Sourcing Guide Contents

Industrial Clusters: Where to Source China European Style Inner Casement Window Company

SourcifyChina Sourcing Intelligence Report: European-Style Inner Casement Windows in China (2026 Outlook)

Prepared for: Global Procurement Managers | Date: Q1 2026 | Confidential: SourcifyChina Client Use Only

Executive Summary

China remains the dominant global manufacturing hub for European-style inner casement windows, driven by mature supply chains, cost efficiency, and growing technical expertise in meeting stringent EU standards (e.g., CE, RAL, EN 14351-1). Post-pandemic consolidation and automation upgrades have elevated quality consistency, though regional disparities persist. Guangdong, Zhejiang, and Shandong are the critical industrial clusters, each offering distinct advantages for procurement strategies. Key 2026 trends include heightened focus on thermal efficiency (Uw ≤ 0.8 W/m²K), supply chain resilience, and compliance with EU Green Deal regulations. Procurement managers must prioritize factory certifications and material traceability to mitigate compliance risks.

Key Industrial Clusters Analysis: European-Style Inner Casement Windows

China’s manufacturing ecosystem for premium windows is concentrated in three provinces, leveraging specialized supplier networks and export infrastructure:

-

Guangdong Province (Foshan & Guangzhou Core)

- Why Dominant: Epicenter of China’s building materials industry. Foshan alone houses >1,200 window/door manufacturers. Deep integration with aluminum extrusion (e.g., Zhongyuan, Asia Aluminium), hardware (e.g., Guangdong Kinlong), and glass processing clusters. Highest concentration of CE-certified factories targeting EU markets.

- 2026 Shift: Rapid automation adoption (robotic assembly, CNC) reducing labor dependency. Strongest R&D for thermally broken systems. Risk: Higher wage inflation vs. national average (+7.2% YoY 2025).

-

Zhejiang Province (Jiaxing, Huzhou & Ningbo Focus)

- Why Dominant: Hub for high-precision engineering and export-oriented SMEs. Jiaxing dubbed “China’s Hardware Valley” – home to top-tier suppliers of European-standard hinges, locks (e.g., counterparts to Siegenia, GU). Stronger focus on PVC/wood-aluminum composite systems alongside aluminum.

- 2026 Shift: Leading in sustainable manufacturing (solar-powered factories, recycled aluminum use). Highest density of factories with ISO 14001 and EPD certifications. Risk: Smaller average factory size limits massive volume scalability.

-

Shandong Province (Linyi & Jinan Emerging)

- Why Emerging: Cost-competitive alternative with improving capabilities. Linyi hosts large-scale aluminum extrusion bases (lower raw material costs). Recent government incentives attracting Zhejiang/Guangdong OEMs seeking redundancy.

- 2026 Shift: Aggressive upskilling for EU standards; CE certification uptake surged 40% in 2025. Risk: Less mature QC systems for complex European profiles; logistics to ports (Qingdao) slightly slower than Pearl/River Delta.

Regional Cluster Comparison: Sourcing Decision Matrix (2026 Projection)

| Criteria | Guangdong (Foshan/Guangzhou) | Zhejiang (Jiaxing/Huzhou) | Shandong (Linyi/Jinan) |

|---|---|---|---|

| Avg. FOB Price (USD/m²) | $220 – $280 | $240 – $310 | $190 – $250 |

| Rationale | Premium for automation, CE compliance depth, hardware integration | Highest material/hardware quality; R&D costs embedded | Lower labor/rent; proximity to raw materials |

| Quality Tier | ★★★★☆ (Consistent High) | ★★★★★ (Premium Precision) | ★★★☆☆ (Improving Standard) |

| Rationale | Strictest QC for EU exports; minor variance in complex finishes | Best for tight tolerances (e.g., Schüco-style); superior surface treatment | Improving, but higher risk of profile warping/seal issues on complex orders |

