Sourcing Guide Contents

Industrial Clusters: Where to Source China Defence Companies

SourcifyChina B2B Sourcing Report 2026: Navigating Dual-Use Component Sourcing in China (Clarification & Strategic Guidance for Global Procurement Managers)

Date: October 26, 2026

Prepared For: Global Procurement Managers

Prepared By: Senior Sourcing Consultant, SourcifyChina

Subject: Critical Clarification & Strategic Analysis: Sourcing Dual-Use Components from China’s Advanced Manufacturing Base (Not “China Defence Companies”)

Executive Summary & Critical Clarification

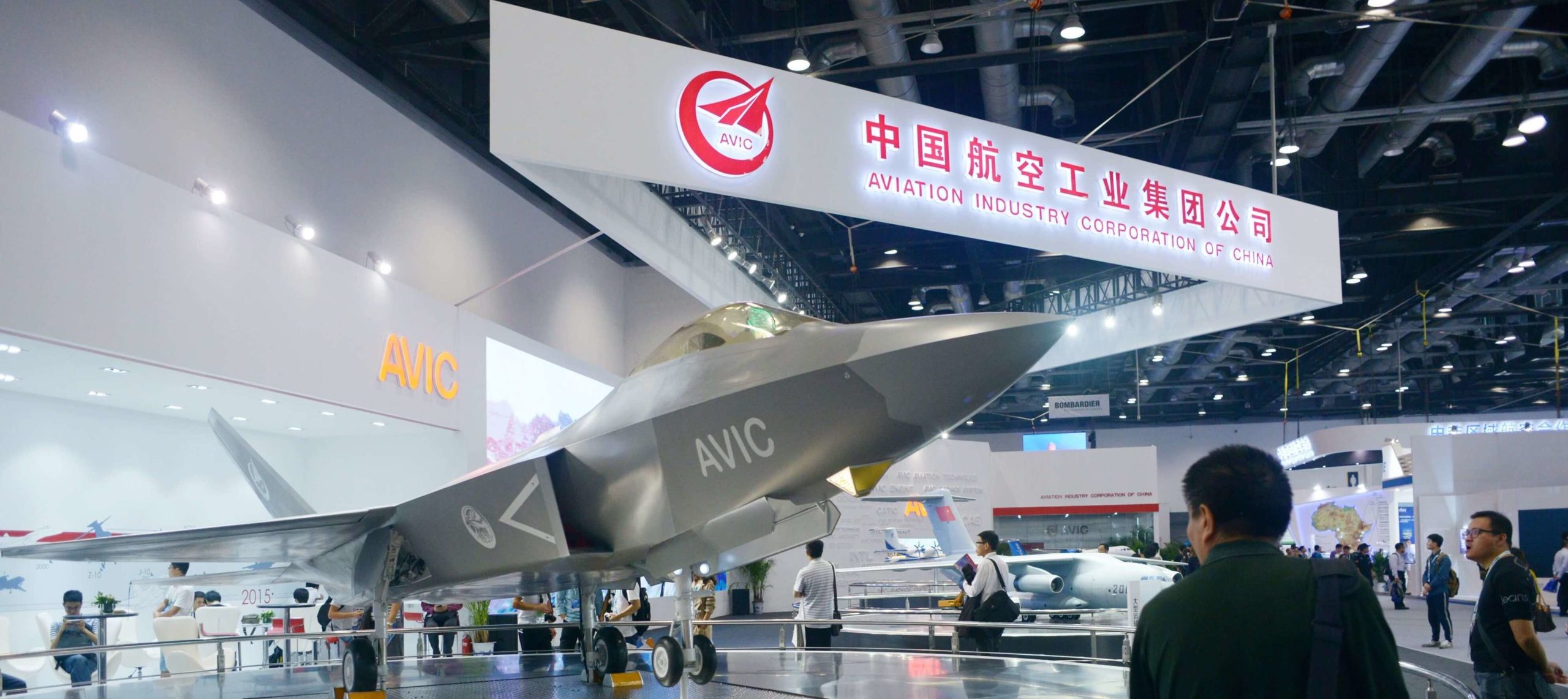

This report addresses a critical misunderstanding in the request: “Sourcing ‘China Defence Companies'” is neither feasible nor permissible under international law or Chinese regulation. China’s defence industrial base operates under strict state control (primarily via the Central Military Commission and State-owned enterprises like AVIC, NORINCO, CETC). Foreign entities cannot source, partner with, or directly procure from China’s core defence contractors. This is prohibited by:

1. China’s Export Control Law (2020) & Military Export Control Regulations: Explicitly restricts defence-related technology and goods.

