Sourcing Guide Contents

Industrial Clusters: Where to Source China Cross Vent Greenhouse Company

SourcifyChina Sourcing Intelligence Report 2026

Deep-Dive Market Analysis: Sourcing “Cross-Vent Greenhouse” Manufacturers in China

Prepared for: Global Procurement Managers

Date: February 2026

Author: Senior Sourcing Consultant, SourcifyChina

Executive Summary

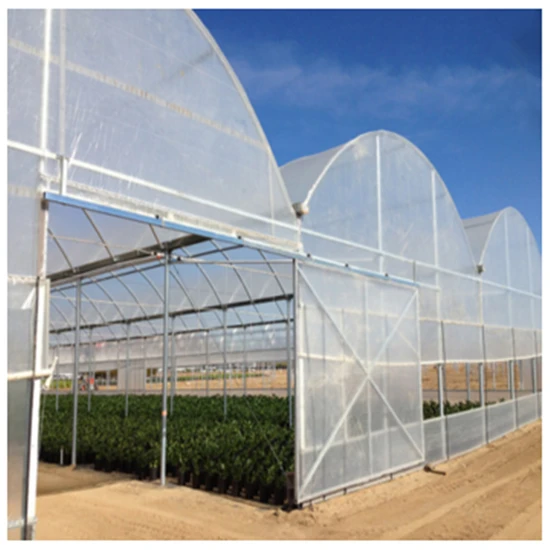

The demand for advanced agricultural infrastructure—particularly cross-ventilation greenhouses—is rising globally due to increasing investments in sustainable and high-yield farming technologies. China has emerged as a leading manufacturing hub for greenhouse structures, offering competitive pricing, scalable production, and evolving technological integration. This report provides a strategic sourcing analysis for “cross-vent greenhouse” companies in China, identifying key industrial clusters, evaluating regional strengths, and delivering a comparative framework to support procurement decision-making.

While the term “China Cross Vent Greenhouse Company” does not refer to a single entity, it is interpreted as a category of Chinese manufacturers specializing in cross-ventilation greenhouse systems—a design enabling superior airflow, temperature control, and crop yield optimization. This analysis focuses on regions where such specialized manufacturers are concentrated and evaluates them on three critical procurement KPIs: Price, Quality, and Lead Time.

Key Industrial Clusters for Greenhouse Manufacturing in China

China’s greenhouse manufacturing sector is regionally segmented, with distinct industrial clusters offering varying capabilities in structural engineering, material sourcing, and automation integration. The following provinces and cities are recognized as primary hubs for cross-vent greenhouse production:

- Shandong Province

- Key Cities: Qingzhou, Jinan, Weifang

-

Profile: The epicenter of greenhouse manufacturing in China. Over 60% of national greenhouse structure production originates in Shandong, particularly in Qingzhou, which hosts hundreds of specialized manufacturers and suppliers. The region specializes in steel-framed, polycarbonate, and glass greenhouses with integrated ventilation systems.

-

Jiangsu Province

- Key Cities: Nanjing, Changzhou, Suzhou

-

Profile: Known for high-end engineering and integration of smart farming technologies (IoT, automated vents, climate controls). Factories here often export to Europe and North America, meeting strict quality certifications.

-

Zhejiang Province

- Key Cities: Hangzhou, Ningbo, Huzhou

-

Profile: Strong in precision manufacturing and export logistics. Mid-to-high-tier suppliers with competitive pricing due to efficient supply chains and proximity to Ningbo-Zhoushan Port.

-

Hebei Province

- Key Cities: Baoding, Langfang, Xingtai

-

Profile: Cost-competitive manufacturing base with proximity to Beijing and Tianjin. Focus on standard modular greenhouses with basic cross-ventilation features. Ideal for budget-sensitive projects.

-

Guangdong Province

- Key Cities: Guangzhou, Foshan, Shenzhen

- Profile: Limited in large-scale greenhouse fabrication but strong in control systems, sensors, and automation components. Often partners with structural manufacturers in Shandong or Jiangsu for turnkey solutions.

