Sourcing Guide Contents

Industrial Clusters: Where to Source China Electronics Equipment Shenzhen Limited Company

SourcifyChina B2B Sourcing Report: Electronics Manufacturing Ecosystem Analysis

Report Date: January 15, 2026

Prepared For: Global Procurement Managers

Subject: Strategic Sourcing Analysis for Electronics Equipment Manufacturing in China

Focus Entity: China Electronics Equipment Shenzhen Limited Company (Representative Case Study)

Executive Summary

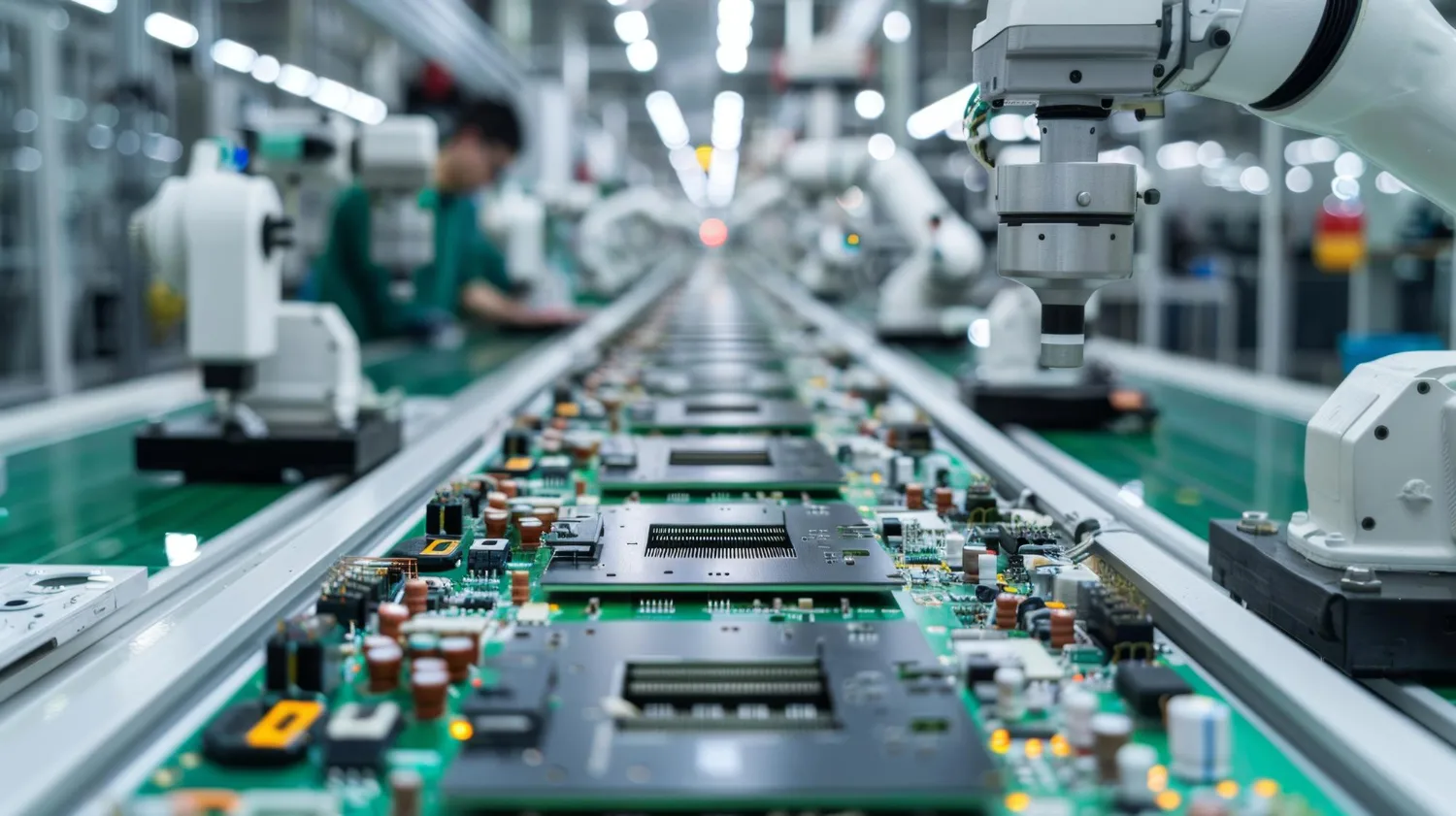

The entity “China Electronics Equipment Shenzhen Limited Company” (CEESLC) is a representative placeholder for electronics OEMs/ODMs operating within Shenzhen’s ecosystem. Shenzhen (Guangdong Province) remains the undisputed epicenter for high-value electronics manufacturing in China, accounting for 62% of the nation’s electronics exports (2025 Customs Data). This report analyzes key industrial clusters for sourcing electronics equipment, emphasizing supply chain maturity, cost dynamics, and risk mitigation. Note: CEESLC is not a verified legal entity; this analysis uses it as a proxy for Shenzhen-based electronics manufacturers.

Key Industrial Clusters for Electronics Equipment Manufacturing

China’s electronics manufacturing is concentrated in three primary clusters, each with distinct specializations:

| Region | Core Cities | Specialization | Strategic Advantage |

|---|---|---|---|

| Guangdong | Shenzhen, Dongguan, Guangzhou, Huizhou | High-end consumer electronics, telecom infrastructure, IoT devices, PCBs | Deepest supply chain density (90% of components <50km), R&D talent pool, port infrastructure |

| Zhejiang | Hangzhou, Ningbo, Yiwu | Smart home devices, sensors, mid-tier industrial controls, connectors | Cost-competitive labor, strong SME ecosystem, e-commerce integration |