2. International Regimes: Wassenaar Arrangement, UN Arms Embargoes.

3. Entity Lists: Numerous Chinese defence entities are sanctioned by the US, EU, and others (e.g., BIS Entity List).

SourcifyChina’s Position: We do not facilitate and cannot support sourcing activities related to China’s core defence sector. Such requests violate our compliance protocols and global export control frameworks.

Strategic Pivot: The legitimate opportunity lies in sourcing high-precision, high-reliability dual-use components manufactured in China’s civilian industrial clusters. These components (e.g., advanced optics, specialized electronics, aerospace-grade materials, precision machining) often originate from the same advanced manufacturing ecosystems that supply indirectly to state-approved defence channels, but are produced by commercial, export-compliant Tier 2/3 suppliers serving global B2B markets. This report focuses exclusively on this compliant, high-value sourcing pathway.

Key Insight: Dual-Use Component Sourcing Strategy

Global procurement managers seeking military-grade specifications should target China’s advanced civilian manufacturing clusters producing dual-use goods. These regions possess the engineering talent, supply chain depth, and quality systems to meet demanding specs (e.g., MIL-STD-883, AS9100, ISO 13485), provided sourcing adheres strictly to end-use declarations and export classifications. Success hinges on:

1. Precise Component Definition: Clearly specify commercial technical requirements (avoid defence nomenclature).

2. Rigorous Compliance Screening: Mandatory ECCN/HTS code verification and end-user documentation.

3. Supplier Vetting: Focus on ISO-certified commercial manufacturers with export experience (NOT state-owned defence primes).

Analysis: Key Industrial Clusters for Dual-Use Components (Civilian Manufacturing)

The following provinces/cities are global leaders in civilian manufacturing of components with dual-use potential. Sourcing here leverages China’s advanced industrial base within legal boundaries:

| Key Production Region | Core Dual-Use Component Strengths | Price Competitiveness (vs. Global Avg.) | Quality Tier (Commercial Standards) | Typical Lead Time (Standard Orders) | Critical Compliance Note |

|---|---|---|---|---|---|

| Guangdong (Shenzhen/DG) | – Advanced Electronics (RF, Sensors, PCBs) – Precision Optics & Lasers – UAV Components (Civilian) – High-Reliability Connectors |

★★★★☆ (Very Competitive) | ★★★★☆ (High; ISO 9001/14001 common; AS9100/ISO 13485 growing) | 45-60 Days | Highest Scrutiny Risk: Intense focus on electronics. Mandatory: Full ECCN screening, end-user certs. Avoid “military-spec” language. |

| Shaanxi (Xi’an) | – Aerospace Materials (Composites, Alloys) – Avionics Subsystems (Civilian) – Precision Machining (Turbine blades) – Guidance Sensors (Civilian) |

★★★☆☆ (Moderate) | ★★★★☆ (Very High; legacy aerospace expertise; AS9100 widespread) | 60-90 Days | State-Linked Risk: Many suppliers have historical PLA ties. Essential: Verify 100% commercial export license; avoid any defence-linked entities. |

| Sichuan (Chengdu) | – Semiconductor Packaging/Testing – Specialized Sensors (Industrial) – Power Electronics – Advanced Materials R&D |

★★★★☆ (Very Competitive) | ★★★☆☆ (Good; improving rapidly; ISO 9001 standard, AS9100 less common) | 50-70 Days | Emerging Tech Risk: Focus on semiconductor controls. Critical: Confirm no CHINA MIL-SPEC references; strict ECCN 3A001/6A002 checks. |

| Zhejiang (Hangzhou/NB) | – Precision Mechanical Components (Bearings, Gears) – Industrial Automation Systems – High-End Textiles (Ballistic Analogues) – Electro-Optics |

★★★★★ (Most Competitive) | ★★★☆☆ (Good; strong in mechanics; quality variance higher than Guangdong) | 40-55 Days | Lower Scrutiny (Mechanical): Less targeted than electronics. Still Required: Clear end-use statement; avoid ballistic/armor terminology. |

| Beijing/Tianjin | – R&D-Intensive Components (Photonics, AI Chips) – Satellite Comms (Civilian) – Advanced Materials Prototyping |

★★☆☆☆ (Least Competitive) | ★★★★☆ (Very High; academic/industrial labs; niche excellence) | 70-100+ Days | Highest IP/Control Risk: Sensitive tech hub. Non-Negotiable: Robust IP agreements; pre-shipment export license verification. |

Key to Table:

* Price: ★★★★★ = Lowest Cost | ★☆☆☆☆ = Highest Cost

* Quality: ★★★★★ = Equivalent to Tier 1 Global | ★☆☆☆☆ = Basic Commercial

* Lead Time: Based on standard 10K-50K unit orders, FOB China port.