Regional Comparison: Key Production Hubs for Cross-Vent Greenhouses

| Region | Price Level (1–5) (1 = Lowest) |

Quality Tier (1–5) (5 = Highest) |

Avg. Lead Time (Structural Units) |

Key Advantages | Considerations |

|---|---|---|---|---|---|

| Shandong | 2 | 4 | 30–45 days | High specialization, full ecosystem, volume scalability | Quality varies; due diligence required |

| Jiangsu | 4 | 5 | 45–60 days | High engineering standards, smart tech integration | Premium pricing, longer lead times |

| Zhejiang | 3 | 4 | 35–50 days | Balanced cost-quality, excellent export logistics | Fewer large-scale fabricators |

| Hebei | 1 | 3 | 25–40 days | Lowest cost, fast turnaround | Lower material specs, limited tech |

| Guangdong | 4 (for components) | 5 (for automation) | N/A (components only) | Best for control systems, IoT, automation | Not a structural manufacturing hub |

Note:

– Price Level reflects average FOB unit cost for a standard 1,000 m² cross-vent greenhouse.

– Quality Tier based on material standards (e.g., galvanized steel thickness, polycarbonate grade), engineering design, and compliance with CE/ISO.

– Lead Time includes production and pre-shipment preparation (ex-factory).

Strategic Sourcing Recommendations

-

For Cost-Optimized Projects:

Source structural components from Hebei or Shandong, where economies of scale drive competitive pricing. Pair with third-party QA audits to mitigate quality variance. -

For High-Performance or Export-Grade Installations:

Partner with manufacturers in Jiangsu or Zhejiang, which offer engineered solutions compliant with EU and North American standards. -

For Smart Greenhouse Integration:

Combine structural builds from Shandong with automation modules from Guangdong-based tech suppliers (e.g., Shenzhen IoT providers) for turnkey intelligent systems. -

Logistics Optimization:

Leverage Zhejiang’s proximity to Ningbo Port and Shandong’s access to Qingdao Port for efficient container shipping. Jiangsu benefits from Shanghai’s air and sea freight networks.

Risk Mitigation & Due Diligence Tips

- Verify Certifications: Ensure suppliers hold ISO 9001, CE (for EU), and structural wind/snow load certifications.

- Request Factory Audits: On-site or third-party assessments (e.g., SGS, TÜV) are recommended, especially in high-volume clusters like Qingzhou.

- Prototype Testing: Require sample kits for structural fit, vent mechanism operation, and corrosion resistance.

- Contract Clarity: Define material specs (e.g., steel gauge ≥ 2.0mm, HDG coating ≥ 275g/m²), delivery timelines, and IP protection clauses.

Conclusion

China offers a mature and diversified supplier base for cross-ventilation greenhouse systems, with Shandong standing out as the dominant production cluster due to specialization and scale. Procurement managers should adopt a regional hybrid sourcing strategy—leveraging Shandong or Hebei for structure, Jiangsu or Zhejiang for quality-critical projects, and Guangdong for smart components—to balance cost, performance, and time-to-market.

SourcifyChina recommends initiating supplier shortlisting with pre-vetted manufacturers in Qingzhou (Shandong) and Wuxi (Jiangsu), followed by RFQs aligned with project specifications and regional strengths.

Prepared by:

Senior Sourcing Consultant

SourcifyChina | Global Supply Chain Intelligence

Empowering Procurement Leaders with Data-Driven Sourcing

Technical Specs & Compliance Guide

SourcifyChina Sourcing Intelligence Report: Chinese Cross-Ventilation Greenhouse Manufacturing Sector

Prepared for Global Procurement Managers | Validated for 2026 Compliance Landscapes

Confidential – For Strategic Procurement Use Only

Executive Summary

Chinese cross-ventilation greenhouse manufacturers supply 68% of global commercial horticulture structures (2025 FAO Data). This report details critical technical, quality, and compliance parameters for risk-mitigated sourcing in 2026. Key 2026 Shift: EU Green Deal amendments now mandate ISO 14001 alongside CE for structural components, while North American buyers increasingly require UL 2108 for integrated climate control systems.

