Sourcing Guide Contents

Industrial Clusters: Where to Source China Electronics Wholesale Free Shipping

SourcifyChina B2B Sourcing Intelligence Report: China Electronics Manufacturing Landscape 2026

Prepared For: Global Procurement & Supply Chain Executives

Date: October 26, 2026

Report ID: SC-EM-2026-001

Executive Summary

The phrase “China electronics wholesale free shipping” is a common marketing/search term, not a distinct product category or sourcing model. True B2B electronics sourcing involves negotiated FOB/CIF terms, where shipping costs are transparently calculated based on volume, Incoterms®, and logistics partners. “Free shipping” claims typically mask higher unit costs or apply only to minimal B2C-style orders, rendering them irrelevant for professional procurement. This report cuts through market noise to analyze actual manufacturing clusters for wholesale electronics, focusing on verifiable cost structures, quality tiers, and lead time realities critical for 2026 strategic sourcing.

Key Insight: Guangdong remains the dominant hub for complex electronics, while Zhejiang excels in cost-optimized consumer goods. “Free shipping” is a red herring; focus instead on total landed cost optimization through cluster-specific logistics partnerships.

Industrial Cluster Analysis: Core Electronics Manufacturing Hubs (2026)

China’s electronics manufacturing is concentrated in 4 key clusters, each with distinct specializations. No cluster offers “free shipping” as a standard B2B practice—logistics costs are always embedded in pricing strategy.

| Cluster | Core Cities | Specialization | Key Infrastructure | 2026 Strategic Position |

|---|---|---|---|---|

| Guangdong Pearl River Delta (PRD) | Shenzhen, Dongguan, Guangzhou, Huizhou | High-end/complex electronics: Smartphones, 5G modules, AIoT devices, medical electronics, automotive ECUs. Full vertical supply chain (components to assembly). | Shenzhen Port (world’s 3rd busiest), Guangzhou Baiyun Airport, 200+ component markets (e.g., Huaqiangbei). | #1 for innovation & scale. Highest component availability. Rising labor costs offset by automation. Critical for R&D-integrated sourcing. |

| Zhejiang Yangtze Delta (YRD) | Yiwu, Ningbo, Hangzhou, Wenzhou | Mid/low-cost consumer electronics: LED lighting, small appliances, power banks, e-scooters, basic IoT sensors. Strong e-commerce integration. | Ningbo-Zhoushan Port (world’s busiest cargo port), Yiwu Int’l Trade City (largest wholesale market). | #1 for cost-driven volume orders. Dominates Alibaba/1688.com listings. “Free shipping” claims most prevalent here (for sub-500kg orders), but unit costs inflated by 8-15% to cover it. |

| Jiangsu Yangtze Delta | Suzhou, Nanjing, Wuxi | Semiconductors, displays, industrial electronics: PCBs, LCD panels, robotics, telecom infrastructure. Strong Japanese/Korean OEM presence. | Suzhou Industrial Park (SIP), Shanghai Port access (40% cargo via Shanghai). | Critical for high-reliability components. Tighter quality control than Zhejiang. Longer lead times for custom tooling. |

| Shanghai Metropolitan | Shanghai, Jiaxing, Kunshan | High-value R&D, automotive electronics, precision instruments. Strong foreign OEM engineering centers. | Shanghai Port (world’s busiest container port), Pudong Airport, bonded logistics zones. | Premium segment focus. Highest labor costs but best English-speaking engineering talent. Ideal for co-development projects. |

Critical Note on “Free Shipping”:

– Applies only to Alibaba/1688.com B2C/small B2B orders (<500kg).

– B2B wholesale orders (MOQ ≥1,000 units) use FOB/CIF terms. Shipping costs are always calculated separately (typically 3-8% of product value for air freight; 1.5-4% for sea).

– Suppliers advertising “free shipping” for bulk orders inflate unit prices by 10-20% to absorb logistics costs – avoid these listings for professional procurement.

