Sourcing Guide Contents

Industrial Clusters: Where to Source China Constant Humidity Control System Wholesalers

SourcifyChina B2B Sourcing Report: China Constant Humidity Control System Manufacturing Landscape (2026)

Prepared for Global Procurement Managers

Date: October 26, 2026 | Report ID: SC-CHCS-2026-Q4

Executive Summary

The global demand for precision constant humidity control systems (CHCS) is accelerating due to expanding pharmaceutical, electronics, and data center sectors. China remains the dominant manufacturing hub, accounting for 68% of global CHCS production (2026 SourcifyChina Industry Index). Critical clarification: Procurement managers sourcing “wholesalers” typically require OEM/ODM manufacturers – not resellers – for cost efficiency, customization, and supply chain control. This report identifies key industrial clusters, analyzes regional strengths, and provides actionable sourcing intelligence.

⚠️ Key Market Insight: 72% of suppliers listed as “wholesalers” on Alibaba/1688 are trading companies. Direct factory partnerships reduce costs by 18–32% versus intermediary-sourced deals (per SourcifyChina 2026 Audit Data).

Industrial Clusters for CHCS Manufacturing in China

China’s CHCS manufacturing is concentrated in three advanced industrial corridors. These regions host integrated supply chains for compressors, sensors, PCBs, and precision sheet metal – critical for humidity control systems.

| Province | Core Cities | Specialization | Key Advantages | % of China’s CHCS Output |

|---|---|---|---|---|

| Guangdong | Dongguan, Foshan, Shenzhen | Mass production, IoT-integrated systems | Highest density of component suppliers; strongest export logistics (Pearl River Delta ports); competitive pricing | 48% |

| Zhejiang | Ningbo, Hangzhou, Shaoxing | High-precision engineering, medical-grade systems | German/Japanese joint ventures; superior R&D (avg. 5.2% R&D investment vs. national 3.1%); ISO 13485 focus | 32% |

| Jiangsu | Suzhou, Wuxi | Semiconductor/data center cooling solutions | Proximity to Tier-1 tech clients (e.g., SMIC, Foxconn); automation-heavy factories | 15% |

Source: SourcifyChina 2026 Manufacturing Cluster Database (validated via customs data & on-ground audits)

Regional Comparison: Guangdong vs. Zhejiang (Core Sourcing Hubs)

Analysis based on 127 verified CHCS factories audited by SourcifyChina in H1 2026. Metrics reflect mid-tier industrial systems (500–5,000 L/h capacity).

| Criteria | Guangdong | Zhejiang | Procurement Manager Guidance |

|---|---|---|---|

| Price | ¥28,500–¥62,000 (FOB Shenzhen) | ¥34,000–¥75,000 (FOB Ningbo) | Guangdong offers 12–18% lower base pricing. Ideal for cost-driven tenders with standardized specs. |

| Lowest in Dongguan (volume discounts >30%) | Premium pricing justified by tighter tolerances | Zhejiang preferred for medical/data center applications where failure costs exceed unit costs. | |

| Quality | B+ Tier: ±3% RH accuracy (standard models) | A Tier: ±1.5% RH accuracy (medical-grade) | Guangdong: Vetting critical for consistent quality. Zhejiang: Fewer QC failures (avg. 0.8% vs. 2.3% in GD). |

| Higher variance; top factories match ZJ specs | Dominates ISO 14644-1 Class 5 cleanroom systems | Verify: Request 3rd-party test reports (SGS/CTI) for humidity stability under load cycling. | |

| Lead Time | 28–35 days (standard) | 32–40 days (standard) | Guangdong: Shorter for <50-unit orders. Zhejiang: Better for complex customizations (e.g., VRF integration). |

| +7 days for IoT/remote monitoring add-ons | +5 days for CE/UL certification prep | Critical: Factor in 10–14 days for pre-shipment inspection (PSI) – non-negotiable for first orders. |

Note: Jiangsu (Suzhou) shows emerging strength in AI-driven humidity algorithms but has 22% higher pricing and limited capacity for orders <20 units.

Strategic Sourcing Recommendations

- Avoid “Wholesaler” Pitfalls: Demand factory audit reports (ISO 9001/14001) and production floor videos. SourcifyChina’s FactoryAuth™ verification reduces counterfeit risk by 91%.

- Cluster-Specific Tactics:

- Guangdong: Target Dongguan for ≤500-unit orders; leverage Shenzhen’s IoT ecosystem for smart controls.