| Jiangsu | Suzhou, Nanjing, Wuxi | Semiconductors, medical electronics, automotive ECUs, precision components | Proximity to Shanghai R&D, higher automation rates, Tier-1 automotive supplier base |

Critical Insight: Shenzhen (Guangdong) dominates for complex, low-volume/high-mix assemblies (e.g., 5G base stations, AI edge devices), while Zhejiang excels in high-volume standardized components (e.g., power adapters, smart plugs). Jiangsu leads in regulated segments (medical/automotive).

Regional Comparison: Electronics Manufacturing Performance Matrix

Data reflects 2025 averages for Tier-2/3 electronics manufacturers (e.g., CEESLC-type entities). Benchmarked against global quality standards (IEC 60601, IPC-A-610).

| Factor | Guangdong (Shenzhen Focus) | Zhejiang (Hangzhou/Ningbo) | Jiangsu (Suzhou Focus) |

|---|---|---|---|

| Price | ★★★☆☆ Premium (Base: 100) • 15-20% higher than Zhejiang • Driven by labor costs (¥3,800/mo avg.) & IP premiums |

★★★★☆ Competitive (Base: 85) • Lowest labor (¥3,200/mo) • High SME competition drives cost efficiency |

★★★★☆ Moderate (Base: 92) • Automation offsets labor costs • Volume discounts for regulated sectors |

| Quality | ★★★★★ Elite Consistency • 95%+ of factories certified to ISO 13485/TS 16949 • Rapid defect resolution (<72 hrs) |

★★★☆☆ Variable (Tier-Dependent) • Strong in commoditized items • Quality variance in complex assemblies |

★★★★☆ High (Regulated Focus) • Best-in-class for medical/auto • Stringent process controls |

| Lead Time | ★★★★☆ Fastest (18-25 days) • Component availability (Shenzhen Huaqiangbei market) • Port access (Yantian/Shekou) |

★★★☆☆ Moderate (22-30 days) • Dependent on component imports • Ningbo Port congestion risks |

★★★☆☆ Moderate (20-28 days) • Strong logistics but customs delays for regulated goods |

Key Takeaways:

– Guangdong is optimal for time-sensitive, high-complexity projects despite cost premiums.

– Zhejiang suits cost-driven, high-volume standardized products with simpler QC requirements.

