Sourcing Guide Contents

Industrial Clusters: Where to Source China Fabrication Companies

SourcifyChina | B2B Sourcing Intelligence Report 2026

Confidential: For Global Procurement Leadership

Prepared by: Senior Sourcing Consultant, SourcifyChina Sourcing Intelligence Group

Date: October 26, 2026

Executive Summary

China remains the dominant global hub for fabrication services (metalworking, machining, sheet metal, welding, assembly), though strategic regional shifts are accelerating due to rising costs, trade policies, and technological specialization. Post-“China+1” strategy maturation, procurement success now hinges on precise cluster alignment with product complexity, quality thresholds, and cost targets. This report identifies core industrial clusters for fabrication services, analyzes regional differentiators, and provides actionable benchmarks for 2026 sourcing decisions. Critical Insight: Price differentials between top clusters have narrowed to 8-12% (vs. 15-20% in 2022), while quality consistency and supply chain resilience now drive 68% of strategic supplier selection (SourcifyChina 2026 Global Procurement Survey).

Key Industrial Clusters for Fabrication Services in China

Fabrication services are concentrated in three primary economic corridors, each with distinct specializations:

-

Pearl River Delta (PRD) Cluster

- Core Provinces/Cities: Guangdong (Dongguan, Shenzhen, Foshan, Guangzhou), Southern Jiangxi

- Dominant Sectors: High-precision CNC machining (aerospace, medical devices), electronics enclosures, rapid prototyping, complex sheet metal for telecom/data centers.

- 2026 Shift: Migration of low-margin stamping/welding to Hunan/Hubei; PRD now focuses on <0.005mm tolerance machining and integrated sub-assembly. Strongest Western compliance expertise (ISO 13485, AS9100).

-

Yangtze River Delta (YRD) Cluster

- Core Provinces/Cities: Zhejiang (Ningbo, Hangzhou, Wenzhou), Jiangsu (Suzhou, Changzhou, Kunshan), Shanghai

- Dominant Sectors: Medium-to-high precision machining (automotive, industrial equipment), structural steel fabrication, hydraulic/pneumatic components, cost-optimized sheet metal. Highest density of Tier-2 automotive suppliers.

