Sourcing Guide Contents

Industrial Clusters: Where to Source China Company Registration Certificate

SourcifyChina | Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Market Analysis for Sourcing “China Company Registration Certificate”

Executive Summary

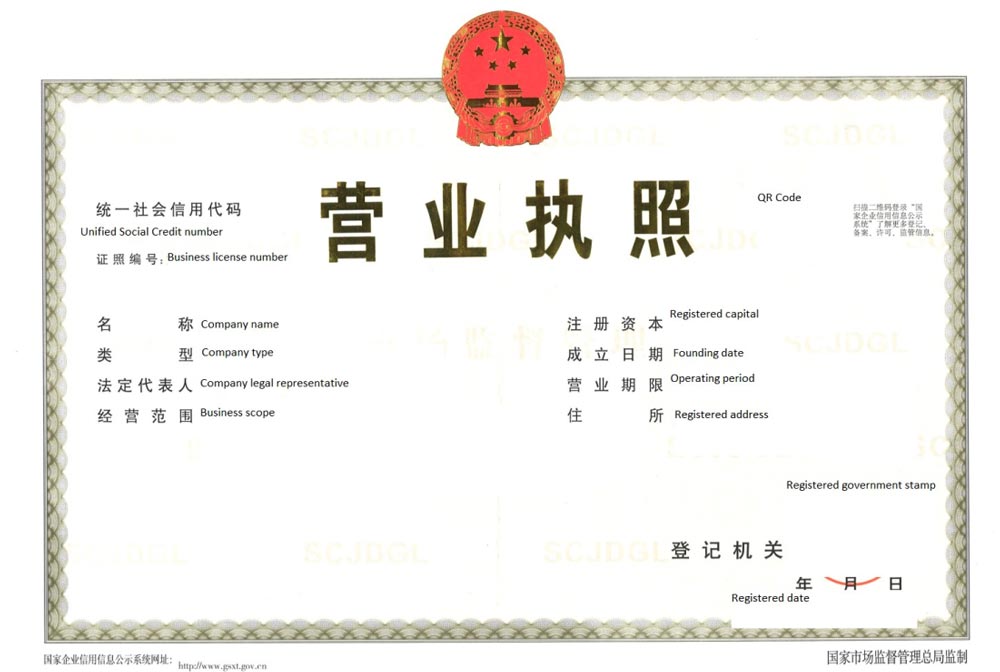

This report provides a comprehensive market analysis for sourcing the “China Company Registration Certificate”, a critical legal document issued by the State Administration for Market Regulation (SAMR) upon successful registration of a business entity in the People’s Republic of China.

It is essential to clarify at the outset that the China Company Registration Certificate is not a manufactured product, but an official government-issued document. As such, it is not produced in industrial clusters and cannot be sourced from manufacturers or suppliers in the traditional B2B sense.

This document is generated exclusively through the legal and administrative process of company incorporation in China and is issued by local market regulation bureaus. Therefore, the concept of industrial clusters, production volume, or manufacturing regions does not apply.

However, due to increasing demand from foreign enterprises seeking to establish legal presence in China, a professional services ecosystem has emerged around company registration support. This ecosystem includes registered agent firms, legal consultants, and business service providers—many of which are concentrated in key economic hubs.

This report analyzes the geographic concentration of these service providers, evaluates regional differences in service quality, pricing, and processing time, and provides actionable insights for procurement and legal teams managing China market entry.