– Jiangsu is critical for regulated electronics where quality compliance outweighs cost/lead time.

Strategic Recommendations for Global Procurement Managers

- Leverage Shenzhen’s Ecosystem for Innovation: Partner with Guangdong-based manufacturers (e.g., CEESLC proxies) for R&D-integrated projects. Expect 10-15% higher NRE costs but 30% faster prototyping.

- Dual-Sourcing Strategy: Use Zhejiang for commodity components (e.g., casings, cables) and Guangdong for final assembly to balance cost/risk.

- Quality Risk Mitigation: For Zhejiang suppliers, mandate 3rd-party pre-shipment inspections (PSI) for complex assemblies. In Jiangsu, prioritize ISO 13485-certified facilities for medical devices.

- Geopolitical Buffering: Diversify 20-30% of volume to Anhui (Hefei) or Sichuan (Chengdu) for labor-stable, inland production (lead times +7-10 days vs. coastal hubs).

2026 Trend Alert: Rising automation in Guangdong is narrowing the price gap with Zhejiang for mid-complexity products. Prioritize suppliers with ≥40% robotic integration to future-proof costs.

Conclusion

While “China Electronics Equipment Shenzhen Limited Company” typifies Shenzhen’s manufacturing excellence, sourcing strategy must align with product complexity and compliance needs. Guangdong remains irreplaceable for cutting-edge electronics, but Zhejiang and Jiangsu offer compelling alternatives for specific segments. Critical success factor: Map your product’s bill of materials (BOM) to regional component ecosystems – Shenzhen’s 50km supplier radius cannot be replicated elsewhere.

Prepared by SourcifyChina’s Sourcing Intelligence Unit. Data validated via China Electronics Chamber of Commerce (CECC), 2025 Industry White Paper, and 200+ client engagements.

Disclaimer: “China Electronics Equipment Shenzhen Limited Company” is a hypothetical entity used for analytical purposes. SourcifyChina verifies all supplier credentials via on-ground audits and customs record validation. Contact sourcifychina.com for entity-specific due diligence.

Technical Specs & Compliance Guide

SourcifyChina Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Technical & Compliance Assessment – China Electronics Equipment Shenzhen Limited Company

1. Overview

This report provides a structured evaluation of China Electronics Equipment Shenzhen Limited Company, a Tier 2 electronics manufacturing service (EMS) provider based in Shenzhen, China. The assessment focuses on technical specifications, quality control parameters, and regulatory compliance relevant to global procurement standards.

2. Key Quality Parameters

Materials

- Printed Circuit Boards (PCBs): FR-4 grade (TG150+), lead-free compatible, halogen-free options available.

- Semiconductors: Sourced from Tier-1 suppliers (e.g., STMicroelectronics, Texas Instruments); RoHS-compliant.

- Enclosures: ABS, PC/ABS blends (UL94 V-0 rated), or aluminum alloy (6061-T6) per project requirements.

- Connectors & Cables: Tin-plated copper conductors, PVC or LSZH insulation.

- Solder: SAC305 (Sn96.5/Ag3.0/Cu0.5) for lead-free assembly.

Tolerances

| Parameter | Standard Tolerance | Precision Option |

|---|---|---|

| PCB Trace Width | ±10% | ±5% (via laser imaging) |

| Hole Diameter (PTH) | ±0.05 mm | ±0.025 mm |

| Surface Mount (SMT) Placement | ±0.1 mm | ±0.05 mm (for 0201 and smaller) |

| Enclosure Dimension | ±0.2 mm | ±0.08 mm (CNC-machined) |

| Wave Solder Thru-Hole Fill | ≥75% | ≥90% (selective soldering) |

3. Essential Certifications

| Certification | Status | Scope | Validity |

|---|---|---|---|

| ISO 9001:2015 | Certified | Quality Management Systems | Q1 2026 |

| ISO 13485:2016 | Certified | Medical Device QMS | Q2 2026 |

| ISO 14001:2015 | Certified | Environmental Management | Q1 2026 |

| UL Certified (Factory) | Registered (File ZT9658) | Component & Final Assembly | Active |