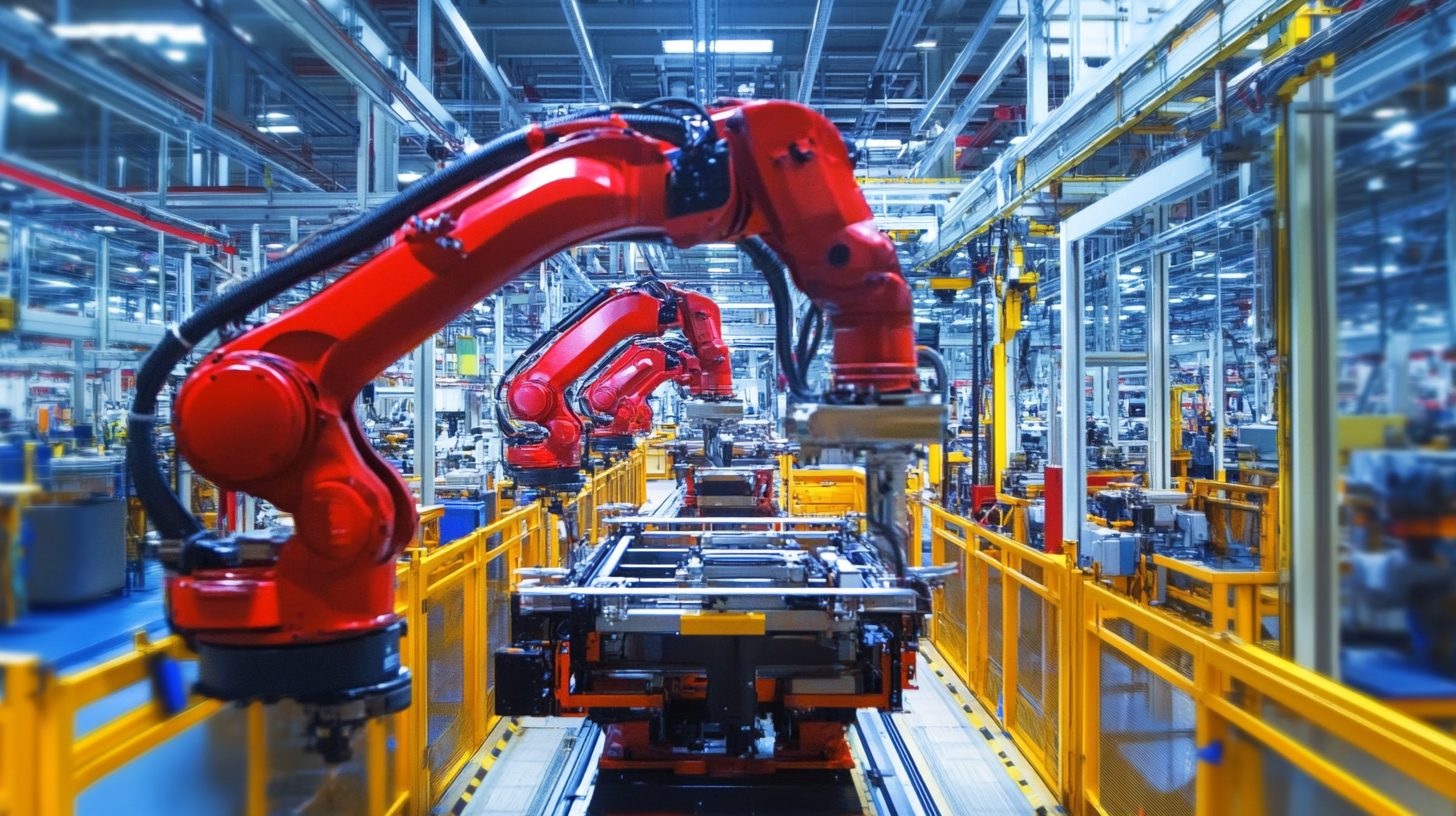

- 2026 Shift: Automation leadership (70%+ of YRD fabrication shops use robotic welding/cell systems); strongest “one-stop-shop” capabilities (casting → machining → surface treatment).

-

Western & Central Expansion Corridor

- Core Provinces/Cities: Sichuan (Chengdu), Chongqing, Hubei (Wuhan), Hunan (Changsha)

- Dominant Sectors: Heavy structural fabrication, large-scale welding (construction, energy), cost-sensitive stamped components, emerging EV battery/casing production.

- 2026 Shift: Government subsidies driving automation adoption; lead times improving but quality consistency remains variable for high-tolerance parts. Primary beneficiary of “China+1” overflow for non-critical components.

Strategic Note: Avoid oversimplifying “China sourcing.” Dongguan (PRD) and Ningbo (YRD) are not interchangeable. Match cluster specialization to your Bill of Materials (BOM) criticality.

Regional Cluster Comparison: Fabrication Services (2026 Benchmarks)

Data Source: SourcifyChina Verified Supplier Database (Q3 2026), 1,200+ Active Fabrication Partners, Median Metrics for ISO 9001 Certified Shops

| Criteria | Pearl River Delta (Guangdong) | Yangtze River Delta (Zhejiang/Jiangsu) | Western/Central (Sichuan/Hubei) | Key Differentiators |

|---|---|---|---|---|

| Price (USD) | $$$$ (Highest) | $$$ (Moderate) | $$ (Lowest) | PRD: +12-15% vs YRD for equivalent CNC work. YRD: 8-10% cost advantage on sheet metal vs PRD. West: 18-22% below PRD for structural weldments. |

| Quality | ⭐⭐⭐⭐⭐ (Consistent Premium) | ⭐⭐⭐⭐ (Very Good) | ⭐⭐⭐ (Good; High Variability) | PRD leads in high-mix/low-volume precision; YRD strongest in volume repeatability; West requires rigorous 3rd-party QC for critical parts. |