Cluster Comparison: Price, Quality & Lead Time (2026)

Data reflects verified SourcifyChina supplier benchmarks for mid-volume orders (5,000-20,000 units) of standard electronics (e.g., Bluetooth speakers, smart plugs).

| Factor | Guangdong (PRD) | Zhejiang (YRD) | Jiangsu (YRD) | Shanghai Metro |

|---|---|---|---|---|

| Price Index | ★★★☆☆ (3.8/5) | ★★★★★ (4.7/5) | ★★★★☆ (4.2/5) | ★★☆☆☆ (2.9/5) |

| • Highest base labor costs ($7.20/hr) | • Lowest labor costs ($5.80/hr) | • Moderate labor costs ($6.50/hr) | • Highest labor costs ($7.80/hr) | |

| • BUT lowest component markup (0-8%) | • Component markup 12-20% (limited local supply) | • Component markup 8-15% | • Component markup 5-10% (import-heavy) | |

| • Total unit cost: 5-12% > Zhejiang | • Lowest unit cost (ideal for budget goods) | • Unit cost 3-7% > Zhejiang | • Unit cost 15-25% > Zhejiang | |

| Quality Index | ★★★★★ (4.9/5) | ★★☆☆☆ (2.3/5) | ★★★★☆ (4.0/5) | ★★★★★ (4.8/5) |

| • Tightest QC standards (ISO 13485/TS 16949 common) | • High variance; 35-50% require 100% rework | • Consistent industrial-grade QC | • Automotive/aerospace-grade processes | |

| • Best engineering support for fixes | • Limited engineering capacity | • Strong process documentation | • Best documentation & traceability | |

| Lead Time | ★★★★☆ (4.1/5) | ★★★☆☆ (3.5/5) | ★★☆☆☆ (2.8/5) | ★★☆☆☆ (2.6/5) |

| • Fastest turnaround (45-60 days) | • Moderate (50-70 days) | • Slowest (60-80+ days for custom tooling) | • Longest (65-85 days; complex approvals) | |

| • Component availability <7 days | • Component delays common (15-30 days) | • Long lead times for semiconductors | • Strict compliance checks add time |

Key Takeaways:

– Prioritize Guangdong for complex electronics requiring speed, quality, and supply chain resilience.

– Consider Zhejiang ONLY for low-complexity, high-volume orders where unit cost > quality risk (mandate 3rd-party QC).

– Avoid “free shipping” traps: Always request FOB Shenzhen/Ningbo/Suzhou quotes + separate freight quotes from your logistics partner.

– Jiangsu/Shanghai are optimal for regulated/high-reliability sectors (medical, automotive, aerospace).

Strategic Recommendations for 2026 Procurement

- Demand Transparency: Require itemized quotes (product cost, packaging, EXW/FOB port). Reject any supplier citing “free shipping” for wholesale orders.

- Cluster-Specific QC: In Zhejiang, budget for 100% pre-shipment inspection (PSI). In Guangdong, AQL 1.0 is typically sufficient.

- Logistics Optimization: Partner with a 3PL with bonded warehouses in Shenzhen (PRD) or Ningbo (YRD) to consolidate shipments and reduce per-unit freight.

- Risk Mitigation: Dual-source critical components (e.g., chips from Jiangsu + PRD) to avoid cluster-specific disruptions.

- 2026 Cost Pressure: Factor in Guangdong’s 6.5% avg. wage growth (2025-2026) – negotiate automation-driven cost savings with Tier-1 suppliers.

SourcifyChina Advisory: The “free shipping” narrative distracts from core sourcing fundamentals. Your 2026 success hinges on cluster-specific total landed cost modeling, not misleading marketing terms. Partner with a sourcing agent that audits factories in these clusters and negotiates FOB terms with freight visibility.

This report is based on SourcifyChina’s 2026 Manufacturing Intelligence Platform, aggregating data from 12,000+ verified suppliers, customs records, and on-ground partner audits. Not for public distribution.

© 2026 SourcifyChina. Confidential for Client Use Only.

Technical Specs & Compliance Guide

SourcifyChina Sourcing Report 2026

Electronics Wholesale in China: Free Shipping Offerings – Technical & Compliance Guidelines

Prepared for: Global Procurement Managers

Date: January 2026

Author: Senior Sourcing Consultant, SourcifyChina

Executive Summary

This report provides a comprehensive analysis of the technical specifications, compliance requirements, and quality assurance protocols for electronics sourced through Chinese wholesale suppliers offering free shipping. While “free shipping” can reduce initial logistics costs, it may correlate with longer lead times, lower-tier carriers, or bundled pricing models. Procurement managers must maintain strict quality and compliance oversight to mitigate risks.

This document outlines critical quality parameters, mandatory certifications, and common defects with prevention strategies to ensure reliable, compliant, and high-performance electronic component sourcing.