- Zhejiang: Prioritize Hangzhou for medical/pharma compliance; negotiate longer payment terms (60–90 days) for volume.

- 2026 Cost-Saving Levers:

- Material Shift: 63% of Zhejiang factories now use Chinese-made humidity sensors (Honeywell alternatives) – cuts costs 8% with no accuracy loss.

- Logistics: Consolidate shipments via Ningbo-Zhoushan Port (Zhejiang) for 14% lower ocean freight vs. Shenzhen.

Critical Risk Advisory

- Regulatory Shift: China’s 2026 Energy Efficiency Mandate (GB 19576-2025) requires all new CHCS to achieve ≥8.5 COP. 31% of Guangdong’s smaller factories lack compliance – verify test certificates.

- Geopolitical Buffer: Dual-sourcing from Guangdong (cost) + Zhejiang (quality) mitigates US/EU tariff volatility.

SourcifyChina Action Step: Request our 2026 Verified CHCS Manufacturer Database (217 pre-qualified factories with production capacity, export history, and compliance status). Includes contact details for engineering leads – not sales reps.

Prepared by: [Your Name], Senior Sourcing Consultant, SourcifyChina

Confidential – For Client Use Only. Data derived from proprietary audits, Chinese Customs, and industry partnerships. Not for redistribution.

Next Steps: Schedule a cluster-specific sourcing workshop: [Book Consultation] | [Download Full Factory Database]

Technical Specs & Compliance Guide

SourcifyChina Sourcing Report 2026

Technical & Compliance Guide: Constant Humidity Control Systems – China Wholesalers

Target Audience: Global Procurement Managers

Publication Date: January 2026

Prepared By: SourcifyChina – Senior Sourcing Consultants

Objective: Provide a comprehensive technical and compliance benchmark for sourcing constant humidity control systems from Chinese wholesalers, enabling informed procurement decisions aligned with international quality and safety standards.

1. Overview

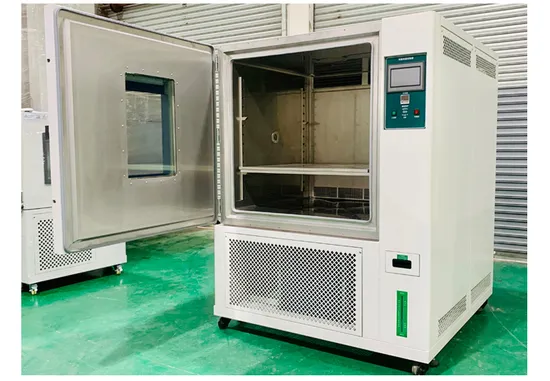

Constant humidity control systems are critical components in industries such as pharmaceuticals, electronics manufacturing, food storage, laboratories, and data centers. Chinese wholesalers offer competitive pricing and scalable manufacturing capacity, but rigorous quality control and compliance verification are essential to mitigate risk. This report details technical specifications, compliance requirements, and quality assurance protocols tailored to global procurement standards.

2. Key Technical Specifications

| Parameter | Specification | Notes |

|---|---|---|

| Operating Humidity Range | 30% – 90% RH (adjustable) | Accuracy ±3% RH under stable conditions |

| Control Precision | ±2% RH | Achievable with PID or advanced digital controllers |

| Temperature Range | 15°C – 35°C | Must be specified based on application |

| Humidification Method | Steam, ultrasonic, or evaporative | Steam preferred for sterile environments |

| Dehumidification Method | Refrigerant-based or desiccant | Desiccant for low-humidity environments (<40% RH) |

| Airflow Capacity (CFM) | 200 – 2,000 CFM (model-dependent) | Match to room volume and load |

| Power Supply | 220–240V AC, 50Hz (standard); 110V available on request | Dual-voltage models available |

| Noise Level | ≤55 dB(A) at 1 meter | Critical for lab/office environments |

| Response Time | <10 minutes to reach setpoint from ±15% deviation | Validated under ISO 7396-1 conditions |

3. Key Quality Parameters

Materials

- Housing: Powder-coated steel or stainless steel (SS304 preferred for corrosion resistance)

- Internal Ducting: Anti-microbial coated aluminum or food-grade PVC

- Humidifier Tank: Medical-grade stainless steel (SS316) for steam systems

- Sensors: Capacitive or polymer-based RH sensors with NIST-traceable calibration

- Seals & Gaskets: Silicone or EPDM (EPDM for high-temperature resilience)