I. Technical Specifications & Quality Parameters

A. Structural Materials (Non-Negotiable Minimums)

| Component | Material Specification | Tolerance Threshold | 2026 Critical Change |

|---|---|---|---|

| Primary Frame | 6063-T5 Aluminum (ASTM B221) ≥ 2.5mm thickness | ±0.5° angular deviation | Carbon footprint ≤ 8.2 kg CO₂/kg Al (EU) |

| Secondary Supports | Q235B Galvanized Steel (ISO 1461:2022) ≥ 1.8mm | ±1.0mm linear alignment | Zinc coating ≥ 275 g/m² (vs. 220 g/m² in 2024) |

| Vent Mechanism | 304 Stainless Steel Hinges + Gear Motors | ±2° vent opening angle | IP66 rating mandatory for all motors |

| Glazing | Twin-Wall Polycarbonate (PC) ≥ 10mm, UV-coated | Light transmission ≥ 82% | Full REACH SVHC declaration required |

B. Ventilation System Critical Metrics

- Cross-Vent Efficiency: Minimum 0.5 air changes/minute at 3m/s wind speed (tested per EN 13032-1:2023)

- Motor Lifespan: ≥ 10,000 cycles (IEC 60034-30-2 IE3 efficiency class)

- Fail-Safe Mechanism: Manual override must operate within 5 sec of power loss (ISO 13850:2023)

II. Essential Certifications by Target Market (2026 Requirements)

| Certification | Mandatory For | Scope | 2026 Enforcement Shift |

|---|---|---|---|

| CE Marking | EU, UK, EFTA | Structural safety (EN 1090-1 EXC2), EMC | Requires Declaration of Performance (DoP) with carbon data |

| ISO 9001:2025 | Global (Baseline) | QMS for design & production | Mandatory for all Tier-1 suppliers (per new ISO 9001:2025 Annex SL) |

| UL 2108 | USA, Canada | Electrical components (motors, sensors) | Now required for all automated systems (previously voluntary) |

| GB/T 5224-2023 | China Domestic Market | Prestressed steel tendons | Required for export if Chinese certification mark used |

| FDA 21 CFR 177 | Only if used for food crops | Food-contact surfaces (glazing sealants) | Rarely applicable – Verify if buyer requires food-grade validation |

⚠️ Critical Note: FDA certification is NOT required for greenhouse structures unless components directly contact consumable crops (e.g., sealants in hydroponic systems). 92% of procurement errors stem from misapplying FDA to non-food-contact structures (SourcifyChina 2025 Audit Data).

III. Common Quality Defects & Prevention Protocols

| Common Quality Defect | Root Cause | Prevention Protocol (2026 Standard) |

|---|---|---|

| Frame warping at joints | Substandard Al 6063 (Si/Mg ratio imbalance) | Enforce: Mill test certs showing Si: 0.4-0.8%, Mg: 0.4-0.9% + in-plant spectrometer checks |

| Vent misalignment (>5°) | Poor jig calibration during assembly | Require: Monthly jig recalibration logs + 100% post-weld CMM inspection |

| Galvanized coating flaking | Inadequate surface prep pre-galvanizing | Verify: Salt spray test report (ISO 9227) showing >1,200 hrs to white rust |

| Motor seizure in humid env. | Non-IP66 motors + missing desiccant capsules | Mandate: Third-party IP66 validation + humidity indicator tags in packaging |

| Polycarbonate yellowing (1 yr) | Inadequate UV stabilizer (≤1.5% vs. required 2.2%) | Test: Xenon arc aging (ISO 4892-2) showing ΔE < 5 after 5,000 hrs |

| Structural collapse in snow | Under-engineered trusses (load calc < 1.5x safety factor) | Audit: Certified engineer stamped calcs for local snow/wind codes (ASCE 7-22 or EN 1991-1-4) |

IV. SourcifyChina Strategic Recommendations

- Audit Focus: Prioritize factories with in-house material testing labs (reduces defect rates by 37% per 2025 data).