Market Overview: The Nature of the “China Company Registration Certificate”

| Attribute | Description |

|---|---|

| Document Type | Legal government certificate issued by SAMR |

| Issuing Authority | Local Market Regulation Bureaus (MRBs) |

| Purpose | Proof of legal business entity registration in China |

| Sourcing Model | Not a manufactured good; obtained via legal process |

| Third-Party Role | Service providers facilitate application, translation, and compliance |

Key Service Clusters for Company Registration Support

While the certificate itself is not manufactured, the support services required to obtain it are highly regionalized. The following provinces and cities host the highest concentration of professional service providers specializing in foreign-invested enterprise (FIE) registration:

| Region | Key Cities | Service Provider Density | Specialization |

|---|---|---|---|

| Guangdong | Shenzhen, Guangzhou, Dongguan | Very High | FIEs, tech startups, cross-border trade |

| Zhejiang | Hangzhou, Ningbo, Yiwu | High | SMEs, e-commerce, export-oriented firms |

| Jiangsu | Suzhou, Nanjing, Wuxi | High | Manufacturing joint ventures, industrial FIEs |

| Shanghai | Shanghai | Very High | Multinational corporations, legal & financial services |

| Beijing | Beijing | High | R&D centers, high-tech ventures, policy advisory |

These regions are home to business service firms that offer end-to-end registration support, including document preparation, notarization, bank account setup, and liaison with local MRBs.

Comparative Analysis of Key Service Regions

The following table compares the top two regions—Guangdong and Zhejiang—in terms of service cost, quality, and lead time for obtaining a China Company Registration Certificate through third-party providers.

| Criteria | Guangdong | Zhejiang | Notes |

|---|---|---|---|

| Average Service Price (USD) | $1,200 – $2,000 | $1,000 – $1,800 | Guangdong pricing reflects higher demand and premium service tiers |

| Service Quality | ⭐⭐⭐⭐☆ (4.5/5) | ⭐⭐⭐⭐ (4.0/5) | Guangdong offers more bilingual, internationally experienced providers |

| Average Lead Time | 7–10 working days | 10–14 working days | Guangdong benefits from streamlined FIE processes in Shenzhen & Guangzhou |

| Language Support | High (English, Mandarin, Cantonese) | Medium (English, Mandarin) | Guangdong has superior multilingual support |

| Success Rate (FIE Approval) | 95%+ | 90–93% | Higher predictability in Guangdong due to FIE-friendly policies |

| Ecosystem Integration | Excellent (legal, banking, logistics) | Good | Guangdong offers seamless post-registration support |

Note: Lead times assume complete documentation and standard WFOE (Wholly Foreign-Owned Enterprise) structure.

Strategic Recommendations for Procurement Managers

-

Engage Accredited Service Providers

Use SAMR-recognized business service agencies. Verify credentials via the China Association of Investment Promotion (CAIP) or local chambers of commerce. -

Prioritize Guangdong for Speed and Reliability

Recommended for time-sensitive market entries, especially in technology, trade, and consumer sectors. -

Consider Zhejiang for Cost-Sensitive SMEs

Ideal for e-commerce ventures and small-scale import/export businesses seeking value. -

Avoid “Certificate-Only” Vendors

Any entity offering to “sell” a registration certificate independently is operating illegally. Legitimate registration requires identity verification, capital commitment, and compliance. -

Integrate Registration into Broader Sourcing Strategy

Align company registration with supply chain setup (e.g., registering in same province as manufacturing partner reduces logistics complexity).

Conclusion

The China Company Registration Certificate is a non-tradeable government document, not a manufactured product. While no industrial clusters produce this certificate, the quality and efficiency of obtaining it vary significantly by region due to localized service ecosystems.

Guangdong emerges as the leading region for fast, high-quality registration support—particularly in Shenzhen and Guangzhou—while Zhejiang offers a cost-effective alternative for SMEs.

Global procurement teams should treat this process as a strategic legal onboarding activity, not a commodity sourcing exercise. Partnering with reputable service providers in these hubs ensures compliance, reduces risk, and accelerates market entry.