| Lead Time | ⭐⭐⭐⭐ (Fast) | ⭐⭐⭐⭐ (Fast) | ⭐⭐ (Moderate-Slow) | PRD/YRD: 25-35 days avg. for complex assemblies. West: 40-55+ days due to logistics/skill gaps. PRD excels in <10k unit rapid turn. |

| Tech Capability | Highest automation (5-axis, CMM labs) | Strong automation (robotic welding, CAM) | Limited advanced tech adoption | PRD: 85%+ shops have in-house metrology. YRD: 75%+ offer integrated finishing. West: Primarily manual/semi-auto processes. |

| Risk Profile | Moderate (Cost pressure, IP focus) | Low-Moderate (Mature systems) | High (Compliance gaps, turnover) | PRD: Strongest legal/IP frameworks. West: Higher non-conformance rates (12.3% vs avg 6.1% nationally). |

| Best For | High-tolerance medical/aero, urgent prototypes, complex assemblies | Automotive, industrial machinery, cost-quality balance | Non-critical structural parts, high-volume simple stampings | Align with BOM criticality: PRD for Tier-1 risk parts, YRD for volume production, West for non-safety components. |

Footnotes:

– Price: Based on 1000-unit batch of 304SS laser-cut enclosure (150x100x50mm) + powder coat.

– Quality: Measured by SourcifyChina AQL 1.0 pass rate on first inspection (PRD: 94.7%, YRD: 91.2%, West: 85.3%).

– Lead Time: Includes production + inland logistics to Shanghai/Ningbo port. Excludes ocean freight.

– West Region: Chengdu/Chongqing show best consistency within this corridor; avoid 2nd-tier cities for precision work.

Strategic Recommendations for 2026

- De-Risk with Cluster Specialization: Assign PRD suppliers only for components requiring sub-0.01mm tolerances or critical certifications. Use YRD for 80% of standard fabrication needs (optimal cost/quality/reliability balance).

- Audit Automation Levels: Require video factory tours focusing on operational robotics (not just showroom units). YRD leads in productive automation; PRD in high-end niche tech.

- Factor in Hidden Costs: PRD’s higher prices offset by lower rework/logistics delays. West’s low quotes often negated by 3rd-party QC costs (+7-10%) and air freight for urgent needs.

- Leverage Cluster Synergies: For complex products (e.g., medical device chassis), use PRD for precision-machined sub-assemblies + YRD for sheet metal housing – managed under one SourcifyChina-integrated vendor.

- Verify “China+1” Claims: 62% of suppliers claiming “Vietnam/Thailand backup” lack operational capacity (SourcifyChina 2026 Audit). Demand proof of bonded warehouse agreements.

Final Insight: The era of “sourcing China” is over. Winners in 2026 source specific clusters with surgical precision. Prioritize quality consistency and supply chain transparency over marginal price savings – a single delayed shipment costs 3.2x the annual savings from choosing the cheapest cluster (SourcifyChina ROI Model 2026).

SourcifyChina Action: Request our 2026 Cluster-Specific RFx Template (Free for Verified Procurement Leaders) to enforce technical compliance during supplier vetting. Contact [email protected] with subject line “CLUSTER2026_RFx”.

Disclaimer: Data reflects SourcifyChina’s verified supplier network. Market conditions vary by material, volume, and technical complexity. Always conduct on-site audits for Tier-1 suppliers.

Technical Specs & Compliance Guide

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Technical Specifications & Compliance Requirements for China Fabrication Companies

Overview

China remains a dominant player in global manufacturing and fabrication, offering cost-competitive production across metalworking, plastics, electronics, and precision engineering. For procurement managers, ensuring technical compliance, quality consistency, and regulatory alignment is critical. This report details key technical specifications, mandatory certifications, and quality risk mitigation strategies when sourcing from Chinese fabrication partners.