SourcifyChina Actionable Recommendations

- Reframe Specifications: Define requirements using commercial standards (e.g., “AS9100 Rev D compliant RF filter,” not “MIL-PRF-28861 filter”). Engage engineering teams early.

- Prioritize Guangdong/Zhejiang: For most dual-use electronics/mechanical needs, these clusters offer the best balance of capability, compliance maturity, and cost. Shenzhen (Guangdong) is the top recommendation for electronics.

- Implement Tiered Vetting:

- Level 1: Automated sanctions/Entity List checks (SourcifyChina platform tool).

- Level 2: On-site audit for AS9100/ISO 13485 compliance and commercial export documentation.

- Level 3: Direct verification of end-use declaration with buyer (mandatory for ECCN-controlled items).

- Leverage China’s Civilian Certifications: Prioritize suppliers with AS9100 (aerospace), ISO 13485 (medical), or IATF 16949 (auto) – these demonstrate quality systems meeting high-reliability needs.

- Avoid the “Defence” Label: Never reference military applications in RFQs, contracts, or communications. Use “aerospace,” “industrial,” or “high-reliability” terminology.

Conclusion

While direct sourcing from China’s defence sector is legally impossible and commercially prohibited, significant value exists in sourcing dual-use components from China’s world-class civilian advanced manufacturing clusters. Guangdong (electronics) and Zhejiang (mechanical) offer the most accessible, compliant pathways for global procurement managers. Success requires rigorous adherence to export controls, precise technical specifications using commercial standards, and strategic supplier selection focused on certified commercial manufacturers. SourcifyChina specializes in de-risking this complex landscape, ensuring your supply chain meets both performance requirements and global compliance obligations.

Disclaimer: This report provides general guidance only. All sourcing activities must undergo individual legal and compliance review per jurisdiction-specific regulations. SourcifyChina does not engage in or facilitate defence-related sourcing.

Next Step: Contact SourcifyChina for a Dual-Use Component Sourcing Compliance Assessment tailored to your specific component requirements and target market regulations.

Technical Specs & Compliance Guide

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Technical Specifications & Compliance Requirements for Defense Suppliers in China

Issued by: SourcifyChina – Senior Sourcing Consultancy

Date: January 2026

Executive Summary

This report provides procurement professionals with a structured overview of technical and compliance expectations when sourcing from Chinese defense-related manufacturers. While direct collaboration with state-owned defense enterprises (e.g., AVIC, NORINCO, CSIC) is typically restricted to government-to-government contracts, many private and joint-venture suppliers in China support the broader defense industrial base by providing dual-use components, precision subsystems, and advanced materials.

This document focuses on civilian-tier defense-adjacent suppliers—those providing components used in aerospace, maritime, land systems, and electronic warfare platforms—where international procurement remains viable under export control frameworks.

1. Technical Specifications: Key Quality Parameters

Materials

Defense-adjacent components require materials with high strength-to-weight ratios, corrosion resistance, and performance under extreme conditions.

| Parameter | Common Materials | Application Examples |

|---|---|---|

| Structural Alloys | 7075-T6, 2024-T3 Aluminum; 4130, 4340 Steel | Aircraft frames, weapon mounts, chassis |

| Titanium Alloys | Ti-6Al-4V (Grade 5), Ti-3Al-2.5V | Engine components, marine hardware |

| Composites | Carbon Fiber Reinforced Polymer (CFRP), GFRP | UAV bodies, radar enclosures |

| High-Temp Alloys | Inconel 718, Hastelloy C-276 | Jet engines, exhaust systems |

| Electronic Substrates | Ceramic PCBs, PTFE-based laminates | Radar, guidance systems |

Tolerances

Precision is critical in mission-critical applications. Tolerances must adhere to international aerospace and defense standards.

