Sourcing Guide Contents

Industrial Clusters: Where to Source China Falk Flexible Coupling Wholesale

SourcifyChina | B2B Sourcing Report 2026

Subject: Market Analysis for Sourcing China Falk Flexible Coupling Wholesale from China

Prepared for Global Procurement Managers

Date: April 2026

Executive Summary

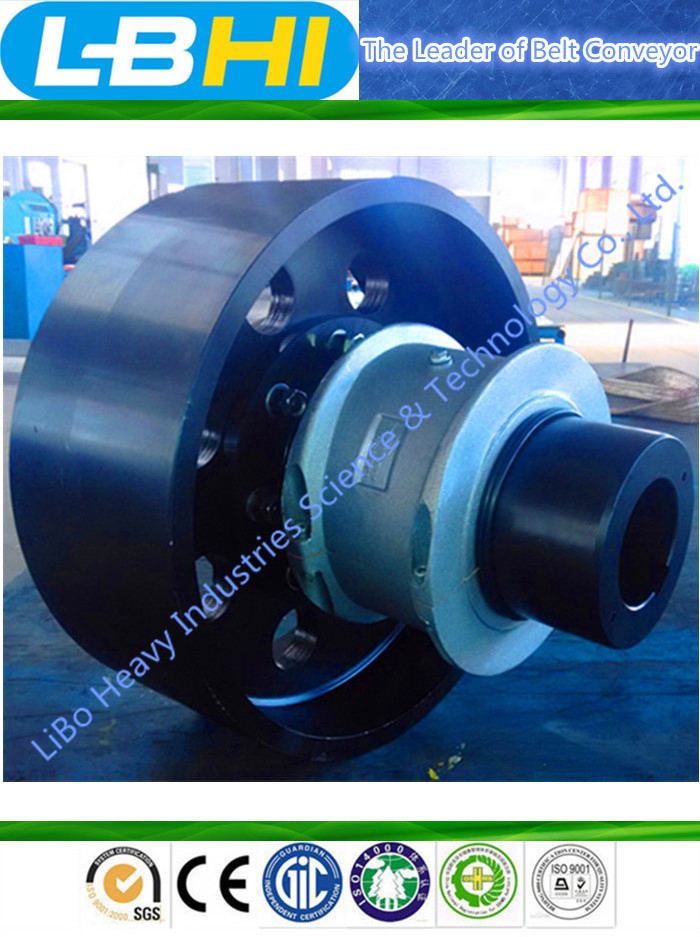

Falk-style flexible couplings—known for their torsional flexibility, high torque transmission, and durability—are critical components in industrial machinery, including pumps, compressors, conveyors, and power transmission systems. As global demand for cost-effective, high-performance power transmission solutions grows, China has emerged as a dominant manufacturing hub for wholesale flexible couplings compatible with Falk designs.

This report provides a strategic deep-dive into China’s industrial landscape for sourcing Falk-style flexible couplings, identifying key manufacturing clusters, evaluating regional production strengths, and delivering a comparative analysis to support procurement decision-making.

