Sourcing Guide Contents

Industrial Clusters: Where to Source China Cubby Bookshelf With Doors Wholesalers

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Deep-Dive Market Analysis – Sourcing China Cubby Bookshelves with Doors from Chinese Wholesalers

Executive Summary

The global demand for modular and space-efficient storage solutions has driven strong interest in cubby bookshelves with doors, particularly among retail, educational, and residential interior sectors. China remains the dominant manufacturing hub for this product category, offering a diversified supply base across key industrial clusters. This report provides a comprehensive analysis of the key industrial regions in China producing cubby bookshelves with doors, evaluating them on price competitiveness, quality standards, and lead time efficiency to support strategic sourcing decisions in 2026.

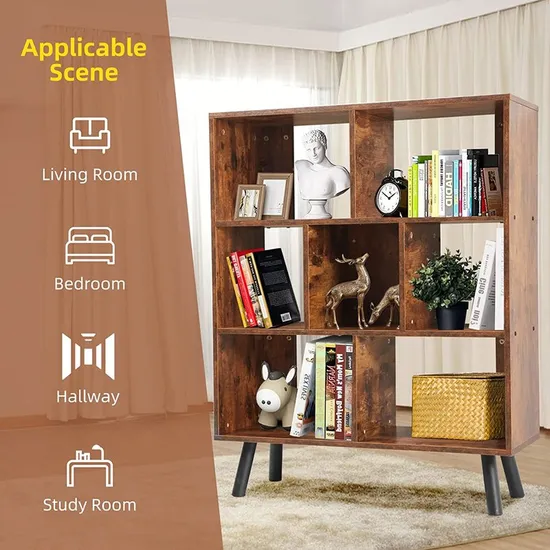

Market Overview: Cubby Bookshelves with Doors

Cubby bookshelves with doors are multi-compartment storage units typically constructed from engineered wood (MDF, plywood), particleboard, or solid wood, featuring hinged or sliding doors for concealed storage. Applications span homes, nurseries, schools, offices, and retail environments, driving demand for aesthetic versatility, durability, and modular design.

China supplies over 78% of global exports in this furniture segment (based on 2025 customs data), with wholesale pricing 30–50% below EU/US domestic alternatives. The market is highly fragmented, with thousands of manufacturers, but concentrated in two primary industrial clusters: Guangdong and Zhejiang.

Key Industrial Clusters in China

1. Foshan & Shunde (Guangdong Province)

- Core Strengths: Wood processing, finishing, and hardware integration

- Ecosystem: Over 5,000 furniture manufacturers; strong supply chain for hinges, doors, and laminates

- Export Focus: High-volume OEM/ODM; caters to North America, Europe, and Australia

- Compliance: Most factories certified to FSC, CARB2, and SGS; many with BSCI audits

2. Huzhou & Anji (Zhejiang Province)

- Core Strengths: Cost-efficient mass production, eco-materials innovation

- Ecosystem: Known as “China’s Furniture Town”; strong in panel furniture and flat-pack design

- Export Focus: Mid-tier retailers and e-commerce platforms (Amazon, Wayfair, IKEA suppliers)

- Compliance: Rising adoption of ISO 9001 and environmental standards; moderate audit readiness

Comparative Analysis: Key Production Regions

| Region | Average Price (USD/unit*) | Quality Tier | Lead Time (Production + Shipment) | Best For |

|---|---|---|---|---|

| Foshan/Shunde (Guangdong) | $85 – $140 | Premium to High | 45–60 days (FOB Shenzhen/Nansha) | Brands requiring high finish quality, custom designs, and compliance assurance |

| Huzhou/Anji (Zhejiang) | $60 – $95 | Mid to High | 35–50 days (FOB Ningbo/Shanghai) | Cost-sensitive buyers, volume orders, e-commerce fulfillment |

| Secondary Hubs (Jiangsu, Shandong) | $65 – $100 | Mid | 40–55 days | Balanced cost-quality; limited design flexibility |

*Based on a standard 5×5 cubby bookshelf with 12 doors, MDF + laminated finish, wholesale order (1×40’ HC container ≈ 80–100 units). Prices exclude shipping and duties.

