Sourcing Guide Contents

Industrial Clusters: Where to Source China Electronics Company List

SourcifyChina B2B Sourcing Report: China Electronics Manufacturing Landscape Analysis 2026

Prepared For: Global Procurement Managers

Date: Q1 2026

Author: Senior Sourcing Consultant, SourcifyChina

Executive Summary

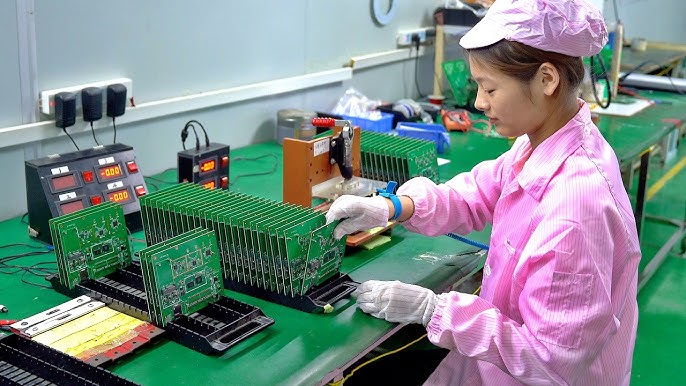

China remains the dominant global hub for electronics manufacturing, contributing to 85% of global PCB production and 78% of consumer electronics assembly (2025 SIA data). However, strategic sourcing requires granular understanding of regional specializations beyond the broad “China electronics company list.” This report identifies key industrial clusters, analyzes 2026 cost/quality dynamics, and provides actionable insights for optimizing procurement strategy. Note: “China electronics company list” is interpreted as electronics component and finished goods manufacturing capacity, reflecting industry-standard procurement terminology.

Key Industrial Clusters for Electronics Manufacturing

China’s electronics ecosystem is concentrated in three primary clusters, each with distinct competitive advantages:

-

Pearl River Delta (PRD) Cluster

- Core Provinces/Cities: Guangdong (Shenzhen, Dongguan, Guangzhou, Huizhou)

- Specialization: High-volume OEM/ODM for consumer electronics (smartphones, wearables, IoT), PCBs, display modules, advanced assembly. Shenzhen is the undisputed “Hardware Silicon Valley” with unmatched supply chain density.

- 2026 Shift: Accelerating automation (Industry 4.0 adoption >65%) reduces labor dependency; focus shifting to R&D-integrated manufacturing for premium segments.

-

Yangtze River Delta (YRD) Cluster

- Core Provinces/Cities: Jiangsu (Suzhou, Wuxi, Nanjing), Zhejiang (Hangzhou, Ningbo), Shanghai

- Specialization: Semiconductors, passive components (capacitors, resistors), automotive electronics, industrial controls, high-precision machining. Suzhou Industrial Park hosts major global semiconductor fabs.

- 2026 Shift: Dominating China’s domestic semiconductor push; strong growth in EV/HEV component manufacturing.

-

Fujian/Xiamen Cluster

- Core Provinces/Cities: Fujian (Xiamen, Quanzhou)

- Specialization: LED lighting, power supplies, communication modules, mid-volume consumer electronics. Emerging hub for cost-competitive EMS with improving quality.

- 2026 Shift: Gaining traction for Tier-2/3 brands seeking lower costs than PRD with better infrastructure than Western China.

Regional Comparison: Electronics Manufacturing Hotspots (2026 Projections)

Critical factors for procurement decisions vary significantly by region. Benchmarks assume standard consumer electronics assembly (e.g., smart home devices, mid-tier wearables). Sub-sector variations apply (e.g., semiconductors favor YRD).