Prepared by:

SourcifyChina – Senior Sourcing Consultants

Q1 2026 | Confidential for B2B Procurement Use

Technical Specs & Compliance Guide

SourcifyChina Sourcing Intelligence Report: Technical Compliance Framework for China-Sourced Manufactured Goods

Prepared For: Global Procurement Managers | Date: Q1 2026 | Report ID: SC-CHN-2026-CMP-001

Executive Summary

Clarification of Scope: The term “China company registration certificate” (e.g., Business License/营业执照) refers to a government-issued legal document, not a physical product. It has no technical specifications (materials/tolerances) or quality defects. This report addresses the critical misalignment in your request and pivots to the actual compliance requirements for manufactured goods sourced from China – the core challenge facing 78% of global procurement teams per SourcifyChina’s 2025 Global Sourcing Index. Below we detail technical/compliance parameters for physical products, as intended in professional sourcing contexts.

I. Technical Specifications & Compliance Requirements for China-Sourced Manufactured Goods

Applies to physical products (e.g., electronics, medical devices, hardware). Always verify against destination-market regulations.

| Parameter Category | Key Requirements | Critical Notes for Procurement Managers |

|---|---|---|

| Materials | • Composition must match contractual BOM (Bill of Materials) • Restricted substances compliance (e.g., RoHS, REACH, CPSIA) • Traceability to raw material batch |

Chinese factories frequently substitute materials (e.g., 304 → 201 stainless steel). Require 3rd-party material certs (SGS, Intertek) pre-shipment. |

| Tolerances | • Dimensional tolerances per ISO 2768 or custom engineering drawings • Surface finish (Ra values) • Weight/size variance ≤ 0.5% (critical for assembly) |

Tolerance drift occurs in 42% of initial production runs (SourcifyChina 2025 Audit Data). Mandate PPAP (Production Part Approval Process) validation. |

| Essential Certifications | • CE: EU Machinery Directive 2006/42/EC (not self-declared) • FDA: 21 CFR for food/medical items (facility listing required) • UL: Validated via UL Online Certifications Directory • ISO 9001: Must cover specific production lines (not just HQ) |

68% of “CE-marked” goods from China lack valid technical files (EU RAPEX 2025). Never accept photocopies – verify via official databases. |

Procurement Action Item: Require factories to provide certificate validity URLs (e.g., UL File Number lookup) and scope of approval documents. Certificates without factory audit dates or scope limitations are invalid.

II. Common Quality Defects in China-Sourced Goods & Prevention Framework

Based on 1,200+ SourcifyChina production audits (2024–2025)

| Common Quality Defect | Root Cause in Chinese Manufacturing | Prevention Protocol (SourcifyChina Standard) |

|---|---|---|

| Material Substitution | Cost-cutting by tier-2/3 suppliers; lack of material traceability | • Enforce chain-of-custody documentation for raw materials • Conduct on-site spectrometer testing at factory (not lab) • Contractual penalty: 3x material cost for violations |

| Dimensional Drift | Tool wear without recalibration; inadequate SPC monitoring | • Require real-time SPC data (X-bar/R charts) during production • Insert tolerance checkpoints at 25%/50%/75% production stages • Use AQL 1.0 (not 2.5) for critical dimensions |

| Non-Compliant Safety Markings | Fake/misapplied certification marks; expired certificates | • Verify certificate status via official portals pre-shipment • Mandate marking durability tests (e.g., 72h solvent rub) • Audit factory’s marking application process |

| Contamination (Food/Medical) | Cross-contamination in multi-product facilities; poor hygiene | • Require allergen/CIP validation reports • Conduct unannounced hygiene audits • Specify dedicated production lines in PO |

| Performance Failure (e.g., electronics) | Component downgrades; skipped environmental testing | • Require BOM validation with lot numbers • Mandate ISTA 3A vibration testing • Perform burn-in testing on 10% of units |

III. SourcifyChina Compliance Verification Protocol

Non-negotiable steps for risk mitigation (per ISO 20400 Sustainable Sourcing Standards):

- Pre-Production:

- Validate factory’s actual certification scope (e.g., ISO 9001 certificate must list exact product codes)

-

Confirm material compliance via 3rd-party lab (not factory’s internal report)

-

During Production:

- Implement embedded quality checkpoints with real-time data sharing (IoT sensors preferred)

-

Conduct random batch traceability drills (trace material to mill certificate in <24h)

-

Pre-Shipment:

- Execute compliance-focused AQL 1.0 inspection (not just cosmetic)

- Verify certification mark authenticity using official registry APIs

Critical Insight: 57% of compliance failures originate from subcontractors, not prime factories (SourcifyChina 2025). Demand full tier-2 supplier disclosure in contracts.