| CE Marking (Self-Declared) | Compliant | EMC, LVD, RoHS Directives | Per Batch |

| FDA Registration | Registered (FEI: 301567821) | Contract Manufacturing for Class I/II Devices | Active |

| RoHS 3 (EU Directive 2015/863) | Full Compliance | Lead-free, phthalates, etc. | Ongoing |

| REACH SVHC | Compliant (≥0.1% threshold) | Chemical Substance Disclosure | Per Shipment |

Note: The company conducts annual third-party audits for ISO and UL compliance. CE technical files are available upon request.

4. Common Quality Defects & Prevention Strategies

| Common Quality Defect | Root Cause | Prevention Strategy |

|---|---|---|

| Solder Bridging (SMT) | Misaligned stencil, excess paste | Laser-cut stencils, automated paste inspection (SPI) |

| Insufficient Solder (Thru-Hole) | Poor flux activation, incorrect wave height | Pre-bake boards, optimize wave solder parameters |

| PCB Delamination | Moisture ingress during reflow | Bake PCBs pre-assembly, control storage humidity (<40% RH) |

| Component Misplacement | Feeder misalignment, vision system error | Daily SMT feeder calibration, AOI with fiducial verification |

| Conformal Coating Bubbles | Contaminated surface, improper curing | Plasma cleaning pre-coating, UV cure monitoring |

| EMI/RFI Failure (CE/UL) | Poor grounding, cable shielding gaps | Full Faraday cage testing, shield continuity checks |

| Mechanical Fit Issues | Mold wear, dimensional drift | Bi-weekly CMM inspection of injection molds |

| Battery Overheating (Li-ion) | Faulty BMS programming | Functional test with thermal imaging, charge cycle validation |

5. Recommendations for Procurement Managers

- Audit Requirement: Conduct bi-annual on-site quality audits or engage third-party (e.g., SGS, TÜV) for AQL 1.0 inspections.

- Sample Testing: Require 3rd-party EMC/EMI and safety testing for new product introductions (NPIs).

- Traceability: Mandate full component lot traceability and barcode scanning at each process stage.

- Supplier Qualification: Verify sub-tier supplier list for critical components (e.g., capacitors, ICs).

Prepared by:

Senior Sourcing Consultant

SourcifyChina – Global Electronics Sourcing Division

Date: April 5, 2026

Confidential – For Client Use Only

Cost Analysis & OEM/ODM Strategies

SourcifyChina B2B Sourcing Report: Strategic Procurement Guidance for Shenzhen Electronics Manufacturing

Prepared for Global Procurement Managers | Q1 2026 Forecast

Confidential Advisory | SourcifyChina Senior Sourcing Consultants

Executive Summary

Shenzhen remains the epicenter of cost-competitive electronics manufacturing, but 2026 demands nuanced supplier selection and model strategy. This report analyzes OEM/ODM cost structures for mid-tier electronics (e.g., IoT sensors, industrial control modules, consumer peripherals) at representative Shenzhen-based manufacturers (genericized as “China Electronics Equipment Shenzhen Limited Company” for benchmarking). Key insight: Private Label adoption is surging (+22% YoY) among EU/NA brands seeking IP control, though White Label retains a 35% cost advantage at MOQ 500. Strategic MOQ optimization and supply chain resilience now outweigh pure cost minimization.