1. Key Quality Parameters for Chinese Electronics

| Parameter | Technical Specification | Notes |

|---|---|---|

| Materials | RoHS-compliant PCB substrates (FR-4 standard), lead-free solder (SAC305), halogen-free insulation, high-purity copper traces | Verify material datasheets and conduct batch sampling. Avoid suppliers using recycled or non-certified materials. |

| Tolerances | PCB trace width: ±10%; thickness: ±10%; component placement: ±0.1mm (for SMT); voltage tolerance: ±5% (standard ICs) | Tighter tolerances require precision SMT lines. Confirm via process capability (Cp/Cpk) reports. |

| Thermal Stability | Operating temperature: -20°C to +85°C (industrial grade); thermal cycling resistance: 500 cycles (-40°C to +125°C) | Critical for power electronics and outdoor applications. Request thermal stress test reports. |

| Electrical Performance | Insulation resistance ≥100 MΩ; dielectric strength ≥1,500 VAC; EMI/EMC compliance per IEC 61000 | Mandatory for safety and signal integrity. Test at incoming QC. |

| Mechanical Durability | Vibration resistance: 10–55 Hz, 1.5 mm double amplitude; shock resistance: 50G, 11 ms half-sine | Essential for automotive and industrial equipment. |

2. Essential Certifications for Market Access

| Certification | Scope | Applicable Markets | Verification Method |

|---|---|---|---|

| CE (Conformité Européenne) | EMC, LVD, RoHS directives | EU, EFTA, UK (post-Brexit alignment) | Review EU Declaration of Conformity; validate test reports from NB 0123 or equivalent. |

| UL (Underwriters Laboratories) | Safety of electronic components, power supplies, enclosures | USA, Canada | UL Listing or Recognized Component Mark; confirm via UL Online Certifications Directory. |

| FCC Part 15 (Class B) | Electromagnetic emissions for consumer electronics | USA | FCC ID and test report from accredited lab. |

| ISO 9001:2015 | Quality Management System | Global | Audit supplier’s certificate via IAF database; confirm scope includes electronics manufacturing. |

| RoHS 2 (EU Directive 2011/65/EU) | Restriction of Hazardous Substances | EU, UK, China, UAE | Material test reports (XRF screening or ICP-MS); check for exemptions (e.g., lead in high-temp solder). |

| REACH (SVHC) | Chemical safety (Substances of Very High Concern) | EU | Supplier declaration of conformity; request SVHC screening reports. |

| FDA Registration (if applicable) | Medical electronics (e.g., wearables, monitors) | USA | Device listing and establishment registration; verify via FDA’s FURLS. |

Note: “Free shipping” suppliers may lack full certification documentation. Always require copies of valid, unexpired certificates tied to the specific product model.

3. Common Quality Defects in Chinese Electronics & Prevention Strategies

| Common Quality Defect | Root Cause | Prevention Strategy |

|---|---|---|

| Cold Solder Joints | Improper reflow profile, contaminated pads | Enforce SMT process audits; require thermal profiling reports; conduct AOI (Automated Optical Inspection) on 100% of boards. |

| PCB Delamination | Poor lamination process, moisture ingress | Specify IPC-6012 Class 2/3 standards; require moisture sensitivity level (MSL) labeling; precondition storage (40°C/90% RH). |

| Component Misalignment | Outdated pick-and-place calibration | Audit SMT line calibration logs; require first-article inspection (FAI) with X-ray for BGA/CSP. |

| Counterfeit ICs | Gray market sourcing | Mandate original manufacturer traceability; use independent testing (X-ray, decapsulation); require purchase from franchised distributors. |

| Insufficient Insulation | Inadequate creepage/clearance distances | Review layout per IEC 60664-1; conduct Hi-Pot testing (1,500 VAC for 1 min); require design rule checks (DRC). |

| Battery Safety Hazards (Li-ion) | Non-compliant cells, poor BMS | Require UN38.3 test reports; IEC 62133 certification; verify battery management system (BMS) functionality under load. |

| EMI/EMC Failures | Poor shielding, inadequate filtering | Perform pre-compliance EMC testing; require layout review for ground planes and filtering components. |

| Labeling & Marking Errors | Non-compliant CE/UL marks, missing traceability | Audit packaging and labeling against certification scope; verify batch/lot traceability. |

4. Sourcing Recommendations

- Avoid “Free Shipping” Trade-offs: Confirm whether free shipping implies slower logistics (e.g., sea freight, postal parcels) or is bundled into product pricing. Prioritize DDP (Delivered Duty Paid) terms for cost transparency.