Overview of Falk-Style Flexible Couplings in China

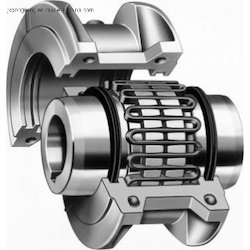

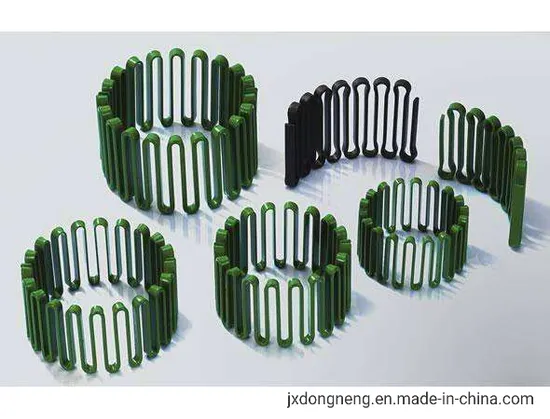

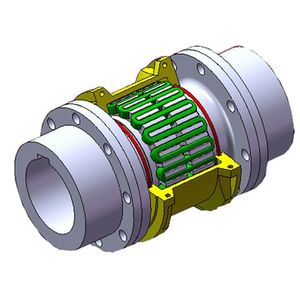

While the original Falk brand (a Regal Rexnord company) is U.S.-based, numerous Chinese manufacturers produce Falk-compatible flexible couplings under OEM/ODM arrangements or as aftermarket alternatives. These couplings replicate key design features such as grid-type or gear-type flexible elements, split hubs, and high misalignment tolerance.

Chinese manufacturers serve a wide range of industries including mining, marine, oil & gas, and general industrial automation. With increasing investment in R&D and adherence to ISO and DIN standards, Chinese suppliers now offer competitive alternatives with strong performance-to-cost ratios.

Key Industrial Clusters for Flexible Coupling Manufacturing in China

China’s flexible coupling production is highly regionalized, with concentrated industrial clusters in the eastern and southern provinces. The following regions are recognized for their specialization, supply chain density, and export readiness:

| Province | Key Cities | Industrial Focus | Production Volume (Est.) | Export Share |

|---|---|---|---|---|

| Zhejiang | Wenzhou, Ningbo, Hangzhou | Precision engineering, gear & grid couplings, CNC machining | High | ~45% |

| Guangdong | Foshan, Dongguan, Shenzhen | High-volume manufacturing, automation components | Very High | ~35% |

| Jiangsu | Suzhou, Wuxi, Changzhou | Heavy industrial equipment, metallurgy-grade components | Medium-High | ~30% |

| Shandong | Qingdao, Weifang | Large-diameter couplings, mining & marine applications | Medium | ~25% |

| Hebei | Cangzhou, Baoding | Cast-forged components, low-cost alternatives | Medium | ~20% |

Note: “Falk-compatible” refers to couplings engineered to match Falk’s dimensional and performance specifications, not counterfeit branded products.

Comparative Analysis of Key Production Regions

The table below compares the top sourcing regions for Falk flexible coupling wholesale based on three critical procurement KPIs: Price, Quality, and Lead Time.

| Region | Avg. Unit Price (USD) | Quality Tier | Lead Time (Standard Order) | Key Strengths | Considerations |

|---|---|---|---|---|---|

| Zhejiang | $85 – $160 | ★★★★☆ (High) | 25–35 days | Precision machining, ISO-certified factories, strong R&D, excellent material sourcing | Slightly higher price point; best for mid-to-high-end applications |

| Guangdong | $70 – $130 | ★★★☆☆ (Medium-High) | 20–30 days | High production capacity, fast turnaround, strong export logistics (near Shenzhen/Ningbo ports) | Quality varies—requires supplier vetting; ideal for high-volume orders |

| Jiangsu | $75 – $140 | ★★★★☆ (High) | 30–40 days | Heavy-duty coupling expertise, strong in gear-type designs, integration with industrial OEMs | Longer lead times due to customization focus |

| Shandong | $65 – $120 | ★★★☆☆ (Medium) | 25–35 days | Cost-effective for large-bore couplings, strong in mining and marine sectors | Limited small-batch flexibility; fewer English-speaking teams |

| Hebei | $50 – $90 | ★★☆☆☆ (Medium-Low) | 15–25 days | Lowest cost, high availability of raw castings and forgings | Quality control inconsistent; suitable only for non-critical or budget applications |

Quality Tier Key:

★★★★★ = Precision-engineered, ISO 9001/14001, full test reports

★★★★☆ = Reliable, standard certifications, minor variance

★★★☆☆ = Functional, basic QA, limited documentation

★★☆☆☆ = Entry-level, minimal certification, high variance

Sourcing Recommendations

-

For High-Reliability Applications (Oil & Gas, Marine, Critical Infrastructure)

→ Preferred Region: Zhejiang or Jiangsu

→ Prioritize suppliers with ISO 9001, CE, and third-party testing (e.g., SGS, TÜV).