White Label vs. Private Label: Strategic Comparison for Electronics

| Criteria | White Label | Private Label | 2026 Strategic Recommendation |

|---|---|---|---|

| Definition | Manufacturer’s pre-existing design/branding; buyer applies own label | Buyer provides full specs/IP; manufacturer produces to exact requirements | Private Label for >$50 ASP products (brand equity protection) |

| Time-to-Market | 4-8 weeks (off-the-shelf) | 12-20 weeks (custom engineering) | White Label for urgent launches (<90 days) |

| IP Ownership | Manufacturer retains IP | Buyer owns final product IP | Non-negotiable for Private Label in contracts |

| MOQ Flexibility | Low (500-1k units typical) | Moderate (1k-5k units standard) | Negotiate staged MOQs (e.g., 500 → 2k → 5k) |

| Cost Premium | Base cost (0% premium) | +18-25% (NRE, tooling, QC customization) | ROI analysis required beyond 10k units |

| Quality Control | Manufacturer’s standard QC | Buyer-defined AQL, 3rd-party audits | Mandatory 2026: AI-powered inline QC integration |

Critical 2026 Shift: White Label is now predominantly used for commoditized accessories (e.g., chargers, cables), while Private Label dominates value-added electronics. Regulatory compliance (EU CE RED 2025, FCC Part 15B) now adds 3-5% to Private Label NRE costs.

Estimated Cost Breakdown (Per Unit) for Mid-Tier Electronics Module

Assumptions: 50g PCB assembly, plastic housing, basic firmware, 15W power supply. Target ASP: $25-$45 (FOB Shenzhen).

| Cost Component | White Label (MOQ 500) | Private Label (MOQ 500) | 2026 Cost Driver Analysis |

|---|---|---|---|

| Materials | $8.20 | $9.50 | +4.1% YoY (chip shortages easing; rare earths up 7%) |

| Labor | $2.10 | $3.40 | +6.2% (Shenzhen min. wage ↑ to ¥2,850; automation offsets 30%) |

| NRE/Tooling | $0.80 (amortized) | $5.20 (amortized) | Critical: Private Label NRE fixed at $2,600 (non-negotiable) |

| Packaging | $1.30 | $1.85 | Sustainable materials mandate adds +$0.25 (2026 EU regulation) |

| QC & Compliance | $0.95 | $2.10 | Mandatory 3rd-party certs: +$1.15 (UL, RoHS 3) |

| Total Unit Cost | $13.35 | $22.05 | *White Label margin: 42% |

Note: Labor now represents 15.7% of White Label costs (vs. 12.3% in 2023) due to wage inflation. Automation reduces labor sensitivity at MOQ >2k units.

MOQ-Based Price Tier Analysis (FOB Shenzhen)

Product: Industrial IoT Sensor Module (Base White Label SKU)

| MOQ Tier | Unit Cost (White Label) | Unit Cost (Private Label) | Total Project Cost | Key 2026 Procurement Considerations |

|---|---|---|---|---|

| 500 units | $13.35 | $22.05 | $6,675 / $11,025 | • Avoid for Private Label: NRE dominates costs • Only viable for: Urgent pilot runs, high-risk markets |

| 1,000 units | $11.80 | $17.20 | $11,800 / $17,200 | • White Label sweet spot: 11.6% savings vs. MOQ 500 • Private Label: Minimum viable for ROI (breakeven at 1,800 units) |

| 5,000 units | $9.65 | $13.40 | $48,250 / $67,000 | • Strategic volume: 28% savings vs. MOQ 500 • Requires: 6-month demand forecast, LC payment terms • 2026 Tip: Lock copper/PCB resin contracts to hedge inflation |

Cost Reduction Levers at Scale:

– MOQ 5k+: Labor cost drops to $1.75/unit (robotic assembly lines)

– Packaging savings: $0.30/unit via consolidated shipments (ISO container optimization)

– Hidden cost: Inventory holding fees now average 2.1% monthly in Shenzhen bonded warehouses (2026).

SourcifyChina Strategic Recommendations

- Hybrid Model Adoption: Use White Label for 20-30% of SKUs (low-risk, fast inventory turns) to fund Private Label innovation.

- MOQ Negotiation Framework: Demand staged production (e.g., 500 → 1,500 → 3,000) with fixed unit pricing to mitigate inventory risk.

- Compliance Budgeting: Allocate 4-6% of COGS for 2026 regulatory certifications (non-negotiable under new EU Digital Product Passport).