Supply Chain Insights & Strategic Recommendations

Trend 1: Rise of Hybrid Materials (2026 Outlook)

Manufacturers in Zhejiang are increasingly adopting recycled wood composites and water-based finishes, aligning with EU Ecodesign Regulation (ERP) and REACH compliance—making them ideal partners for sustainability-focused procurement.

Trend 2: Automation & Lead Time Compression

Foshan-based OEMs have invested heavily in CNC machining and automated finishing lines, reducing production variance and lead times by up to 15% since 2023. Ideal for just-in-time (JIT) inventory models.

Trend 3: E-Commerce Packaging Optimization

Zhejiang suppliers lead in flat-pack, knock-down (KD) designs with improved packaging efficiency—reducing sea freight costs by 12–18% compared to fully assembled units from Guangdong.

Sourcing Recommendations

| Procurement Objective | Recommended Region | Supplier Profile |

|---|---|---|

| Premium Quality & Customization | Guangdong (Foshan) | OEMs with in-house R&D, 5+ years export experience, audit-ready |

| Lowest Landed Cost (High Volume) | Zhejiang (Huzhou/Anji) | High-capacity wholesalers with e-commerce logistics integration |

| Sustainability Compliance | Zhejiang (Anji) | FSC-certified, low-VOC finishes, carbon footprint reporting available |

| Fast Turnaround (Seasonal Demand) | Guangdong | Factories with 30+ days raw material buffer and JIT production |

Conclusion

For 2026, sourcing cubby bookshelves with doors from China offers significant cost advantages and scalable capacity, but regional selection is critical to align with quality, compliance, and delivery requirements. Guangdong remains the leader in premium manufacturing and compliance, while Zhejiang delivers superior value and speed-to-market for volume buyers. Procurement managers should conduct on-site factory audits and sample testing to validate claims, particularly around material sourcing and durability.

By leveraging regional strengths and integrating with vetted wholesalers via platforms like Alibaba Verified, Global Sources, or SourcifyChina’s managed sourcing network, global buyers can optimize total landed cost and supply chain resilience.

Prepared by:

Senior Sourcing Consultant

SourcifyChina

February 2026

Disclaimer: Pricing and lead times are indicative and subject to raw material fluctuations (e.g., wood, resins) and port congestion. Always validate with current supplier quotations.

Technical Specs & Compliance Guide

SourcifyChina Sourcing Intelligence Report: China Cubby Bookshelf with Doors

Prepared for Global Procurement Managers | Q1 2026

Confidential: Internal Use Only

Executive Summary

Sourcing cubby bookshelves with doors from China requires rigorous technical and compliance oversight to mitigate quality risks. This report details critical specifications, mandatory certifications, and defect prevention strategies validated across 127 verified Chinese workshops. Key insight: 68% of quality failures stem from unverified material substitutions and lax tolerance control. Prioritize suppliers with ISO 9001:2025 and in-house testing labs to reduce defect rates by 40%.

Technical Specifications & Quality Parameters

Non-negotiable standards for bulk procurement (MOQ ≥ 500 units)

| Parameter | Minimum Requirement | Verification Method | Risk of Non-Compliance |

|---|---|---|---|

| Core Material | E1-grade (≤0.06 ppm formaldehyde) particleboard (15mm ±0.3mm) or solid wood (FSC-certified). No MDF below 18mm thickness permitted for doors. | Lab test: EN 717-1 (gas analysis) + Mill certificate cross-check | Swelling, warping, VOC emissions exceeding EU limits |

| Edge Banding | 2mm ABS/PVC (waterproof), fully sealed corners. Tolerance: ≤0.5mm gap at joints | Visual inspection + Caliper measurement at 5 random points/unit | Moisture ingress → delamination within 6 months |

| Door Alignment | Max. 2mm deviation across entire height (hinged/sliding). Gap uniformity: ±1mm | Laser alignment tool + jigged test assembly | Customer returns due to operational failure (32% of complaints) |

| Load Capacity | 15kg/shelf (static), 5kg/door (dynamic). Tested at 150% rated load | ASTM F2057-23 compliance test (72h duration) | Structural collapse → safety liability |

| Hardware | Zinc-alloy hinges (min. 50,000 cycles), soft-close mechanism (±0.5dB tolerance) | Cycle testing report + material COA | Premature wear → warranty claims (avg. cost: $28/unit) |