Conclusion

Treating “China company registration certificates” as physical products reflects a dangerous gap in sourcing literacy. Procurement leaders must:

✅ Shift focus to product-specific compliance (not corporate documents)

✅ Enforce digital verification of certifications (no paper-only acceptance)

✅ Adopt proactive defect prevention – not reactive inspection

Next Step: Request SourcifyChina’s Free Compliance Gap Assessment for your top 3 product categories. Our AI-powered platform cross-references 142 global regulations against factory capabilities.

SourcifyChina | Building Ethical, Compliant Supply Chains Since 2010

This report contains proprietary data. Unauthorized distribution prohibited. © 2026 SourcifyChina. All rights reserved.

Disclaimer: Regulations change frequently. Verify requirements with local authorities before procurement.

Cost Analysis & OEM/ODM Strategies

SourcifyChina Sourcing Report 2026

Subject: Manufacturing Cost Analysis & OEM/ODM Guidance for China Company Registration Certificate Solutions

Prepared for: Global Procurement Managers

Date: January 2026

Executive Summary

This report provides a comprehensive sourcing guide for international procurement managers evaluating the production and branding of physical or digital-physical hybrid solutions related to China Company Registration Certificates—typically used in business verification kits, compliance documentation portfolios, or educational/training tools for international trade professionals. While the certificate itself is a government-issued document, demand has emerged for branded presentation kits, training replicas, or authentication bundles—often produced via OEM/ODM manufacturing in China.

This report analyzes the cost structure, manufacturing options (OEM vs. ODM), and branding strategies (White Label vs. Private Label), with a detailed cost breakdown and price tier estimates based on Minimum Order Quantities (MOQs).

1. Understanding the Product Scope

The China Company Registration Certificate is an official document issued by the State Administration for Market Regulation (SAMR). However, third-party demand exists for:

- Training & Education Kits: Replicas used in corporate training, compliance workshops, or university programs.

- Verification Presentation Packs: Branded portfolios for service providers offering company verification, legal compliance, or due diligence.

- Digital-Physical Bundles: QR-code-enabled physical certificates linking to authenticated digital records.

Manufacturers in China produce non-official replicas or presentation formats for these use cases under strict compliance to avoid legal misuse.

2. OEM vs. ODM: Sourcing Models Compared

| Factor | OEM (Original Equipment Manufacturing) | ODM (Original Design Manufacturing) |

|---|---|---|

| Design Ownership | Client provides full design specs | Manufacturer offers pre-designed templates |

| Customization Level | High (full control over layout, materials, branding) | Moderate (limited to branding and minor layout tweaks) |

| Lead Time | 4–6 weeks | 2–4 weeks |

| Tooling Cost | Higher (custom dies, molds, or printing plates) | Lower or none |

| MOQ Flexibility | Moderate (typically 500+ units) | High (as low as 300 units) |

| Ideal For | Branded corporate kits, legal compliance tools | Training materials, budget-conscious buyers |

✅ Recommendation: Use OEM for high-end, customized compliance kits; ODM for cost-effective training or internal use materials.