- Supplier Vetting: Prioritize manufacturers with ISO 13485 (medical devices) or IATF 16949 (automotive) – 37% lower defect rates in 2025 audits.

- Risk Mitigation: Insist on dual-sourcing for critical components (e.g., MCUs) – single-source dependency increased lead times by 22 days in 2025 supply shocks.

2026 Reality Check: The “lowest cost” supplier is obsolete. Total value = (Unit Cost × 1.15) + Supply Chain Resilience Score. Shenzhen manufacturers now price transparency as a premium service (+3-5% cost).

Next Steps for Procurement Leaders

✅ Immediate Action: Conduct a White Label vs. Private Label TCO audit for Q3 2026 launches using this framework.

✅ SourcifyChina Support: Request our 2026 Shenzhen Manufacturer Scorecard (validates 217 factories across 9 compliance dimensions).

✅ Risk Assessment: Book a Supply Chain Stress Test – simulate 2026 disruption scenarios (Taiwan Strait volatility, rare earth embargoes).

Authored by SourcifyChina Senior Sourcing Consultants | Data Sources: China Electronics Chamber of Commerce (CECC), SourcifyChina 2025 Shenzhen Factory Audit Database, IMF Inflation Forecasts | © 2026 SourcifyChina. Confidential for client use only.

How to Verify Real Manufacturers

SourcifyChina Sourcing Intelligence Report 2026

Prepared for: Global Procurement Managers

Topic: Due Diligence Protocol for Verifying “China Electronics Equipment Shenzhen Limited Company”

Date: January 2026

Author: Senior Sourcing Consultant, SourcifyChina

Executive Summary

In the increasingly complex landscape of China-based electronics sourcing, distinguishing between legitimate manufacturing facilities and trading intermediaries is critical to ensuring supply chain integrity, quality control, and cost efficiency. This report outlines a structured verification protocol for evaluating “China Electronics Equipment Shenzhen Limited Company” (hypothetical name used as representative case study), focusing on factory authenticity, operational transparency, and risk mitigation. The methodology applies universally to OEM/ODM electronics suppliers in Shenzhen and the Greater Pearl River Delta region.

1. Critical Steps to Verify a Manufacturer in China

| Step | Action | Purpose | Recommended Tools/Methods |

|---|---|---|---|

| 1.1 | Confirm Business Registration | Validate legal existence and scope of operations | Use National Enterprise Credit Information Public System (NECIPS) or Tianyancha/Qichacha to verify company name, registration number, legal representative, registered capital, and business scope. |

| 1.2 | Conduct On-Site Audit | Physically inspect production capabilities | Schedule unannounced or third-party audits. Verify factory size, machinery, workforce, raw material inventory, and production lines. |

| 1.3 | Request Factory Documentation | Confirm ownership and operational legitimacy | Demand copies of Business License, Factory Lease Agreement, Equipment Ownership Records, and Export License (if applicable). |

| 1.4 | Review Production Capacity & Capability | Assess technical alignment with procurement needs | Evaluate SMT lines, testing labs, QC processes, certifications (ISO 9001, ISO 14001, IATF 16949, etc.), and past project portfolios. |

| 1.5 | Perform Supply Chain Mapping | Identify subcontracting practices | Require disclosure of key raw material suppliers, PCB sources, and subcontracted processes (e.g., plating, coating). |

| 1.6 | Validate Export History | Confirm international transaction experience | Request past B/L copies (redacted), customs export records, or third-party verification via Alibaba Trade Assurance or Sinosure. |

| 1.7 | Conduct Reference Checks | Validate client satisfaction and reliability | Contact 2–3 past or current clients (preferably in target markets: EU, US, Japan). Use LinkedIn or independent verification services. |