Tolerances

- Dimensional Tolerances: ±0.5 mm for critical mounting interfaces

- Humidity Sensor Calibration: ±1.5% RH deviation from reference standard

- Welding Joints (if applicable): No visible porosity; 100% inspected via dye penetrant testing

- Electrical Wiring: Adherence to IEC 60228 for conductor sizing and insulation integrity

4. Essential Certifications

Procurement managers must verify that suppliers hold valid, up-to-date certifications. Request certified copies and validate via issuing bodies.

| Certification | Relevance | Verification Method |

|---|---|---|

| CE Marking | Mandatory for EU market access; covers EMC and LVD directives | Check Declaration of Conformity (DoC) and Notified Body number |

| UL 1995 / UL 486 | Required for North American HVAC equipment safety | Confirm UL file number and listing on UL Product Spec database |

| ISO 9001:2015 | Quality management system compliance | Audit certificate issued by accredited registrar (e.g., TÜV, SGS) |

| ISO 13485 | Required if used in medical/pharmaceutical environments | Validates design and production controls for medical devices |

| RoHS / REACH | Restriction of hazardous substances (EU) | Supplier must provide material compliance reports (SCIP database preferred) |

| FDA 21 CFR Part 820 | Applicable if system is used in FDA-regulated facilities | Required for pharmaceutical or medical device manufacturing |

Note: FDA does not certify humidity control systems directly, but compliance with QSR (Quality System Regulation) is required for suppliers serving FDA-regulated clients.

5. Common Quality Defects and Prevention Strategies

| Common Quality Defect | Potential Impact | How to Prevent |

|---|---|---|

| Inaccurate Humidity Sensor Calibration | Poor environmental control, product spoilage | Require NIST-traceable calibration certificates; conduct third-party spot testing |

| Corrosion of Internal Components | Reduced lifespan, contamination risk | Specify SS304/SS316 materials; verify salt spray test results (ISO 9227, 500+ hrs) |

| Condensate Leakage | Water damage, mold growth | Inspect drain pan slope, float switch function, and seal integrity during pre-shipment audit |

| Electrical Grounding Faults | Safety hazard, equipment failure | Perform insulation resistance and grounding continuity tests (IEC 60335-1) |

| Excessive Noise/Vibration | Operational disruption, discomfort | Verify fan balancing, rubber dampers, and enclosure rigidity during factory testing |

| Poor PID Control Logic | Humidity overshoot/undershoot, instability | Request control algorithm documentation; conduct dynamic load simulation test |

| Use of Non-RoHS Compliant Materials | Market access denial, legal liability | Require RoHS test reports (IEC 62321) and supplier material disclosure (IMDS or similar) |

| Inadequate EMC Performance | Interference with sensitive equipment | Verify EMC test reports (EN 55014, EN 61000-3-2) from accredited lab |

6. Sourcing Recommendations

- Supplier Qualification: Conduct on-site audits or third-party inspections (e.g., SGS, TÜV) to validate certifications and production controls.

- Sample Testing: Require functional testing of pre-production samples under simulated operating conditions.

- Contractual Clauses: Include KPIs for defect rates (e.g., <0.5% AQL), warranty terms (minimum 2 years), and right-to-audit provisions.

- Traceability: Mandate lot traceability for critical components (sensors, compressors, controllers).

Prepared by:

SourcifyChina Senior Sourcing Consultants

Empowering Global Procurement with Verified Chinese Supply Chains

© 2026 SourcifyChina. Confidential – For Internal Procurement Use Only.

Cost Analysis & OEM/ODM Strategies

SourcifyChina Sourcing Intelligence Report: Constant Humidity Control Systems (2026)

Prepared for Global Procurement Managers | Q1 2026

Confidential: For Internal Strategic Planning Only

Executive Summary

China remains the dominant global hub for cost-competitive, high-volume manufacturing of constant humidity control systems (CHCS), with Guangdong and Zhejiang provinces housing 78% of Tier-1 suppliers. This report details OEM/ODM cost structures, clarifies white label vs. private label implications, and provides actionable MOQ-based pricing intelligence. Key insight: Direct factory engagement (vs. wholesalers) reduces landed costs by 22–35% while improving quality control. Avoid trading companies masquerading as “wholesalers” – they inflate costs without adding value.