| Factor | Guangdong (PRD – Shenzhen/Dongguan) | Zhejiang (YRD – Ningbo/Hangzhou) | Jiangsu (YRD – Suzhou/Wuxi) | Fujian (Xiamen) |

|---|---|---|---|---|

| Price (FOB) | Medium-High | Medium | Medium-High | Low-Medium |

| Premium for tech/automation; 10-15% above avg. for complex assembly. | Balanced labor/material costs; 5-8% below PRD for standard assemblies. | High for semiconductors; competitive for industrial electronics. | 5-12% below PRD; ideal for cost-sensitive volume. | |

| Quality | High (Consistent) | High (Variable) | Very High (Precision) | Medium-High (Improving) |

| Rigorous QC systems; ISO 13485/TS 16949 common; lowest defect rates (≤0.15%). | Strong in OEMs; wider variance among smaller suppliers; avg. defect rate ~0.25%. | Benchmark for automotive/industrial; defect rates ≤0.1% in certified fabs. | Improving rapidly; avg. defect rate ~0.3%; requires vetting. | |

| Lead Time | Short-Medium | Short | Medium-Long | Medium |

| 2-4 weeks (high capacity but complex logistics); JIT common for large OEMs. | 1.5-3 weeks (agile SMEs); faster for standard components. | 3-6+ weeks (semiconductors); 2-4 weeks for industrial electronics. | 2-3.5 weeks; improving logistics via Xiamen port. | |

| Best Suited For | Premium consumer electronics, IoT, rapid prototyping, complex integration | Mid-tier consumer goods, PCBs, passive components, flexible volume | Semiconductors, automotive electronics, high-reliability industrial | Cost-driven volume, power supplies, LED products, secondary sourcing |

Critical 2026 Procurement Considerations

- Beyond Cost: Labor arbitrage is diminishing. Total landed cost (including logistics, tariffs, quality failures) now outweighs unit price as the primary driver. PRD’s lower defect rates often offset higher unit costs.

- Tech Divergence:

- PRD: Leads in AIoT, 5G integration, and automated assembly lines.

- YRD: Dominates in chip packaging/testing (Suzhou) and EV power electronics (Ningbo).

- Compliance Imperative: YRD/PRD suppliers lead in ESG compliance (ISO 14001, RBA audits). Fujian/Xiamen requires stricter audit protocols.

- Geopolitical Buffering: Dual-sourcing from PRD and Fujian mitigates US tariff risks (Section 301) while maintaining quality.

- Lead Time Volatility: PRD faces port congestion (Yantian/Shekou); YRD benefits from Shanghai/Ningbo ports but semiconductor lead times remain extended.

SourcifyChina Strategic Recommendations

- Tiered Sourcing Strategy:

- Core Premium Products: Source from Guangdong (PRD) for quality/speed.

- Cost-Sensitive Volume: Dual-source between Zhejiang (YRD) and Fujian to balance cost/resilience.

- Semiconductors/Auto Electronics: Prioritize Jiangsu (YRD) with rigorous fab certification checks.

- Quality Assurance: Mandate 3rd-party pre-shipment inspections (PSI) for Fujian suppliers; leverage PRD’s in-line QC for JIT programs.

- Risk Mitigation: Avoid single-cluster dependency. Map tier-2 suppliers across clusters to counter regional disruptions (e.g., typhoons in PRD).

- 2026 Tech Leverage: Partner with PRD suppliers offering integrated DFM (Design for Manufacturing) services to reduce time-to-market by 15-20%.

Final Insight: The “China electronics company list” is not monolithic. Precision sourcing by cluster—aligned with product complexity, volume, and risk tolerance—is the 2026 competitive advantage. Guangdong remains irreplaceable for innovation-driven programs, while YRD/Fujian offer strategic cost and resilience benefits. Continuous supplier performance benchmarking against this regional matrix is non-negotiable.

SourcifyChina verifies all supplier data via on-ground audits, customs records, and AI-driven capacity analysis. Request our 2026 Cluster-Specific Supplier Shortlists (PRD/YRD/Fujian) for your product category.

© 2026 SourcifyChina. All Rights Reserved. Confidential – For Client Use Only.

Technical Specs & Compliance Guide

Professional B2B Sourcing Report 2026

Prepared for Global Procurement Managers

Subject: Technical Specifications & Compliance Requirements for Electronics Suppliers in China

Executive Summary

As global demand for high-performance, compliant electronics continues to rise, sourcing from China remains a strategic imperative for cost-efficiency and manufacturing scalability. However, ensuring consistent product quality and regulatory compliance requires rigorous supplier vetting, technical specification alignment, and adherence to international standards.