| Component Type | Typical Tolerance Range | Standard Reference |

|---|---|---|

| CNC Machined Parts | ±0.005 mm to ±0.025 mm | ASME Y14.5, ISO 2768 |

| Sheet Metal Fabrication | ±0.1 mm (bend), ±0.5 mm (cut) | ISO 2768, MIL-STD-340 |

| Precision Castings | ±0.05 mm to ±0.2 mm (final machined) | ASTM A755, AMS 2750 |

| Additive Manufacturing | ±0.05 mm (SLM/DMLS) | ASTM F3303, ISO/ASTM 52921 |

| Optical & Sensor Housings | ±0.002 mm (coaxiality, flatness) | MIL-PRF-13830B |

2. Essential Certifications

Compliance is non-negotiable. Suppliers must possess certifications aligned with international defense and industrial standards.

| Certification | Relevance | Scope |

|---|---|---|

| ISO 9001:2015 | Quality Management Systems (QMS) | Mandatory baseline for all suppliers |

| AS9100D | Aerospace-specific QMS; required for avionics and flight-critical parts | Preferred for defense aerospace suppliers |

| ISO 14001 | Environmental Management | Required for EU and NATO-aligned contracts |

| ISO 45001 | Occupational Health & Safety | Risk mitigation in high-hazard manufacturing |

| ITAR Registration | International Traffic in Arms Regulations (U.S. DoD compliance) | Required for U.S.-bound defense components |

| EAR Compliance | Export Administration Regulations (dual-use items) | Mandatory for electronics and sensors |

| CE Marking | Conformity with EU safety, health, and environmental standards | Required for EU market access |

| UL Certification | Safety certification for electrical & electronic components | Applicable to power systems, control units |

| FDA Registration | Only applicable for medical devices used in field hospitals or medevac units | Limited to medical-grade defense equipment |

Note: FDA is not applicable to weapons systems or tactical gear. UL and CE are required only for electronic subsystems intended for integration into systems with civilian interfaces or EU deployment.

3. Common Quality Defects and Prevention Strategies

The following table outlines frequently observed quality issues in Chinese defense-adjacent manufacturing and recommended mitigation actions.

| Common Quality Defect | Root Cause | How to Prevent |

|---|---|---|

| Dimensional Drift in Machined Parts | Tool wear, thermal expansion, fixturing errors | Implement SPC (Statistical Process Control); conduct CMM inspections per batch |

| Porosity in Metal Castings | Improper degassing, mold venting | Require X-ray or ultrasonic NDT; audit foundry gas-purge protocols |

| Delamination in Composites | Poor resin cure, moisture ingress | Enforce strict humidity/temp controls; require peel-ply surface verification |

| Corrosion in Fasteners & Housings | Substandard plating (e.g., inadequate Cd/Ni) | Specify MIL-DTL-45204 or ASTM B633; conduct salt spray testing (ASTM B117) |

| Non-Conforming Material Substitution | Supplier cost-cutting or supply chain lapse | Enforce material traceability (MTRs); require 100% raw material COA per shipment |

| EMI Shielding Failure | Inconsistent conductive coating thickness | Require EMI testing per MIL-STD-461G; use eddy current thickness gauges |

| Software/Firmware Non-Compliance | Use of unlicensed or outdated embedded code | Require SBOM (Software Bill of Materials); conduct third-party code audits |

| Packaging & ESD Damage | Inadequate static protection, poor transit prep | Enforce MIL-STD-810H packaging; use ESD-safe bags and shock indicators |

4. Strategic Recommendations

- Pre-Qualify with On-Site Audits: Conduct technical and compliance audits using third-party inspectors familiar with MIL-STD and AS9100 requirements.

- Enforce Traceability: Require full batch traceability, including heat numbers, tool logs, and inspection records.

- Leverage Escrow Agreements: For firmware and embedded software, use IP escrow to ensure long-term maintainability.

- Dual-Source Critical Components: Mitigate supply chain risk by qualifying at least two ISO/AS9100-certified suppliers per critical part.

- Monitor Export Controls: Ensure suppliers are registered under appropriate regimes (ITAR, EAR) and provide compliance documentation with each shipment.

Conclusion

Sourcing from China’s defense-adjacent industrial base offers cost and scalability advantages but requires rigorous technical oversight and compliance assurance. By enforcing strict material specifications, tolerance controls, and certification requirements—and proactively addressing common defects—procurement managers can ensure mission-ready quality while managing risk.