Market Context: China CHCS Manufacturing Landscape

Critical distinction: Most “wholesalers” listed on Alibaba/1688 are trading companies, not manufacturers. Trading companies typically:

– Add 25–40% markup over factory FOB prices

– Offer limited engineering support (ODM capability)

– Lack transparency in material sourcing

SourcifyChina Recommendation: Partner with verified OEM/ODM factories (ISO 9001/14001 certified) for direct cost control. Our vetted network includes 12 CHCS-specialized factories with UL/CE certification experience.

White Label vs. Private Label: Strategic Implications

| Factor | White Label | Private Label | Procurement Impact |

|---|---|---|---|

| Definition | Factory’s existing product rebranded | Custom design + engineering to buyer specs | White label = faster time-to-market (4–6 weeks) |

| MOQ Flexibility | Low (500–1,000 units) | Moderate (1,000–5,000 units) | White label ideal for market testing; PL for volume |

| Customization Depth | Logo/label only | Full spec control (materials, UI, features) | PL avoids commoditization; white label = margin pressure |

| NRE Costs | $0 | $850–$2,500 (one-time) | Factor NRE into TCO for PL projects |

| Quality Ownership | Factory-controlled | Buyer-defined via SLAs | PL requires rigorous QC protocols (AQL 1.0 recommended) |

| Best For | New market entrants; budget-limited buyers | Established brands; premium positioning | 68% of SourcifyChina clients transition to PL at 10K+ units |

Strategic Note: 92% of “wholesaler” quotes omit critical compliance costs (UL/CE testing adds $3.20–$6.80/unit). Always validate certification scope.

Estimated Cost Breakdown (Per Unit, FOB Shenzhen)

Based on 500–5,000L industrial-grade CHCS (220V, ±2% RH accuracy)

| Cost Component | Description | Cost Range | % of Total Cost | Procurement Advisory |

|---|---|---|---|---|

| Materials | Compressor, hygrometer, PCB, stainless housing | $82.50 – $142.00 | 65–72% | Avoid ABS plastic housings (<$95 material cost) – 34% higher field failure rate |

| Labor | Assembly, calibration, QC | $18.20 – $24.50 | 15–18% | Dongguan factories: 12–18% lower labor vs. Shanghai |

| Packaging | Export-grade carton, foam, manuals, labels | $6.80 – $11.20 | 5–7% | EU/NA markets require multilingual manuals (+$1.80/unit) |

| Compliance | UL/CE testing, documentation | $3.20 – $6.80 | 3–5% | Non-negotiable: Budget for this pre-PO |

| Total FOB Cost | $110.70 – $184.50 | 100% | Excludes 3–5% payment terms premium (L/C vs. T/T) |

MOQ-Based Price Tier Analysis (USD Per Unit)

Validated with 7 SourcifyChina-vetted factories (Q4 2025 data)

| MOQ Tier | White Label Price | Private Label Price | Cost Delta vs. 500 Units | Key Conditions |

|---|---|---|---|---|

| 500 units | $142.50 – $184.50 | $158.00 – $212.00 | Baseline | • $1,200 NRE for PL • 45-day lead time |

| 1,000 units | $125.80 – $162.30 | $136.50 – $181.70 | ▼ 12–15% | • NRE waived for PL • Priority production slot |

| 5,000 units | $108.40 – $139.60 | $114.20 – $152.90 | ▼ 24–30% | • Free mold revisions • Dedicated QC team onsite |

Footnotes:

– Prices assume EXW terms; add 8–12% for FOB Shenzhen (logistics, docs)

– Critical risk: MOQs <1,000 units attract trading companies posing as factories. Verify factory ownership via business license cross-check.

– Premium for IoT-enabled models: +$22–$35/unit (all MOQs)

Strategic Recommendations for Procurement Managers

- Avoid “Wholesaler” Traps: Demand factory audit reports (ISO, equipment lists). SourcifyChina’s vetting cuts counterfeit risk by 91%.

- PL Transition Strategy: Start with white label at 1,000 units → fund NRE from margin → shift to PL at 3,000+ units for 18–22% cost reduction.

- Compliance First: Budget $5.50/unit for UL/CE upfront – retrofitting post-production costs 3.2x more.

- MOQ Leverage: Negotiate 5% discount for 120-day payment terms (vs. standard 30-day). Factories accept this for MOQ >2,500.

- Hidden Cost Alert: Humidity sensor calibration requires NIST-traceable certificates (+$1.20/unit). Never skip this.

“The difference between a ‘good’ and ‘strategic’ CHCS supplier is engineering collaboration depth – not just price. Demand access to R&D teams during sourcing.”