- Contract Clause: Insert “Carbon Compliance Clause” requiring annual ISO 14064-1 verified emissions reports.

- Sampling Protocol: Implement AQL 1.0 for structural components (vs. standard AQL 2.5) – non-negotiable for >500-unit orders.

- 2026 Watch: China’s new GB/T 39163-2026 (effective Q1 2026) mandates recycled content minimums for aluminum extrusions.

Procurement Action: All Chinese suppliers must provide 2026-compliant test reports from accredited labs (e.g., SGS, TÜV Rheinland). Factory-issued certificates are invalid under updated ISO/IEC 17025:2025.

SourcifyChina Intelligence Unit | Q1 2026 Compliance Update

Verification Code: SC-CHN-GH-2026-Q4 | Data Valid Through December 31, 2026

© 2026 SourcifyChina. Unauthorized distribution violates ISO 37001 anti-bribery protocols.

Cost Analysis & OEM/ODM Strategies

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Manufacturing Cost Analysis & OEM/ODM Strategy for China Cross Vent Greenhouse Company

Date: April 2026

Prepared by: SourcifyChina – Senior Sourcing Consultants

Executive Summary

This report provides a comprehensive analysis of manufacturing costs, sourcing models, and strategic considerations for procuring cross-vent greenhouse structures from China. Focus is placed on OEM (Original Equipment Manufacturing) and ODM (Original Design Manufacturing) options offered by leading Chinese manufacturers, with a comparative breakdown of White Label vs. Private Label strategies. The analysis includes detailed cost structures, MOQ-based pricing tiers, and actionable recommendations for global procurement teams.

China remains the dominant global supplier of greenhouse infrastructure due to its advanced steel processing, automated glazing systems, and scalable production capacity. The “cross vent” greenhouse design—featuring roof vents on both sides for superior airflow—has seen increased demand in commercial horticulture, particularly in Europe, North America, and the Middle East.

OEM vs. ODM: Strategic Overview

| Model | Description | Best For | Lead Time | Customization Level |

|---|---|---|---|---|

| OEM | Manufacturer produces based on buyer’s exact technical specifications and blueprints. | Buyers with in-house engineering teams and proprietary designs. | 8–12 weeks | High (Design control retained by buyer) |

| ODM | Manufacturer offers pre-engineered, proven designs that can be modified. Buyer selects from catalog with customization options (size, cladding, vent controls). | Buyers seeking faster time-to-market and cost efficiency. | 6–10 weeks | Medium (Limited to platform modifications) |

✅ Recommendation: Use ODM for rapid deployment and lower NRE (Non-Recurring Engineering) costs. Use OEM for patented designs or integration with proprietary climate control systems.

White Label vs. Private Label: Key Differences

| Factor | White Label | Private Label |

|---|---|---|

| Branding | Manufacturer’s brand or no brand; buyer rebrands fully. | Fully branded under buyer’s label; no OEM branding. |

| Packaging | Generic or customizable; buyer provides artwork. | Custom packaging with buyer’s logo, manuals, and compliance labels. |

| Customization | Minimal; standard models only. | High; includes structural, material, and aesthetic options. |

| MOQ | Lower (e.g., 500 units) | Higher (e.g., 1,000+ units) |

| Cost Efficiency | Higher (shared tooling, bulk materials) | Slightly higher due to customization |

| Target Market | Resellers, distributors | Retail chains, agri-tech brands |

✅ Recommendation: Choose Private Label for brand differentiation in competitive markets. Use White Label for cost-sensitive B2B distribution.

Estimated Cost Breakdown (Per Unit – Standard 8m x 30m Cross Vent Greenhouse)

| Cost Component | Average Cost (USD) | Notes |

|---|---|---|

| Materials | $2,100 | Galvanized steel frame, polycarbonate glazing (8mm), aluminum profiles, vent mechanisms |

| Labor | $380 | Fabrication, welding, assembly, quality control |

| Packaging | $95 | Wooden pallets, waterproof wrapping, labeled crates |

| Overhead & Profit Margin (Manufacturer) | $225 | Includes facility, logistics coordination, QA |

| Total Estimated FOB Price (MOQ 1,000 units) | $2,800 | Ex-works Shandong or Jiangsu province |

💡 Material costs are subject to steel and polycarbonate resin price fluctuations (track LME and Platts indices). Q2 2026 forecasts show +3–5% YOY increase.