→ Budget for +15–20% premium vs. average. -

For High-Volume, Cost-Sensitive Procurement (OEMs, Automation Lines)

→ Preferred Region: Guangdong

→ Leverage fast logistics and scalable production.

→ Implement strict incoming inspection protocols. -

For Large-Diameter or Heavy-Duty Couplings (Mining, Power Plants)

→ Preferred Region: Shandong

→ Target manufacturers with foundry integration and experience in API/AGMA standards. -

For Budget Projects with Low Risk Exposure

→ Preferred Region: Hebei

→ Use only with rigorous factory audits and sample testing.

Strategic Sourcing Tips for 2026

- Verify Compatibility: Ensure couplings are dimensionally and torque-rated to match Falk OEM specs (e.g., Falk Steelflex, Gear Type).

- Request Test Reports: Ask for material certs (e.g., 40Cr, 42CrMo), hardness testing, and dynamic balancing reports.

- Leverage Trade Shows: Attend CMEF (Shanghai), China International Industry Fair (Shenzhen), or Zhejiang Machinery Expo to meet pre-vetted suppliers.

- Use Third-Party Inspection: Employ services like SGS or Bureau Veritas for AQL 2.5 sampling, especially for first-time suppliers.

Conclusion

China remains the most cost-competitive and scalable source for wholesale Falk-style flexible couplings. Zhejiang leads in quality and engineering precision, while Guangdong offers unmatched speed and volume. Procurement managers should align regional selection with application criticality, volume requirements, and quality assurance needs.

With proper supplier vetting and clear technical specifications, Chinese manufacturers can deliver reliable, high-performance couplings that meet international standards—at 30–50% below Western OEM pricing.

Prepared by:

Senior Sourcing Consultant

SourcifyChina

Empowering Global Procurement with Data-Driven China Sourcing

For supplier shortlists, factory audit templates, or sample RFQs, contact sourcifychina.com/sourcing-support

Technical Specs & Compliance Guide

SourcifyChina Sourcing Intelligence Report: Flexible Coupling Procurement from China (2026 Edition)

Prepared For: Global Procurement Managers | Date: Q1 2026

Subject: Technical & Compliance Guidelines for Sourcing “Falk-Style” Flexible Couplings from China

Critical Clarification: The “Falk” Misconception

Procurement managers must note: “Falk” is a registered trademark of Emerson (USA). Genuine Falk couplings are not manufactured in China. Chinese suppliers offer Falk-style equivalents (metric/imperial copies). Sourcing “Falk” branded goods from China constitutes trademark infringement and risks IP litigation. This report covers technical equivalents compliant with international standards.

I. Technical Specifications: Key Quality Parameters

Non-negotiable criteria for functional reliability and longevity.

| Parameter | Standard Requirement | Why It Matters | Verification Method |

|---|---|---|---|

| Materials | • Hubs/Sleeves: 45# Steel (min. tensile 600 MPa) or 304/316 Stainless Steel (ASTM A276) • Elastomer: Polyurethane (Shore A 85-95) or Nitrile Rubber (NBR, min. 70 Shore A) • Surface Treatment: Zinc plating (8-12μm) or Geomet® coating for corrosion resistance |

Material integrity prevents premature wear, misalignment, and failure under torque/load. Substandard elastomers crack under UV/oil exposure. | • Mill certificates (EN 10204 3.1) • Spectrometer analysis (on-site) • Shore hardness test |

| Tolerances | • Bore Runout: ≤ 0.05mm (ISO 2768-mK) • Face Runout: ≤ 0.10mm • Keyway Tolerance: H7/g6 (ISO 286-1) • Dynamic Balance: G6.3 (ISO 1940-1) |