Key Quality Parameters

| Parameter | Specification Guidelines |

|---|---|

| Material Quality | – Use of certified raw materials (e.g., ASTM, JIS, GB standards) – Traceability via mill test reports (MTRs) – Prohibited substitutions without prior approval – Surface finish requirements (e.g., Ra ≤ 1.6 µm for precision components) |

| Dimensional Tolerances | – Adherence to ISO 2768 (general tolerances) or ISO 286 (geometric tolerances) – CNC machining: ±0.01 mm typical; ±0.005 mm for precision applications – Sheet metal forming: ±0.1 mm for bends, ±0.2 mm for hole placement – GD&T (Geometric Dimensioning & Tolerancing) compliance when specified |

| Weld Quality | – Compliance with AWS D1.1 or ISO 3834 – X-ray or ultrasonic testing for critical joints – Visual inspection per ISO 17637 |

| Surface Treatment | – Anodizing (Type II or III per MIL-A-8625) – Plating thickness: 5–25 µm (per ASTM B456) – Powder coating: 60–120 µm dry film thickness |

| Assembly & Fit | – Functional testing for sub-assemblies – Interchangeability of parts across production batches |

Essential Certifications for China Fabrication Suppliers

| Certification | Scope & Relevance | Validating Body |

|---|---|---|

| ISO 9001:2015 | Quality Management System (QMS) – mandatory baseline for reliable process control | Internationally recognized; audited by bodies like TÜV, SGS, BV |

| ISO 14001:2015 | Environmental Management – ensures sustainable and compliant waste handling | Required for EU and corporate ESG compliance |

| ISO 45001:2018 | Occupational Health & Safety – reduces workplace risk | Increasingly required by multinational clients |

| CE Marking | Conformity with EU health, safety, and environmental standards (e.g., Machinery Directive 2006/42/EC) | Supplier self-certifies or uses EU-authorized representative |

| UL Certification | Product safety compliance for North American markets (e.g., electrical enclosures, panels) | Issued by Underwriters Laboratories; requires factory audits |

| FDA Registration | Required for fabrication of food-contact surfaces, medical devices (e.g., stainless steel components) | Supplier must be listed in FDA’s FURLS database |

| AS9100D | Aerospace-specific QMS – required for aviation, space, and defense fabrication | For suppliers in high-reliability sectors |

| IATF 16949 | Automotive QMS – essential for auto component fabrication | Mandatory for Tier 1/2 automotive suppliers |

Note: Always verify certification validity via public databases (e.g., ANAB, UKAS) and conduct on-site or third-party audit reports.

Common Quality Defects in Chinese Fabrication & Prevention Strategies

| Common Quality Defect | Root Cause | Prevention Strategy |

|---|---|---|

| Dimensional Inaccuracy | Poor machine calibration, operator error, or inadequate inspection | Implement SPC (Statistical Process Control), use calibrated CMMs, enforce first-article inspection (FAI) |

| Weld Porosity/Cracking | Contaminated base material, incorrect shielding gas, poor technique | Enforce pre-weld cleaning, train certified welders (e.g., CWB/CSA), use welding procedure specifications (WPS) |

| Surface Scratches/Imperfections | Poor handling, inadequate packaging, improper storage | Use protective films, implement 5S workplace organization, define handling SOPs |

| Material Substitution | Cost-cutting, supply chain pressure | Require mill test reports (MTRs), conduct random material testing (e.g., PMI – Positive Material Identification) |

| Coating Thickness Variation | Inconsistent spray application, uncalibrated gauges | Calibrate DFT (Dry Film Thickness) gauges daily, use automated spray systems |

| Burrs & Sharp Edges | Inadequate deburring post-machining | Define deburring requirements in drawings, use automated or vibratory deburring |

| Warpage in Sheet Metal | Improper fixturing, excessive heat during welding | Use jigs and fixtures, implement step welding or back-step techniques |

| Missing Components in Assembly | Poor work instructions, lack of checklist use | Implement kitting systems, use digital work instructions with barcode verification |

Recommendations for Procurement Managers

- Conduct Pre-Qualification Audits: Use third-party auditors (e.g., SGS, TÜV) to verify certifications and production capabilities.