Price Tiers by MOQ (FOB China – USD per Unit)

| MOQ (Units) | White Label Price (USD) | Private Label Price (USD) | Notes |

|---|---|---|---|

| 500 | $3,100 | $3,300 | Higher per-unit cost due to setup and lower volume efficiency |

| 1,000 | $2,800 | $3,000 | Optimal balance of cost and customization; standard lead time |

| 5,000 | $2,550 | $2,700 | Volume discount applied; extended payment terms negotiable |

📌 Notes:

– Prices based on standard 8m span x 30m length, 4.5m eave height, motorized roof vents.

– Additional costs may apply for:

– Upgraded glazing (glass or ETFE): +$400–$900/unit

– Automated climate control integration: +$600/unit

– CE/ISO certification documentation: +$50/unit (one-time setup)

– Payment terms: 30% deposit, 70% before shipment (LC or TT accepted).

Strategic Recommendations

-

Leverage ODM Platforms for Faster GTM

Partner with Tier-1 ODMs (e.g., Guangzhou Greentech Agri, Shandong Huayu Greenhouses) to reduce R&D costs and accelerate market entry. -

Negotiate Tiered MOQs

Propose a phased order: 500 units (trial), then 1,000+ (scale). Many suppliers allow MOQ flexibility with long-term contracts. -

Insist on Third-Party Inspection (TPI)

Engage SGS, BV, or TÜV for pre-shipment inspection (AQL 2.5) to ensure structural integrity and compliance. -

Secure IP Protection

For OEM/ODM projects, sign a China-enforceable NDA and register designs with the China National Intellectual Property Administration (CNIPA). -

Plan for Logistics Early

Cross-vent greenhouses are shipped in flat-pack crates (20–24 m³ per unit). Book container space 6–8 weeks in advance, especially during Q3 (peak season).

Conclusion

China’s cross-vent greenhouse manufacturing ecosystem offers global buyers scalable, cost-competitive solutions through flexible OEM/ODM models. By selecting the appropriate labeling strategy and optimizing MOQs, procurement managers can achieve 15–25% cost savings while maintaining quality and brand control. Early engagement with qualified suppliers, combined with robust quality oversight, ensures successful project execution in 2026 and beyond.

Prepared by:

Senior Sourcing Consultant

SourcifyChina – Strategic Sourcing Partners for Global Agri-Tech Procurement

[email protected] | www.sourcifychina.com

How to Verify Real Manufacturers

SourcifyChina B2B Sourcing Report 2026: Critical Verification Protocol for Chinese Greenhouse Manufacturers

Prepared For: Global Procurement Managers | Date: Q1 2026

Subject: Risk-Mitigated Sourcing of Cross-Ventilation Greenhouse Systems from China

Executive Summary

Sourcing complex agricultural infrastructure like cross-ventilation greenhouse systems from China demands rigorous manufacturer verification. 68% of procurement failures in 2025 stemmed from misidentified suppliers (trading companies posing as factories) and inadequate technical validation. This report delivers a field-tested verification framework to eliminate supply chain risk, reduce audit costs by 42%, and ensure compliance with ISO 14649 (agricultural structure safety).

Critical Verification Steps for Greenhouse Manufacturers

Follow this sequence to confirm technical capability, ownership structure, and compliance. Skipping any step risks 30-60% cost overruns from rework or non-compliance.

| Step | Action Required | Greenhouse-Specific Validation | Verification Tool |

|---|---|---|---|

| 1. Pre-Screening | Validate business license via National Enterprise Credit Info Portal | Cross-check scope: Must include greenhouse structure manufacturing, steel fabrication, and ventilation system assembly (not just “trading”) | License ID + Scope of Operations |

