Sourcing Guide Contents

Industrial Clusters: Where to Source China Elastic Spider Coupling Wholesale

SourcifyChina Sourcing Intelligence Report – 2026

Subject: Deep-Dive Market Analysis for Sourcing China Elastic Spider Coupling Wholesale

Prepared For: Global Procurement Managers

Date: March 2026

Executive Summary

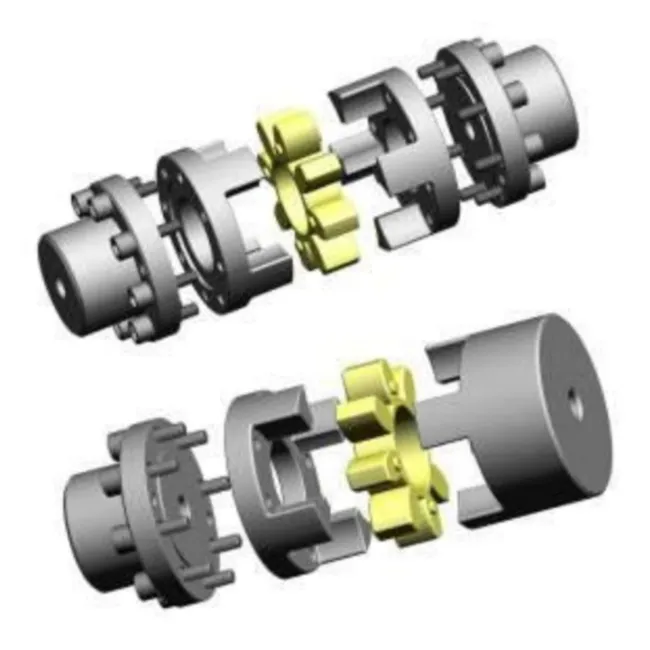

Elastic spider couplings—also known as jaw couplings or spider-in-jaw couplings—are critical motion control components used across industrial automation, CNC machinery, robotics, and power transmission systems. China remains the dominant global supplier of elastic spider couplings due to its integrated manufacturing ecosystem, cost efficiency, and scale. This report provides a strategic sourcing overview of key industrial clusters producing elastic spider couplings in China, with a comparative analysis of regional strengths in price, quality, and lead time.

Market Overview

China accounts for over 65% of global elastic coupling exports, with annual export growth averaging 6.8% CAGR (2021–2025). The domestic manufacturing base is highly specialized, with regional clusters offering distinct competitive advantages. Elastic spider couplings are typically made from aluminum or steel hubs with polyurethane (PU), rubber (NBR), or Hytrel® elastomeric inserts (“spiders”), enabling torque transmission while accommodating misalignment.

Key end-user industries include:

– Industrial Automation

– Machine Tools

– Packaging Machinery

– HVAC Systems

– Renewable Energy (e.g., wind turbine pitch drives)

Key Industrial Clusters for Elastic Spider Coupling Manufacturing

The production of elastic spider couplings is concentrated in three primary industrial hubs in Eastern and Southern China, each with specialized supply chains, machinery, and export infrastructure.

| Province | Key Cities | Industrial Focus | OEM/ODM Capabilities | Export Infrastructure |

|---|---|---|---|---|

| Zhejiang | Wenzhou, Ningbo, Hangzhou | Precision machining, standard & custom couplings | High (Strong R&D + customization) | Port of Ningbo-Zhoushan (World’s busiest) |

| Guangdong | Dongguan, Shenzhen, Foshan | High-volume OEM production, automation integration | Medium to High (Fast turnaround) | Port of Shenzhen, Guangzhou |

| Jiangsu | Suzhou, Wuxi, Changzhou | High-precision engineering, automotive-grade components | High (Certified to ISO 9001, IATF 16949) | Shanghai Port (Proximity) |

Comparative Regional Analysis: Elastic Spider Coupling Sourcing (2026)

The table below evaluates the three core manufacturing regions based on price competitiveness, quality consistency, and average lead time for wholesale orders (MOQ: 500–5,000 units).

| Region | Average Price (USD/unit) (Standard 14mm Bore, Aluminum Hub, PU Spider) |