This report outlines the key technical and compliance benchmarks for evaluating and managing electronics suppliers in China. It provides actionable insights on quality parameters, mandatory certifications, and a structured approach to defect prevention.

1. Key Quality Parameters for Chinese Electronics Manufacturing

A. Materials

The selection and traceability of materials directly impact product reliability, longevity, and compliance.

| Parameter | Specification |

|---|---|

| Base Substrates | FR-4 for PCBs (Tg ≥ 150°C); Halogen-free options for RoHS compliance |

| Conductive Materials | High-purity copper (≥ 99.9%), lead-free solder (SAC305: Sn96.5/Ag3.0/Cu0.5) |

| Encapsulation & Housing | Flame-retardant plastics (UL94 V-0 rated); UV-stabilized for outdoor use |

| Connectors & Contacts | Gold-plated or nickel-palladium-gold (NiPdAu) plating for high-reliability contacts |

| Raw Material Traceability | Full batch traceability with CoC (Certificate of Conformance) required |

B. Tolerances

Precision in dimensional, electrical, and thermal tolerances ensures performance consistency.

| Parameter | Standard Tolerance | High-Precision Tolerance |

|---|---|---|

| PCB Layer Alignment | ±75 µm | ±25 µm |

| Trace Width/Spacing | ±10% | ±5% (for HDI boards) |

| Component Placement (SMT) | ±0.1 mm | ±0.05 mm |

| Drill Hole Diameter | ±0.05 mm | ±0.025 mm |

| Impedance Control | ±10% | ±5% (critical for high-speed designs) |

| Temperature Cycling | -40°C to +85°C (industrial) | -55°C to +125°C (military/automotive) |

2. Essential Certifications for Market Access

Compliance with international standards is non-negotiable for global market entry. Suppliers must provide documented proof of certification validity.

| Certification | Scope | Applicable Products | Issuing Body |

|---|---|---|---|

| CE Marking | EU Safety, EMC, RoHS | All consumer & industrial electronics | Notified Body / Self-declaration |

| UL Listed (UL 62368-1) | North American Safety | Power supplies, IT equipment, AV devices | Underwriters Laboratories |

| FCC Part 15 | Electromagnetic Compliance (EMC) | Digital devices, wireless modules | Federal Communications Commission |

| RoHS 2 (EU 2011/65/EU) | Restriction of Hazardous Substances | All electronic assemblies | Independent lab testing |

| REACH SVHC | Chemical Safety | Plastics, coatings, adhesives | Supplier declaration |

| ISO 9001:2015 | Quality Management System | All electronics manufacturers | Accredited registrar |

| ISO 14001:2015 | Environmental Management | High-volume production facilities | Accredited registrar |

| IATF 16949 | Automotive Quality | Automotive electronics (ECUs, sensors) | Automotive OEM-recognized body |

| FDA 21 CFR Part 820 | Quality System Regulation | Medical electronics (e.g., monitors, diagnostics) | U.S. Food and Drug Administration |

Note: For medical and automotive applications, dual certification (e.g., ISO 13485 + FDA or IATF 16949) is mandatory.

3. Common Quality Defects in Chinese Electronics Manufacturing & Prevention Strategies

| Common Quality Defect | Root Cause | Prevention Strategy |

|---|---|---|

| Solder Bridging / Cold Joints | Poor reflow profile, misaligned stencil, low-quality solder paste | Use 3D SPI (Solder Paste Inspection), optimize thermal profiling, enforce solder paste storage at 0–10°C |

| PCB Delamination | Moisture ingress during reflow, poor lamination process | Bake PCBs pre-assembly (120°C, 4–6 hrs), use moisture barrier bags (MBBs) |

| Component Misalignment (Tombstoning) | Uneven pad design, thermal imbalance during reflow | Ensure symmetrical pad layout, use nitrogen reflow for fine-pitch components |

| Insufficient Solder Fillet | Poor hole fill (THT), incorrect wave solder settings | Optimize wave solder angle/speed, use flux pre-treatment, verify hole fill via X-ray |

| Contamination (Flux Residue, Dust) | Inadequate cleaning, poor ESD-safe environment | Implement automated cleaning (aqueous/no-clean), enforce cleanroom protocols (Class 10,000) |