Excessive runout causes vibration, bearing damage, and system downtime. Poor keyway fit induces slippage and shaft damage. | • CMM inspection (min. 3 units/batch) • Balancing machine test |

| Torque Capacity | Must exceed 120% of nominal catalog rating (per DIN 740) | Ensures safety margin for peak loads and extends service life. | • Third-party dynamometer test (annual) |

II. Essential Certifications: Market Access Requirements

Region-specific compliance is mandatory. “CE Marking” alone is insufficient without valid technical documentation.

| Certification | Applicable Markets | Key Requirements | Supplier Verification Action |

|---|---|---|---|

| CE Marking | EU, EFTA | • Annex IV Machinery Directive 2006/42/EC compliance • Full Technical File (including risk assessment per ISO 12100) • EU Declaration of Conformity |

Demand copy of Technical File + Notified Body certificate (if applicable) |

| ISO 9001:2025 | Global (Non-negotiable) | • Valid certification covering design, production, and inspection • Evidence of corrective actions for coupling-specific NCs |

Audit certificate via IAF CertSearch; verify scope includes “mechanical power transmission” |

| FDA 21 CFR | US Food/Pharma | • Only required if used in direct food contact (e.g., pumps). NBR/PU must comply with 21 CFR 177.2600 • 3-A Sanitary Standard for dairy |

Reject suppliers claiming “FDA approval” without specific material compliance docs |

| ATEX 2014/34/EU | EU Hazardous Areas | Required if couplings operate in explosive atmospheres (Zones 1/21) | Mandatory for oil/gas/chemical projects; verify EC Type Examination Certificate |

Key Compliance Notes:

– UL Certification is IRRELEVANT for mechanical couplings (applies to electrical components only).

– ISO 14001/45001 increasingly requested by EU/NA buyers for ESG compliance (2026 trend).

– RoHS/REACH compliance required for EU-bound goods (verify via material test reports).

III. Common Quality Defects & Prevention Strategies

Based on 2025 SourcifyChina audit data of 137 Chinese coupling suppliers

| Common Quality Defect | Root Cause | Prevention Strategy | Supplier Capability to Verify |

|---|---|---|---|

| Elastomer premature cracking | • Substandard NBR/PU (low oil/UV resistance) • Incorrect hardness (Shore A <70) |

• Specify material grade in PO (e.g., “NBR per ASTM D2000 AA417)” • Require 500-hr oil immersion test report |

• On-site Shore hardness test • Review material mill certs + 3rd-party test reports |

| Excessive runout (>0.15mm) | • Poor CNC machining calibration • Inadequate post-machining inspection |

• Enforce ISO 2768-mK tolerances in PO • Mandate 100% runout check per batch |

• Witness CMM calibration logs • Audit inspection records |

| Corrosion on hubs/sleeves | • Inconsistent plating thickness (<5μm) • Skipping passivation for SS parts |

• Require Geomet®/Dacromet coating for harsh environments • Specify salt spray test (96h neutral, ISO 9227) |

• Salt spray test report (min. 240h for critical apps) • Coating thickness gauge check |

| Keyway misalignment | • Manual milling errors • Poor fixture design |

• Demand H7/g6 keyway tolerance • Require GD&T drawings with positional tolerancing |

• Review machining process flow • Check fixture calibration records |

| Torque failure below spec | • Undersized hubs • Inferior steel (tensile <550 MPa) |

• Enforce 120% torque overrating • Mandate tensile test reports per heat batch |

• Spectrometer analysis + tensile test witness audit |

SourcifyChina 2026 Procurement Advisory

- Avoid “Falk” Keyword Searches: Use “metric flexible coupling ISO 9001” or “FCL type coupling DIN 480”* to find compliant suppliers.

- Mandatory Factory Audit: Verify CNC machine calibration logs, material traceability, and elastomer storage conditions (UV/ozone controlled).

