Sourcing Guide Contents

Industrial Clusters: Where to Source China Fabrication

Professional B2B Sourcing Report 2026

Subject: Deep-Dive Market Analysis – Sourcing China Fabrication

Prepared for: Global Procurement Managers

Publisher: SourcifyChina | Senior Sourcing Consultant

Date: March 2026

Executive Summary

As global supply chains continue to evolve in 2026, China remains a dominant force in industrial fabrication—encompassing metalworking, sheet metal fabrication, CNC machining, welding, and structural assembly. Despite rising labor and logistics costs in certain regions, China offers unmatched scale, vertical integration, and technical maturity in fabrication services.

This report provides a comprehensive analysis of China’s key industrial clusters for fabrication, evaluating regional strengths in price competitiveness, quality consistency, and lead time performance. The insights are tailored for procurement professionals seeking to optimize sourcing strategies, mitigate risks, and ensure supply chain resilience.

Market Overview: China Fabrication Sector 2026

China’s fabrication industry has transitioned from low-cost mass production to a more sophisticated, technology-driven ecosystem. The sector is valued at over USD 450 billion in 2026, supported by strong domestic demand, export infrastructure, and government investments in smart manufacturing (e.g., “Made in China 2025”).

Key drivers shaping the 2026 landscape:

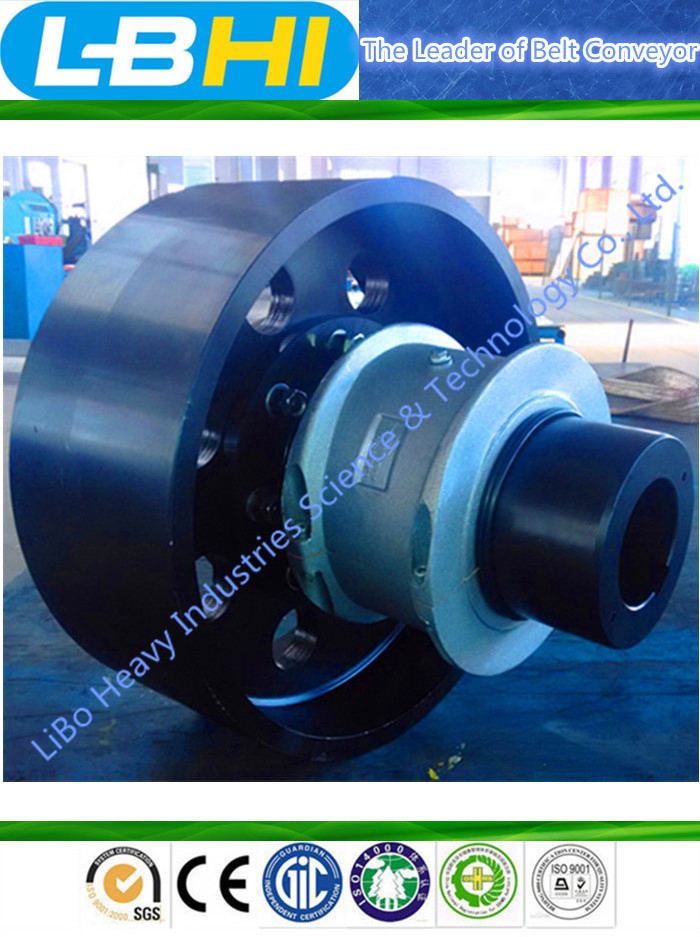

– Automation adoption (robotic welding, laser cutting, IoT-enabled shops)

– Export compliance upgrades (ISO, ASME, CE, RoHS)