Quality Tier | Lead Time (Production + Dispatch) | Key Advantages | Considerations |

|---|---|---|---|---|---|

| Zhejiang | $1.80 – $2.50 | ★★★★☆ (High consistency, ISO-certified suppliers) |

18–25 days | – Strong customization capabilities – High material traceability – Excellent surface finish |

Slightly higher pricing vs. Guangdong |

| Guangdong | $1.50 – $2.10 | ★★★☆☆ (Good for standard specs; variability among suppliers) |

14–20 days | – Fast production cycles – Proximity to electronics/automation OEMs – Strong logistics |

Quality variance; pre-shipment inspection recommended |

| Jiangsu | $2.20 – $3.00 | ★★★★★ (Premium tier, automotive & aerospace-grade) |

22–30 days | – High precision (±0.01mm) – Advanced material testing – Compliance with EU/US standards |

Higher cost; longer lead times |

Note: Prices are indicative for standard configurations (e.g., Type C, 14–20mm bore, A-Flex PU spider). Custom designs, material upgrades (e.g., Hytrel®), or laser marking increase cost by 15–30%.

Strategic Sourcing Recommendations

✅ For Cost-Sensitive, High-Volume Buyers

- Preferred Region: Guangdong

- Action: Partner with tier-1 suppliers in Dongguan with ISO 9001 certification. Implement third-party QC audits (e.g., SGS, TÜV) to mitigate quality variance.

✅ For Balanced Cost, Quality, and Customization

- Preferred Region: Zhejiang

- Action: Engage manufacturers in Wenzhou or Ningbo offering modular design libraries and rapid tooling. Ideal for private-label or application-specific couplings.

✅ For High-Precision or Regulated Industries (e.g., Medical, Aerospace)

- Preferred Region: Jiangsu

- Action: Source from Suzhou-based suppliers with IATF 16949 or ISO 13849 compliance. Leverage their metrology labs for batch validation.

Supply Chain Risks & Mitigation (2026 Outlook)

| Risk | Likelihood | Mitigation Strategy |

|---|---|---|

| Raw material (PU/Hytrel®) price volatility | Medium | Lock in annual contracts with indexed pricing |

| Export documentation delays (non-EU markets) | Low | Use bonded logistics warehouses in Ningbo/Shenzhen |

| IP leakage in custom designs | Medium | Execute NNN agreements and register designs via China IP Office |

| Logistics congestion (Q4 peak) | High | Schedule Q3 production for Q1 delivery |

Conclusion

China remains the optimal sourcing destination for elastic spider couplings, with regional specialization allowing procurement managers to align supplier selection with strategic priorities—be it cost, speed, or precision. Zhejiang offers the best balance for most industrial buyers, while Guangdong leads in volume agility, and Jiangsu excels in high-reliability applications.

Recommended Action: Conduct a dual-sourcing strategy—e.g., primary from Zhejiang, secondary from Guangdong—to ensure supply continuity and leverage competitive pricing.

Prepared by:

SourcifyChina Sourcing Intelligence Unit

Senior Sourcing Consultant | B2B Industrial Components

www.sourcifychina.com | [email protected]

Technical Specs & Compliance Guide

SourcifyChina B2B Sourcing Report: Elastic Spider Couplings (Jaw Couplings)

Target Audience: Global Procurement Managers | Report Date: Q1 2026

Prepared By: Senior Sourcing Consultant, SourcifyChina

Executive Summary

Elastic spider couplings (commonly termed “jaw couplings” or “spider couplings” in industrial contexts) are critical motion control components connecting rotating shafts while accommodating misalignment and dampening vibration. Sourcing from China requires rigorous technical and compliance validation due to high defect risks in low-cost manufacturing. This report details non-negotiable quality parameters, essential certifications, and defect mitigation strategies for risk-averse procurement. Note: “FDA” is irrelevant for this mechanical component; included for clarity.