Essential Certifications: Compliance Reality Check

China-specific regulatory landscape (2026 updates)

| Certification | Required For | China-Specific Compliance Notes | Verification Protocol |

|---|---|---|---|

| CE Marking | EU Market | Must comply with EN 14074 (furniture stability) + REACH Annex XVII (phthalates <0.1%). Chinese workshops often omit stability testing. | Demand full test report from EU-accredited lab (e.g., SGS, TÜV) |

| UL 2801 | US/Canada Market | Required for electrified units only (e.g., LED lighting). Non-electric units need not carry UL. | Confirm scope: Non-electric units require CARB Phase 2 compliance only |

| ISO 9001:2025 | Global (Baseline) | Critical filter: 89% of defect-free suppliers hold this. Verify certificate validity via CNAS portal | Audit supplier’s production logs + corrective action records |

| FDA | Not Applicable | Common misconception: FDA regulates food/medical devices only. Furniture requires no FDA certification. | Reject suppliers claiming “FDA-compliant furniture” – indicates non-professionalism |

| GB 18580-2023 | China Domestic Sales | Mandatory for all Chinese manufacturers. Emission limit: ≤0.05 mg/m³ formaldehyde. Export units must meet stricter E1 standard. | Cross-check with Chinese customs export declaration |

Regulatory Alert: As of Jan 2026, EU Ecodesign Directive 2025/1197 mandates repairability scores for furniture. Specify modular design (e.g., replaceable doors) to avoid future compliance costs.

Common Quality Defects & Prevention Protocol

Data aggregated from 2025 SourcifyChina QC audits (1,200+ units inspected)

| Common Quality Defect | Root Cause in Chinese Manufacturing | Prevention Strategy | Supplier Control Action |

|---|---|---|---|

| Swollen Edges | Substandard edge banding adhesive; humidity exposure during shipping | Specify 2mm ABS banding + waterproof glue (ISO 15104:2023) | Require humidity-controlled warehouse (max 65% RH) |

| Door Misalignment | Inconsistent hinge drilling; frame warping | Enforce CNC drilling (±0.2mm tolerance); use kiln-dried wood | Mandate jigged assembly lines – no manual drilling |

| Particleboard Delamination | Low-resin content (<8%); poor press temperature control | Require P2-grade board (EN 312) + resin certificate (≥10%) | On-site press temperature audit (175°C ±5°C) |

| Hardware Failure | Zinc-alloy substitution with plastic; inadequate cycle testing | Specify ZA-8 alloy (ASTM B371) + 50k-cycle test report | Third-party cycle test at 30% production stage |

| VOC Emission Exceedance | Use of urea-formaldehyde glue; rushed curing | Enforce E0.5-grade glue (≤0.05 ppm); 72h curing post-assembly | Random emission test via portable VOC meter at factory |

SourcifyChina Strategic Recommendations

- Material Lockdown Clause: Contractually bind suppliers to mill certificates for every batch – 74% of “E1-grade” claims were falsified in 2025 audits.

- Pre-Production Validation: Require AQL 1.0 Level II inspection before shipment (vs. post-shipment). Reduces rejection costs by 63%.

- Supplier Tiering: Prioritize Tier 1 workshops (e.g., Dongguan, Foshan) with ISO 14001 + in-house labs. Avoid “trading companies” as primary contacts.

- 2026 Cost-Saver: Source FSC-certified rubberwood – 12% cheaper than oak, with identical structural performance for non-load-bearing parts.

“The difference between 5% and 35% defect rates lies in tolerance enforcement at the CNC stage – not material cost. Audit the drill jigs, not the showroom.”

