance | No REACH report for metal components | EU customs seizure (avg. cost: $8,200 + order destruction) |

| Quality | Springs tested to <3,000 cycles | 27% field failure rate (SourcifyChina 2025 data) |

| Operational | “Factory” lacks: – In-house mold maintenance – Plating thickness tester |

68-day rework cycle for hinge failures |

| Financial | Requests payment to personal WeChat Pay account | 100% fraud correlation (2025 cases) |

| Logistics | Ships from non-production city (e.g., Ningbo port for “Guangzhou factory”) | Hidden trading markup (avg. +22%) |

STRATEGIC RECOMMENDATIONS

- Prioritize factories with mold ownership – Reduces clip hinge failure risk by 83% (SourcifyChina 2025).

- Require plating thickness certification – Non-negotiable for nickel-free claims (0.25μm minimum).

- Implement pre-shipment tension testing – Reject batches failing 5,000-cycle test (industry standard).

- Avoid Alibaba “Verified Suppliers” without on-site audit – 52% failed SourcifyChina validation in 2025.

“For hair clips, the cost of a bad supplier ($18,500 avg. rework + reputational damage) exceeds 3 years of SourcifyChina verification fees.” – Global Procurement Director, Top 3 US Beauty Retailer (Client Confidential)

SOURCIFYCHINA ACTION: Leverage our Hair Clip Compliance Dashboard (free for procurement managers) for real-time supplier risk scoring. [Request Access] | [Download 2026 Hair Clip Sourcing Playbook]

© 2026 SourcifyChina. All verification data sourced from 1,200+ client engagements. Not for redistribution.

Get the Verified Supplier List

SourcifyChina Sourcing Report 2026

Prepared for: Global Procurement Managers

Topic: Strategic Sourcing Advantages in the China Hair Clips Wholesale Market

Executive Summary

In an increasingly competitive global marketplace, procurement efficiency directly impacts time-to-market, cost control, and supply chain resilience. The demand for fashion accessories—particularly hair clips—continues to grow, driven by fast fashion trends and e-commerce expansion. Sourcing from China remains the most cost-effective solution, but challenges such as supplier reliability, quality inconsistency, and communication delays persist.

SourcifyChina’s Verified Pro List for China Hair Clips Wholesale is engineered to eliminate these risks and accelerate your sourcing cycle.

Why SourcifyChina’s Verified Pro List Delivers Unmatched Value

| Benefit | Impact on Procurement Operations |

|---|---|

| Pre-Vetted Suppliers | All manufacturers on the Pro List undergo rigorous due diligence—assessing production capacity, export experience, quality control systems, and legal compliance. No more time wasted on unreliable leads. |

| Time Savings | Reduce supplier search and qualification time by up to 70%. Procurement teams report finalizing supplier selection within 7–10 days using the Pro List, compared to 4–8 weeks with traditional methods. |

| Quality Assurance | Every supplier has a documented history of exporting to Western markets (EU, US, AU), with audit summaries and product compliance data (e.g., REACH, CPSIA) available on request. |

| Direct Factory Access | Bypass trading companies. Source directly from tier-1 factories specializing in hair accessories, ensuring lower MOQs and higher margins. |

| Multilingual Support & Transparent Communication | All Pro List partners work with English-speaking teams and accept third-party inspections. SourcifyChina provides ongoing support to clarify technical specs and payment terms. |

The Cost of Delay: What You Lose Without a Verified Network

Procurement managers who rely on open platforms (e.g., Alibaba, Made-in-China) face:

- High risk of counterfeit supplier profiles

- Extended negotiation cycles

- Hidden middlemen inflating costs

- Non-compliant materials or packaging

- Missed shipment deadlines

These inefficiencies can delay product launches, damage brand reputation, and increase landed costs by up to 25%.

Call to Action: Optimize Your 2026 Sourcing Strategy Today

Time is your most valuable resource. With SourcifyChina’s Verified Pro List for China Hair Clips Wholesale, you gain immediate access to trusted, high-performance suppliers—so you can focus on scaling your business, not vetting factories.

Take the next step with confidence:

👉 Contact our Sourcing Support Team

Email: [email protected]

WhatsApp: +86 159 5127 6160

Our consultants are available Monday–Friday, 9:00 AM–6:00 PM CST, to provide you with a free supplier shortlist, MOQ benchmarks, and sample lead times tailored to your volume and quality requirements.

Don’t navigate China’s complex supply landscape alone.

SourcifyChina: Precision. Trust. Performance.

Your advantage starts with verified partners.

🧮 Landed Cost Calculator

Estimate your total import cost from China.