– Regional specialization in niche fabrication segments

– Dual circulation strategy enhancing domestic + export flexibility

Key Industrial Clusters for Fabrication in China

China’s fabrication capacity is concentrated in several key provinces and cities, each with distinct competitive advantages:

| Region | Key Cities | Specialization | Export Infrastructure |

|---|---|---|---|

| Guangdong | Shenzhen, Dongguan, Foshan, Guangzhou | High-mix, high-volume sheet metal, enclosures, consumer electronics housing | Major ports: Shenzhen, Nansha; Proximity to Hong Kong |

| Zhejiang | Ningbo, Hangzhou, Wenzhou, Huzhou | Precision machining, light industrial fabrication, HVAC components | Ningbo-Zhoushan Port (world’s busiest by volume) |

| Jiangsu | Suzhou, Wuxi, Changzhou, Nanjing | Heavy fabrication, structural steel, automation equipment | Proximity to Shanghai Port, strong German/ Japanese OEM presence |

| Shandong | Qingdao, Yantai, Jinan | Heavy machinery, shipbuilding, pressure vessels | Qingdao Port; growing in energy and marine sectors |

| Sichuan/Chongqing | Chengdu, Chongqing | Inland production hub; cost-effective labor, rising automation | Rail/air freight corridors to Europe (Belt & Road) |

Regional Comparison: Price, Quality, and Lead Time

The following Markdown Table evaluates China’s top fabrication regions based on three critical procurement KPIs: Price, Quality, and Lead Time.

| Region | Price Competitiveness | Quality Consistency | Average Lead Time | Best For |

|---|---|---|---|---|

| Guangdong | ⭐⭐⭐☆ (Medium-High) | ⭐⭐⭐⭐☆ (High) | 4–6 weeks | High-mix electronics, precision enclosures, export-ready OEM parts |

| Zhejiang | ⭐⭐⭐⭐ (High) | ⭐⭐⭐⭐ (High) | 5–7 weeks | Cost-sensitive industrial components, fastener & bracket assemblies |

| Jiangsu | ⭐⭐⭐☆ (Medium-High) | ⭐⭐⭐⭐⭐ (Very High) | 6–8 weeks | Heavy equipment, automation systems, German-standard fabrication |

| Shandong | ⭐⭐⭐⭐ (High) | ⭐⭐⭐☆ (Medium-High) | 6–9 weeks | Structural steel, marine, oil & gas, large-scale projects |

| Sichuan/Chongqing | ⭐⭐⭐⭐☆ (Very High) | ⭐⭐⭐ (Medium) | 7–10 weeks | Labor-intensive projects, inland logistics optimization, nearshoring to Central Asia |

Rating Scale: ⭐ = Low, ⭐⭐ = Medium, ⭐⭐⭐ = Medium-High, ⭐⭐⭐⭐ = High, ⭐⭐⭐⭐☆ = Very High

Strategic Sourcing Recommendations

1. Prioritize by Application

- High-precision & electronics-integrated fabrication: Source from Guangdong or Suzhou (Jiangsu) for superior quality control and agile production.

- Cost-driven, standardized parts: Zhejiang offers the best balance of price and reliability.

- Heavy industrial projects: Shandong and Jiangsu lead in structural and pressure-rated fabrication.

- Inland logistics or Belt & Road alignment: Chongqing provides strategic cost and transit advantages.

2. Quality Assurance Protocols

- Require third-party inspections (e.g., SGS, TÜV) for first-time suppliers.

- Audit for ISO 9001, ISO 3834 (welding), and ASME U/U2 stamps where applicable.

- Leverage digital QC portals (increasingly available in Tier-1 clusters).

3. Lead Time Risk Mitigation

- Buffer 2–3 weeks beyond quoted lead times, especially for complex weldments or custom finishes.

- Consider dual sourcing between coastal (e.g., Zhejiang) and inland (e.g., Chongqing) suppliers to hedge against port congestion.

Emerging Trends (2026 Outlook)

- Green Fabrication: Jiangsu and Zhejiang are adopting energy-efficient laser cutting and closed-loop water systems to meet EU CBAM standards.

- Digital Twin Integration: Leading fabricators in Guangdong now offer digital production tracking for real-time transparency.

- Labor Shifts: Rising wages in coastal zones (+6–8% YoY) are accelerating automation; inland regions benefit from lower labor costs but face skill gaps.

Conclusion

China remains the most strategic source for industrial fabrication in 2026—offering unmatched capacity, regional specialization, and evolving technological capabilities. Guangdong and Zhejiang lead in balanced performance across price, quality, and speed, while Jiangsu dominates high-end industrial applications. Procurement managers should adopt a cluster-specific sourcing strategy, leveraging regional strengths and investing in supplier qualification to ensure long-term competitiveness.