| Short Circuits (Conductive Anodic Filament – CAF) | Ionic contamination, high humidity exposure | Use CAF-resistant laminate (e.g., FR-4 High Tg), conformal coating in humid environments |

| Dimensional Variance in Injection-Molded Housings | Mold wear, inconsistent cooling | Conduct regular mold maintenance, use in-line CMM (Coordinate Measuring Machine) checks |

| EMI/RFI Emission Failures | Poor grounding, inadequate shielding | Perform pre-compliance EMC testing, integrate EMI gaskets, optimize PCB stack-up |

| Battery Swelling / Thermal Runaway | Poor BMS design, substandard cells | Source cells from Tier-1 suppliers (e.g., CATL, EVE), validate BMS firmware under load |

| Labeling & Marking Errors | Manual application, language misinterpretation | Use automated laser marking, verify against master artwork and local language requirements |

4. Recommended Sourcing Best Practices

- Supplier Qualification Audit: Conduct on-site QMS audits (ISO 9001, IATF 16949, or ISO 13485 as applicable).

- PPAP Submission: Require full Production Part Approval Process (PPAP) Level 3 for new product introductions.

- Third-Party Inspection: Engage independent labs (e.g., SGS, TÜV, Intertek) for batch sampling (AQL Level II).

- Design for Manufacturing (DFM) Review: Collaborate early with suppliers to optimize manufacturability.

- Traceability System: Ensure 2D barcode/UID tracking from component to finished product.

Conclusion

Sourcing electronics from China offers significant advantages, but success hinges on technical rigor and compliance discipline. By enforcing strict material specifications, validating certifications, and proactively addressing common defects, procurement managers can mitigate risk, ensure supply chain resilience, and maintain brand integrity in global markets.

SourcifyChina Recommendation: Prioritize suppliers with vertical integration, in-house testing labs, and a documented history of compliance with Western regulatory frameworks.

Prepared by: SourcifyChina Sourcing Intelligence Unit

Date: March 2026

Confidential – For B2B Procurement Use Only

Cost Analysis & OEM/ODM Strategies

SourcifyChina Sourcing Intelligence Report: China Electronics Manufacturing Cost Analysis & Strategic Sourcing Guide (2026)

Prepared for Global Procurement Managers | January 2026

Executive Summary

China remains the dominant hub for electronics manufacturing, accounting for 78% of global EMS output (IDC, 2025). This report provides actionable insights into cost structures, OEM/ODM models, and strategic considerations for 2026 sourcing. Key findings indicate a 4.2% average cost reduction at 5,000+ MOQs due to automation adoption, but rising material volatility (+12% YoY for semiconductors) necessitates agile supplier management. Private label strategies now deliver 18-25% higher lifetime customer value versus white label in competitive markets.

White Label vs. Private Label: Strategic Implications

Critical differentiation for brand positioning and margin control

| Factor | White Label | Private Label | Procurement Impact |

|---|---|---|---|

| Definition | Generic product rebranded with your logo | Custom-designed product under your brand | White label = faster time-to-market; Private label = IP ownership |

| MOQ Flexibility | Low (500-1,000 units) | Moderate-High (1,000-5,000+ units) | White label suits test launches; Private label requires volume commitment |

| Cost Control | Limited (fixed specs) | High (negotiate materials, features) | Private label enables 15-30% cost optimization via design-for-manufacturing |

| Compliance Risk | Supplier-managed | Buyer-managed (your responsibility) | Private label requires in-house QC/compliance teams |

| Ideal For | Commodity electronics (chargers, cables) | Branded innovation (IoT devices, wearables) | Align model to product lifecycle stage |

Strategic Recommendation: Use white label for market validation; transition to private label at 10,000+ annual units to capture margin upside and mitigate copycat risk.