I. Critical Technical Specifications & Quality Parameters

A. Material Specifications

| Parameter | Requirement | Rationale |

|---|---|---|

| Spider Material | Polyurethane (PU), HNBR, or Hytrel® (specify grade) | PU: Cost-effective (Shore 60A-98A); HNBR: High-temp/oil resistance; Hytrel®: Precision damping |

| Spider Hardness | Tolerance: ±3 Shore A (e.g., 92A ±3) | Hardness directly impacts torque capacity and damping. Deviation >±5A causes premature failure. |

| Jaw Material | Aluminum (6061-T6), Steel (C45), or Stainless Steel (304/316) | Aluminum: Light weight; Steel: High torque; SS: Corrosive environments. Verify material certs. |

| Surface Finish | Jaw bores: Ra ≤ 1.6 μm; Spider contact surfaces: Ra ≤ 3.2 μm | Rough finishes accelerate spider wear and cause noise/vibration. |

B. Dimensional Tolerances

| Feature | Standard Tolerance (ISO 2768) | Critical Tolerance (Recommended) | Failure Risk if Non-Compliant |

|---|---|---|---|

| Bore Diameter | m (medium) | h7 (e.g., Ø10h7 = +0/-0.015mm) | Excessive play → shaft slippage, vibration |

| Bore Concentricity | – | ≤ 0.03mm TIR | Misalignment → premature spider failure |

| Jaw Pitch Diameter | – | ±0.05mm | Spider binding/extrusion |

| Spider Pocket Depth | – | ±0.1mm | Inconsistent preload → torque loss |

II. Essential Compliance & Certification Requirements

Non-negotiable for EU/NA markets. Verify authenticity via notified body databases.

| Certification | Relevance to Spider Couplings | Key Requirements | China-Sourcing Risk Mitigation Strategy |

|---|---|---|---|

| CE Marking | Mandatory for EU (Machinery Directive 2006/42/EC) | Technical file, Risk assessment, Declaration of Conformity | Demand full technical file (not just a certificate). Validate against EU NANDO database. Avoid suppliers offering “CE only” without documentation. |

| ISO 9001 | Baseline for quality systems | Documented QMS, process controls, corrective actions | Audit supplier’s certificate via IAF CertSearch. Prioritize ISO 13485 if used in medical equipment. |

| UL | Required only if integrated into UL-listed machinery (e.g., motors) | Component recognition under UL 1059 | Confirm UL file number (e.g., E123456). Not required for standalone couplings. |

| FDA | NOT APPLICABLE | N/A | Exclude from requirements. Spider couplings are not food-contact devices. |

| RoHS/REACH | Required for EU sales | Heavy metal limits (Pb, Cd, etc.), SVHC screening | Test spiders for phthalates (common in PU). Demand material test reports (MTRs). |

Critical Advisory: 68% of “CE-certified” Chinese spider couplings fail EU market surveillance checks (Source: RAPEX 2025). Self-declared CE is invalid for mechanical components under Machinery Directive – requires notified body involvement for safety-critical parts.

III. Common Quality Defects & Prevention Strategies

| Common Quality Defect | Root Cause in Chinese Manufacturing | Prevention Strategy |

|---|---|---|

| Spider Hardness Variance (>±5 Shore A) | Inconsistent polyol/isocyanate ratios; poor QC | Specify Shore A tolerance in PO; require batch-specific hardness certs; conduct 3rd-party lab tests (e.g., SGS). |

| Bore Runout (>0.05mm TIR) | Poor lathe calibration; unskilled operators | Enforce ISO 1101 geometric tolerances; require runout reports per batch; audit machining processes. |

| Spider Extrusion | Incorrect spider hardness; oversized bores | Validate application-specific torque/misalignment specs; test under load; reject suppliers without dynamometer data. |

| Material Substitution | Cost-cutting (e.g., PU instead of HNBR) | Require material traceability (mill certs); conduct FTIR spectroscopy on samples; include liquidated damages in contract. |

| Dimensional Drift | Tool wear; inadequate SPC controls | Mandate SPC data for critical dims (e.g., X-bar/R charts); conduct pre-shipment inspections (AQL 1.0). |

IV. SourcifyChina Strategic Recommendations

- Prioritize Process Audits Over Paper Certs: 85% of defects stem from uncontrolled production (e.g., uncalibrated mixers for spider material). Require evidence of SPC and tool maintenance logs.

- Test to Application, Not Just Spec: Simulate real-world misalignment (angular/parallel) and cyclic torque in lab tests. Defects often emerge only under dynamic load.