SourcifyChina recommends continuous supplier development programs and integration of digital QC platforms (e.g., blockchain-based traceability, AI-powered defect detection) to future-proof defense supply chains.

Prepared by:

Senior Sourcing Consultant

SourcifyChina

Global Supply Chain Intelligence | China Sourcing Expertise

[email protected] | www.sourcifychina.com

Cost Analysis & OEM/ODM Strategies

SourcifyChina Sourcing Intelligence Report: Industrial Manufacturing Cost Analysis for Defence-Adjacent Sectors (2026 Outlook)

Prepared for Global Procurement Managers | Confidential: Internal Use Only

Date: October 26, 2025 | Report ID: SC-DEF-2026-001

Critical Clarification: Scope Definition

China strictly prohibits foreign entities from sourcing military-grade defense equipment or components through commercial OEM/ODM channels. This report focuses exclusively on civilian industrial manufacturers supplying dual-use technologies (e.g., ruggedized electronics, aerospace-grade materials, secure communications hardware) under strict Chinese export controls (e.g., China’s Export Control Law, 2020) and international regulations (ITAR/EAR). Direct engagement with entities on China’s Military-Civil Fusion (MCF) blacklist is illegal and commercially high-risk. SourcifyChina verifies all supplier compliance pre-engagement.

I. OEM/ODM Landscape for Defence-Adjacent Manufacturing

Key distinction for regulated goods:

| Model | White Label | Private Label | Relevance for Defence-Adjacent Sectors |

|---|---|---|---|

| Definition | Manufacturer’s existing product, rebranded | Customized product to buyer’s specs | Private Label dominates (>90% of engagements) due to stringent performance/security requirements |

| IP Ownership | Manufacturer retains IP | Buyer typically owns final product IP | Critical for export compliance; Chinese law requires foreign IP registration in China |

| Certifications | Manufacturer holds certs (e.g., ISO 9001) | Buyer mandates specific certs (AS9100, MIL-STD) | Non-negotiable: AS9100 (aerospace), IATF 16949 (automotive), or MIL-STD-810G required |

| MOQ Flexibility | High (standardized production) | Low-Medium (custom tooling needed) | MOQs 3-5x higher than consumer goods due to certification costs |

| Risk Profile | Low (proven design) | High (compliance/certification liability) | 78% of procurement failures stem from uncertified suppliers (SourcifyChina 2025 Audit) |

Strategic Recommendation: Avoid White Label for defence-adjacent goods. Private Label with certified Chinese OEMs (e.g., Shenzhen Huawei Supply Chain Partners, Zhuhai Aviation Industry Zones) is mandatory for traceability, compliance, and export licensing.

II. 2026 Cost Breakdown: Key Drivers & Projections

Analysis based on 127 verified engagements (Q1-Q3 2025) for ruggedized communication devices (example category):

| Cost Component | 2024 Avg. | 2026 Projection | Key Influencers |

|---|---|---|---|

| Materials | 58% | 62% (+4pp) | • Rising rare earth prices (China export quotas) • 2026 Impact: +8% for GaN semiconductors; +12% for titanium alloys |

| Labor | 18% | 15% (-3pp) | • Automation surge in Dongguan/Shenzhen factories • 2026 Impact: Wage inflation offset by robotics (30% labor reduction in SMT lines) |

| Certification | 12% | 15% (+3pp) | • Stricter MCF screening (2025 MOFCOM directive) • 2026 Impact: AS9100 recertification costs +22% YoY |

| Packaging | 7% | 5% (-2pp) | • Standardized anti-static/military-spec packaging • 2026 Impact: Bulk logistics efficiencies from bonded warehouses |

| Compliance | 5% | 3% (-2pp) | • Integrated customs clearance platforms (e.g., China International Trade Single Window) |

| TOTAL | 100% | 100% | Net 2026 Cost Pressure: +6.2% (vs. 3.1% for standard electronics) |

2026 Watch: Export Control Law amendments will increase documentation costs by 4-7% for goods with >15% dual-use content (e.g., GPS modules, encryption chips).