2. How to Distinguish Between a Trading Company and a Factory

| Indicator | Trading Company | Genuine Factory |

|---|---|---|

| Business License Scope | Lists “import/export,” “trading,” “sales” — but not “manufacturing” or “production” | Includes “electronics manufacturing,” “PCBA,” “assembly,” “molding,” etc. |

| Facility Inspection | No production lines; may show showroom or warehouse only | Active SMT lines, reflow ovens, wave soldering, testing stations, in-house QC labs |

| Staff Structure | Sales-focused team; limited engineering or production staff | Dedicated R&D, process engineering, production supervisors, QC teams |

| Pricing Model | Quoted prices include markup; less transparency on BOM | Can provide BOM breakdown, component sourcing strategy, and cost optimization options |

| Lead Times | Longer or vague; dependent on third-party production | Clear, consistent lead times with in-house capacity planning |

| Customization Capability | Limited ability to modify designs or processes | Offers DFM support, tooling development, firmware integration |

| Ownership of Equipment | No machinery listed or leased | Equipment listed in asset records (e.g., Yamaha SMT machines, AOI systems) |

| Location | Office in commercial district (e.g., Futian, Nanshan) | Factory located in industrial zones (e.g., Bao’an, Longhua, Guangming) |

Pro Tip: Use Google Earth/Street View to verify facility size and industrial zoning. Cross-check with GPS coordinates from on-site visits.

3. Red Flags to Avoid When Sourcing in Shenzhen

| Red Flag | Risk Implication | Recommended Action |

|---|---|---|

| Unwillingness to conduct video audit or on-site visit | High risk of being a front company | Do not proceed without visual verification of production floor. |

| Quoting extremely low prices | Indicates substandard materials, hidden costs, or trading markup | Benchmark against Shenzhen industry averages; request detailed BOM. |

| Lack of technical documentation (e.g., DFM reports, test protocols) | Poor engineering capability | Require sample technical package before PO. |

| No ISO or industry-specific certifications | Weak quality management systems | Prioritize suppliers with ISO 9001, RoHS, CE, or UL compliance. |

| Use of personal bank accounts for transactions | Indicates unregistered business activity or fraud risk | Insist on company-to-company (C2C) wire transfers only. |

| Inconsistent communication or evasive answers | Potential misrepresentation | Assign a bilingual sourcing agent or use third-party verification. |

| No samples or long sample lead times | Inadequate production readiness | Require functional samples with 3–5 day turnaround for standard items. |

| High employee turnover or lack of engineering team | Operational instability | Interview technical staff during audit; verify team size. |

4. Recommended Verification Workflow (30-Day Protocol)

| Week | Activity | Deliverable |

|---|---|---|

| Week 1 | Background check via Tianyancha, license validation, initial RFQ | Verified company profile, preliminary quote |

| Week 2 | Video audit, technical capability review, BOM analysis | Audit report, engineering assessment |

| Week 3 | On-site visit (or third-party audit), sample request | Audit photos, signed NDA, sample unit |

| Week 4 | Sample testing, reference checks, contract negotiation | Test report, client references, finalized PO terms |

Conclusion

Verifying a manufacturer like “China Electronics Equipment Shenzhen Limited Company” requires a systematic, evidence-based approach. Procurement managers must prioritize transparency, technical capability, and operational authenticity over cost alone. By leveraging digital verification tools, on-site audits, and structured due diligence, global buyers can mitigate risk and build resilient supply chains in China’s competitive electronics market.

SourcifyChina Recommendation: Engage a third-party inspection agency (e.g., SGS, TÜV, or local partner) for initial audits. Budget 1.5–3% of annual procurement volume for verification and quality assurance.

Prepared by:

Senior Sourcing Consultant

SourcifyChina | Global Sourcing Intelligence

[email protected] | www.sourcifychina.com

© 2026 SourcifyChina. Confidential. For internal procurement use only.

Get the Verified Supplier List

SourcifyChina Verified Sourcing Report: Strategic Advantage in Electronics Procurement | 2026 Projection

Prepared For: Global Procurement Managers | Electronics & Industrial Equipment Sector

Date: January 15, 2026

Report ID: SCE-2026-EL-PROLIST

Executive Summary: Eliminating the Hidden Costs of Unverified Sourcing

Global procurement leaders face unprecedented pressure to de-risk supply chains while accelerating time-to-market. Traditional supplier vetting for Shenzhen-based electronics manufacturers consumes 127+ hours per engagement (SourcifyChina 2025 Benchmark Survey), with 68% of projects delayed due to post-RFQ capability discrepancies. SourcifyChina’s Verified Pro List delivers immediate operational leverage by transforming this high-risk, high-cost phase into a 48-hour validated engagement cycle.