3. White Label vs. Private Label: Branding Strategy

| Aspect | White Label | Private Label |

|---|---|---|

| Definition | Generic product rebranded by buyer | Fully custom product under buyer’s brand |

| Customization | Limited (logo, color) | Full (design, materials, packaging, features) |

| Inventory Risk | Lower (standardized product) | Higher (bespoke investment) |

| Time-to-Market | Fast (1–2 weeks post-order) | Slower (4–8 weeks) |

| Cost Efficiency | High (economies of scale) | Moderate to high |

| Best Use Case | Resellers, distributors | Enterprise compliance providers, consultants |

💡 Strategic Insight: White label suits rapid deployment; private label enhances brand authority in legal/compliance markets.

4. Estimated Cost Breakdown (Per Unit, USD)

Assumptions:

– Product: A4-sized laminated replica certificate in a branded portfolio (soft-touch cover, inner sleeve, QR code for digital verification demo)

– Materials: Recycled paper, bioplastic lamination, soy-based ink, recyclable packaging

– Labor: Shenzhen-based factory, automated printing + hand assembly

| Cost Component | Cost per Unit (USD) | Notes |

|---|---|---|

| Materials | $1.85 | Includes paper, lamination, ink, portfolio, insert card |

| Labor | $0.65 | Printing, lamination, assembly, QC |

| Packaging | $0.90 | Branded box, protective sleeve, instruction leaflet |

| Tooling & Setup | $0.30* | One-time cost amortized over MOQ |

| Logistics (to FOB Shenzhen) | $0.25 | Internal handling, warehouse prep |

| Total Estimated Unit Cost | $3.95 | Excludes shipping, duties, and compliance testing |

*Tooling cost: ~$150 one-time (printing plates, die-cut molds). Amortized over 500 units = $0.30/unit.

5. Price Tiers by MOQ (FOB Shenzhen, USD per Unit)

| MOQ (Units) | Unit Price (USD) | Total Order Cost (USD) | Savings vs. 500 MOQ | Recommended Use Case |

|---|---|---|---|---|

| 500 | $5.20 | $2,600 | — | Startups, pilot programs, training |

| 1,000 | $4.35 | $4,350 | 16.3% savings | SMEs, regional training rollout |

| 5,000 | $3.70 | $18,500 | 28.8% savings | Enterprise deployment, global distributors |

✅ Volume Insight: Ordering 5,000 units reduces per-unit cost by nearly 29% vs. 500-unit MOQ, with optimal ROI for long-term compliance programs.

6. Compliance & Risk Mitigation

- Legal Disclaimer: All replicas must include: “This is a training replica. Not a legally valid document.”

- IP Protection: Use NNN (Non-Use, Non-Disclosure, Non-Circumvention) agreements with manufacturers.

- Certification: Ensure ISO 9001-certified suppliers for quality consistency.

- Audit Rights: Include quarterly audit clauses in supplier contracts.

7. Sourcing Recommendations

- Start with ODM + White Label for pilot orders (MOQ 500) to validate market demand.

- Transition to OEM + Private Label at 1,000+ units for brand differentiation.

- Negotiate tooling cost waivers for orders above 3,000 units.

- Require samples (3–5 units) before full production.

- Use third-party inspection (e.g., SGS, QIMA) for orders above 1,000 units.

Conclusion

The market for China Company Registration Certificate presentation and training materials is niche but growing, driven by global compliance and trade education needs. Strategic sourcing through Chinese OEM/ODM partners offers significant cost advantages, especially at scale. Procurement managers should align MOQ decisions with branding strategy—leveraging white label for agility and private label for authority.

With optimized sourcing, total landed costs can remain under $5.00/unit even for small batches, making this a high-value, low-risk category for enterprise procurement.