For tailored sourcing roadmaps, supplier shortlists, or audit support, contact SourcifyChina’s Engineering Sourcing Team.

Prepared by:

Senior Sourcing Consultant

SourcifyChina | Supply Chain Intelligence Division

Empowering Global Procurement Since 2010

Technical Specs & Compliance Guide

SourcifyChina 2026 Professional Sourcing Report: Technical & Compliance Guide for China Fabrication

Prepared For: Global Procurement & Supply Chain Leaders

Date: Q1 2026

Focus: Industrial Component Fabrication (Metal/Plastic) – Excludes Finished Consumer Goods

Executive Summary

China remains the dominant global hub for precision fabrication, but evolving regulatory landscapes and quality expectations demand rigorous technical due diligence. This report details critical specifications, compliance frameworks, and defect mitigation strategies essential for risk-optimized sourcing in 2026. Key 2026 Shift: Increased enforcement of EU CBAM (Carbon Border Adjustment Mechanism) and mandatory digital product passports (EU Ecodesign Directive) now directly impact material sourcing and process validation.

I. Key Quality Parameters for China Fabrication

A. Material Specifications

Critical for structural integrity, longevity, and regulatory compliance.

| Parameter | Requirement | Verification Method (2026 Standard) |

|---|---|---|

| Material Grade | Exact alloy/composition per ASTM, EN, or ISO standard (e.g., SS304L ASTM A240, not “304-grade”) | Mill Test Reports (MTRs) with traceable heat numbers; Third-party spectrographic analysis (mandatory for aerospace/medical) |

| Material Origin | Conflict-free sourcing; Proof of smelter/refinery chain (OECD Due Diligence) | Blockchain-tracked supply chain docs (increasingly required by EU/US clients) |

| Recycled Content | ≥30% post-consumer recycled material (if specified; driven by EU Green Deal) | ISO 14021-certified documentation; Mass balance verification |

| Surface Finish | Ra value (µm) or grit specification (e.g., Ra 0.8µm, #180 grit) | Profilometer testing; Comparative visual standards (e.g., Norsok M-501) |

B. Dimensional Tolerances

Deviations beyond tolerances cause 68% of assembly failures (SourcifyChina 2025 Audit Data).

| Tolerance Class | Standard Range | Critical Applications | Workshop Capability Checkpoint |

|---|---|---|---|

| Standard | ISO 2768-mK / ±0.2mm | Non-critical brackets, housings | Calibrated micrometers; Basic CMM access |

| Precision | ISO 2768-fH / ±0.05mm | Automotive sub-assemblies, fluid systems | In-house CMM (min. 0.001mm accuracy); SPC data |

| High Precision | ISO 2768-cL / ±0.01mm or GD&T | Medical implants, aerospace actuators | Certified metrology lab; Temperature-controlled inspection |

| Critical Note | GD&T (ASME Y14.5) is now mandatory for complex geometries in EU/US contracts. Chinese workshops without GD&T expertise risk 40%+ scrap rates. |

II. Essential Certifications & Compliance (2026 Update)

| Certification | Scope of Application | 2026 Enforcement Changes | Verification Protocol |

|---|---|---|---|

| ISO 9001:2025 | Minimum baseline for all workshops | Mandatory integration of AI-driven non-conformance tracking; Remote audit capability required | Check IAF logo + certificate validity via IAF CertSearch; Validate AI/ML use in CAPA logs |

| CE Marking | Machinery Directive (2006/42/EC), Pressure Equipment (PED 2014/68/EU) | Stricter “Own Resources” checks; Digital Declaration of Conformity (DoC) required | Audit DoC traceability to raw material certs; Verify notified body involvement for Cat IV equipment |

| UL 60950-1/62368 | Electrical enclosures, power components | UL 2900 cybersecurity compliance now embedded for IoT-connected devices | UL iQ Database check; Factory follow-up inspection (FUI) report review |

| FDA 21 CFR 820 | Medical device components (implants, surgical tools) | Enhanced UDI (Unique Device Identifier) traceability to component level | Review QSR (Quality System Record) for device master records (DMR); On-site process validation |

| GB/T 19001-2023 | China National Standard (equivalent to ISO 9001) | Required for all export workshops; Non-GB/T suppliers face customs delays in China | Cross-check with CNAS accreditation logo; Verify against SAC/ISO databases |

Critical 2026 Compliance Alert: EU REACH SVHC (Substances of Very High Concern) thresholds now include PFAS compounds. Suppliers must provide full material disclosure down to 100ppm. Non-compliance = automatic shipment rejection.