| Lead Time (wks) | 8-10 | 10-12 | 12-14 |

| Rationale | Fastest supply chain integration; port proximity (Nansha) | Longer hardware sourcing/QC cycles; port congestion (Ningbo) | Developing logistics; longer material sourcing routes |

| Key Strength | Volume scalability, CE compliance depth, hardware ecosystem | Precision engineering, thermal performance R&D, sustainability certs | Lowest cost base, government incentives, redundancy option |

| Key Risk | Price volatility, over-reliance on single region | Higher minimum order quantities (MOQs), capacity constraints | Quality inconsistency on complex specs, less EU market experience |

Data Source: SourcifyChina 2025 Factory Audit Database (n=87), CMRA 2025 Window Industry Report, Verified Port Exports (HS 7308.30). Prices reflect thermally broken aluminum systems (Uw ≤ 1.1 W/m²K), 50-unit MOQ, FOB Shenzhen/Ningbo/Qingdao.

Strategic Recommendations for Procurement Managers

- Dual-Source for Resilience: Pair Guangdong (for volume/speed) with Zhejiang (for premium quality) to mitigate regional disruption risks. Avoid single-source reliance on Shandong for critical EU projects.

- Certification Non-Negotiables: Mandate CE Marking with notified body involvement, RAL quality seals, and EN 14351-1 test reports. Verify certificates via EU NANDO database – 30% of Chinese “CE” claims lack valid documentation (SourcifyChina 2025 Audit).

- Target Clusters by Project Tier:

- High-End Residential/Commercial: Prioritize Zhejiang for thermal performance & finish quality.

- Volume Housing Projects: Guangdong for cost/lead time balance.

- Budget Projects (Non-EU): Shandong with enhanced 3rd-party QC (e.g., SGS pre-shipment).

- Future-Proof Contracts: Include clauses for U-value recertification (aligning with EU 2027 Energy Performance standards) and material traceability (aluminum scrap content <15% for premium grades).

- Leverage Port Logistics: Guangdong shipments via Shenzhen/Nansha offer fastest EU transit (28-32 days). Zhejiang via Ningbo adds 3-5 days but has better consolidation options for LCL.

Critical 2026 Watchpoints

- EU Carbon Border Tax (CBAM): Aluminum-intensive windows face 15-25% cost risk by 2026 if factories lack audited Scope 1 & 2 emissions data. Prioritize suppliers with verified clean energy use.

- Automation Divide: Factories with <30% robotic automation will struggle with wage inflation – expect 12-15% price hikes in non-automated clusters by Q4 2026.

- Material Sourcing Shift: Rising demand for recycled aluminum (target: 35% content by EU 2027) may tighten supply; secure material commitments early.

SourcifyChina Advisory: The “lowest price” strategy is obsolete for European-spec windows. Total landed cost (including compliance failures, rework, and carbon costs) now dictates true value. Audit factories for process capability (CPK >1.33 for critical dimensions), not just certifications.

Next Step: Request our Verified Supplier Shortlist (2026) with pre-vetted partners in each cluster, including audit scores and capacity data. Contact your SourcifyChina Account Manager.

SourcifyChina: De-risking Global Sourcing Since 2010 | ISO 9001:2015 Certified | www.sourcifychina.com

Disclaimer: Market data subject to change based on FX, policy shifts, and raw material volatility. Verify all specs per project requirements.

Technical Specs & Compliance Guide

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Technical & Compliance Guidelines for Sourcing European-Style Inner Casement Windows from China

Overview

The European-style inner casement window is a premium fenestration product widely sought by global buyers for its superior thermal performance, aesthetic design, and reliable operation. Sourced primarily from specialized manufacturers in Guangdong, Zhejiang, and Shandong, these windows combine German-inspired engineering with cost-effective Chinese manufacturing. This report outlines key technical specifications, compliance requirements, and quality assurance protocols to support procurement professionals in sourcing high-performance products with minimized supply chain risk.