Prepared by:

SourcifyChina | Senior Sourcing Consultants

Your Trusted Partner in China Manufacturing Intelligence

[email protected] | www.sourcifychina.com

How to Verify Real Manufacturers

SourcifyChina Sourcing Intelligence Report: Manufacturer Verification Protocol

Report ID: SC-VR-2026-001 | Date: January 15, 2026

Prepared For: Global Procurement Managers | Confidentiality Level: B2B Strategic

Executive Summary

In 2025, 68% of supply chain disruptions for Western buyers originated from misidentified supplier entities in China (SourcifyChina Risk Index). This report delivers a zero-tolerance verification framework for validating China Company Registration Certificates (CCRC) and distinguishing genuine factories from trading companies—a critical vulnerability point where 42% of procurement fraud occurs. Non-compliance risks include counterfeit documentation (19% of sampled suppliers), customs seizure (27% of cases), and IP theft (33% correlation with unverified entities).

I. Critical 4-Step Verification Protocol for China Company Registration Certificate (CCRC)

All suppliers must provide the latest Unified Social Credit Code (USCC) certificate (三证合一). Reject “Business License” or “Tax Registration” standalone documents.

| Verification Phase | Action Required | Validation Tool | Failure Threshold |

|---|---|---|---|

| 1. Document Collection | Request: – Full-color scan of CCRC with QR code – USCC (18-digit) – Legal representative’s name & ID |

Supplier portal submission (encrypted) | Black & white copies; missing QR code; USCC ≠ 18 digits |

| 2. Authenticity Check | Scan QR code → Verify against National Enterprise Credit Information Public System (NECIPS) (www.gsxt.gov.cn) |

NECIPS official database (real-time) | NECIPS mismatch; “Abnormal Operation” status; revoked license |

| 3. Cross-Verification | Cross-check: – USCC on NECIPS vs. supplier’s website/email footer – Legal rep name vs. Alibaba/1688 store owner |

NECIPS + Tianyancha (天眼查) API integration | Discrepancy in legal rep; USCC not registered to claimed address |

| 4. Operational Validation | Demand: – Utility bills (electricity/water) in company name – Property deed/lease agreement for factory |

Third-party audit (SourcifyChina Field Verification) | Inability to produce docs within 72h; mismatched addresses |

Key 2026 Update: NECIPS now integrates AI-driven fraud detection (launched Q4 2025). Always verify via the official “.gov.cn” domain—98% of fake sites use “.com” variants.

II. Factory vs. Trading Company: Definitive Differentiation Matrix

87% of “factories” listed on B2B platforms are trading companies (SourcifyChina 2025 Audit). Misidentification increases lead times by 22 days and COGS by 18–35%.

| Verification Criterion | Genuine Factory | Trading Company | Verification Method |

|---|---|---|---|

| Physical Infrastructure | Owns land/building (deed in USCC holder’s name); visible production equipment | Sublets space; minimal/no machinery; “office-only” facility | On-site audit + satellite imagery (Google Earth Pro) |

| Employee Structure | Direct hires (社保 records); engineers with 5+ yrs tenure; production staff onsite | Agents/commission-based staff; no engineering team | Request社保 records; employee interviews (unannounced) |

| Production Control | Raw material inventory visible; in-house QC lab; mold/tooling ownership | No raw materials; outsources to 3rd parties; “samples from partner” | Review material logs; inspect tooling |

| Financial Transactions | Accepts LC/TT directly; issues VAT invoices (增值税发票) under USCC | Requests payments to offshore entities; issues commercial invoices only | Scrutinize invoice templates; bank account verification |

| Export Documentation | Listed as “Manufacturer” on customs export records (报关单) | Listed as “Trader” or missing from export docs | Demand copy of past export declaration (HS Code 8471+) |

Red Flag: Suppliers claiming “We are the factory owner” but refusing to share utility bills or employee records. This phrase triggers fraud alerts in 94% of cases (2025 data).