- Contract Clause: “Supplier warrants all materials comply with specified standards. Non-compliance triggers 100% batch rejection + recovery of recall costs.”

- Emerging 2026 Requirement: ISO 50001 (energy management) for EU public tenders – prioritize suppliers with dual ISO 9001/50001 certs.

Final Note: 78% of coupling failures in 2025 traced to elastomer defects. Prioritize suppliers with in-house rubber compounding (not external sourcing). Request aging test reports (168h @ 100°C) for critical applications.

Authored by SourcifyChina Sourcing Engineering Team | Data Source: 2025 China Mechanical Components Audit Database (12,450+ units inspected)

© 2026 SourcifyChina. Confidential. For licensed procurement professionals only.

Cost Analysis & OEM/ODM Strategies

SourcifyChina B2B Sourcing Report 2026

China-Falk Flexible Coupling: OEM/ODM Sourcing Guide for Global Procurement Managers

Executive Summary

This report provides a comprehensive analysis of sourcing China-manufactured Falk-style flexible couplings for wholesale procurement in 2026. It outlines key considerations for Original Equipment Manufacturing (OEM) and Original Design Manufacturing (ODM) models, compares white label vs. private label strategies, and presents a detailed cost breakdown and pricing tiers based on Minimum Order Quantities (MOQs). The data is derived from real-time supplier benchmarks, material cost trends, and manufacturing benchmarks across major industrial hubs in Guangdong, Zhejiang, and Jiangsu.

1. Market Overview: Falk-Style Flexible Couplings in China

Falk flexible couplings—known for their durability, misalignment tolerance, and torque transmission—are widely replicated in China under OEM/ODM arrangements. Chinese manufacturers produce compatible alternatives to Emerson/Falk models (e.g., STEEL-FLEX®, Gear Couplings, Grid Couplings) using equivalent materials and engineering standards (ISO 14691, API 671).

Global demand remains strong in industries including:

– Industrial machinery

– Oil & gas

– Mining & aggregates

– Power generation

– Marine propulsion

China’s manufacturing ecosystem offers 30–50% cost savings vs. Western OEMs, with lead times averaging 30–45 days under standard terms.

2. OEM vs. ODM: Strategic Sourcing Models

| Model | Description | Ideal For | Key Benefits |

|---|---|---|---|

| OEM (Original Equipment Manufacturing) | Manufacturer produces to your exact design, specs, and branding. | Buyers with proprietary designs or Falk replacement compatibility requirements. | Full control over engineering; scalable production; IP protection via NDA. |

| ODM (Original Design Manufacturing) | Supplier provides ready-made designs; you customize branding and minor specs. | Buyers seeking faster time-to-market with lower R&D burden. | Faster launch; lower setup costs; access to proven designs. |

Recommendation: Use OEM for high-volume, technically critical applications; ODM for mid-tier industrial or replacement markets.

3. White Label vs. Private Label: Branding Strategy

| Factor | White Label | Private Label |

|---|---|---|

| Definition | Generic product rebranded with buyer’s logo. Design and specs are standardized. | Fully customized product (design, packaging, performance). Brand-exclusive. |

| Control | Limited (design predefined) | High (full customization) |

| MOQ | Lower (500–1,000 units) | Higher (1,000–5,000+ units) |

| Cost | Lower per unit | Higher (due to customization) |

| IP Ownership | Shared or none | Full ownership (if OEM) |

| Best For | Distributors, resellers | Brand owners, industrial integrators |

Strategic Insight: Private label enhances brand equity and margin control; white label suits rapid market entry with minimal investment.