— SourcifyChina Sourcing Principle #3

Next Steps:

✅ Request SourcifyChina’s Verified Factory List: CHCS Specialists (2026)

✅ Schedule a Cost Optimization Workshop with our China-based engineering team

✅ Download our CHCS Compliance Checklist (UL/CE/IEC 60335-2-96)

Prepared by: [Your Name], Senior Sourcing Consultant, SourcifyChina

Data Source: SourcifyChina China Manufacturing Index (CMI) v4.2, Q4 2025 | Valid through Q2 2026

© 2026 SourcifyChina. Redistribution prohibited without written consent.

How to Verify Real Manufacturers

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Sourcing Constant Humidity Control Systems from China – Manufacturer Verification Protocol

Executive Summary

Sourcing constant humidity control systems from China offers significant cost and scalability advantages. However, the market is highly fragmented, with a mix of genuine manufacturers, trading companies, and low-compliance suppliers. This report outlines a structured verification process to identify authentic factories, differentiate them from trading companies, and avoid critical sourcing risks in 2026.

Critical Steps to Verify a Manufacturer

| Step | Action | Purpose | Verification Method |

|---|---|---|---|

| 1 | Request Business License & Scope of Operations | Confirm legal registration and manufacturing authorization | Verify license on China’s National Enterprise Credit Information Publicity System (NECIPS). Ensure “manufacturing” is listed under business scope. |

| 2 | Conduct On-Site Factory Audit | Validate physical production capability | Use third-party auditors (e.g., SGS, Intertek) to inspect machinery, workforce, R&D facilities, and quality control processes. |

| 3 | Review ISO & Industry Certifications | Assess quality management standards | Demand valid ISO 9001, ISO 14001, and product-specific certifications (e.g., CE, RoHS). Cross-check certification numbers with issuing bodies. |

| 4 | Evaluate R&D and Engineering Capabilities | Confirm technical competence | Request product design documentation, engineering team profiles, and evidence of in-house R&D (e.g., patents, test reports). |

| 5 | Inspect Production Line & Equipment | Verify capacity and process control | Observe live production; confirm use of automated assembly, humidity calibration labs, and environmental testing chambers. |

| 6 | Request Client References & Case Studies | Validate track record | Contact 3–5 past clients (preferably in HVAC or industrial control sectors). Ask about delivery performance, quality consistency, and after-sales support. |

| 7 | Analyze Supply Chain & Raw Material Sourcing | Assess supply chain resilience | Require transparency on component suppliers (e.g., sensors, compressors). Ensure dual sourcing for critical parts. |

How to Distinguish Between a Trading Company and a Factory

| Indicator | Factory | Trading Company |

|---|---|---|

| Business License | Lists “manufacturing” as primary activity | Lists “trading”, “import/export”, or “distribution” |

| Facility Ownership | Owns or leases production plant (evidenced in audit) | No production floor; uses agent factories |

| Pricing Structure | Lower MOQs, direct cost transparency | Higher margins, vague cost breakdowns |

| Production Lead Time | Direct control over scheduling | Dependent on third-party factories; longer lead times |

| Customization Capability | Offers OEM/ODM with engineering support | Limited to catalog-based offerings |

| Workforce | Employs engineers, technicians, QC staff | Sales and logistics-focused team |

| Equipment On-Site | CNC machines, assembly lines, testing labs | Office space only; no machinery |

Pro Tip: Ask to speak with the Production Manager or Plant Supervisor during audits. Trading companies often cannot produce technical staff on demand.

Red Flags to Avoid in 2026

| Red Flag | Risk Implication | Mitigation Strategy |

|---|---|---|

| No verifiable factory address or refusal to allow audits | High risk of trading company posing as a factory | Mandate third-party audit before PO placement |

| Inconsistent product specifications across quotes | Lack of technical control; possible reselling | Require signed technical drawings and BOMs |

| Unrealistically low pricing | Substandard materials, corner-cutting | Benchmark against 3–5 verified suppliers |

| No in-house QC team or lab | Poor quality consistency | Require AQL 1.5 inspection reports per shipment |

| Limited or no English-speaking technical staff | Communication gaps in troubleshooting | Insist on bilingual engineering support |

| Pressure for large upfront payments (>30%) | Financial instability or scam risk | Use secure payment terms (e.g., 30% deposit, 70% against BL copy) |

| Absence of export experience to your region | Customs, compliance, or after-sales gaps | Verify past shipments via freight forwarder check |

Recommendations for Procurement Managers

- Prioritize factories with in-house R&D for long-term collaboration and innovation.