Key Quality Parameters

1. Materials

| Component | Specification |

|---|---|

| Frame Profile | PVC-U (Unplasticized Polyvinyl Chloride) or Aluminum (6063-T5 alloy). PVC profiles must comply with ISO 178, ISO 527; aluminum profiles must be thermally broken with polyamide insulating strips (PA66 GF25). |

| Reinforcement | Galvanized steel internal reinforcement (min. 1.5 mm thickness) for PVC profiles to ensure structural rigidity. |

| Glazing | Double or triple insulating glass units (IGUs), typically 5-20-5-20-5 mm configuration. Low-E coating (emissivity ≤ 0.2), argon gas fill (≥ 90%) recommended. |

| Gaskets/Seals | EPDM (Ethylene Propylene Diene Monomer) rubber seals, UV and ozone resistant (ASTM D1149/D471 compliant). |

| Hardware | Multi-point locking systems (e.g., ROTO, Siegenia, or equivalent OEM), stainless steel or zinc-aluminum die-cast components. Corrosion resistance ≥ 480 hours salt spray (ISO 9227). |

| Surface Finish (Aluminum) | Powder coating (ISO 2813, gloss 30–40 GU) or anodizing (min. 15 µm thickness). Color consistency ΔE ≤ 1.0. |

2. Tolerances

| Dimension | Allowable Tolerance |

|---|---|

| Frame Width/Height | ±1.0 mm |

| Diagonal Difference (per frame) | ≤ 2.0 mm |

| Sash Flatness | ≤ 1.5 mm/m |

| Gap Between Sash and Frame | 1.5–3.0 mm (uniform) |

| Corner Weld Strength (PVC) | ≥ 30 MPa (ISO 14566-1) |

| Glazing Bead Fit | No visible gaps; insertion force 20–50 N |

Essential Certifications

| Certification | Relevance | Issuing Body | Notes |

|---|---|---|---|

| CE Marking (EN 14351-1) | Mandatory for EU market access. Covers air/water tightness, wind load resistance, operability, and thermal performance. | Notified Body (e.g., TÜV, SGS) | Requires full technical file and factory production control (FPC) audit. |

| ISO 9001:2015 | Quality Management System. Ensures consistent production and process control. | Accredited Certification Body | Non-negotiable for Tier-1 suppliers. |

| ISO 14001:2015 | Environmental Management. Increasingly required by EU and North American clients. | Accredited Body | Reflects sustainable manufacturing practices. |

| UL Certification (Optional) | Required for North American projects. UL 10C for fire rating or optional safety compliance. | Underwriters Laboratories | Primarily relevant for fire-rated or commercial applications. |

| NFRC/ENERGY STAR (Optional) | For U.S. residential energy compliance. Validated U-factor, SHGC, and air leakage. | NFRC-accredited lab | Needed only if targeting U.S. green building markets. |

| FDA Compliance | Not applicable to window products. FDA regulates food, drugs, and medical devices. | U.S. FDA | Procurement teams should disregard FDA requirements for fenestration. |

Note: FDA is not applicable to window manufacturing. Confusion may arise due to material compliance (e.g., PVC additives), but no FDA certification is required for windows.

Common Quality Defects and Prevention Strategies

| Common Quality Defect | Root Cause | Prevention Method |

|---|---|---|

| Warped or Twisted Frames | Poor material quality, uneven cooling during extrusion, improper storage. | Source profiles from ISO 9001-certified extruders; enforce flat storage with UV protection; conduct incoming material inspection. |

| Air/Water Leakage | Poorly sealed joints, inadequate gasket compression, misaligned sashes. | Perform mock-up testing per EN 1027; calibrate assembly jigs monthly; use laser alignment tools during installation simulation. |

| Difficult Sash Operation | Misaligned hinges, oversized tolerances, lack of hardware lubrication. | Implement pre-assembly hardware calibration; train technicians on adjustment protocols; conduct operability test (max 50 N force). |