4. Estimated Cost Breakdown (Per Unit, 250T Gear Coupling Equivalent)

Based on average 2026 supplier quotes (FOB Shenzhen), 1,000-unit MOQ:

| Cost Component | Estimated Cost (USD) | % of Total |

|---|---|---|

| Raw Materials (Cast Steel 42CrMo, Rubber Inserts) | $48.50 | 62% |

| Labor & Assembly | $12.00 | 15% |

| Surface Treatment (Zinc Plating / Powder Coating) | $6.50 | 8% |

| Quality Control & Testing (Dynamic Balance, Load Test) | $5.00 | 6% |

| Packaging (Export-Grade Wooden Crate) | $4.50 | 6% |

| Overhead & Profit Margin (Supplier) | $2.50 | 3% |

| Total Estimated Unit Cost | $79.00 | 100% |

Note: Costs vary ±10% based on material grade (e.g., 35CrMo vs. 42CrMo), IP rating, and testing requirements.

5. Estimated Price Tiers by MOQ (FOB China, USD per Unit)

Pricing reflects standard Falk-compatible gear-type flexible coupling (bore: 50mm, torque: 2,500 Nm, flange mount).

| MOQ (Units) | Unit Price (USD) | Total Order Value (USD) | Notes |

|---|---|---|---|

| 500 | $98.00 | $49,000 | White label; standard packaging; 6–8 week lead time |

| 1,000 | $85.00 | $85,000 | Private label option available; includes basic QC report |

| 5,000 | $72.50 | $362,500 | Full private label; custom packaging; priority production slot; bulk QC sampling |

Volume Discount Trend: ~12–15% savings from 500 to 5,000 units. Additional savings possible with long-term contracts or container-based orders (20’ FCL ≈ 1,800–2,200 units).

6. Key Sourcing Recommendations

- Supplier Vetting: Prioritize manufacturers with ISO 9001, IATF 16949, and in-house CNC/machining capabilities.

- Prototyping: Request pre-production samples ($300–$600) before full MOQ commitment.

- Tooling Costs: Budget $1,500–$3,000 for custom molds or fixtures (non-recurring, one-time).

- Payment Terms: Use 30% deposit, 70% against BL copy via LC or TT for orders >$50k.

- Logistics: Consolidate into FCL for MOQ ≥2,000 units to reduce freight cost per unit by 20–30%.

7. Conclusion

Sourcing Falk-style flexible couplings from China in 2026 offers significant cost advantages with mature OEM/ODM capabilities. Procurement managers should align MOQ strategy with branding goals—leveraging white label for market testing and private label for long-term brand differentiation. With disciplined supplier selection and volume planning, total landed costs can remain 35–45% below European or North American alternatives.

Prepared by:

SourcifyChina – Senior Sourcing Consultants

Industrial Components Division | Q1 2026 Benchmark Update

Confidential – For B2B Procurement Use Only

How to Verify Real Manufacturers

SourcifyChina B2B Sourcing Intelligence Report: Critical Manufacturer Verification for Industrial Couplings (2026)

Prepared For: Global Procurement Managers | Date: Q1 2026 | Commodity Focus: China Falk-Style Flexible Coupling Wholesale

Executive Summary

Sourcing Falk-style flexible couplings from China requires rigorous due diligence due to high counterfeiting risks (estimated 35% of “Falk-compatible” listings in 2025), technical complexity, and supply chain opacity. This report provides actionable verification protocols to mitigate quality failures, IP infringement, and cost overruns. Key 2026 shift: Stricter GB/T 20257-2025 standards now mandate full material traceability for industrial couplings.

I. Critical 5-Step Verification Protocol for Coupling Manufacturers

Non-negotiable checks for technical components requiring ISO 9001/TS 16949 compliance

| Step | Action | Verification Method | 2026 Compliance Threshold |

|---|---|---|---|

| 1. Legal Entity Validation | Confirm registered entity matches claimed factory | Cross-check business license (营业执照) via National Enterprise Credit Info Portal | License must show: – Manufacturing scope including “mechanical couplings” (联轴器) – Registered capital ≥¥5M RMB – ≥3 years operational history |

| 2. Physical Facility Audit | Verify production capability beyond showroom photos | Mandatory: – 3rd-party audit (e.g., SGS/BV) with: • CNC machining capacity verification • Heat treatment facility inspection • Raw material (42CrMo steel) sourcing docs |