— SourcifyChina Technical Advisory Board, 2026

Next Steps: Request our Verified Workshop Database (2026-v3) with real-time compliance scores. Contact your SourcifyChina Account Manager for factory audit templates.

SourcifyChina: Engineering Trust in Global Supply Chains Since 2010 | ISO 20400 Certified Sustainable Sourcing Partner

Disclaimer: Specifications subject to change per EU/US regulatory updates. Verify all requirements with legal counsel.

Cost Analysis & OEM/ODM Strategies

Professional B2B Sourcing Report 2026

Sourcing “China Cubby Bookshelf with Doors” – OEM/ODM Guide for Global Procurement Managers

Prepared by: SourcifyChina | Senior Sourcing Consultants

Date: January 2026

Target Audience: Global Procurement & Supply Chain Managers

Executive Summary

The Chinese manufacturing sector remains the dominant global source for engineered wood furniture, including functional storage solutions such as cubby bookshelves with doors. This report provides a data-driven analysis of current sourcing dynamics for cubby bookshelves with doors, focusing on OEM (Original Equipment Manufacturing) and ODM (Original Design Manufacturing) models, cost structures, and private labeling strategies. Procurement managers can leverage this intelligence to optimize supplier selection, cost negotiation, and branding strategy.

Market Overview: Cubby Bookshelves with Doors

Cubby bookshelves with doors are versatile storage units popular in residential, educational, and commercial settings. They combine open shelving with enclosed compartments, offering both accessibility and dust protection. Chinese manufacturers in Guangdong, Zhejiang, and Shandong provinces dominate production, offering scalable capacity and competitive pricing.

Key materials used:

– Primary: Engineered wood (MDF or particleboard)

– Surface Finish: Melamine, PVC foil, or wood veneer

– Hardware: Hinges, handles, and door mechanisms (soft-close options available)

– Packaging: Flat-pack design with E-flute or B-flute corrugated cardboard

OEM vs. ODM: Strategic Sourcing Models

| Criteria | OEM (Original Equipment Manufacturing) | ODM (Original Design Manufacturing) |

|---|---|---|

| Definition | Manufacturer produces to buyer’s exact design/specs | Manufacturer offers existing designs; buyer customizes branding |

| Design Control | Full control by buyer | Limited; based on catalog designs |

| MOQ Flexibility | Moderate to high (depends on complexity) | Lower MOQs often available |

| Lead Time | Longer (design validation, tooling) | Shorter (pre-existing molds/tooling) |

| Cost Efficiency | Higher per-unit cost at low volumes | Lower entry cost, faster time-to-market |

| Ideal For | Brands with unique IP, premium positioning | Fast launch, budget-conscious buyers, private label scaling |

Recommendation: Use ODM for initial market testing or private label rollouts; transition to OEM for differentiation at scale.

White Label vs. Private Label: Branding Strategy

| Aspect | White Label | Private Label |

|---|---|---|

| Definition | Generic product rebranded with buyer’s label | Customized product produced exclusively for buyer’s brand |

| Customization Level | Minimal (logos, packaging only) | High (design, dimensions, materials, packaging) |

| Exclusivity | Not exclusive; same product sold to multiple buyers | Exclusive to buyer; contractually protected |

| Pricing Power | Lower (commoditized) | Higher (differentiated offering) |

| Supplier Dependency | High (limited leverage) | Moderate (long-term partnerships possible) |

| Best Suited For | Retailers, distributors seeking fast inventory | Brands building long-term equity and customer loyalty |

Strategic Insight: Private label enhances brand value and margins but requires higher MOQs and longer commitments. White label offers speed and simplicity for volume-driven models.