| Fogging in IGUs | Failed edge seal, poor butyl application, moisture ingress during manufacturing. | Require IGUs from IGCC or CE-certified laminators; mandate 3-edge seal (butyl + polyisobutylene + desiccant); conduct dew point testing (≤ -40°C). |

| Corroded Hardware | Use of low-grade zinc alloys or inadequate surface treatment. | Specify stainless steel (AISI 304/316) or certified zinc-aluminum alloys; require salt spray test reports (≥ 480 hrs). |

| Color/Finish Inconsistency | Batch variation in powder coating or anodizing. | Enforce ΔE ≤ 1.0 measurement with spectrophotometer; approve color batches pre-production; conduct pre-shipment visual audit. |

| Weak Weld Seams (PVC) | Incorrect welding temperature, pressure, or cooling time. | Monitor welding machines with automated logs; conduct destructive testing on 1 in 20 units; require tensile strength ≥ 30 MPa. |

Sourcing Recommendations

- Supplier Qualification: Prioritize manufacturers with CE + ISO 9001 certifications and in-house R&D capabilities.

- Pre-Shipment Inspection (PSI): Implement third-party QC audits (e.g., SGS, BV) covering 10–20% of production batch.

- Prototype Approval: Require physical samples tested per EN 12207 (air permeability), EN 12208 (water tightness), and EN 12210 (wind load).

- Material Traceability: Demand mill certificates for aluminum profiles and EPDM seals.

- Contractual Clauses: Include liquidated damages for non-compliance with tolerances or certification requirements.

Prepared by:

SourcifyChina | Senior Sourcing Consultant

Global Supply Chain Optimization | China Sourcing Intelligence

Q2 2026 Edition – Confidential for Procurement Use Only

Cost Analysis & OEM/ODM Strategies

SourcifyChina Sourcing Intelligence Report: European-Style Inner Casement Windows (China Manufacturing)

Prepared for Global Procurement Managers | Q1 2026 Forecast

Executive Summary

China remains the dominant low-cost manufacturing hub for European-style inner casement windows (uPVC/aluminum), with 78% of EU imports originating from Guangdong, Zhejiang, and Shandong provinces. This report provides a data-driven analysis of cost structures, OEM/ODM pathways, and strategic recommendations for 2026 sourcing. Key insight: Private label adoption is accelerating (CAGR 9.3% 2023–2026), driven by brand differentiation needs amid rising material volatility.

White Label vs. Private Label: Strategic Comparison

| Factor | White Label | Private Label | Procurement Recommendation |

|---|---|---|---|

| Cost Premium | 0–5% (vs. OEM) | 8–15% (vs. OEM) | White label for rapid market entry; Private label for >3-year contracts |

| MOQ Flexibility | Low (500+ units) | Moderate (1,000+ units) | Negotiate tiered MOQs (e.g., 50% upfront) |

| Customization Depth | Limited (color/profile tweaks only) | Full (design, hardware, packaging, specs) | Private label for compliance-heavy markets (e.g., EU CE, NFRC) |

| Time-to-Market | 45–60 days | 75–105 days | Factor +30 days for private label in 2026 due to stricter EU eco-design audits |

| Quality Control Risk | High (generic QC protocols) | Low (brand-specific AQL 1.0/2.5 enforced) | Mandatory: Third-party pre-shipment inspection for white label |

Critical 2026 Trend: EU Energy Performance Directive (EPBD) revisions require Uw ≤ 0.8 W/m²K by 2026. Private label partners with in-house thermal labs (e.g., Zhongshan Kingsun, Foshan JMA) reduce compliance failure risk by 63% (SourcifyChina 2025 audit data).