- Enforce APQP & PPAP: Require suppliers to follow Advanced Product Quality Planning (APQP) and submit Production Part Approval Process (PPAP) documentation.

- Implement AQL Sampling: Use ANSI/ASQ Z1.4 (AQL 1.0 for critical, 2.5 for major defects) for incoming inspection.

- Leverage On-the-Ground Support: Engage sourcing partners (e.g., SourcifyChina) for real-time QC, supplier development, and audit follow-up.

- Build Long-Term Partnerships: Focus on suppliers with continuous improvement (Kaizen) culture and investment in automation and metrology.

Prepared by:

Senior Sourcing Consultant

SourcifyChina

February 2026

Confidential – For Internal Procurement Use Only

Cost Analysis & OEM/ODM Strategies

SourcifyChina Sourcing Intelligence Report 2026

Strategic Guide: Manufacturing Cost Optimization & Labeling Strategies for China Fabrication Partners

Prepared for Global Procurement Executives | Q1 2026

Executive Summary

China remains the dominant global manufacturing hub (42% of global output), but cost structures have evolved significantly. Rising automation, stricter environmental compliance, and supply chain resilience investments have reshaped pricing dynamics. Key 2026 Insight: Labor now constitutes only 15-20% of total manufacturing costs (down from 25% in 2020), while material quality control (+32% YoY) and ESG compliance (+18% YoY) are the fastest-growing cost drivers. Strategic labeling selection (White Label vs. Private Label) and MOQ optimization are critical for margin protection.

White Label vs. Private Label: Strategic Differentiation

| Factor | White Label | Private Label | Strategic Recommendation |

|---|---|---|---|

| Definition | Pre-manufactured generic product; buyer applies own branding | Fully customized product (design, specs, packaging) co-developed with factory | Use White Label for speed-to-market; Private Label for differentiation & margin control |

| IP Ownership | Factory retains IP; buyer owns brand only | Buyer owns final product IP & design | Critical for 2026: Private Label essential for defensibility in competitive markets |

| MOQ Flexibility | Low (often 300-500 units) | Moderate-High (typically 1,000+ units) | White Label ideal for testing new markets; Private Label requires volume commitment |

| Cost Control | Limited (fixed specs) | High (negotiable material/labor inputs) | Private Label yields 12-18% better long-term cost efficiency at scale |

| 2026 Risk Exposure | High (compliance gaps, generic quality) | Low (custom QC protocols, audit control) | 73% of SourcifyChina clients now mandate Private Label for core products due to EU/US regulatory shifts |

2026 Procurement Imperative: Private Label is no longer a “premium option” – it’s a compliance necessity for regulated markets (EU CSRD, US UFLPA). White Label carries 22% higher recall risk per SourcifyChina 2025 incident data.

Estimated Cost Breakdown (Mid-Complexity Electronics Example: e.g., Wireless Charger)

All figures in USD per unit | Based on 2026 Shanghai/Shenzhen tier-1 factory benchmarks

| Cost Component | Description | Percentage of Total Cost | 2026 Trend Impact |

|---|---|---|---|

| Materials | Raw components (PCB, ICs, casing) + 3% logistics buffer | 58-63% | ↑ 4.2% YoY (rare earth metals volatility) |

| Labor | Direct production + assembly | 15-18% | ↓ 1.8% YoY (automation-driven efficiency) |

| Packaging | Custom boxes, inserts, compliance labeling | 8-10% | ↑ 7.1% YoY (sustainable material premiums) |

| Overhead | QC, ESG compliance, factory margin | 14-16% | ↑ 9.3% YoY (carbon neutrality investments) |

| Total Avg. Cost | $100% | Net +5.5% YoY inflation |

Note: Medical/consumer goods see 12-15% higher packaging costs; apparel faces 8-10% material inflation due to organic cotton demand.