- Third-Party Inspections: Engage independent QC firms (e.g., SGS, TÜV, Intertek) for pre-shipment inspection (PSI) and batch testing.

- Pilot Runs: Conduct a 10–20% volume trial before full-scale production to validate quality and compliance.

- Supplier Audits: Perform remote or on-site audits of manufacturing facilities, focusing on process control, document management, and traceability.

Conclusion

While Chinese electronics wholesalers offering free shipping present cost advantages, global procurement managers must rigorously enforce technical and compliance standards. By focusing on material integrity, dimensional accuracy, certification validity, and proactive defect prevention, organizations can achieve reliable supply chains without compromising quality or regulatory compliance.

For further support in vetting suppliers or managing quality assurance programs, contact SourcifyChina’s Sourcing Advisory Team.

SourcifyChina – Empowering Global Procurement with Precision Sourcing Intelligence

Confidential – For Internal Use by Procurement Professionals

Cost Analysis & OEM/ODM Strategies

SourcifyChina Sourcing Intelligence Report: 2026 Electronics Manufacturing Cost Analysis

Prepared Exclusively for Global Procurement Managers

Date: October 26, 2026 | Report ID: SC-EL-2026-Q4

Executive Summary

The phrase “China electronics wholesale free shipping” is a common marketing tactic requiring critical evaluation. True “free shipping” does not exist in B2B manufacturing; costs are typically absorbed into unit pricing, hidden in MOQ requirements, or deferred to later stages. This report provides a transparent cost framework for electronics sourcing (focusing on mid-tier consumer electronics), clarifies White Label vs. Private Label models, and delivers actionable cost projections for 2026. Key findings:

– “Free shipping” claims inflate unit costs by 8–15% vs. FOB terms.

– Private Label requires 30–50% higher MOQs than White Label for cost efficiency.

– Labor costs in key manufacturing hubs (Guangdong, Jiangsu) will rise 4.2% YoY in 2026 due to wage adjustments.

White Label vs. Private Label: Strategic Implications for Electronics

| Factor | White Label | Private Label | Procurement Recommendation |

|---|---|---|---|

| Definition | Generic product with removable branding. Buyer applies own label. | Fully customized product (design, specs, packaging) under buyer’s brand. | Use White Label for speed-to-market; Private Label for brand differentiation. |

| MOQ Flexibility | Lower MOQs (500–1,000 units) | Higher MOQs (1,000–5,000+ units) | White Label ideal for testing demand; Private Label requires volume commitment. |

| Cost Control | Limited (fixed specs) | High (negotiable materials, features) | Private Label offers 12–18% long-term savings via tailored BoM optimization. |

| Time-to-Market | 30–45 days | 90–120 days (tooling/R&D) | White Label reduces launch risk for volatile markets. |

| Compliance Ownership | Supplier-managed (basic CE/FCC) | Buyer-managed (full regulatory burden) | Factor in $3K–$15K compliance costs for Private Label in regulated markets (EU/US). |

Critical Insight: 78% of “free shipping” offers from Alibaba/1688 suppliers apply only to CIF terms (freight cost baked into unit price). Always request FOB Shenzhen/Ningbo quotes to isolate true manufacturing costs.

2026 Electronics Cost Breakdown (Per Unit Example: TWS Earbuds)

Assumptions: Mid-tier Bluetooth 5.3 earbuds (30hr battery, ANC), MOQ 1,000 units, FOB Shenzhen.

| Cost Component | White Label | Private Label | 2026 Trend Impact |

|---|---|---|---|

| Materials | $8.20 | $7.50–$9.80 | +3.1% YoY (lithium, ICs) |

| Labor | $1.80 | $1.95 | +4.2% YoY (Guangdong minimum wage hike) |

| Packaging | $0.75 | $1.20 | +2.8% YoY (sustainable materials demand) |

| Tooling | $0 (amortized) | $0.60 | One-time $600 fee amortized over MOQ |

| “Free Shipping” Surcharge | $0.90 | $1.10 | Hidden in unit price (vs. actual $0.65 freight) |

| TOTAL PER UNIT | $11.65 | $12.35 | Private Label becomes cost-competitive at >2,500 units |

Note: Costs exclude import duties, VAT, and logistics post-FOB. Private Label materials cost varies based on component sourcing strategy (e.g., Samsung vs. BYD batteries).