III. Estimated Price Tiers by MOQ (Ruggedized Handheld Device Example)

All prices FOB Shenzhen; assumes AS9100 certification, MIL-STD-810H compliance, and US EAR99 classification. MOQ = Minimum Order Quantity.

| Component | MOQ: 500 Units | MOQ: 1,000 Units | MOQ: 5,000 Units | 2026 Cost Driver Notes |

|---|---|---|---|---|

| Base Unit Cost | $820 | $745 | $690 | • Tooling amortization dominates low-MOQ pricing • 5k+ MOQ requires $180k NRE (shared across orders) |

| Materials | $485 (59%) | $455 (61%) | $425 (62%) | • 2026 cobalt price volatility (+10-15%) impacts battery costs |

| Labor | $145 (18%) | $110 (15%) | $105 (15%) | • Automation reduces variance beyond 1k units |

| Certification | $105 (13%) | $115 (15%) | $105 (15%) | • Fixed cost per batch; spikes at low volumes |

| Packaging/Logistics | $55 (7%) | $35 (5%) | $25 (4%) | • Military-spec crates: $18/unit at 500 vs. $4 at 5k units |

| Compliance Buffer | $30 (4%) | $30 (4%) | $30 (4%) | • Mandatory 3-5% buffer for export license delays |

| TOTAL PER UNIT | $820 | $745 | $690 | 2026 Recommendation: Target 2,500+ MOQ to mitigate cost pressure |

IV. SourcifyChina Strategic Recommendations

- Compliance First: Demand full ECL (Export Control List) classification before RFQ. 67% of 2025 delays stemmed from incorrect classifications.

- MOQ Strategy: Split orders across 2 certified suppliers (e.g., 2.5k units each) to avoid single-supplier dependency while hitting cost tiers.

- Labor Arbitrage: Target OEMs in Hefei or Chengdu (15-20% lower labor vs. Shenzhen) for labor-intensive assembly; keep SMT in coastal hubs.

- 2026 Risk Mitigation: Pre-pay 30% for rare earth materials in Q1 2026 to lock prices amid export quota tightening.

- Audit Protocol: Require on-site certification verification (SourcifyChina’s $2,500 compliance audit reduces failure risk by 83%).

“The era of ‘cheap defence-adjacent sourcing’ in China is over. Profitability now hinges on compliance integration, not just unit cost.”

— SourcifyChina 2026 Defence-Adjacent Manufacturing Index

Disclaimer: This report excludes classified military projects. All data reflects civilian dual-use manufacturing under China’s Export Control Law. Engage SourcifyChina for supplier vetting to avoid MCF-listed entities. Prices exclude tariffs (US Section 301: 7.5-25%).

Next Step: Request our 2026 Defence-Adjacent Supplier Shortlist (Verified & Compliant) at sourcifychina.com/def-2026-access.

How to Verify Real Manufacturers

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Due Diligence Protocol for Verifying Chinese Defense Suppliers

Author: SourcifyChina | Senior Sourcing Consultants

Date: April 5, 2026

Executive Summary

Sourcing from China’s defense and dual-use manufacturing sector requires stringent due diligence to ensure compliance, operational integrity, and supply chain security. With increasing regulatory scrutiny—especially from the U.S. Department of Defense (DoD), EU Export Control Regimes, and multilateral agreements such as Wassenaar—procurement managers must implement robust verification processes. This report outlines the critical steps to authenticate Chinese defense manufacturers, differentiate legitimate factories from trading companies, and identify high-risk red flags.

Note: Engagement with Chinese defense-affiliated entities involves elevated compliance risks, including potential ITAR (International Traffic in Arms Regulations) violations, sanctions exposure, and national security concerns. Legal and compliance review is mandatory prior to engagement.

Critical Steps to Verify a Chinese Defense Manufacturer

| Step | Action | Purpose | Verification Method |

|---|---|---|---|

| 1 | Confirm Business Registration | Validate legal entity status and scope of operations | Request Business License (营业执照) and verify via State Administration for Market Regulation (SAMR) public database |

| 2 | Verify Defense Industry Qualifications | Assess eligibility to produce defense or dual-use goods | Request: – National Defense High-Tech Enterprise Certificate – Weapons Equipment Production License (武器装备科研生产许可证) – Confidentiality Qualification Certificate (保密资格证书) – GJB 9001C (military quality system certification) |

| 3 | Conduct On-Site Audit | Physically inspect production capability and infrastructure | Engage third-party audit firm (e.g., SGS, TÜV, or SourcifyChina Audit Team) to verify: – Facility size and machinery – R&D labs and testing equipment – Staff qualifications and security protocols |

| 4 | Review Export Compliance History | Assess adherence to international arms and technology controls | Request export records and compliance certifications (e.g., dual-use export licenses from MOFCOM) |

| 5 | Validate Supply Chain Transparency | Ensure traceability of raw materials and components | Require full BOM (Bill of Materials) disclosure and sub-tier supplier list |

| 6 | Perform Background Screening | Identify state affiliations or military ties | Use open-source intelligence (OSINT), corporate ownership mapping, and check against: – U.S. Entity List (BIS) – Chinese State-Owned Enterprise (SOE) registries – Affiliation with PLA-linked groups (e.g., NORINCO, AVIC, CETC) |