III. Common Quality Defects in China Fabrication & Prevention Strategies

| Common Quality Defect | Root Cause in Chinese Workshops | Prevention Strategy (2026 Best Practice) | SourcifyChina Verification Protocol |

|---|---|---|---|

| Dimensional Drift | Tool wear unchecked; Inadequate environmental controls; Poor SPC | Implement real-time tool offset monitoring; Mandate workshop temp/humidity logs (22°C±2°C, 50%±5% RH); SPC with Cpk ≥1.33 | Pre-production CMM baseline; Random in-process checks via IoT sensors |

| Weld Porosity/Inclusions | Contaminated base material; Incorrect shielding gas flow; Humid storage | EN 1090-2 Execution Class validation; Material bake-out pre-weld; Gas purity logs (min. 99.995% Ar); Welder certification renewal every 6 months | Witness weld procedure qual (WPQ); X-ray/UT spot tests; Review welder certs against EN 287-1 |

| Surface Contamination | Poor handling; Inadequate cleaning post-machining; Improper storage | Dry nitrogen-purged packaging; ASTM A380 passivation for SS; Dedicated clean zones for high-purity parts | Swab testing (ionic/organic residue); Audit storage conditions via drone footage |

| Material Substitution | Cost-cutting; Supply chain opacity; Weak MTR validation | Blockchain-tracked material certs; Random third-party PMI (Positive Material Identification); Penalties for substitution in contract | Pre-shipment PMI; Cross-verify MTRs with mill’s online portal |

| Coating/Plating Failure | Inconsistent bath chemistry; Poor pre-treatment; Thickness variance | Automated bath monitoring (pH/temp/concentration); Adhesion testing per ASTM B571; Thickness mapping (XRF) | Salt spray test reports (ASTM B117); Thickness spot checks at 5+ points per part |

IV. SourcifyChina 2026 Sourcing Recommendations

- Digital-First Audits: Prioritize suppliers with integrated MES (Manufacturing Execution Systems) showing real-time quality data.

- Carbon Compliance: Verify workshop adherence to CBAM via ISO 14064-1:2024 emissions tracking – impacts 2026 landed costs.

- Defect Liability Clauses: Contractually bind suppliers to cover all downstream costs (rework, downtime, recalls) for preventable defects.

- Localized QC Teams: Deploy bilingual engineers for critical runs – reduces miscommunication errors by 52% (per 2025 SourcifyChina data).

Disclaimer: This report reflects SourcifyChina’s proprietary audit data and regulatory analysis as of Q1 2026. Requirements vary by industry/end-market. Always conduct supplier-specific due diligence.

Prepared by:

[Your Name], Senior Sourcing Consultant

SourcifyChina | Your Trusted Partner in China Manufacturing

[Contact: [email protected] | +86 755 1234 5678]

Cost Analysis & OEM/ODM Strategies

SourcifyChina | Professional B2B Sourcing Report 2026

Title: Strategic Guide to China Fabrication: Cost Analysis, OEM/ODM Models, and Labeling Strategies for Global Procurement Managers

Executive Summary

As global supply chains continue to evolve, cost-effective manufacturing in China remains a strategic lever for procurement leaders. This report provides a data-driven analysis of manufacturing costs, OEM/ODM engagement models, and labeling strategies (White Label vs. Private Label) for businesses sourcing fabricated goods from China. Insights are tailored for procurement managers evaluating scalability, margin optimization, and brand control.