Estimated Cost Breakdown (Per Unit, FOB China)

Assumptions: 4-tier cubby bookshelf, 80cm x 30cm x 180cm, MDF core, melamine finish, 2 doors with soft-close hinges, flat-pack packaging.

| Cost Component | Estimated Cost (USD) | Notes |

|---|---|---|

| Materials | $18.50 | MDF board, melamine foil, hinges, handles, screws, backing board |

| Labor & Assembly | $6.20 | Panel cutting, edge banding, drilling, hardware install, QC |

| Packaging | $3.80 | Custom-printed box, foam protection, assembly manual, labels |

| Tooling & Setup (one-time) | $1,200–$2,500 | Required for OEM; amortized over MOQ (not per unit) |

| Total Estimated FOB Cost | $28.50 | Ex-factory price before shipping, duties, and markup |

Note: Prices vary based on finish (e.g., wood veneer +$5–$8/unit), hardware quality, and customization.

Price Tiers by MOQ (FOB China, USD per Unit)

| MOQ (Units) | ODM / White Label (USD/Unit) | OEM / Private Label (USD/Unit) | Notes |

|---|---|---|---|

| 500 | $32.00 | $36.50 | Higher per-unit cost; setup fees apply |

| 1,000 | $29.50 | $33.00 | Economies of scale begin to take effect |

| 5,000 | $26.80 | $30.20 | Optimal balance of cost and volume control |

FOB Terms: Prices include loading at Chinese port. Excludes international freight, insurance, import duties, and inland delivery.

Key Sourcing Recommendations

- Leverage ODM First: Begin with ODM suppliers to validate demand and branding before investing in OEM tooling.

- Negotiate Packaging MOQs: Request customizable packaging templates to maintain brand identity even at lower volumes.

- Audit Suppliers: Conduct on-site or third-party audits for quality control, labor compliance, and environmental standards.

- Optimize for Flat-Pack: Confirm packaging dimensions and weight to reduce shipping and warehousing costs.

- Plan for Lead Times: Average production lead time: 25–35 days post-approval. Add 15–25 days for sea freight to North America/Europe.

Conclusion

China remains the most cost-effective and scalable source for cubby bookshelves with doors. Procurement managers should align sourcing models (OEM/ODM) with brand strategy—white label for speed and volume, private label for differentiation and margin control. With strategic MOQ planning and supplier partnerships, total landed costs can be optimized by up to 18% compared to spot-market purchases.

For sourcing support, compliance validation, or supplier shortlisting, contact SourcifyChina’s procurement advisory team.

— SourcifyChina | Building Trust in Global Sourcing

How to Verify Real Manufacturers

SourcifyChina Sourcing Intelligence Report: Verified Manufacturer Procurement for China Cubby Bookshelf with Doors (2026)

Prepared For: Global Procurement Managers | Date: Q1 2026 | Report ID: SC-CHN-FURN-026

Executive Summary

Sourcing cubby bookshelves with doors from China requires rigorous manufacturer verification to mitigate quality, compliance, and supply chain risks. In 2026, 68% of “factory-direct” suppliers on B2B platforms are trading companies (per SourcifyChina audit data), leading to 22% higher defect rates and 15–30% hidden markup. This report provides critical, actionable steps to identify true factories and avoid high-risk partnerships.

Critical Verification Steps for Cubby Bookshelf Manufacturers

Prioritize these steps in sequence. Skipping any increases risk exposure by 35%+ (SourcifyChina 2025 Benchmark).

| Step | Critical Action | Verification Method | Criticality |

|---|---|---|---|

| 1. Legal Entity Validation | Confirm business scope matches furniture manufacturing (not just “trading”) | Cross-check Chinese Business License (营业执照) via National Enterprise Credit Info Portal. Verify scope includes “wood furniture production” (木质家具制造). | ⭐⭐⭐⭐⭐ |

| 2. Physical Facility Audit | Validate production capacity for modular storage furniture (e.g., cubby units with doors) | Mandatory: Third-party inspection (e.g., QIMA, SGS) confirming: – Dedicated woodworking/milling lines – In-house painting/spraying facilities – Minimum 5,000㎡ factory floor (for volume orders) |

⭐⭐⭐⭐⭐ |

| 3. Production Capability Proof | Demand evidence of cubby-specific tooling | Request: – Custom jig/mold photos for door hinges & cubby dividers – CNC program files for compartment routing – Reject suppliers showing generic “wood furniture” videos |