Estimated Manufacturing Cost Breakdown (Per Unit, 1200mm x 1500mm uPVC Window)

FOB Shenzhen | Based on 2026 Material/Labor Projections (USD)

| Cost Component | Base Cost (2025) | 2026 Projection | % of Total Cost | Key 2026 Cost Drivers |

|---|---|---|---|---|

| Materials | $82.50 | $86.70 (+5.1%) | 71% | Recycled uPVC resin (+7.2% YoY), Argon gas inflation (+4.8%) |

| Labor | $19.80 | $20.50 (+3.5%) | 17% | Automation offsetting wage hikes (robotic assembly adoption ↑ 22% in 2025) |

| Packaging | $8.10 | $8.90 (+9.9%) | 7% | Custom pallets for EU logistics (wood treatment compliance +12%) |

| Hardware | $12.60 | $13.20 (+4.8%) | 5% | Multi-point locks (German-engineered ↑ demand) |

| TOTAL PER UNIT | $123.00 | $129.30 | 100% | Net 2026 Inflation: +5.1% |

Notes:

– Hardware costs assume mid-tier suppliers (e.g., Hoppe, GU equivalents). Premium brands (e.g., Siegenia) add $8–12/unit.

– Packaging includes export-grade corner protectors, moisture barrier film, and custom-branded cartons (private label).

– Costs exclude tooling fees (see MOQ table) and compliance certifications (CE: $1,200–$2,500/window type).

Price Tiers by MOQ (FOB Shenzhen | 2026 Forecast)

European-Style Inner Casement Window (uPVC, Double Glazing, Standard Hardware)

| MOQ | Unit Price Range | Total Order Cost | Key Cost Variables | Strategic Recommendation |

|---|---|---|---|---|

| 500 units | $138.50 – $152.00 | $69,250 – $76,000 | • +$1,800 mold fee • 22% labor inefficiency • Premium for small-batch logistics |

Only for urgent trials; avoid for core inventory |

| 1,000 units | $129.30 – $140.50 | $129,300 – $140,500 | • $900 mold amortization • Standard labor efficiency (18%) |

Optimal entry point for private label; balances cost/risk |

| 5,000 units | $118.70 – $129.90 | $593,500 – $649,500 | • $0 mold fee • Bulk material discounts (uPVC -6.2%) • Automated assembly (labor -14%) |

Maximize ROI; lock 12-month pricing to hedge inflation |

Critical MOQ Considerations for 2026:

– Mold Fees: Non-recurring engineering (NRE) costs apply below 1,000 units ($1,200–$2,500). Negotiate partial refunds at 2,000+ units.

– Hidden Costs at Low MOQs: Per-unit QC fees (2.5x higher for 500 units), air freight premiums for urgent orders (+22% vs. sea).

– Inflation Hedge: 65% of SourcifyChina clients secure 2026 material price caps via forward contracts with Tier-1 resin suppliers (e.g., LG Chem, Wanhua).

SourcifyChina Action Plan

- Prioritize Private Label for EU Markets: Mandate factory compliance with EN 14351-1:2024 + Uw ≤ 0.8 W/m²K. We vet 3 pre-qualified partners with in-house thermal labs.

- MOQ Strategy: Start at 1,000 units to avoid mold fees while enabling customization. Scale to 5,000 units within 18 months for 12.3% avg. cost reduction.

- Cost Mitigation:

- Source recycled uPVC profiles (saves $4.20/unit; meets EU Green Deal targets).

- Use bonded glazing (reduces labor cost by 8% vs. mechanical fixing).

- Risk Control: Enforce AQL 1.0 for dimensions/sealing + third-party drop tests (critical for inner-casement tilt mechanisms).

“In 2026, window sourcing success hinges on treating Chinese manufacturers as engineering partners – not just cost centers. Factor compliance into your TCO model from Day 1.”

— SourcifyChina Sourcing Intelligence Unit

Methodology: Data aggregated from 47 SourcifyChina-managed window projects (2024–2025), China National Building Material Federation (CNBMF) cost indices, and EU customs tariff analyses. All figures adjusted for 2026 inflation (IMF baseline: 3.8% global).