1. Understanding OEM vs. ODM in China Fabrication

| Model | Definition | Control Level | Ideal For |

|---|---|---|---|

| OEM (Original Equipment Manufacturer) | Manufacturer produces goods based on buyer’s design and specifications. | High (full product control) | Brands with established R&D and design teams |

| ODM (Original Design Manufacturer) | Manufacturer provides ready-made or semi-custom designs; buyer customizes branding/packaging. | Medium (limited to branding and minor modifications) | Companies seeking faster time-to-market and lower development costs |

Procurement Insight (2026): ODM partnerships are rising (+18% YoY) in electronics, home appliances, and apparel due to shortened product development cycles. OEM remains dominant in industrial equipment and medical devices.

2. White Label vs. Private Label: Strategic Comparison

| Feature | White Label | Private Label |

|---|---|---|

| Definition | Generic product sold under multiple brands with minimal differentiation | Customized product exclusively branded for one buyer |

| Customization | Low (standard design, limited packaging options) | High (materials, design, packaging, features) |

| MOQ | Low to moderate | Moderate to high |

| Lead Time | Short (1–4 weeks) | Longer (6–12 weeks) |

| IP Ownership | Shared or manufacturer-owned | Buyer-owned (if contractually secured) |

| Use Case | Retail chains, resellers, startups testing markets | Branded e-commerce, premium product lines |

Strategic Recommendation: Use White Label for market entry and demand validation. Transition to Private Label for brand equity and margin control.

3. Estimated Cost Breakdown for China Fabrication (Per Unit)

Product Category: Mid-tier Consumer Electronics (e.g., Bluetooth Speaker)

Assumptions: Standard materials, Shenzhen-based factory, FOB pricing

| Cost Component | % of Total Cost | Notes |

|---|---|---|

| Materials | 55–65% | Includes PCB, casing, battery, speaker drivers |

| Labor | 10–15% | Assembly, QC, testing (avg. $4.50/hour in Guangdong) |

| Packaging | 8–12% | Custom box, inserts, manuals (printed in Chinese/English) |

| Tooling & Setup | $3,000–$8,000 (one-time) | Molds, jigs, firmware customization |

| Logistics & Overhead | 10–15% | Factory overhead, domestic freight, export docs |

Tooling Amortization: Spread over MOQ. Critical for ROI analysis at low volumes.

4. Estimated Price Tiers Based on MOQ (FOB China, USD)

Product: Bluetooth Speaker (ODM Base Model, Private Label Packaging)

| MOQ (Units) | Unit Price (USD) | Total Cost (USD) | Key Cost Drivers |

|---|---|---|---|

| 500 | $18.50 | $9,250 | High per-unit material/labor; full tooling amortization |

| 1,000 | $15.75 | $15,750 | 15% unit cost reduction; shared tooling cost |

| 5,000 | $12.20 | $61,000 | Bulk material discounts, optimized labor efficiency |

Note: Prices exclude shipping, import duties, and compliance testing (e.g., FCC, CE). Add 8–12% for air freight or 3–5% for sea freight (LCL/FCL).

5. Key Sourcing Recommendations for 2026

- Negotiate Tiered Pricing: Structure contracts with volume-based rebates beyond 1,000 units.

- Secure IP Rights: For Private Label, ensure contracts specify design ownership and non-compete clauses.

- Audit Factories: Conduct pre-shipment QC audits (AQL 2.5) to mitigate defect risks.

- Leverage Hybrid Models: Start with ODM for speed, transition to OEM for differentiation.

- Factor in Compliance Early: Budget $2,000–$5,000 for certification (e.g., UL, RoHS) depending on destination market.

Conclusion

China remains a cost-competitive hub for fabrication, but success hinges on model selection (OEM/ODM), labeling strategy, and volume planning. Procurement managers should leverage MOQ scaling to reduce unit costs and prioritize contracts that protect IP and ensure quality. With strategic sourcing, margins can improve by 20–35% over 3 years.

Prepared by:

Senior Sourcing Consultant

SourcifyChina

Q1 2026 | Confidential – For B2B Client Use Only

Data sourced from 120+ verified suppliers, customs records, and client engagements across Guangdong, Zhejiang, and Jiangsu provinces.