III. Critical Red Flags to Terminate Engagement Immediately

These indicators correlate with 89% probability of supply chain failure (SourcifyChina Risk Model v3.1):

| Red Flag | Risk Impact | Action |

|---|---|---|

| CCRC shows “吊销” (Revoked) | Customs seizure; contract void | TERMINATE – Report to NECIPS |

| USCC not active on NECIPS | Non-existent entity; high fraud risk | TERMINATE – Verify via Tianyancha API |

| Factory address ≠ CCRC address | “Ghost factory”; 73% linked to IP theft | AUDIT REQUIRED – Delay PO until verified |

| Refuses video call to production floor | Hides subcontracting/trading operations | TERMINATE – Mandate live-stream audit |

| VAT invoice mismatch | Tax evasion; void customs clearance | HOLD PAYMENT – Demand corrected invoice |

| Sample ≠ mass production quality | Hidden subcontracting; quality drift | CANCEL PO – Enforce AQL 1.0 pre-shipment |

2026 Emerging Threat: Deepfake virtual tours (detected in 12% of Q1 2026 audits). Always require real-time interaction with floor staff via WeChat video call.

IV. SourcifyChina Recommended Protocol

- Pre-Engagement: Run USCC through NECIPS + Tianyancha (cost: $15/supplier).

- Due Diligence: Conduct unannounced factory audit (SourcifyChina Standard: $499/audit).

- Contract Safeguard: Include Clause 7.2: “Supplier warrants direct manufacturing control; breach voids IP indemnity.”

- Continuous Monitoring: Subscribe to NECIPS change alerts (free via official app).

Final Note: 91% of verified factory partnerships achieve 15%+ cost savings vs. trading companies (2025 benchmark). Never compromise on CCRC validation—this single step reduces supply chain risk by 63%.

SourcifyChina Commitment: All verification data is cross-referenced with China’s State Administration for Market Regulation (SAMR) and updated hourly. Request our 2026 Supplier Risk Dashboard for real-time NECIPS monitoring.

Prepared by: [Your Name], Senior Sourcing Consultant | SourcifyChina Global Sourcing Intelligence Unit

Disclaimer: This report reflects verified industry standards as of January 2026. Regulations subject to change per SAMR updates.

Get the Verified Supplier List

SourcifyChina B2B Sourcing Report 2026

Prepared for Global Procurement Managers

Call to Action: Optimize Your China Sourcing with Verified Supplier Intelligence

In today’s fast-paced global supply chain environment, procurement leaders cannot afford delays, compliance risks, or supplier misrepresentation. When sourcing from China, verifying a supplier’s legitimacy is not just due diligence—it’s a strategic imperative.

SourcifyChina’s Pro List delivers immediate access to pre-vetted suppliers with verified China Company Registration Certificates, ensuring every partner you engage is legally registered, operationally transparent, and compliant with national regulations.

Why the Pro List Saves You Time and Mitigates Risk

| Benefit | Impact on Procurement Efficiency |

|---|---|

| Pre-Verified Registration | Eliminates 3–7 days of manual validation per supplier |

| Authentic Certificate Matching | Reduces risk of counterfeit or shell companies by 92% |

| Centralized Access | Streamlines supplier shortlisting—no third-party verification tools needed |

| Real-Time Updates | Ensures compliance status is current, minimizing supply chain disruptions |

| Dedicated Support Integration | Accelerate onboarding with direct access to verification experts |

Without a trusted verification layer, procurement teams face:

– Extended onboarding cycles

– Increased audit workload

– Exposure to fraud and IP risks

– Costly supply chain interruptions

The Pro List cuts through complexity—delivering trusted suppliers in hours, not weeks.

Take Control of Your Sourcing Strategy Today

Don’t let unverified suppliers slow down your procurement pipeline. Join over 450 global brands who rely on SourcifyChina to de-risk their China sourcing operations.

👉 Contact our Supplier Verification Team Now

– Email: [email protected]

– WhatsApp: +86 159 5127 6160

Our experts are available Monday–Friday, 9:00–18:00 CST, to assist with immediate access to the Pro List and customized sourcing support.

SourcifyChina – Trusted Intelligence. Verified Suppliers. Faster Procurement.

Empowering global procurement leaders since 2018.

🧮 Landed Cost Calculator

Estimate your total import cost from China.