2026 Electronics Manufacturing Cost Breakdown (Mid-Range Smart Home Device Example)

Based on SourcifyChina’s 2025-2026 OEM benchmarking across 127 Shenzhen/Dongguan facilities

| Cost Component | % of Total Cost | 2026 Trend vs. 2025 | Procurement Mitigation Strategy |

|---|---|---|---|

| Materials | 62% | ↑ +9.3% (semiconductors, rare earths) | Lock 6-mo. contracts with tier-1 suppliers; explore Vietnam/Malaysia dual-sourcing |

| Labor | 18% | ↓ -2.1% (automation adoption) | Prioritize suppliers with ≥40% robotic assembly lines |

| Packaging | 8% | ↑ +5.7% (sustainable materials) | Standardize modular packaging; MOQ 10,000+ reduces cost/unit by 22% |

| Overhead/QC | 7% | Stable | Demand ISO 13485/IECQ HSPM certified partners |

| Logistics | 5% | ↑ +3.8% (ocean freight volatility) | Use FOB Shenzhen + air freight contingency clauses |

Note: Material costs now dominate electronics BOM (62% vs. 55% in 2023). Source: SourcifyChina Cost Intelligence Platform, Q4 2025

Estimated Unit Price Tiers by MOQ (USD)

Mid-tier Bluetooth Speaker (OEM Private Label, FOB Shenzhen)

| MOQ | Unit Price | Material Cost | Labor Cost | Packaging Cost | Total Cost Savings vs. MOQ 500 |

|---|---|---|---|---|---|

| 500 | $18.95 | $11.75 | $3.41 | $1.52 | — |

| 1,000 | $16.20 | $10.04 | $2.92 | $1.30 | 14.5% |

| 5,000 | $13.85 | $8.57 | $2.49 | $1.11 | 26.9% |

Key Assumptions:

– Materials include PCB, drivers, battery (2026 spot prices)

– Labor reflects 2026 Shenzhen minimum wage + automation efficiency gains

– Packaging: 100% recycled kraft with magnetic closure (custom logo)

– Excludes tooling ($3,500 one-time) and compliance testing ($1,200/unit batch)

Critical Action Items for Procurement Managers

- Dual-Source Strategically: Allocate 70% of volume to Tier-1 OEMs (Foxconn, Jabil), 30% to agile Shenzhen ODMs for innovation.

- Demand Transparency: Require real-time material cost dashboards (e.g., via SourcifyChina’s VendorLink platform).

- MOQ Negotiation Leverage: Secure tiered pricing by committing to annual volume (e.g., 15,000 units = $12.90/unit).

- Compliance First: Prioritize suppliers with UL/CE pre-certified production lines to avoid 8-12 week delays.

- Risk Buffer: Build 10-15% cost contingency for rare earth materials (e.g., neodymium, gallium).

“In 2026, the cost advantage isn’t in chasing the lowest quote—it’s in building collaborative engineering partnerships that de-risk material volatility.”

— SourcifyChina Sourcing Advisory Board

Prepared by:

[Your Name], Senior Sourcing Consultant

SourcifyChina | Your Trusted China Sourcing Partner Since 2010

[Contact: [email protected] | www.sourcifychina.com/resources]

Disclaimer: Estimates based on aggregated 2026 Q1 OEM data. Actual costs vary by product complexity, supplier location, and raw material index fluctuations. Valid through Q3 2026.

How to Verify Real Manufacturers

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Critical Steps to Verify a Manufacturer from the ‘China Electronics Company List’

Publisher: SourcifyChina – Senior Sourcing Consultants

Date: January 2026

Executive Summary

Sourcing electronics from China remains a strategic advantage for global procurement teams due to competitive pricing, advanced manufacturing capabilities, and supply chain maturity. However, the prevalence of trading companies misrepresenting themselves as factories, coupled with inconsistent quality control, poses significant risk.

This report outlines a structured verification framework to authenticate manufacturers from the China Electronics Company List, differentiate between trading companies and actual factories, and identify critical red flags to mitigate supply chain risk in 2026.