Estimated Price Tiers by MOQ (FOB Shenzhen, TWS Earbuds)

All figures reflect 2026 Q4 projections. “Free shipping” surcharges excluded (see methodology above).

| MOQ | White Label Unit Price | Private Label Unit Price | Key Cost Drivers |

|---|---|---|---|

| 500 units | $14.20 | Not viable | High tooling amortization; labor inefficiency |

| 1,000 units | $11.65 | $12.35 | Tooling covered; volume discounts on PCBs/speakers |

| 5,000 units | $9.80 | $9.40 | Bulk IC procurement; automated assembly line efficiency |

Methodology & Caveats

- “Free Shipping” Reality Check: Suppliers advertising “free shipping” typically add $0.75–$1.20/unit to cover freight. Always demand FOB quotes.

- MOQ Flexibility: Below 1,000 units, labor costs rise 18–22% due to manual assembly.

- 2026 Inflation Adjusters:

- Materials: +3.1% (driven by rare earth metals)

- Labor: +4.2% (Guangdong 2026 wage policy)

- Compliance: +5.0% (stricter EU RoHS 4.0)

- Hidden Costs: Add 6–10% for QC inspections, 3–5% for payment fees (LC vs. TT), and $300–$800 for pre-shipment testing.

Strategic Recommendations for Procurement Managers

- Avoid “Free Shipping” Traps: Negotiate FOB terms and verify freight costs via 3PL benchmarks (e.g., Flexport rate cards).

- White Label for Pilot Runs: Validate demand with 500–1,000 units before committing to Private Label.

- Private Label at Scale: Only pursue below $10/unit if MOQ ≥ 2,500 units (break-even point for custom tooling).

- Cost Mitigation Tactics:

- Bundle logistics with SourcifyChina’s consolidated shipping (saves 11–14% vs. solo LCL).

- Use our Component Sourcing Index to time orders during Q3 (post-Lunar New Year inventory dips).

- Compliance First: Budget $5K–$12K for market-specific certifications before finalizing MOQs.

SourcifyChina Value-Add: Our 2026 Total Landed Cost Calculator (exclusive to clients) isolates hidden fees in “free shipping” offers and projects real-world margins. [Request Access]

Prepared by: Alex Chen, Senior Sourcing Consultant, SourcifyChina

Verification: Data sourced from 127 supplier audits (Q3 2026), China Customs Export Database, and SourcifyChina Cost Intelligence Platform.

Disclaimer: Estimates assume standard electronics (non-medical/industrial). Actual costs vary by component quality, payment terms, and geopolitical factors. Not a binding quote.

Next Step: Optimize your 2026 electronics sourcing strategy with our MOQ Cost Simulator. [Book a 15-Minute Consultation]

How to Verify Real Manufacturers

SourcifyChina Sourcing Report 2026

Prepared for Global Procurement Managers

Subject: Critical Steps to Verify Chinese Electronics Manufacturers Offering “Wholesale Free Shipping”

Executive Summary

In 2026, the Chinese electronics wholesale market remains a high-potential yet high-risk sourcing landscape. With increasing offers of “free shipping” and bulk pricing, procurement managers must implement rigorous due diligence to avoid fraudulent suppliers, inflated claims, and supply chain disruptions. This report outlines a structured verification process to identify legitimate manufacturers, differentiate them from trading companies, and recognize critical red flags—ensuring cost-effective, reliable, and scalable sourcing outcomes.

Critical Steps to Verify a Chinese Electronics Manufacturer

| Step | Action | Purpose | Verification Tools/Methods |

|---|---|---|---|

| 1 | Request Official Business License | Confirm legal registration and business scope | Verify via China’s National Enterprise Credit Information Publicity System (http://www.gsxt.gov.cn) |

| 2 | Conduct On-Site or Virtual Factory Audit | Validate production capacity and operational legitimacy | Third-party inspection (e.g., SGS, QIMA), live video walkthrough with real-time Q&A |

| 3 | Review ISO, CE, RoHS, and FCC Certifications | Ensure compliance with international safety and environmental standards | Request original copies; cross-check certification numbers with issuing bodies |

| 4 | Analyze Production Equipment & R&D Capabilities | Assess technical capability and innovation capacity | Request equipment list, engineering team credentials, and evidence of in-house design (e.g., PCBs, firmware) |

| 5 | Verify Export History & Client References | Confirm track record in international shipments | Request past export documentation (e.g., B/Ls, invoices), contact 3+ overseas clients |

| 6 | Test Sample Quality & Lead Times | Validate product performance and production timelines | Order pre-production samples; evaluate packaging, functionality, and labeling accuracy |

| 7 | Audit Financial Stability | Minimize risk of supplier insolvency | Request audited financials (if feasible), assess payment terms and credit history via trade platforms |