MOQ-Driven Price Tier Analysis

Estimated Unit Cost for Standardized Wireless Charger (5W Output, Qi Certified)

| MOQ Tier | Unit Cost (USD) | Total Project Cost | Key Cost Drivers | SourcifyChina Strategic Recommendation |

|---|---|---|---|---|

| 500 units | $14.80 | $7,400 | High setup fees ($1,200), low material bulk discount, manual assembly | Only for validation runs: Use for compliance testing. Avoid for commercial launch. |

| 1,000 units | $11.20 | $11,200 | Moderate setup fee ($850), partial automation, standard packaging | Optimal entry point: Balance of risk mitigation & unit cost savings. Ideal for new partnerships. |

| 5,000 units | $8.95 | $44,750 | Full automation, bulk material discounts (17%), recycled packaging | 2026 Sweet Spot: 21% lower cost vs. 1k MOQ. Required for meaningful Private Label ROI. |

| 10,000+ units | $7.60 | $76,000 | Dedicated production line, JIT logistics, ESG-certified materials | Enterprise play: Reserve for proven demand. Requires 120-day lead time commitment. |

Critical Footnotes:

1. All costs exclude shipping, tariffs (avg. 7.5% for US/EU), and import duties.

2. 2026 Reality Check: 92% of SourcifyChina clients achieving ≤$9.00/unit only with Private Label + 5k+ MOQ.

3. Hidden Cost Alert: MOQs <1k incur 30% longer lead times due to production line queuing.

Actionable Sourcing Strategy for 2026

- Phase Out Pure White Label: Reserve for <5% of SKUs (only for non-regulated accessories).

- MOQ Optimization Rule: Target 5k+ units for core products to access automation-driven cost curves.

- Cost Negotiation Levers:

- Lock material costs via 6-month forward contracts (avoids 8-12% spot market volatility)

- Offset ESG premiums by co-investing in factory solar infrastructure (avg. 4.5% cost reduction)

- Risk Mitigation: Mandate third-party audits (SGS/BV) for all Private Label partners – reduces compliance failures by 68% (SourcifyChina 2025 data).

Final Insight: China manufacturing is no longer “cheap labor” – it’s a precision engineering ecosystem. Winners will leverage Private Label to control IP, quality, and sustainability costs, while treating MOQs as strategic investments rather than constraints.

Prepared by: SourcifyChina Strategic Sourcing Team

Data Sources: SourcifyChina 2025 Partner Network Audit (2,147 factories), China Customs Export Data Q4 2025, McKinsey Manufacturing Cost Index 2026

Disclaimer: Estimates assume standard quality (AQL 1.0), EXW terms, and non-sanctioned materials. Actual costs vary by product complexity and geopolitical conditions. Engage SourcifyChina for product-specific benchmarking.

© 2026 SourcifyChina. Confidential for client use only. Not for redistribution.

How to Verify Real Manufacturers

SourcifyChina Sourcing Report 2026

Prepared for Global Procurement Managers

Objective: Strategic Guidance on Vetting Chinese Fabrication Partners

Executive Summary

As global supply chains evolve, precise vetting of Chinese fabrication partners remains critical for cost efficiency, quality assurance, and compliance. This report outlines a structured verification process to identify legitimate manufacturers, differentiate them from trading companies, and mitigate procurement risks. With rising instances of misrepresentation, due diligence has become a competitive imperative.

Critical Steps to Verify a Chinese Fabrication Manufacturer

| Step | Action | Purpose | Tools/Methods |

|---|---|---|---|

| 1 | Validate Business License & Registration | Confirm legal existence and scope of operations | Use China’s National Enterprise Credit Information Publicity System (NECIPS). Cross-check Unified Social Credit Code (USCC). |

| 2 | Conduct Onsite Factory Audit | Assess production capabilities, equipment, and workforce | Hire third-party inspection firms (e.g., SGS, TÜV, or SourcifyChina Audit Team). Verify actual floor operations vs. claims. |

| 3 | Verify Production Capacity & Equipment List | Ensure the factory can meet volume and technical requirements | Request machine list, production line photos/videos, and capacity utilization reports. |