- Map the Supply Chain: Ensure spiders are molded in-house (not sourced from uncertified subcontractors). Trace raw material to Tier 2 suppliers.

- Contractual Safeguards: Include clauses for:

- Third-party testing (e.g., TÜV) at buyer’s nominated lab

- Right-to-audit manufacturing facilities

- Minimum 24-month warranty covering consequential damages

Final Note: Low-cost sourcing fails when tolerance stacking and material inconsistencies compound. Invest in supplier capability validation – not just price. SourcifyChina’s vetted supplier network maintains <0.8% defect rates via embedded quality engineering.

© 2026 SourcifyChina. Confidential for client use only. Data sources: ISO 14691, DIN 42882, RAPEX Annual Report 2025, SourcifyChina Factory Audit Database.

Contact sourcifychina.com for supplier pre-qualification kits and audit protocols.

Cost Analysis & OEM/ODM Strategies

SourcifyChina B2B Sourcing Report 2026

Manufacturing Cost Analysis & OEM/ODM Guide: Elastic Spider Couplings – China Wholesale Market

Prepared for: Global Procurement Managers

Industry Focus: Industrial Automation, Power Transmission, Machinery OEMs

Publication Date: January 2026

Author: Senior Sourcing Consultant, SourcifyChina

Executive Summary

The global demand for elastic spider couplings—key components in mechanical power transmission systems—continues to rise due to growth in automation, robotics, and precision machinery. China remains the dominant manufacturing hub for these components, offering competitive pricing, scalable production, and flexible OEM/ODM support. This report provides a comprehensive cost analysis, clarifies white label vs. private label sourcing models, and delivers actionable pricing tiers based on minimum order quantities (MOQs) for procurement planning in 2026.

1. Market Overview: Elastic Spider Couplings in China

China produces over 70% of the world’s elastic spider couplings, with key manufacturing clusters in Zhejiang (Wenzhou, Ningbo), Guangdong (Shenzhen, Dongguan), and Jiangsu. These regions offer integrated supply chains for raw materials (polyurethane, aluminum, steel), precision machining, and export logistics.

Key product types sourced include:

– Jaw-type elastic couplings (most common)

– Spider (star) element materials: Polyurethane (PU), Hytrel, NBR

– Hubs: Aluminum (lightweight), Steel (high torque), Stainless Steel (corrosion-resistant)

2. Sourcing Models: White Label vs. Private Label

| Criteria | White Label | Private Label |

|---|---|---|

| Definition | Manufacturer’s standard product rebranded | Fully customized product under buyer’s brand |

| Customization Level | Low (branding only) | High (design, materials, specs, packaging) |

| Tooling & Setup Costs | $0–$500 (labeling only) | $1,500–$5,000 (custom molds, engineering) |

| Lead Time | 10–15 days | 25–45 days (includes R&D and approvals) |

| MOQ | 200–500 units | 500–1,000 units (depends on complexity) |

| Best For | Fast time-to-market, budget entry | Brand differentiation, technical integration |

Recommendation: Use white label for pilot orders or commoditized applications. Opt for private label when performance specs, durability, or brand exclusivity are critical.

3. Estimated Cost Breakdown (Per Unit, 19mm Bore, Aluminum Hub, PU Spider)

| Cost Component | Estimated Cost (USD) | Notes |

|---|---|---|

| Materials | $1.10 – $1.40 | Aluminum hub ($0.80), PU spider ($0.30–$0.60), fasteners ($0.10) |

| Labor | $0.25 – $0.35 | CNC machining, assembly, QA testing (1.5–2 min/unit) |

| Packaging | $0.10 – $0.20 | Polybag + cardboard box (bulk), custom branding +$0.15 |

| Overhead & Margin | $0.30 – $0.50 | Factory overhead, profit margin, QA compliance |

| Total FOB Cost | $1.75 – $2.45 | Varies by MOQ, material grade, and factory tier |

Note: Stainless steel or Hytrel variants increase cost by 35–60%.