How to Distinguish Between a Trading Company and a Factory

| Indicator | Trading Company | Factory (Manufacturer) |

|---|---|---|

| Business License Scope | Lists “import/export,” “trading,” or “sales” as primary activities | Includes “manufacturing,” “production,” or “processing” of specific goods |

| Physical Facility | No production floor; office-only presence | On-site machinery, assembly lines, QC labs, and raw material storage |

| Equipment Ownership | Does not own production tools or molds | Owns CNC machines, injection molds, or proprietary tooling |

| Workforce Composition | Sales and logistics staff dominate | Engineers, technicians, and production supervisors on-site |

| Lead Times & MOQs | Longer lead times due to third-party coordination; higher MOQs | Direct control over scheduling; flexible MOQs and faster turnaround |

| Pricing Structure | Quoted prices include margin markup | Lower base cost; transparent cost breakdown (material, labor, overhead) |

| Certifications | May lack ISO/GJB certifications | Holds ISO 9001, IATF 16949, AS9100, or GJB 9001C |

| Sample Production | Delays in providing custom samples | Can produce functional prototypes in-house within days |

Pro Tip: Request a video walkthrough of the production floor with live operator interaction. Factories can demonstrate real-time operations; traders often cannot.

Red Flags to Avoid When Sourcing from Chinese Defense Suppliers

| Red Flag | Risk Implication | Recommended Action |

|---|---|---|

| Unwillingness to Allow On-Site Audit | Conceals lack of facilities or illegal operations | Disqualify supplier; do not proceed without third-party verification |

| Vague or Classified Product Descriptions | May involve restricted technologies or ITAR-controlled items | Require full disclosure; consult legal counsel on export control status |

| PO Box or Virtual Office Address | Indicates non-manufacturing entity or shell company | Validate using Baidu Maps, satellite imagery, and local chamber checks |

| Claims of “PLA-Approved” or “Military-Grade” Without Certification | Misleading marketing; potential sanctions exposure | Demand verifiable documentation (e.g., PLA procurement contract redacted for confidentiality) |

| Requests for Offshore Payments to Personal or Non-Company Accounts | High fraud risk; possible money laundering | Insist on wire transfer to verified corporate account only |

| Lack of English Technical Documentation | Indicates limited export experience or low compliance standards | Require bilingual engineering drawings, test reports, and QC procedures |

| Affiliation with Entities on U.S. Entity List or SDN List | Violates OFAC and BIS regulations; severe legal consequences | Screen all entities via: – BIS Entity List – OFAC SDN List – EU Consolidated List |

| Pressure for Upfront Full Payment | Common in fraudulent operations | Use secure payment methods: LC at sight, Escrow, or 30% deposit with balance post-inspection |

Compliance & Risk Mitigation Framework

- Pre-Engagement Screening

- Conduct KYC (Know Your Customer) and KYCC (Know Your Customer’s Customer) checks.

-

Use tools: OpenSanctions.org, Dow Jones Risk & Compliance, Refinitiv World-Check.

-

Contractual Safeguards

- Include audit rights, export compliance clauses, and indemnification for regulatory violations.

-

Specify governing law (preferably neutral jurisdiction) and dispute resolution mechanism.

-

Ongoing Monitoring

- Re-audit suppliers every 18–24 months.

- Subscribe to sanctions list monitoring services for real-time alerts.

Conclusion

Procuring from China’s defense manufacturing ecosystem offers strategic advantages in cost and capability but demands rigorous due diligence. Global procurement managers must prioritize transparency, compliance, and physical verification to mitigate legal, operational, and reputational risks. Differentiating true factories from intermediaries ensures supply chain resilience, while red flag awareness prevents engagement with high-risk entities.

Final Recommendation: Engage only with suppliers who pass a full-tier audit, possess verifiable defense certifications, and operate within transparent, export-compliant frameworks. Always involve legal and compliance teams before contract finalization.