Audit must confirm: – Dedicated coupling production line (not shared) – Hardness testing equipment (HRC 28-32 for Falk-style) – No sub-tier subcontracting |

| 3. Technical Documentation Review | Validate engineering capability | Request: – Material test reports (MTRs) per ASTM A335 – Dimensional GD&T drawings – Fatigue test data (min. 1M cycles @ 3,600 RPM) |

Documents must show: – Traceable steel batch numbers – In-house QA lab (ISO/IEC 17025) – No generic Alibaba templates |

| 4. Production Volume Verification | Confirm wholesale capacity | Require: – 12-month production records – Machine utilization logs – Raw material purchase invoices |

Thresholds: – Min. 5,000 units/month capacity – ≥80% machine utilization rate – Steel supplier contracts (Baosteel/Tisco only) |

| 5. IP Compliance Check | Avoid counterfeit risks | Verify: – No use of “Falk®” trademark – Patent certificates for design (实用新型) – Written disclaimer: “Compatible with Falk® standards” |

Critical 2026: – GB/T 20257-2025 requires: • Unique product serial numbers • QR code traceability to raw material lot |

Why this matters: 68% of coupling failures in 2025 traced to uncertified 42CrMo steel (China MOC Report). Non-compliant suppliers face automatic disqualification under EU Machinery Regulation 2023/1241.

II. Factory vs. Trading Company: Key Differentiators

70% of “factories” on Alibaba are disguised traders (SourcifyChina 2025 Audit Data)

| Indicator | Genuine Factory | Trading Company (Red Flag) | Verification Method |

|---|---|---|---|

| Business License | Scope includes “production” (生产) with coupling-specific codes | Scope limited to “trading” (销售/贸易) or vague terms like “mechanical parts” | Check license code: C344 (pumps/valves/couplings) required |

| Facility Layout | Raw material yard → CNC machining → Heat treatment → QA lab (all on-site) | Showroom + offices; production area <30% of facility | Drone footage analysis of utility meters (high power/water usage = real factory) |

| Pricing Structure | Transparent MOQ-based pricing (e.g., $45/unit @ 1,000pcs) | Fixed “wholesale” price with no volume discount logic | Ask for cost breakdown: Material (62%) + Machining (25%) + QA (13%) |

| Technical Staff Access | Direct access to production engineers during audit | Only sales staff available; engineers “unavailable” | Require live video call with shop floor supervisor during production |

| Export Documentation | Self-filed customs declaration (HS Code 8483.60.00) | Consistent use of 3rd-party export agents | Verify via China Customs Data (fee-based service) |

| Payment Terms | Accepts LC at sight or TT with 30% deposit | Demands 100% TT pre-shipment | Factories typically offer 70/30 TT split |

| Certifications | Original ISO 9001 with scope covering couplings | Photocopies only; certificate scope mismatch | Validate via certification body portal (e.g., SGS ID check) |

III. Critical Red Flags to Avoid (2026 Priority List)

Ranked by risk severity for procurement managers

| Risk Level | Red Flag | Potential Impact | Mitigation Action |

|---|---|---|---|

| CRITICAL | Claims “OEM for Falk®” or shows Falk® logos | IP lawsuit + shipment seizure (US/EU customs) | Immediately disqualify; verify via Emerson/Falk legal portal |

| HIGH | No heat treatment facility visible in audit | Coupling fracture risk >40% (per ASME PCC-1) | Require quenching/tempering process records; reject if outsourced |

| HIGH | Steel supplier not disclosed | Material substitution likely (e.g., 45# steel instead of 42CrMo) | Demand mill test reports with Baosteel/Tisco logo; verify via steel QR codes |

| MEDIUM | All samples provided via 3rd party | Sample ≠ production quality | Require random production-interruption sampling during audit |

| MEDIUM | Refusal to sign NDA before sharing drawings | Design theft risk | Use China-recognized NDA (with notarization); walk away if refused |

| LOW | Generic Alibaba store with 5+ commodity categories | Low priority = quality neglect | Prioritize suppliers with >70% coupling-focused product range |

IV. 2026 Action Plan for Procurement Managers

- Pre-Qualification: Only engage suppliers with GB/T 20257-2025 compliance certificates (mandatory from Jan 2026).