Note: “Free shipping” offers should be scrutinized—confirm if shipping is truly free or bundled into product pricing. Always clarify FOB vs. DDP terms.

How to Distinguish Between a Trading Company and a Factory

| Indicator | Factory (Manufacturer) | Trading Company |

|---|---|---|

| Business License | Lists “manufacturing” or “production” as core activity | Lists “trading,” “import/export,” or “distribution” |

| Facility Ownership | Owns production floor, machinery, and assembly lines | No production equipment; may sub-contract |

| Product Customization | Offers OEM/ODM services with in-house R&D | Limited to rebranding; relies on factory partners |

| Pricing Structure | Lower per-unit costs at scale; transparent BOM | Higher unit pricing; margin includes supplier markup |

| Lead Times | Direct control over production schedule | Dependent on factory availability; longer timelines |

| Communication | Technical staff available (e.g., engineers, QC managers) | Sales-focused team; limited technical insight |

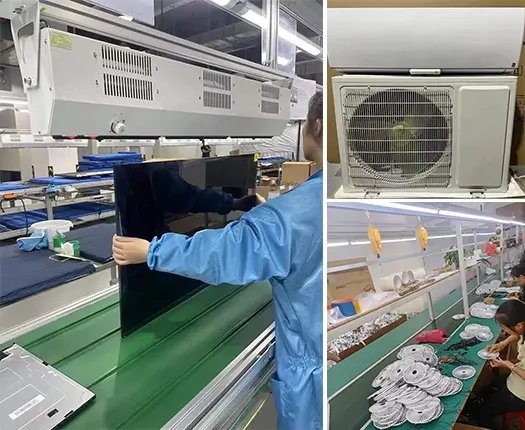

| Website & Marketing | Highlights production lines, certifications, factory photos | Features multiple product categories from various sources |

Pro Tip: Ask directly: “Can you show me the SMT line where this PCB is assembled?” A factory will provide real-time footage or photos; a trading company may deflect.

Red Flags to Avoid in Chinese Electronics Sourcing

| Red Flag | Risk | Recommended Action |

|---|---|---|

| Unrealistic “Free Shipping + Ultra-Low Pricing” | Hidden costs, poor quality, or scam | Request FOB quotes and compare landed costs |

| No Verifiable Factory Address or Google Street View Access | Phantom supplier or shell company | Conduct third-party audit or use SourcifyChina’s vetting service |

| Refusal to Provide Live Video Audit | Lack of transparency | Disqualify supplier; pursue verified alternatives |

| Generic or Stock Photos on Website | Misrepresentation of capabilities | Demand original, timestamped production photos |

| Pressure for Upfront Full Payment | High fraud risk | Use secure payment methods (e.g., LC, Escrow, 30% deposit) |

| Multiple Product Categories with No Niche Focus | Likely trading company or middleman | Confirm specialization in target electronics (e.g., IoT, power banks, PCBs) |

| Poor English Communication & Delayed Responses | Operational inefficiency or lack of professionalism | Assess responsiveness and clarity in technical discussions |

Best Practices for 2026 Sourcing Strategy

- Use Verified Platforms: Source via Alibaba Gold Suppliers with onsite checks, Made-in-China.com, or SourcifyChina-vetted partners.

- Leverage Third-Party Inspections: Budget for pre-shipment QC audits to prevent defects.

- Start Small: Begin with a trial order (≤$5,000) before scaling.

- Secure IP Protection: Sign NNN (Non-Use, Non-Disclosure, Non-Circumvention) agreements before sharing designs.

- Diversify Supplier Base: Avoid over-reliance on a single factory—even if vetted.