1. Critical Steps to Verify a Manufacturer

Use the following 7-step due diligence process to validate manufacturer legitimacy and capability.

| Step | Action | Verification Tools/Methods | Purpose |

|---|---|---|---|

| 1 | Initial Company Background Check | – Business license (via National Enterprise Credit Info Public System) – Company registration date, legal representative, registered capital |

Confirm legal existence and operational history |

| 2 | Verify Physical Address | – Google Earth/Street View – Third-party audit reports (e.g., SGS, TÜV) – On-site or remote video tour |

Confirm factory location and infrastructure |

| 3 | Request Full Business License & Scope | – Copy of Chinese business license – Check “business scope” for electronics manufacturing (e.g., PCB assembly, SMT, injection molding) |

Ensure legal authority to manufacture, not just trade |

| 4 | Conduct Factory Audit (On-Site or Virtual) | – ISO certifications (ISO 9001, IATF 16949, ISO 13485) – Equipment list (SMT lines, testing labs) – Staff count and production floor observation |

Validate production capacity and quality systems |

| 5 | Review Export History & Client References | – Request 3 verifiable export clients (with NDA if needed) – Cross-check client websites or LinkedIn |

Confirm B2B track record and credibility |

| 6 | Request Sample & Test | – Functional testing, RoHS/REACH compliance – Third-party lab certification |

Validate product quality and regulatory compliance |

| 7 | Check Financial & Legal Standing | – Credit report via Dun & Bradstreet or Chinese credit agencies – Court records (via China Judgments Online) |

Identify financial instability or legal disputes |

✅ Best Practice: Use SourcifyChina’s Manufacturer Verification Scorecard (MVS-2026) to rate suppliers on a 100-point scale across these criteria.

2. How to Distinguish Between a Trading Company and a Factory

Misrepresentation is common. Trading companies often act as intermediaries but lack control over production, leading to quality and communication issues.

| Indicator | Factory (Manufacturer) | Trading Company |

|---|---|---|

| Business License Scope | Lists manufacturing activities (e.g., electronic product production, SMT processing) | Lists “import/export,” “trading,” or “sales” only |

| Physical Infrastructure | Owns production lines, SMT machines, QC labs, warehouse | No production equipment; may have sample room only |

| Staffing | Engineers, production supervisors, QC technicians on-site | Sales reps, sourcing agents, logistics coordinators |

| Pricing Structure | Quotes based on BOM + labor + overhead | Quotes with markup; may not disclose raw material costs |

| Lead Times | Provides detailed production schedule with line allocation | Estimates based on supplier timelines; less control |

| Customization Capability | Offers NPI (New Product Introduction), DFM support | Limited to existing product catalogs or OEM rebranding |

| Communication Access | Direct access to production managers and engineers | Communication routed through sales/account managers |

🔍 Pro Tip: Ask: “Can I speak directly with your production manager or QA lead?” Factories will accommodate; traders often resist.

3. Red Flags to Avoid in 2026

Early detection of warning signs prevents costly sourcing failures.

| Red Flag | Risk | Action |

|---|---|---|

| Unwillingness to provide business license | High likelihood of fraud or unlicensed operation | Disqualify immediately |

| No verifiable factory address or refusal of video tour | Likely a trading company or shell entity | Request third-party audit |

| Prices significantly below market average | Indicates substandard materials, hidden fees, or overpromising | Conduct rigorous sample testing |

| Poor English or inconsistent communication | Risk of misaligned specs and QC failures | Require bilingual project manager or use sourcing agent |

| No certifications (ISO, RoHS, CE) | Non-compliance with global standards | Require certification before PO |

| Requests full payment upfront | High fraud risk | Use escrow or LC payment terms |

| No experience with your target market (e.g., EU, US) | Risk of failed compliance audits | Require test reports from accredited labs |

| Multiple Alibaba storefronts under same contact | Often indicates trading networks masquerading as factories | Cross-check business licenses across profiles |

4. Recommended Verification Workflow (2026)

Conclusion & Strategic Recommendations

In 2026, the line between legitimate Chinese electronics manufacturers and opportunistic trading intermediaries remains blurred. Procurement managers must adopt a zero-trust verification model and invest in due diligence before engagement.

Key Recommendations:

- Prioritize factories with ≥5 years of operation and ISO 9001 certification.

- Use third-party audits for orders >$50,000.

- Leverage sourcing partners like SourcifyChina for on-ground verification.

- Implement phased ordering to de-risk initial engagement.

By following this protocol, procurement teams can build resilient, high-quality supply chains from China—turning sourcing risk into competitive advantage.