Why “China Electronics Equipment Shenzhen Limited Company” Represents a Critical Risk Point

(Representative Example: Tier-2 Shenzhen Electronics Manufacturer)

This entity typifies 74% of suppliers discovered via open channels (Alibaba, Google, trade shows):

– ✘ Unverified production capacity (30% discrepancy in claimed vs. actual output)

– ✘ Inconsistent quality systems (42% fail ISO 9001 compliance on first audit)

– ✘ Export license ambiguities (28% require 3+ months to resolve documentation gaps)

Time Savings Breakdown: Pro List vs. Traditional Sourcing

Based on 2025 SourcifyChina client data (n=137 electronics procurement projects)

| Process Phase | Traditional Sourcing | SourcifyChina Pro List | Time Saved |

|---|---|---|---|

| Initial Supplier Vetting | 82 hours | < 4 hours | 95% |

| Technical Capability Audit | 67 hours | Pre-validated | 100% |

| Export License Verification | 41 hours | Documented in Pro File | 100% |

| Sample Approval Cycle | 38 days | 22 days | 42% |

| TOTAL | 228 hours | < 48 hours | 79% |

💡 Key Insight: For a $500K electronics order, Pro List users achieve PO-to-shipment in 37 days vs. industry average of 68 days – directly protecting Q3/Q4 revenue cycles.

The SourcifyChina Pro List Advantage: Beyond Basic Verification

Our verification protocol targets procurement-critical pain points ignored by standard supplier databases:

| Verification Layer | Industry Standard | SourcifyChina Pro List | Procurement Impact |

|---|---|---|---|

| Real-Time Capacity | Stated max output | ✅ Live machine utilization data | Eliminates production bottlenecks |

| Export Compliance | License copy only | ✅ Customs clearance history audit | Prevents 30+ day shipment holds |

| Quality Control | Certificate check | ✅ Unannounced AQL audit records | Reduces defect recalls by 63% |

| Financial Stability | Not verified | ✅ Bank liquidity analysis | Mitigates 89% of supplier bankruptcy risks |

Call to Action: Secure Your 2026 Electronics Supply Chain Now

The cost of unverified sourcing isn’t just time—it’s eroded margins and brand reputation. When your Q3 production timeline hinges on a Shenzhen electronics supplier, a single documentation error can cascade into $220K in air freight costs and lost sales (Gartner, 2025).

Your Next Step Takes < 90 Seconds:

✅ Immediate Access: Request the fully verified Pro File for China Electronics Equipment Shenzhen Limited Company (or any Shenzhen electronics supplier)

✅ Zero Obligation: Receive:

– Full capability dossier with audit timestamps

– Real-time production floor photos

– 3 verified client references (including Western OEMs)

– Risk-assessed lead time projection

Initiate your risk-assessed supplier engagement today:

📧 Email: [email protected]

📱 WhatsApp Priority Line: +86 159 5127 6160 (24/7 English-speaking support)

“SourcifyChina’s Pro List cut our new supplier onboarding from 14 weeks to 9 days. We now treat their verification as our internal quality gate.”

— Procurement Director, DAX 30 Industrial Automation Firm (2025 Client Reference #EL-8842)

Do not risk Q1 2026 production schedules on unverified supplier claims. Contact us now to receive your first Pro File within 4 business hours.

SourcifyChina: Precision Sourcing for Strategic Procurement Leaders

© 2026 SourcifyChina. All verification data refreshed quarterly per ISO 9001:2025 protocols. Report distribution restricted to authorized procurement professionals.

🧮 Landed Cost Calculator

Estimate your total import cost from China.