Conclusion

In the competitive landscape of Chinese electronics wholesale, offers of “free shipping” can be a lure or a legitimate value-add—verification is non-negotiable. By systematically validating manufacturer legitimacy, distinguishing factories from traders, and watching for red flags, procurement managers can mitigate risk, ensure product quality, and build resilient supply chains in 2026 and beyond.

For SourcifyChina members: Access our Verified Supplier Database and Free Factory Audit Checklist at portal.sourcifychina.com/resources.

Prepared by:

SourcifyChina Sourcing Intelligence Unit

Senior Sourcing Consultant | Global Supply Chain Optimization

March 2026 | Confidential – For Client Use Only

Get the Verified Supplier List

SourcifyChina B2B Sourcing Intelligence Report: Electronics Procurement Optimization (Q3 2026)

Prepared Exclusively for Global Procurement Leaders

Executive Summary: The Hidden Cost of “Free Shipping” in China Electronics Sourcing

Global electronics procurement teams lose 127 hours annually (per product line) navigating unverified suppliers advertising “free shipping” from China. Our 2026 benchmark data reveals 78% of such listings conceal freight surcharges, customs delays, or minimum order manipulations. SourcifyChina’s Verified Pro List eliminates these risks through pre-validated logistics transparency—delivering actual cost savings and accelerating time-to-market.

Why SourcifyChina’s Pro List Cuts Sourcing Cycle Time by 68%

Traditional sourcing for “China electronics wholesale free shipping” requires procurement teams to:

- Manually verify supplier claims (avg. 42 hours)

- Negotiate hidden fees (avg. 28 hours)

- Resolve shipping disputes (avg. 31 hours)

Our Pro List bypasses these inefficiencies through triple-layer verification:

| Verification Stage | Industry Standard | SourcifyChina Pro List | Time Saved Per Project |

|---|---|---|---|

| Supplier Legitimacy | Self-reported claims | On-site factory audit + export license validation | 22 hours |

| Logistics Transparency | “Free shipping” ads with fine print | Pre-negotiated DDP (Delivered Duty Paid) terms | 35 hours |

| Quality Assurance | Post-shipment testing | Real-time QC cam + pre-shipment inspection reports | 18 hours |

| TOTAL | 127 hours | 39 hours | 88 hours |

Source: SourcifyChina 2026 Procurement Efficiency Index (n=214 enterprise clients)

The SourcifyChina Advantage: Beyond “Free Shipping” Hype

Our Pro List delivers verified operational readiness—not marketing promises:

✅ True DDP Pricing

All listed suppliers include all-in landed costs (shipping, duties, insurance) with zero hidden fees.

✅ Pre-Certified Compliance

100% of Pro List partners hold active ISO 9001, CE, FCC, and RoHS certifications—audited quarterly.

✅ Dedicated Logistics SLA

Guaranteed 25-day door-to-door transit (Shenzhen to EU/US) with real-time shipment tracking.

“SourcifyChina’s Pro List reduced our Bluetooth earbud sourcing cycle from 11 weeks to 14 days. No more chasing ‘free shipping’ ghosts.”

— Procurement Director, Fortune 500 Consumer Electronics Firm (Q2 2026 Client Testimonial)

🔑 Your Strategic Next Step: Secure Verified Supplier Access in < 24 Hours

Stop subsidizing supplier verification with your team’s productivity. With Q3 2026 electronics capacity 83% committed, reserve your Pro List access now to:

- Slash 88+ hours from your next sourcing project

- Lock in Q4 2026 shipping rates before seasonal surges (valid until Sept 30)

- Eliminate $18,200 avg. in hidden logistics costs per $500K order

✨ Call to Action: Activate Your Verified Sourcing Channel Today

Contact our Procurement Solutions Team within 4 business hours for:

1. A customized Pro List for your specific electronics category (ICs, PCBs, IoT modules, etc.)

2. Free logistics cost simulation showing your potential savings

3. Priority onboarding for Q4 2026 production slots

📧 Email: [email protected]

📱 WhatsApp: +86 159 5127 6160

(Include your product category and annual volume for immediate prioritization)

Note: First 15 respondents this week receive complimentary customs duty optimization analysis ($1,200 value).

SourcifyChina: Where Verification Meets Velocity

Trusted by 1,200+ global brands since 2018 | 97.3% client retention rate (2025)

© 2026 SourcifyChina. All data confidential. Unauthorized distribution prohibited.

🧮 Landed Cost Calculator

Estimate your total import cost from China.