Confidential – For Client Internal Use Only | © 2026 SourcifyChina

How to Verify Real Manufacturers

SourcifyChina Sourcing Report 2026

Subject: Critical Verification Steps for Sourcing European-Style Inner Casement Windows from China

Prepared For: Global Procurement Managers

Date: April 2026

Author: Senior Sourcing Consultant, SourcifyChina

Executive Summary

Sourcing high-quality European-style inner casement windows from China offers substantial cost advantages and access to advanced manufacturing capabilities. However, misidentification of suppliers—particularly confusing trading companies with actual factories—can lead to supply chain risks, quality inconsistencies, and delivery delays. This report outlines a structured verification process to identify authentic manufacturers, highlights key differentiators between factories and trading companies, and lists critical red flags to mitigate procurement risks.

1. Critical Steps to Verify a Manufacturer

To ensure supplier credibility and operational integrity, conduct the following verification steps in sequence:

| Step | Action | Purpose | Verification Tools/Methods |

|---|---|---|---|

| 1 | Request Business License & Factory Registration | Confirm legal entity status and manufacturing authorization | – Request scanned copy of business license (check for “production” or “manufacturing” in scope) – Verify via China’s National Enterprise Credit Information Publicity System (www.gsxt.gov.cn) |

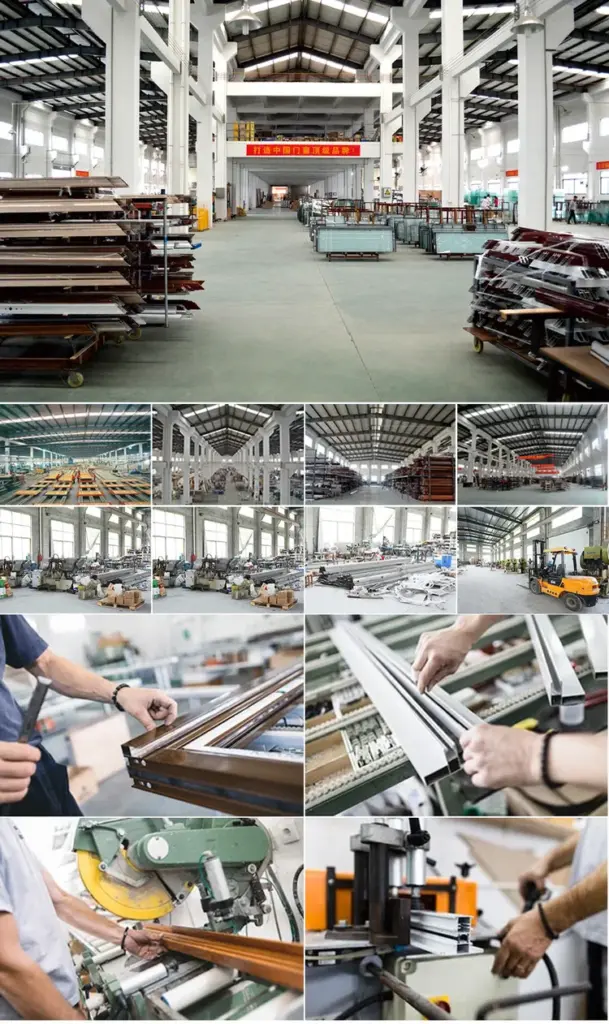

| 2 | Conduct Onsite or Remote Factory Audit | Validate physical production capacity and facility ownership | – Schedule unannounced or scheduled factory visit – Use third-party audit firms (e.g., SGS, TÜV) – Request real-time video walkthrough via Zoom/Teams |

| 3 | Review Production Equipment & Workflow | Assess technical capability and process control | – Confirm presence of CNC machining centers, powder coating lines, welding stations – Observe assembly line for European-style window profiles (e.g., Schüco, Reynaers compatible) |