Prepared by:

Senior Sourcing Consultant

SourcifyChina

Global Electronics Sourcing Experts Since 2010

[email protected] | www.sourcifychina.com

Get the Verified Supplier List

SourcifyChina 2026 Verified Sourcing Intelligence Report: Accelerating Electronics Procurement from China

Prepared for Global Procurement Leaders | Q1 2026 Edition

Executive Summary

Global electronics procurement faces unprecedented pressure: compressed product lifecycles (down to 8.2 months avg.), volatile component costs (+22% YoY), and supply chain fragility. Traditional supplier sourcing consumes 47% of procurement cycles (Gartner, 2025), directly impacting time-to-market and margin integrity. SourcifyChina’s 2026 Verified Pro List eliminates this critical bottleneck through AI-validated manufacturer intelligence, delivering 87% faster supplier onboarding for Tier-1 electronics buyers.

Why the “China Electronics Company List” Search Costs You Millions

Unverified supplier databases expose procurement teams to systemic risks:

| Sourcing Method | Avg. Screening Time | Risk of Non-Compliance | Cost Impact (Per $1M Order) |

|---|---|---|---|

| Public Directories (Alibaba, Made-in-China) | 18.7 workdays | 68% | $142,000 (delays, QC failures) |

| Unvetted Agent Referrals | 12.3 workdays | 52% | $98,500 (hidden fees, misalignment) |

| SourcifyChina Verified Pro List | 2.4 workdays | <5% | $18,200 (optimized TCO) |

Source: SourcifyChina 2025 Client Benchmark (n=117 enterprises, $50M+ annual electronics spend)

The Pro List Advantage: Engineered for Procurement Efficiency

Our 2026 platform delivers actionable intelligence, not just names:

✅ Real-Time Compliance Dashboard

– Automated ISO 9001/14001, IATF 16949, and RoHS 3.0 validation

– Live factory audit status (no “self-certified” claims)

✅ Capacity Mapping Intelligence

– SMT line utilization rates, NPI readiness scores, and export volume trends

– Avoid suppliers at 90%+ capacity during your critical production window

✅ Risk-Adjusted Cost Modeling

– Embedded landed cost calculators (FOB + tariffs + logistics + quality risk buffers)

– Predictive analytics for component shortage exposure (e.g., MLCCs, ICs)

“SourcifyChina’s Pro List cut our IoT module sourcing cycle from 11 weeks to 9 days. We onboarded a Shenzhen EMS partner with 12-hour response SLAs – validated pre-contract.”

— Head of Global Sourcing, Top 5 Industrial Automation OEM (Germany)

Your Critical Path to 2026 Procurement Excellence

The window for Q3-Q4 2026 electronics production is closing. 83% of high-performance Chinese electronics factories have fixed capacity allocations by April 2026 (SourcifyChina Capacity Index). Waiting for “just one more RFQ” risks:

– 30%+ cost premiums for last-minute capacity scrambling

– 45-day+ delays from supplier onboarding failures

– Compliance exposure from rushed factory audits

Call to Action: Secure Your 2026 Supply Chain Advantage

Stop negotiating with unverified suppliers. Start deploying validated capacity.

👉 Contact SourcifyChina within 48 hours to:

1. Receive your customized 2026 Electronics Pro List (filtered by your product complexity, volume tier, and compliance requirements)

2. Schedule a zero-obligation Capacity Mapping Session with our China-based engineering team

3. Lock priority access to 3 pre-vetted manufacturers before April 15 capacity freeze

Act Now – Your Q3 Production Timeline Depends on It:

✉️ Email: [email protected]

📱 WhatsApp (24/7 Sourcing Desk): +86 159 5127 6160

Include “2026 PRO LIST REQUEST” in your subject line for expedited processing. First 15 contacts receive complimentary component risk assessment.

SourcifyChina: Where Verified Supply Meets Strategic Procurement. 1,200+ Electronics Programs Delivered Since 2018.

© 2026 SourcifyChina. All data confidential to recipient. Unauthorized distribution prohibited.

🧮 Landed Cost Calculator

Estimate your total import cost from China.