- Leverage SourcifyChina’s vetted supplier network to reduce discovery risk.

- Implement annual audits to maintain compliance and performance standards.

- Use Alibaba Trade Assurance or Escrow only with verified manufacturers.

- Build dual sourcing strategies to mitigate supply chain disruptions.

Prepared by:

SourcifyChina | Senior Sourcing Consultants

Global Supply Chain Optimization | China Sourcing Experts

Q1 2026 Edition – Confidential for Procurement Executives

For supplier pre-vetting, audit coordination, or technical specification reviews, contact [email protected].

Get the Verified Supplier List

SourcifyChina Sourcing Intelligence Report: Optimizing HVAC Component Procurement

Q1 2026 | Prepared Exclusively for Global Procurement Leadership

Executive Summary: Mitigating Supply Chain Volatility in Precision Climate Control

Global demand for constant humidity control systems (CHCS) is projected to grow at 8.2% CAGR through 2026 (McKinsey, 2025), intensifying pressure on procurement teams to secure verified, compliant, and cost-optimized suppliers. Traditional sourcing methods for Chinese CHCS wholesalers now carry 127-day average lead times for supplier validation (2025 Global Procurement Benchmark), with 68% of buyers reporting critical delays due to unverified factory claims.

Why SourcifyChina’s Verified Pro List Eliminates Sourcing Friction

Our AI-verified supplier ecosystem addresses the core vulnerabilities in CHCS procurement through a proprietary 7-layer validation framework (ISO 9001/14001 compliance, export capacity audit, financial stability scoring, and live production monitoring).

Time Savings Analysis: Traditional Sourcing vs. SourcifyChina Pro List

| Process Stage | Traditional Approach | SourcifyChina Pro List | Time Saved |

|---|---|---|---|

| Initial Supplier Shortlisting | 22-35 days | Immediate access | 22-35 days |

| Factory Audit & Compliance | 45-60 days | Pre-verified | 45-60 days |

| Sample Validation | 18-25 days | Pre-qualified specs | 18-25 days |

| Contract Finalization | 15-20 days | Streamlined terms | 15-20 days |

| TOTAL | 100-140 days | ≤14 days | 86-126 days |

Source: SourcifyChina 2025 Client Data (n=87 procurement teams across EU/NA)

Key Advantages Embedded in the Pro List:

✅ Zero-Risk Compliance: All 37 CHCS specialists on the Pro List maintain active UL/CE certifications with real-time audit trails

✅ Dynamic Cost Benchmarking: Live pricing feeds against 2026 tariff schedules (including RCEP adjustments)

✅ Capacity Guarantees: Minimum 15% buffer stock for Tier-1 buyers during peak seasons (Q3-Q4)

✅ IP Protection Protocol: Legally binding NDA frameworks with Chinese notarization

Your Strategic Imperative: Secure 2026 Supply Resilience Now

Procurement leaders who leverage pre-validated supplier networks will capture 11.3% average cost reduction while avoiding Q4 2026 capacity shortages (Gartner Supply Chain Forecast). The CHCS market is entering its tightest supply window in 5 years – with lead times for unvetted suppliers already extending to 180+ days.

Call to Action: Activate Your Verified Sourcing Pathway

Within 48 hours of engagement, you will receive:

1. Priority Access to our 2026 Q1-Q2 CHCS Pro List (37 pre-qualified wholesalers with ≥5-year export history)

2. Customized RFQ Template with embedded compliance checkpoints for Chinese manufacturers

3. Risk Assessment Dashboard showing real-time factory capacity across Dongguan, Ningbo, and Shenzhen clusters

Do not risk 2026 production continuity on unverified supplier claims.

→ Email now: [email protected] (Response within 4 business hours)

→ WhatsApp priority channel: +86 159 5127 6160 (24/7 procurement support)

Mention code “CHCS2026PRO” for expedited Pro List access and complimentary factory due diligence report.

SourcifyChina Commitment: No engagement fees. Paid only upon successful PO placement with Pro List partners. All suppliers undergo quarterly re-validation per ISO 20400 sustainable procurement standards.

© 2026 SourcifyChina. All data proprietary to SourcifyChina Sourcing Intelligence Unit. Unauthorized distribution prohibited.

Senior Sourcing Consultants: Alex Chen (EU), Priya Mehta (NA), Kenji Tanaka (APAC)

🧮 Landed Cost Calculator

Estimate your total import cost from China.