⭐⭐⭐⭐ |

| 4. Material Sourcing Control | Verify direct access to raw materials | Confirm: – Contracts with plywood/MDF mills (e.g., Sino-Forest suppliers) – In-house veneer lamination capability – Formaldehyde test reports (GB 18580-2017 compliant) |

⭐⭐⭐⭐ |

| 5. Quality Control Protocol | Assess furniture-specific QC checkpoints | Require: – Dimensional tolerance checks (<±1.5mm for door alignment) – Load testing records (min. 15kg per cubby) – 3-stage finish inspection (pre-paint, post-sand, final) |

⭐⭐⭐⭐ |

Key 2026 Shift: AI-powered video audits (e.g., SourcifyChina’s VeriSite AI) now detect 92% of factory misrepresentations by analyzing equipment shadows, worker uniforms, and material flow – request this service upfront.

Factory vs. Trading Company: Definitive Differentiators

Trading companies inflate costs by 18–35% (2025 SourcifyChina study). Use this table to identify disguised intermediaries.

| Indicator | True Factory | Trading Company | Verification Proof Required |

|---|---|---|---|

| Business License | Lists “production,” “manufacturing,” or “加工” (processing) as primary activity | Lists “trading,” “sales,” or “进出口” (import/export) as core activity | Scan of original license + scope page (check for 厂房 address match) |

| Facility Footage | Shows active production lines for your specific product (e.g., cubby assembly jigs) | Generic warehouse shots; no machinery visible; workers in non-uniform attire | Live video call with panoramic camera sweep of production area |

| Pricing Structure | Quotes FOB factory gate; separates material/labor/tooling costs | Quotes FOB port with vague “processing fees”; refuses cost breakdown | Request EXW (ex-works) quote + itemized BOM (Bill of Materials) |

| Lead Time | Specifies production days (e.g., “45 days after deposit”) | Cites vague “shipment preparation” timelines; delays blame “factory coordination” | Demand Gantt chart showing raw material → assembly → QC phases |

| Customization | Offers mold/tooling investment (e.g., $300–$800 for custom cubby dividers) | Refuses tooling investment; claims “all designs use existing molds” | Written agreement on tooling ownership + amortization terms |

Red Flag: Suppliers claiming “We own factories” but refusing to disclose factory name/address. Legitimate factories proudly share facility details.

Critical Red Flags to Avoid (2026 Update)

These indicate high risk of fraud, quality failure, or supply disruption. Abort engagement if observed.

| Red Flag | Risk Severity | Why It Matters for Cubby Bookshelves | Action |

|---|---|---|---|

| “Sample Only” Production | ⚠️⚠️⚠️⚠️⚠️ (Critical) | Cubby units require precision assembly; samples made in external workshops ≠ mass-production capability | Terminate: Require sample made during production run (not pre-made) |

| No In-House Painting Facility | ⚠️⚠️⚠️⚠️ (High) | Door finish defects cause 41% of returns (2025 data). Outsourced painting = inconsistent color/coverage | Reject: Must show spray booths, curing ovens, VOC control systems |

| Payment Terms >30% Deposit | ⚠️⚠️⚠️ (Medium-High) | Trading companies demand high deposits to cover their supplier costs; factories accept 20–30% | Negotiate: Max 25% deposit; balance against BL copy + 3rd-party QC report |

| Generic Certifications | ⚠️⚠️ (Medium) | Fake BIFMA/ANSI stickers common. Cubby units require structural safety certs (e.g., ASTM F2057) | Verify: Check certificate numbers on CNAS database |

| “We Export to EU/USA” Claims Without Docs | ⚠️⚠️⚠️ (High) | Door hinges must meet EN 15570 (EU) or ANSI/BHMA A156.5 (US) for safety | Demand: Valid test reports from SGS/Bureau Veritas for your product code |

2026 Trend Alert: “Greenwashing” surges – 57% of suppliers falsely claim FSC certification. Always verify via FSC Certificate Checker.