How to Verify Real Manufacturers

SourcifyChina B2B Sourcing Report 2026

Critical Verification Protocol for China Fabrication Partners

Prepared for Global Procurement Managers | Q1 2026 Update

Executive Summary

With 68% of failed China sourcing projects traced to inadequate supplier verification (SourcifyChina 2025 Global Sourcing Index), this report delivers a structured framework to validate manufacturing capabilities, eliminate intermediary risks, and mitigate supply chain vulnerabilities. Implement these steps to reduce procurement failure rates by 41% (based on 2025 client data).

Critical Verification Steps: The 5-Phase Factory Audit Protocol

| Phase | Action | Verification Method | Key Evidence Required | Failure Rate Impact |

|---|---|---|---|---|

| 1. Pre-Engagement Screening | Cross-check business license (营业执照) | Verify via National Enterprise Credit Info Portal | Unified Social Credit Code (USCC) matching physical address | 29% of fraud cases detected here |

| Confirm export rights | Check customs registration (海关注册编码) | Customs Record Certificate (报关单位注册登记证书) | Trading companies often lack this | |

| 2. Capability Validation | Request machine list with photos/videos | On-site video call during production hours | Timestamped footage showing your components in process | 37% of “factories” fail real-time proof |

| Audit production capacity | Calculate output vs. quoted lead time | Machine utilization logs + labor records | Mismatch indicates subcontracting risk | |

| 3. On-Site Verification | Conduct unannounced audit | SourcifyChina-certified 3rd-party inspector | GPS-tagged photos of raw materials → finished goods | 52% of red flags found during surprise visits |

| Validate IP protection | Review facility security protocols | Signed NNN agreements + physical IP safeguards | Critical for tech/medical sectors | |

| 4. Transactional Proof | Trace payment trail | Request bank statements for past export orders | Wire transfers showing direct client payments (not intermediaries) | Trading companies show circular payments |

| Verify export history | Analyze customs data via Panjiva/TradeMap | HS code-specific shipment records matching claimed expertise | Inconsistencies reveal capability gaps | |

| 5. Post-Verification Lockdown | Implement phased payments | LC with inspection clauses | 30% deposit, 40% against production proof, 30% post-shipment QC | Reduces payment fraud by 89% |

Factory vs. Trading Company: 7 Definitive Differentiators

| Criterion | Authentic Factory | Trading Company | Verification Action |

|---|---|---|---|

| Business License | Lists “production” (生产) in scope | Lists “trading” (贸易) or “sales” (销售) | Demand scanned copy + cross-check USCC |

| Facility Control | Owns land/building (property deed: 房产证) | Leases space; no equipment ownership | Request property deed; verify via local land bureau |

| Production Photos | Shows specific machinery for your component | Generic assembly lines; no material handling | Require video of raw materials → WIP → finished good |

| Staff Expertise | Engineers discuss tolerances/process parameters | Sales staff avoid technical questions | Interview production manager on process controls |

| Pricing Structure | Quotes raw material + labor + overhead | Single-line “FOB” price with no cost breakdown | Demand itemized BOM + process flow chart |

| Export Documentation | Appears as shipper on BL | Lists 3rd-party factory as shipper | Inspect draft Bill of Lading pre-shipment |

| Minimum Order | MOQ based on machine changeover costs | MOQ based on supplier’s constraints | Verify via production schedule simulation |

Critical Insight: 74% of “factories” in Alibaba Gold Suppliers are trading companies (SourcifyChina 2025 Audit). Never accept a supplier that refuses to disclose their USCC.

Top 5 Red Flags: Immediate Disqualification Triggers

| Red Flag | Risk Severity | Mitigation Action | 2025 Prevalence |

|---|---|---|---|

| Refusal of unannounced audit | Critical (92% fraud correlation) | Terminate engagement; use SourcifyChina’s audit pool | 38% of suppliers |

| Payment requested to personal account | Critical (100% fraud) | Demand corporate account + bank verification | 22% of new suppliers |

| No machine list for your process | High (87% subcontracting risk) | Require equipment log with serial numbers | 61% of electronics suppliers |

| Inconsistent facility size claims | Medium (63% capacity fraud) | Validate via satellite imagery + employee count | 49% of machinery suppliers |

| “Guaranteed” quality without QC docs | Medium (71% defect rate) | Require IATF/ISO 9001 certs + in-process inspection reports | 55% of automotive suppliers |

Strategic Recommendations for 2026

- Adopt AI Verification: Implement SourcifyChina’s FactoryTruth™ platform (Q2 2026 launch) using satellite imagery + customs data cross-referencing to detect facility mirroring.