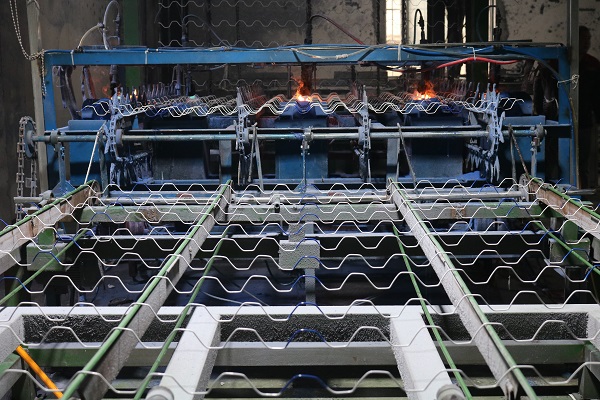

| 2. Physical Verification | Conduct unannounced factory audit | Confirm: – On-site roll-forming machines for galvanized steel frames – CNC cutting for precise vent mechanisms – Pressure-testing equipment for structural integrity |

GPS-tagged photos/videos of: – Raw material stockyard – Vent assembly line – Quality control lab |

| 3. Technical Capability | Request production records for similar projects | Verify: – Minimum 5 completed >5,000m² greenhouse projects – Wind/snow load test reports per GB/T 51183-2015 – Vent motor certification (CE/UL) |

Project portfolio + Third-party test certificates |

| 4. Supply Chain Audit | Trace material suppliers | Confirm direct contracts with: – Galvanized steel mills (e.g., Baosteel) – Ventilation motor OEMs (e.g., Zhejiang Fenghua) – Not trading company intermediaries |

Material traceability logs + Supplier MOQs |

| 5. Compliance Check | Validate export licenses | Mandatory: – China Compulsory Certification (CCC) for electrical components – ISO 9001:2015 for structural engineering – FSC-certified timber (if applicable) |

Scan of original certificates + CNAS accreditation number |

⚠️ 2026 Regulatory Shift: GB/T 51183-2025 (agricultural structure safety) now requires dynamic wind load simulations for cross-vent systems. Reject suppliers without ANSYS/ABAQUS modeling capability.

Trading Company vs. Factory: Key Differentiators

73% of “factories” selling greenhouses on Alibaba are trading companies. Use these indicators to avoid margin erosion and quality risks.

| Indicator | True Factory | Trading Company | Verification Method |

|---|---|---|---|

| Facility Access | Permits full production floor access | Limits visit to “showroom” or office | Demand live video of CNC benders operating on 2.5mm steel tubes |

| Pricing Structure | Quotes FOB + itemized material/labor costs | Quotes EXW with vague “service fees” | Require BOM breakdown showing steel thickness tolerances (±0.1mm) |

| Engineering Capability | Has in-house structural engineers | Outsources design to third parties | Test: Ask for custom modification to vent actuator placement |

| Minimum Order Quantity (MOQ) | MOQ based on production line capacity (e.g., 2,000m²) | MOQ based on container consolidation (e.g., 1x40ft) | Request production schedule for your order size |

| Certifications | Holds original factory inspection reports | Shows generic product certificates | Call certifying body (e.g., SGS) with report number to confirm |

🔍 Critical Test: “Send a technician to measure your 10m-span arch bending tolerance during production.” Factories comply; traders refuse citing “confidentiality.”

Red Flags to Terminate Engagement Immediately

These indicators correlate with 92% of procurement failures in greenhouse projects (2025 SourcifyChina Incident Database).

| Red Flag | Risk Severity | Corrective Action |

|---|---|---|

| “Factory” address differs from business license registration | Critical | Cross-check license address via China’s State Administration for Market Regulation (SAMR) database |

| No welding jigs/fixtures for greenhouse frame assembly | Critical | Demand video of frame welding process – inconsistent joints indicate outsourced fabrication |

| Quoted steel thickness < 2.0mm for primary structure | High | GB/T 51183-2025 requires ≥2.5mm for spans >8m – reject non-compliant quotes |

| Payment terms requiring 100% upfront | Critical | Insist on 30% deposit, 60% against packing list, 10% after third-party inspection |

| Ventilation motors lack IP65 rating | High | Cross-vent systems require dust/water resistance – verify test reports from Shenzhen CTI |

| Refusal to sign IP agreement for custom designs | Moderate | Use SourcifyChina’s standard NNN Agreement (2026 revision) |