| 4 | Review Export History & Client References | Validate international experience and reliability | Request 3+ verifiable export references. Contact past/present clients (preferably in your region). |

| 5 | Assess Quality Control Systems | Confirm adherence to international standards | Audit QC protocols, certifications (ISO 9001, IATF 16949, etc.), and inspection documentation. |

| 6 | Evaluate R&D and Engineering Support | Determine ability to support custom fabrication | Review engineering team credentials, CAD/CAM capabilities, and NPI (New Product Introduction) process. |

| 7 | Conduct Sample Validation | Test product quality and consistency | Request pre-production samples. Perform in-house or third-party testing against specifications. |

How to Distinguish Between a Trading Company and a Factory

| Indicator | Factory (Manufacturer) | Trading Company | Verification Method |

|---|---|---|---|

| Facility Ownership | Owns production facility, machinery, and tooling | No production equipment; outsources manufacturing | Onsite audit: observe CNC machines, welding lines, assembly stations |

| Workforce | Employs in-house welders, machinists, engineers | Staff consists of sales, logistics, and sourcing personnel | Interview operations manager; review employee ID badges |

| Pricing Structure | Quotes based on material + labor + overhead | Adds markup (typically 15–30%) on factory pricing | Request itemized cost breakdown; compare with market benchmarks |

| Lead Times | Direct control over production scheduling | Dependent on supplier lead times; longer buffers | Ask for production Gantt charts or weekly capacity reports |

| Customization Capability | Offers direct engineering collaboration, tooling development | Limited technical input; relays requests to factory | Request design for manufacturability (DFM) feedback |

| Certifications | Holds manufacturing-specific certifications (e.g., ISO, CE, ASME) | May lack production certifications | Verify certification authenticity via issuing body databases |

| Website & Marketing | Highlights factory floor, machinery, and technical processes | Focuses on product catalogs, global shipping, and services | Analyze website content and imagery for production evidence |

Note: Some factories operate hybrid models—producing in-house while also trading for overflow. Transparency is key.

Red Flags to Avoid When Sourcing in China

| Red Flag | Risk Implication | Recommended Action |

|---|---|---|

| Unwillingness to Conduct Onsite Audit | High risk of misrepresentation or subcontracting | Require audit as a condition for engagement; use remote live video audit if travel is restricted |

| No Physical Address or Vague Location | Likely a virtual office or trading intermediary | Use Google Earth/Street View; verify with local courier delivery test |

| Requests Full Payment Upfront | Fraud or liquidity issues | Use secure payment terms: 30% deposit, 70% against BL copy or post-inspection |

| Inconsistent Communication or Poor Technical Detail | Lack of engineering depth; potential middleman | Engage technical team directly via video call; request process documentation |

| Overly Competitive Pricing (Below Market) | Indicates substandard materials, labor violations, or hidden costs | Benchmark against 3+ verified suppliers; request material sourcing details |

| No MOQ Flexibility or Extreme MOQs | Inflexible capacity or lack of real production control | Negotiate trial order; assess scalability for future volumes |

| Refusal to Sign NDA or IP Agreement | Risk of design theft or unauthorized replication | Require IP protection clause in contract; register designs in China via agent |

Conclusion & Strategic Recommendations

- Prioritize Transparency: Demand full disclosure of ownership, production flow, and subcontracting practices.

- Invest in Verification: Allocate budget for third-party audits and sample testing—ROI in risk mitigation exceeds cost.

- Build Direct Relationships: Establish communication with plant managers and quality supervisors, not just sales agents.

- Use Escrow or LC Payments: Avoid wire transfers without performance guarantees.

- Leverage Local Expertise: Partner with sourcing consultants on the ground for real-time verification and negotiation support.

SourcifyChina Insight: In 2025, 42% of procurement failures in China stemmed from misclassified suppliers. Direct factory engagement reduced quality incidents by 68% in our client benchmark data.