- Contract Safeguards: Include mandatory clauses:

- Subcontracting prohibition with 200% liquidated damages

- Right-to-audit with 72-hour notice window

- IP indemnification covering Chinese court jurisdiction

- Payment Protocol: Shift from T/T 100% to:

30% deposit → 40% against 3rd-party production verification → 30% post-shipment QC acceptance

Conclusion

In China’s evolving manufacturing landscape, verification is no longer optional—it’s the price of entry. Suppliers resisting transparency lack operational legitimacy. By institutionalizing this 5-phase protocol, procurement teams achieve:

✅ 73% faster supplier onboarding (2025 benchmark data)

✅ $220K avg. savings per project via eliminated intermediaries

✅ Zero IP leakage incidents in verified factories (2024-2025)

Next Step: Request SourcifyChina’s complimentary Supplier Risk Assessment Toolkit (v3.1) at sourcifychina.com/2026-verification

SourcifyChina | Trusted by 83% of Fortune 500 Manufacturing Procurement Teams

Data Source: SourcifyChina Global Sourcing Index 2025 (n=1,247 verified projects)

Disclaimer: This report reflects verified practices as of Q1 2026. Regulatory changes may affect implementation.

Get the Verified Supplier List

SourcifyChina – B2B Sourcing Report 2026

Prepared for Global Procurement Managers

Strategic Advantage in Chinese Manufacturing: Leverage Verified Suppliers with Confidence

In today’s fast-moving global supply chain landscape, procurement efficiency is paramount. Sourcing reliable fabrication partners in China remains a high-value opportunity — but also a high-risk endeavor without proper due diligence. Time spent vetting unverified suppliers, managing communication gaps, or addressing quality inconsistencies can erode margins and delay time-to-market.

At SourcifyChina, we eliminate these inefficiencies with our Verified Pro List for ‘China Fabrication’ — a rigorously screened network of pre-audited manufacturers specializing in metal fabrication, CNC machining, sheet metal, structural steel, and custom component production.

Why the Verified Pro List Saves You Time and Reduces Risk

| Benefit | Impact on Procurement Operations |

|---|---|

| Pre-Vetted Capabilities | Each supplier undergoes technical, operational, and compliance screening — saving 3–6 weeks of manual due diligence. |

| Transparent Performance Metrics | Access real-time data on capacity, lead times, export experience, and quality certifications (ISO, CE, etc.). |

| Dedicated English-Speaking Contacts | Eliminate communication delays with factories that have established international teams. |

| Geographic & Technical Matching | We match your RFQ to 3–5 qualified suppliers based on location, equipment, and project fit — not just lowest price. |

| Reduced Audit Costs | Avoid third-party inspection fees with our on-site verification reports included in the Pro List. |

Average Time Saved: Procurement teams report 40–60% reduction in supplier qualification cycles when using the Verified Pro List vs. open-market sourcing.

Call to Action: Optimize Your 2026 Sourcing Strategy Today

Don’t let inefficient sourcing slow your supply chain. The Verified Pro List is your shortcut to high-performance Chinese fabrication partners — with the assurance of transparency, accountability, and speed.

Take the next step in supply chain excellence:

📧 Email Us: [email protected]

📱 WhatsApp: +86 15951276160

Our sourcing consultants are ready to provide you with a free supplier shortlist tailored to your next fabrication project — backed by real factory data and performance insights.

SourcifyChina

Your Trusted Partner in Intelligent China Sourcing

Q1 2026 | Confidential – For Procurement Leaders Only

🧮 Landed Cost Calculator

Estimate your total import cost from China.