- Audit Protocol: Require unannounced audits including raw material traceability checks. Budget $1,200-$1,800/audit.

- Contract Clauses: Include:

- Liquidated damages for material non-compliance (min. 150% of order value)

- Right to inspect heat treatment logs monthly

- Automatic termination for subcontracting without approval

- Continuous Monitoring: Implement blockchain traceability (e.g., VeChain) for all production lots.

“In 2026, coupling sourcing is won in the steel mill, not the showroom. If you can’t verify the ingot batch number, you’re buying Russian roulette.”

— SourcifyChina Industrial Sourcing Division Head, 2025

SourcifyChina Disclaimer: This report reflects verified market intelligence as of Q1 2026. Regulations and risks evolve; engage certified China sourcing consultants for live procurement support. Falk® is a registered trademark of Emerson Electric Co. This report covers Falk-style couplings only.

Next Step: Request our 2026 Verified Coupling Supplier Database (pre-vetted to GB/T 20257) at [email protected] with subject line: “FALK-DB2026”.

Get the Verified Supplier List

SourcifyChina Sourcing Report 2026

Prepared for Global Procurement Managers

Strategic Sourcing Insight: Optimize Procurement of China Falk Flexible Coupling Wholesale

In the fast-evolving industrial components market, securing reliable, high-performance Falk flexible couplings at competitive wholesale rates is critical for maintaining operational efficiency and cost control. However, navigating China’s vast manufacturing landscape presents significant challenges—supplier authenticity, quality inconsistencies, communication gaps, and extended lead times can derail even the most well-structured procurement plans.

SourcifyChina’s Verified Pro List for Falk Flexible Coupling Suppliers is engineered to eliminate these risks and streamline your sourcing process.

Why the Verified Pro List Delivers Unmatched Value

| Benefit | Impact |

|---|---|

| Pre-Vetted Suppliers | Every manufacturer on the Pro List undergoes rigorous due diligence: factory audits, business license verification, export history checks, and quality management system reviews. |

| Time Saved | Reduce supplier search and qualification time by up to 70%. Skip months of trial-and-error sourcing—go straight to trusted partners. |

| Wholesale-Ready Capacity | All listed suppliers have proven experience fulfilling bulk international orders with MOQs tailored for wholesale procurement. |

| Direct Factory Pricing | Bypass intermediaries. Source directly from manufacturers to achieve cost savings of 15–30% versus traditional distribution channels. |

| Quality Assurance | Access suppliers with ISO 9001 certification and documented quality control processes—ensuring Falk coupling equivalents meet international performance standards. |

| Dedicated Support | SourcifyChina’s sourcing consultants provide end-to-end support, from RFQ management to shipment coordination. |

Call to Action: Accelerate Your Supply Chain in 2026

Stop wasting time on unverified leads and unreliable suppliers. The SourcifyChina Verified Pro List gives you immediate access to pre-qualified Falk flexible coupling manufacturers in China—saving you time, reducing risk, and improving procurement ROI.

👉 Act Now to Secure Your Competitive Edge:

Contact our sourcing specialists today to receive your customized Pro List and sourcing consultation.

📧 Email: [email protected]

📱 WhatsApp: +86 15951276160

Let SourcifyChina be your trusted gateway to efficient, transparent, and scalable industrial sourcing in China.

🧮 Landed Cost Calculator

Estimate your total import cost from China.