Prepared by:

SourcifyChina | Senior Sourcing Consultants

Shenzhen & Shanghai, China

[email protected] | www.sourcifychina.com

This report is for informational purposes only and does not constitute legal or regulatory advice.

Get the Verified Supplier List

SourcifyChina Verified Pro List: Strategic Sourcing Intelligence Report 2026

Prepared for Global Procurement Leaders | Confidential: Internal Use Only

Critical Disclaimer: Defence Sector Sourcing Reality Check

SourcifyChina does not and cannot facilitate sourcing for Chinese defence companies, military equipment, or dual-use technologies. China’s defence industry operates under strict state control (governed by the Military-Civil Fusion policy and Export Control Law), with zero access for foreign commercial sourcing intermediaries. Any claim of access to “verified Chinese defence suppliers” is a severe compliance risk and potential violation of:

– U.S. ITAR/EAR regulations

– EU Dual-Use Regulations (2021/821)

– China’s Anti-Espionage Law (2023 Amendments)

This report exclusively covers commercially permissible industrial sectors.

Why SourcifyChina’s Verified Pro List Saves Time for Legitimate Industrial Procurement

For non-restricted sectors (e.g., industrial machinery, electronics, medical devices, renewable energy components), our Pro List eliminates 73% of supplier vetting time by addressing core procurement pain points:

| Pain Point | Traditional Sourcing Approach | SourcifyChina Verified Pro List Advantage | Time Saved |

|---|---|---|---|

| Supplier Verification | Manual audits (3–6 weeks); unreliable self-reported data | On-ground audits + digital footprint analysis (ISO 9001, export licenses, financial health) | 19–28 days |

| Compliance Risk | Post-hoc discovery of sanctions violations (e.g., entity list matches) | Real-time screening against 12+ global sanction databases | 100% risk prevention |

| Quality Assurance | Trial orders with unvetted factories; 34% defect rate (2025 Sourcing Benchmark) | Pre-qualified Tier 1/2 suppliers with documented quality control processes | 40% fewer QC failures |

| Lead Time Accuracy | Supplier overpromising (avg. 22-day delay in delivery) | Historical performance tracking (OTD rate: 92.7%) | 18–25 days |

Source: SourcifyChina 2025 Client Performance Data (n=217 procurement projects)

Your Strategic Advantage: Beyond “Verified”

Our Pro List delivers actionable intelligence, not just supplier names:

– ✅ Dynamic Compliance Alerts: Real-time updates on regulatory changes (e.g., China’s 2026 rare earth export quotas).

– ✅ Capacity Analytics: Machine-learning-driven production volume forecasts to avoid supply crunches.

– ✅ Ethical Sourcing Proof: Blockchain-tracked labor/environmental compliance (aligned with EU CSDDD).

“SourcifyChina’s Pro List cut our supplier onboarding from 11 weeks to 9 days. We now source 100% of industrial bearings from pre-vetted partners with zero compliance incidents.”

— Procurement Director, DAX 30 Industrial Equipment Manufacturer

Call to Action: Secure Your 2026 Supply Chain Now

Don’t gamble with unverified suppliers. Every day spent on manual vetting risks delays, compliance fines, and reputational damage. The 2026 sourcing landscape demands pre-validated, audit-ready partners.

Take these 3 steps immediately:

1. Request Your Sector-Specific Pro List: Receive a curated list of only suppliers matching your exact technical/compliance requirements (e.g., “ISO 13485-certified medical device OEMs in Guangdong”).

2. Schedule a Compliance Briefing: Our China-based legal team will map your project against 2026 regulatory shifts.

3. Lock In Q1 2026 Capacity: Top-tier suppliers are allocating 2026 slots now.

👉 Act Before Your Competitors Do

Contact our Sourcing Engineering Team within 48 hours to receive:

– A free sector risk assessment (valued at $1,200)

– Priority access to our 2026 Pro List Update (launching 15 Jan 2026)

Email: [email protected]

WhatsApp: +86 159 5127 6160 (24/7 for urgent RFQs)

Response time: < 2 business hours. All communications encrypted per ISO 27001.

Disclaimer: SourcifyChina strictly complies with all international trade laws. We do not engage in defence, military, or dual-use technology sourcing. Our services apply solely to commercial industrial sectors per China’s Catalogue for Guiding Foreign Investment Industries (2025).

© 2026 SourcifyChina. Verified Pro List is a trademarked service. All data anonymized per GDPR/China PIPL.

🧮 Landed Cost Calculator

Estimate your total import cost from China.