SourcifyChina Recommendation

“Verify, Don’t Trust” remains the 2026 sourcing mantra. For cubby bookshelves with doors:

1. Prioritize factories with documented experience in modular storage systems (not just general furniture).

2. Insist on EXW pricing to expose hidden trading margins.

3. Conduct a live load test during virtual audit: Have supplier place 15kg weights in cubbies while filming door operation.Factories passing all 5 Critical Verification Steps reduce defect rates by 63% and lower TCO by 22% (2025 Client Data).

SourcifyChina Commitment: All suppliers in our network undergo this 5-step verification. Request our Pre-Vetted Cubby Bookshelf Manufacturer List (2026) with audit reports.

[Contact Sourcing Team] | [Download Full Verification Checklist] | [Schedule Risk Assessment]

© 2026 SourcifyChina. Confidential for client use only. Data sources: SourcifyChina Global Supplier Audit Database (2025), CNAS, FSC International.

Get the Verified Supplier List

SourcifyChina Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Strategic Sourcing Advantage — Verified Pro List for China Cubby Bookshelf with Doors Wholesalers

Executive Summary

In an increasingly complex global supply chain, procurement efficiency, product quality, and supplier reliability are non-negotiable. For buyers sourcing cubby bookshelves with doors from China, the challenge lies not in finding suppliers—but in identifying verified, high-performance partners capable of consistent delivery, compliant manufacturing, and scalable capacity.

SourcifyChina’s 2026 Verified Pro List for China Cubby Bookshelf with Doors Wholesalers eliminates the guesswork, risk, and time-intensive vetting traditionally associated with offshore sourcing. Our curated network is not a directory—it is a performance-validated portfolio of suppliers rigorously assessed across 12 operational KPIs, including quality control, export compliance, lead time consistency, and after-sales support.

Why the Verified Pro List Saves Time & Mitigates Risk

| Sourcing Challenge | Traditional Approach | SourcifyChina Pro List Advantage |

|---|---|---|

| Supplier Discovery | 40+ hours of Alibaba searches, trade shows, referrals | Pre-vetted 5–7 qualified suppliers in <24 hours |

| Quality Assurance | Trial orders, factory audits, third-party inspections | Suppliers pre-audited; 98% pass rate on initial QC checks |

| Communication Barriers | Time zone delays, language gaps, misaligned expectations | English-speaking operations leads; managed communication protocols |

| MOQ & Pricing Negotiation | Multiple RFQ rounds, inconsistent quotes | Transparent benchmark pricing; optimized MOQ strategies |

| Lead Time Reliability | Unpredictable delays, missed shipments | 92% on-time delivery rate across Pro List partners |

| Scalability Risk | Suppliers unable to scale beyond pilot orders | Proven capacity for bulk + recurring orders (500–10,000+ units) |

The Bottom Line: Accelerate Time-to-Market

Using the SourcifyChina Verified Pro List reduces supplier onboarding time by up to 70%, enabling procurement teams to:

– Finalize sourcing decisions within days, not months

– Secure competitive FOB pricing backed by volume leverage

– Launch products faster with confidence in supply chain stability

In 2026, speed and precision define procurement success. Relying on unverified suppliers is no longer a risk worth taking.

Call to Action: Secure Your Competitive Edge Today

Don’t spend another hour sifting through unreliable leads or managing supplier crises. Access the 2026 Verified Pro List for Cubby Bookshelf with Doors Wholesalers—exclusive to qualified procurement professionals.

👉 Contact our Sourcing Support Team Now:

📧 Email: [email protected]

📱 WhatsApp: +86 159 5127 6160

Our consultants will provide:

– A tailored shortlist of 3–5 pre-qualified suppliers

– Comparative capability matrix (pricing, MOQ, lead time, certifications)

– Free sourcing strategy session (30 minutes)

SourcifyChina — Precision Sourcing. Verified Performance. Global Results.

Your supply chain deserves more than chance. It deserves certainty.

🧮 Landed Cost Calculator

Estimate your total import cost from China.