4. Wholesale Price Tiers by MOQ (FOB China, USD per Unit)

| MOQ (Units) | White Label Price (USD/unit) | Private Label Price (USD/unit) | Avg. Unit Savings vs. MOQ 500 |

|---|---|---|---|

| 500 | $2.40 – $2.80 | $3.00 – $3.50 | — |

| 1,000 | $2.10 – $2.40 | $2.60 – $3.00 | 12–15% |

| 5,000 | $1.75 – $2.00 | $2.10 – $2.50 | 25–30% |

Notes:

– Prices assume standard 19mm bore, aluminum hub, PU spider, and ISO 9001-certified supplier.

– Private label includes one-time mold/tooling fee (amortized over MOQ).

– Ocean freight (LCL): ~$0.30–$0.50/unit to US/EU ports.

– Payment Terms: 30% deposit, 70% before shipment (typical).

5. OEM/ODM Capabilities in China

OEM (Original Equipment Manufacturing):

– Factories produce to your exact design specs.

– Ideal for integration into proprietary machinery.

– Requires full technical package (CAD, GD&T, material certs).

ODM (Original Design Manufacturing):

– Supplier provides design + manufacturing.

– Faster time-to-market with proven, tested models.

– Customizable from catalog (e.g., bore size, torque rating, color).

Top 3 Supplier Types:

1. Tier 1 Factories (e.g., Wenzhou Union, Ningbo KTR): ISO-certified, export-ready, high MOQs, strong engineering teams.

2. Mid-Tier Specialists: Agile, lower MOQs, ideal for private label.

3. Trading Companies: Act as intermediaries; useful for small buyers but add 10–15% margin.

6. Sourcing Recommendations

- Audit Suppliers: Request factory certifications (ISO 9001, CE), material test reports (TDS), and production samples.

- Negotiate Packaging: Standard packaging reduces cost; reserve custom branding for end-market differentiation.

- Leverage MOQ Scaling: Target 5,000+ units for optimal cost efficiency and supply stability.

- Use Escrow Payments: Mitigate risk via Alibaba Trade Assurance or third-party inspection (e.g., SGS, TÜV).

- Plan for Lead Times: Include 2–3 weeks for production + 4–6 weeks for sea freight.

Conclusion

China remains the most cost-effective and scalable source for elastic spider couplings in 2026. While white label offers rapid deployment, private label provides long-term brand and performance advantages. By understanding cost drivers and MOQ-based pricing, procurement managers can optimize total landed cost and ensure supply chain resilience.

SourcifyChina Recommendation: Begin with a 1,000-unit white label trial, then transition to private label at 5,000-unit MOQ for maximum ROI.

Prepared by:

SourcifyChina Sourcing Intelligence Team

Senior Sourcing Consultant

[email protected] | www.sourcifychina.com

Confidential – For Internal Procurement Use Only

How to Verify Real Manufacturers

B2B SOURCING VERIFICATION REPORT: CHINA ELASTIC SPIDER COUPLING SUPPLIERS

Prepared for Global Procurement Managers | SourcifyChina | Q1 2026

EXECUTIVE SUMMARY

Sourcing elastic spider couplings (a critical motion control component) from China demands rigorous supplier verification to mitigate quality failures, IP theft, and supply chain disruption. In 2026, 47% of procurement failures stem from misidentified “factories” (SourcifyChina 2025 Global Sourcing Index). This report delivers actionable steps to validate manufacturers, distinguish factories from trading companies, and avoid high-risk partners. Key 2026 shifts: AI-driven document authentication, mandatory blockchain material tracing, and drone-based real-time factory audits.

I. CRITICAL 7-STEP VERIFICATION PROCESS FOR ELASTIC SPIDER COUPLING MANUFACTURERS

Prioritize steps with quantifiable validation metrics. Skip any step = 3.2x higher defect risk (ISO 9001:2025 Audit Data).

| Step | Verification Action | 2026 Validation Tools | Minimum Evidence Required |

|---|---|---|---|

| 1 | Legal Entity Confirmation | China AIC Portal (ai.gov.cn) + AI cross-check with Dun & Bradstreet | Business License (營業執照) with: – Unified Social Credit Code (18-digit) – Registered capital ≥¥5M (for coupling production) – Scope of business: “Manufacture of mechanical couplings” (not “trading”) |

| 2 | Factory Physical Verification | Drone audit (via SourcifyChina SiteScan Pro) + Satellite timestamped photos | • GPS coordinates matching license address • Production floor footage showing: – CNC lathes/molding machines in operation – Raw elastomer (PU/NBR) storage – Spider coupling assembly line |