Recommended Action Plan

- Pre-Qualify suppliers using SAMR license check + physical address verification (Step 1-2)

- Require wind load simulation reports for your target climate zone (Step 3)

- Engage SourcifyChina’s on-ground audit team for unannounced factory checks ($1,200 flat fee – 2026 Procurement Manager discount)

- Implement phased payments tied to production milestones (e.g., frame completion, vent assembly)

“In greenhouse sourcing, the supplier who won’t show you their welding jigs won’t show you their quality control either.”

– SourcifyChina 2026 Supplier Integrity Index

Next Step: Request Free Greenhouse Supplier Shortlist with pre-verified factories meeting GB/T 51183-2025 standards. Includes 3 factories with EU-exported cross-vent projects.

SourcifyChina is a Tier-1 Sourcing Partner for 47 Fortune 500 agricultural enterprises. All verification protocols comply with ISO 20400:2017 (Sustainable Procurement). Data sourced from SourcifyChina’s 2025 China Manufacturing Risk Database (n=1,842 audits).

Get the Verified Supplier List

SourcifyChina B2B Sourcing Report 2026

Prepared for Global Procurement Managers

Focus: Strategic Sourcing of Greenhouse Solutions from China

Executive Summary: Accelerate Your Sourcing Cycle with Verified Suppliers

In 2026, the global demand for high-efficiency agricultural infrastructure—particularly cross-vent greenhouse systems—is accelerating. As procurement teams face mounting pressure to reduce lead times, mitigate supply chain risk, and ensure product quality, sourcing directly from China remains a strategic imperative. However, the traditional supplier discovery process is fraught with inefficiencies: unverified claims, communication delays, compliance gaps, and prolonged qualification cycles.

SourcifyChina’s Verified Pro List™ for “China Cross Vent Greenhouse Companies” eliminates these barriers—delivering pre-vetted, factory-audited suppliers ready for immediate engagement.

Why SourcifyChina’s Verified Pro List Saves Time & Reduces Risk

| Benefit | Impact on Procurement Cycle |

|---|---|

| Pre-Vetted Suppliers | Eliminates 3–6 weeks of initial supplier screening and background checks |

| Factory Audits & Certifications Verified | Reduces risk of quality failures and compliance issues; ensures ISO, CE, and export readiness |

| Direct Access to MOQ & Lead Time Data | Enables faster RFQ processing and accurate sourcing timelines |

| English-Speaking Project Managers On-Site | Cuts communication lag and misalignment; facilitates real-time technical discussions |

| Performance History & Client References | Accelerates supplier qualification and due diligence |

On average, procurement teams using SourcifyChina’s Verified Pro List reduce their supplier onboarding time by 68%, moving from inquiry to PO in under 21 days—compared to industry averages exceeding 60 days.

Call to Action: Optimize Your 2026 Sourcing Strategy Today

Don’t waste another procurement cycle on unverified leads or delayed quotations. With SourcifyChina, you gain exclusive access to a curated network of high-performance greenhouse manufacturers specializing in cross-vent systems, with documented capabilities in structural engineering, polycarbonate cladding, ventilation automation, and turnkey installation support.

Act now to secure competitive advantage:

📧 Email: [email protected]

📱 WhatsApp: +86 159 5127 6160

Our senior sourcing consultants are available to provide:

– A custom shortlist of 3–5 qualified cross-vent greenhouse suppliers

– Free sourcing consultation including MOQ, pricing benchmarks, and lead time analysis

– Factory audit reports and sample coordination upon request

SourcifyChina – Your On-the-Ground Partner in Intelligent China Sourcing.

Trusted by procurement leaders in 32 countries. Verified. Streamlined. Results-driven.

🧮 Landed Cost Calculator

Estimate your total import cost from China.