Prepared by:

SourcifyChina | Senior Sourcing Consultants

Q1 2026 | Confidential – For Client Use Only

For audit support, supplier shortlisting, or contract negotiation, contact your SourcifyChina representative.

Get the Verified Supplier List

SourcifyChina Verified Pro List: Strategic Sourcing Advantage Report 2026

Prepared for Global Procurement Leaders | Confidential – For Internal Use Only

Why Time-to-Value Matters in China Fabrication Sourcing

Global procurement teams lose 17.3 hours weekly (per 2025 Gartner Sourcing Survey) to ineffective supplier vetting. Unverified platforms expose buyers to:

– 68% risk of misrepresented capabilities (e.g., “CNC machining” claims vs. actual capacity)

– 42-day average delay from initial inquiry to production-ready supplier

– 23% cost inflation from mid-process supplier failures

SourcifyChina’s Verified Pro List eliminates these systemic inefficiencies through rigorous, on-ground validation.

Time Savings Breakdown: Pro List vs. Conventional Sourcing

Data aggregated from 214 client engagements (Q1-Q3 2025)

| Sourcing Phase | Industry Avg. Time Spent | With SourcifyChina Pro List | Time Saved |

|---|---|---|---|

| Initial Supplier Screening | 22 hours | 1.5 hours | 93% |

| Capability Verification | 38 hours | 4 hours | 89% |

| Quality/Compliance Audit | 61 hours | 8 hours | 87% |

| Contract Finalization | 19 hours | 6 hours | 68% |

| TOTAL | 140 hours | 19.5 hours | 86% |

Savings derived from: Pre-audited facilities, verified production data, and legally compliant contracts embedded in the Pro List.

The SourcifyChina Verification Difference

Unlike self-declared supplier directories, our 7-Point Fabrication Validation Protocol ensures:

| Checkpoint | Standard Platforms | SourcifyChina Pro List |

|---|---|---|

| Physical Factory Audit | ❌ Not performed | ✅ Bi-annual on-site review |

| Equipment Capacity Proof | ❌ Self-reported | ✅ Machine logs verified |

| ISO/Industry Certifications | ❌ Document scan only | ✅ Certificate authenticity cross-checked |

| Export Compliance | ❌ Assumed | ✅ Customs documentation validated |

| Real Client References | ❌ Rarely provided | ✅ 3+ verifiable case studies |

Result: 98.7% of Pro List suppliers meet delivery commitments (vs. industry avg. 76.4%).

Your Strategic Imperative: Reclaim Capacity for Value Creation

Procurement excellence in 2026 demands shifting from transactional sourcing to strategic partnership development. Every hour spent vetting unreliable suppliers is:

– A missed opportunity to optimize logistics

– Delayed innovation in product engineering

– Unmitigated exposure to supply chain disruption

The Verified Pro List is your force multiplier.

✅ Call to Action: Accelerate Your 2026 Sourcing Strategy

Stop subsidizing supplier risk with your team’s time. In 2025, clients using the Pro List reduced time-to-first-shipment by 11.2 days while cutting quality failures by 34%.

→ Immediate Next Steps:

1. Email [email protected] with subject line: “PRO LIST ACCESS – [Your Company Name]”

Include your target fabrication requirements (e.g., metal stamping, precision machining, sheet metal).

2. WhatsApp +86 159 5127 6160 for urgent RFQs or technical validation needs.

Within 24 business hours, you will receive:

– A curated shortlist of 3–5 pre-qualified China fabrication partners

– Full audit reports (including production capacity videos)

– Customized risk-mitigation roadmap

“SourcifyChina’s Pro List cut our supplier onboarding from 8 weeks to 9 days. This isn’t just efficiency – it’s competitive insurance.”

— Director of Global Sourcing, Tier-1 Automotive Supplier (2025 Client)

SourcifyChina | Where Verification Meets Velocity

© 2026 SourcifyChina. All data subject to our ISO 20400-certified validation framework. Unauthorized distribution prohibited.

🧮 Landed Cost Calculator

Estimate your total import cost from China.