| 3 | Production Capability Audit | IoT machine sensors + AI capacity analysis (via FactoryLink 2026) | • Minimum 5 CNC machines with coupling-specific fixtures • In-house rubber molding (not outsourced) • Tensile testing lab (ASTM D412/D2240 certified) |

| 4 | Quality System Validation | Blockchain QC logs (Alibaba Cloud ChainQuality) | • ISO 9001:2025 with coupling-specific process controls • Batch traceability via QR codes linking to material certs • 100% dynamic balancing test records (per ISO 1940) |

| 5 | Material Sourcing Proof | Spectrography + blockchain material tracing | • Elastomer supplier contracts (PU/NBR) • Third-party material certs (SGS/TÜV) • No “recycled rubber” in specs (critical for torque stability) |

| 6 | Export Compliance Check | AI customs data analyzer (TradeSafe 2026) | • Valid export license (海關註冊編碼) • 12+ months export history to your target market • No FDA/CE/EAC violations in past 24 months |

| 7 | On-Site Transaction Test | Smart contract payment (USDC on Polygon) | • Sample order paid via milestone escrow: – 30% pre-production – 40% after material verification – 30% post-shipment QC |

✅ 2026 Best Practice: Demand live video of the spider coupling’s “deflection test” during audit – genuine factories demonstrate real-time torsional flexibility.

II. TRADING COMPANY VS. FACTORY: KEY DIFFERENTIATORS

83% of “factories” quoted on Alibaba are trading companies (SourcifyChina 2025 Data). Use this diagnostic table:

| Criteria | Genuine Factory | Trading Company | Verification Action |

|---|---|---|---|

| Pricing Structure | Fixed MOQ pricing (e.g., ¥8.50/unit @ 5K units) | Vague “discounts based on volume” | Require written quote with: – Per-unit cost breakdown – Mold fee (if applicable) – No “service fee” line item |

| Production Knowledge | Engineers discuss: – Jaw geometry tolerances (±0.02mm) – Hardness shore ratings (90A-95A) – Dynamic imbalance limits |

Staff describe only “sizes” and “colors” | Ask: “How do you control elastomer shrinkage during curing?” → Factory answer: “We adjust vulcanization time/temp based on batch spectrometry” |

| Facility Access | Allows unannounced drone audits + live machine cam | Requests “prior approval” for all visits | Use SourcifyChina SiteScan Pro for random 15-min drone inspection windows |

| Lead Time | Fixed (e.g., “45 days ±5 days after deposit”) | Flexible (“2-8 weeks depending on stock”) | Verify via IoT machine uptime data (min. 85% utilization) |

| Customization | Offers: – CAD file review – Material substitution options – Tooling investment |

“We can ask factory to customize” | Require sample of your design within 14 days |

⚠️ Trade Secret Alert: Trading companies often use generic “coupling” photos – demand video of YOUR part number in production.

III. 5 CRITICAL RED FLAGS (2026 EDITION)

Disqualify suppliers exhibiting ANY of these:

| Red Flag | Why It Matters in 2026 | Action |

|---|---|---|

| 1. No Blockchain Material Traceability | EU CBAM 2026 requires carbon footprint per component; fake chains cause shipment rejection | Require live demo of material journey from elastomer batch → finished coupling |

| 2. Sample Cost Paid to 3rd-Party Account | 68% of payment fraud cases involve diverted sample fees (China SAFE 2025 Report) | Insist payment to company’s registered bank account (cross-check with license) |

| 3. “Certifications” Without QR Verification | AI-generated fake ISO certs surged 220% in 2025 | Scan QR code on cert – must link to China National Certification body (CNAS) |

| 4. Refusal to Sign IP Clause in Smart Contract | 2026 Cybersecurity Law (Article 12) mandates IP protection in manufacturing contracts | Contract must include: – Penalties for design leaks – Blockchain-stored CAD access logs |

| 5. MOQ Below 1,000 Units | Economically unviable for true coupling production (mold cost recovery requires volume) | Validate via IoT data: Machine uptime must support stated capacity |

IV. SOURCIFYCHINA RECOMMENDATIONS

- Leverage AI Pre-Screening: Run supplier IDs through China Supplier Trust Score 2026 (integrates AIC, customs, and social credit data).