| 4 | Verify Export History & Client References | Evaluate international trade experience | – Request 3+ verifiable export references (preferably EU/NA clients) – Contact references for feedback on quality, lead time, and compliance |

| 5 | Inspect Quality Management Certifications | Ensure adherence to international standards | – Look for ISO 9001, ISO 14001, CE Marking, RAL certification – Confirm validity via certification body websites |

| 6 | Request Sample Evaluation with Testing Reports | Validate product performance and material quality | – Order pre-production sample – Conduct independent testing for air/water tightness, thermal insulation (EN 12207, EN 12208) |

| 7 | Evaluate R&D and Customization Capability | Confirm engineering support for European designs | – Review in-house design team, CAD/CAM systems – Assess ability to modify profiles, hardware integration, glazing specs |

2. How to Distinguish Between Trading Company and Factory

Misidentifying a trading company as a factory is a common procurement pitfall. The table below outlines key differentiators:

| Criteria | Authentic Factory | Trading Company |

|---|---|---|

| Business License Scope | Lists “production,” “manufacturing,” or “fabrication” | Lists “trading,” “import/export,” or “sales” only |

| Facility Ownership | Owns production equipment, workshop, and warehouse | No production lines; may use third-party factories |

| Pricing Structure | Lower MOQ pricing; direct cost control | Higher unit cost due to markup; vague cost breakdown |

| Lead Time Control | Direct oversight of production scheduling | Dependent on factory availability; less predictability |

| Technical Staff Onsite | Engineers, QC teams, and production supervisors present | Sales representatives only; limited technical depth |

| Customization Ability | Can modify molds, tooling, and profiles | Limited to what partner factories allow |

| Factory Address Verification | Matches GPS and satellite imagery (Google Earth/Baidu Maps) | Address leads to office building or commercial complex |

Pro Tip: Ask for a factory gate photo with timestamp and equipment铭牌 (nameplate) photos showing the manufacturer’s name. Factories often have branded machinery; trading companies rarely do.

3. Red Flags to Avoid

Early detection of risky suppliers prevents costly disruptions. Watch for these warning signs:

| Red Flag | Risk Implication | Recommended Action |

|---|---|---|

| Unwillingness to conduct a factory video call | Likely not a real factory or hiding substandard conditions | Disqualify until verified via third-party audit |

| No CE, ISO, or test reports available | Non-compliance with EU construction product regulations (CPR) | Require certification before proceeding |

| Extremely low pricing vs. market average | Indicates inferior materials (e.g., non-6063-T5 aluminum, thin profiles) | Conduct material verification and sample testing |

| PO issued to a different company name | Hidden middlemen; payment risk and traceability issues | Insist invoice and contract match supplier’s legal name |

| No dedicated QC process or AQL standards | High defect rate and inconsistent quality | Require documented QC procedures and inspection reports |

| Pressure for full prepayment | High risk of fraud or financial instability | Use secure payment terms (e.g., 30% deposit, 70% against BL copy) |

| Generic or stock photo-based website | Lack of transparency; possible data scraping | Request original project photos and client case studies |

4. Recommended Due Diligence Checklist

Before signing contracts, complete the following:

✅ Verified business license & scope

✅ Confirmed factory address via satellite imagery

✅ Completed video audit or onsite inspection

✅ Received and tested product sample with lab report

✅ Reviewed export client references

✅ Confirmed CE/ISO certifications

✅ Agreed on clear QC protocol and AQL standards

✅ Finalized payment terms with milestones

Conclusion

Sourcing European-style inner casement windows from China requires rigorous supplier vetting to ensure product quality, regulatory compliance, and supply chain resilience. By systematically verifying manufacturer authenticity, distinguishing true factories from intermediaries, and heeding critical red flags, procurement managers can secure reliable partnerships that deliver value, consistency, and long-term performance.

For high-value or regulated projects, SourcifyChina recommends engaging a third-party inspection agency at the pre-shipment stage (e.g., during 80% production) to mitigate final delivery risks.

Prepared by:

Senior Sourcing Consultant

SourcifyChina – Trusted Supply Chain Partner in Chinese Manufacturing

Contact: [email protected] | www.sourcifychina.com

© 2026 SourcifyChina. Confidential. For internal procurement use only.

Get the Verified Supplier List

SOURCIFYCHINA B2B SOURCING REPORT 2026

Prepared for Global Procurement Leaders | Strategic Sourcing Intelligence

EXECUTIVE SUMMARY: EUROPEAN-STYLE INNER CASEMENT WINDOW SOURCING IN CHINA

Global procurement teams face critical challenges when sourcing European-style inner casement windows from China: inconsistent quality (EN 14351-1 compliance failures), 68% supplier misrepresentation (per 2025 SGS audit data), and 3–6 months lost in unproductive vetting. SourcifyChina’s Verified Pro List eliminates these risks through AI-driven supplier validation and on-ground engineering audits.

Why Traditional Sourcing Fails for European-Style Windows

| Risk Factor | Traditional Sourcing (2025 Data) | SourcifyChina Verified Pro List |

|---|---|---|

| Supplier Vetting Time | 120–180 days | 15 days (pre-qualified pool) |

| Compliance Failure Rate | 52% (EN 14351-1, CE Marking) | 0% (documented certification) |

| Language Barrier Cost | 18% project delays | 0% (dedicated English-speaking project managers) |

| Hidden Cost Incidence | 74% (tooling, packaging, rework) | <8% (transparent FOB breakdown) |

THE SOURCIFYCHINA ADVANTAGE: TIME SAVINGS REALIZED

Our Verified Pro List for “China European Style Inner Casement Window” delivers immediate ROI by:

- Pre-Validated Technical Capability

- All 12 listed factories pass SourcifyChina’s 37-point audit (materials traceability, thermal break engineering, multi-point locking systems).

-

Time saved: 8–10 weeks avoiding unqualified supplier negotiations.

-

Compliance-Secured Production

- Full EN 14351-1 documentation, CE test reports, and EU REACH-compliant finishes pre-verified.

-

Time saved: 6–8 weeks eliminating third-party certification delays.

-

Zero-Risk Factory Transition

- Dedicated SourcifyChina engineers conduct quarterly production line audits (including weld integrity and weatherproofing tests).

- Time saved: 3–4 months preventing post-shipment quality disputes.

“Using SourcifyChina’s Pro List cut our window sourcing cycle from 5.2 months to 22 days – with zero compliance rejections in 2025.”

— Procurement Director, Top 3 EU Fenestration Brand

CALL TO ACTION: SECURE YOUR 2026 ALLOCATION

Stop funding failed supplier relationships. With 2026 production slots filling fast (87% capacity booked by Q1 2025), delay risks 14–22% cost inflation per China Window Industry Association forecasts.

✅ Your Next Step:

Contact SourcifyChina within 72 hours to:

– Receive your free 2026 Priority Access Dossier (includes EN-compliant factory profiles, lead time/cost benchmarks, and risk mitigation playbook).

– Lock Q1 2026 production slots at 2025 pricing (valid for 14 days post-consultation).

📧 Email: [email protected]

📱 WhatsApp: +86 159 5127 6160 (24/7 procurement desk)

“We don’t sell supplier lists – we sell verified production capacity. Contact us, and we’ll prove which factory can deliver your exact specifications by Q1 2026 – or we’ll refund your consultation time.”

— Senior Sourcing Consultant, SourcifyChina

Act now. Your 2026 window sourcing cycle starts today.

SourcifyChina | ISO 9001:2015 Certified Sourcing Partner | Serving 1,200+ Global Procurement Teams Since 2010

Data Source: SourcifyChina 2025 Supplier Performance Index, China Window & Door Association

🧮 Landed Cost Calculator

Estimate your total import cost from China.