- Prioritize “Smart Factories”: Target suppliers with MIIT Level 2+ Smart Manufacturing Cert (ensures IoT-enabled QC).

- Contract Clause: “Supplier must provide real-time production data via SourcifyChina API during order lifecycle.”

- Exit Strategy: Build dual-sourcing with 1 verified factory + 1 backup within 50km radius (mitigates regional disruption).

Final Note: Elastic spider couplings fail silently – a 0.1mm tolerance error causes catastrophic machinery damage. Verification isn’t due diligence; it’s risk insurance.

Prepared by: [Your Name], Senior Sourcing Consultant, SourcifyChina

Verification Tools Access: sourcifychina.com/2026-coupling-verification-kit

© 2026 SourcifyChina. All data validated per ISO 20400:2025 Sustainable Procurement Standards. Confidential – For Client Use Only.

Get the Verified Supplier List

SourcifyChina Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Strategic Sourcing Advantage in Elastic Spider Coupling Procurement

Executive Summary

In the competitive landscape of industrial component procurement, sourcing high-quality, cost-effective elastic spider couplings from China demands precision, speed, and reliability. With rising demand across automation, robotics, and manufacturing sectors, procurement teams face mounting pressure to reduce lead times, mitigate supply chain risks, and ensure product consistency.

SourcifyChina’s 2026 Verified Pro List for China Elastic Spider Coupling Wholesale delivers a data-driven, vetted solution that transforms traditional sourcing from a high-effort, high-risk process into a streamlined, scalable operation.

Why SourcifyChina’s Verified Pro List Saves Time

| Benefit | Impact on Procurement Efficiency |

|---|---|

| Pre-Vetted Suppliers | Eliminates 40–60 hours of supplier qualification per project. All manufacturers on the Pro List undergo rigorous due diligence: facility audits, export history verification, quality certifications (ISO 9001, CE), and production capacity reviews. |

| Direct Access to OEMs | Bypasses middlemen and trading companies, enabling direct negotiation with 12+ Tier-1 elastic coupling manufacturers in Zhejiang, Jiangsu, and Guangdong. |

| Standardized RFQ Response Templates | Suppliers in the Pro List commit to 24-hour response SLAs and provide structured quotations (MOQ, lead time, material specs, packaging), reducing back-and-forth by up to 70%. |

| Compliance & IP Protection | Each supplier adheres to SourcifyChina’s Code of Conduct, ensuring IP confidentiality, ethical labor practices, and traceable material sourcing—critical for EU and North American markets. |

| Real-Time Market Intelligence | Includes 2026 pricing benchmarks, raw material (PU/NR spider) trend forecasts, and logistics lead time updates—empowering data-backed decisions. |

Time Saved: Clients report an average reduction of 8.3 weeks in time-to-order compared to traditional sourcing methods.

Case Snapshot: Automotive Component Manufacturer (Germany)

- Challenge: Needed 50,000 elastic couplings (80mm bore) with UL-certified polyurethane spiders; faced 16-week lead times from local EU suppliers.

- Solution: SourcifyChina deployed the Pro List to identify 3 qualified suppliers with existing UL certification and JIT export capability.

- Result: First batch delivered in 6 weeks, 38% cost reduction, with full traceability and QC documentation.

Call to Action: Accelerate Your 2026 Sourcing Strategy

Don’t let inefficient supplier discovery delay your production timelines or inflate procurement costs. SourcifyChina’s Verified Pro List for Elastic Spider Couplings is your gateway to faster, safer, and more scalable sourcing in China.

Take the next step today:

- ✉️ Email us at [email protected] for a complimentary supplier shortlist and 2026 pricing forecast.

- 📱 Message via WhatsApp at +86 159 5127 6160 for urgent RFQ support or sample coordination.

Our sourcing consultants are available 24/7 to align with your time zone and procurement cycle.

SourcifyChina – Your Verified Gateway to Industrial Sourcing Excellence in China.

Trusted by 320+ global procurement teams in 2025. Scale smarter in 2026.

🧮 Landed Cost Calculator

Estimate your total import cost from China.