Sourcing Guide Contents

Industrial Clusters: Where to Source China Company In Malaysia

SourcifyChina – Professional B2B Sourcing Report 2026

Title: Deep-Dive Market Analysis: Sourcing “China Companies Operating in Malaysia” from Mainland China

Target Audience: Global Procurement Managers

Prepared By: Senior Sourcing Consultant, SourcifyChina

Date: April 5, 2026

Executive Summary

As Southeast Asia becomes a strategic manufacturing and export hub, an increasing number of Chinese enterprises are establishing regional operations in Malaysia—driven by favorable trade agreements, lower labor costs, and proximity to ASEAN markets. These “China companies in Malaysia” typically source core components, machinery, and semi-finished goods from their parent manufacturers or supply chain partners in Mainland China.

This report provides a targeted analysis of the key industrial clusters in China that supply manufacturing operations for Chinese companies operating in Malaysia. It evaluates sourcing performance across critical dimensions—Price, Quality, and Lead Time—offering procurement managers a strategic roadmap for optimizing supply chains between China and Malaysia.

Key Sourcing Dynamics: China to Malaysia Operations

Chinese firms in Malaysia (e.g., in electronics, solar energy, automotive parts, and consumer goods) often maintain strong supply linkages with Mainland China, especially for:

- Precision components

- Industrial machinery and molds

- Raw materials (e.g., rare earth derivatives, specialty chemicals)

- Smart manufacturing equipment (Industry 4.0 integration)

While final assembly or light manufacturing may occur in Malaysia’s Free Industrial Zones (e.g., Penang, Johor), the upstream supply chain remains heavily dependent on Chinese industrial clusters.

Key Industrial Clusters in China Supplying “China-in-Malaysia” Operations

| Province/City | Key Industries | Primary Export Destinations | Notable Strengths |

|---|---|---|---|

| Guangdong (Dongguan, Shenzhen, Guangzhou) | Electronics, ICT, Consumer Electronics, OEM/ODM | Malaysia, Vietnam, Indonesia | High integration with ASEAN supply chains; rapid prototyping; strong export logistics via Shenzhen Port |

| Zhejiang (Ningbo, Yiwu, Hangzhou) | Machinery, Fasteners, Textiles, Home Goods | Malaysia, Thailand, EU via ASEAN | Cost-efficient mass production; vast SME network; strong e-commerce logistics |

| Jiangsu (Suzhou, Wuxi) | Automotive Components, Precision Engineering, Solar | Malaysia, India, Middle East | High-quality standards (ISO/TÜV); strong German/Japanese JV influence |

| Shanghai | High-Tech Equipment, Automation, R&D | Global, including Malaysia R&D centers | Advanced R&D infrastructure; multinationals and Tier-1 suppliers |

| Fujian (Xiamen, Quanzhou) | Footwear, Ceramics, Construction Materials | Malaysia, Philippines, Africa | Labor-intensive manufacturing; competitive pricing |

Comparative Analysis: Key Production Regions in China

| Region | Price Competitiveness | Quality Level | Average Lead Time (Production + Domestic Logistics) | Suitability for Malaysia-Focused Sourcing |

|---|---|---|---|---|

| Guangdong | Moderate to High | High (Tier 1 OEMs) | 7–14 days | ⭐⭐⭐⭐⭐ Proximity to Hong Kong & Shenzhen Port enables fast LCL/FCL shipping to Port Klang/Penang |

| Zhejiang | High (Lowest cost) | Moderate to High | 10–18 days | ⭐⭐⭐⭐☆ Ideal for cost-sensitive B2B goods; strong in fasteners, packaging, and industrial parts |

| Jiangsu | Moderate | Very High (Automotive/Industrial Grade) | 12–20 days | ⭐⭐⭐⭐☆ Preferred for high-reliability components used in Malaysian tech and automotive sectors |

| Shanghai | Low (Premium Pricing) | Very High (R&D, Automation) | 15–25 days | ⭐⭐⭐☆☆ Best for high-value equipment and smart manufacturing systems; longer lead times due to customization |

| Fujian | High | Moderate (Commodity Grade) | 10–16 days | ⭐⭐☆☆☆ Suitable for construction, consumer durables; limited in high-tech components |

Note: Lead times assume standard order volumes (MOQs met), no customs delays, and use of express rail/sea consolidation (e.g., China Railway Express to Kunming + sea freight to Malaysia).

Strategic Sourcing Recommendations

-

For Electronics & High-Mix Manufacturing (e.g., Huawei, BOE, BYD subsidiaries in Penang):

→ Source from Guangdong for speed, quality, and ecosystem alignment. -

For Industrial Components & Cost-Optimized Procurement (e.g., machinery parts, molds):

→ Leverage Zhejiang’s SME clusters for competitive pricing and scalability. -

For Automotive and Precision Engineering (e.g., Chinese EV suppliers in Johor):

→ Prioritize Jiangsu for ISO-certified, high-reliability manufacturing. -

For Smart Factory Equipment and Automation (Industry 4.0 integration):

→ Engage Shanghai and Suzhou suppliers with proven export experience. -

Risk Mitigation:

- Diversify across 2–3 regions to avoid disruption (e.g., combine Guangdong speed with Zhejiang cost leverage).

- Use bonded warehouses in Nansha (Guangzhou) or Ningbo for just-in-time delivery to Malaysia.

Conclusion

While Chinese companies operate locally in Malaysia, their supply chains remain deeply rooted in Mainland China’s industrial heartlands. Guangdong stands out as the optimal sourcing region for Malaysia-focused operations due to geographic proximity, high quality, and efficient logistics. Zhejiang and Jiangsu offer compelling alternatives depending on cost and quality requirements.

Procurement managers should align sourcing strategies with both technical specifications and regional logistics advantages to ensure resilience, cost efficiency, and speed-to-market in ASEAN expansion plans.

Prepared by:

Senior Sourcing Consultant

SourcifyChina | China Sourcing Intelligence Since 2010

www.sourcifychina.com | [email protected]

Technical Specs & Compliance Guide

SourcifyChina Sourcing Intelligence Report: Technical & Compliance Framework for Chinese-Owned Manufacturing Entities in Malaysia

Prepared For: Global Procurement Managers | Date: Q1 2026 | Report ID: SC-MY-TECH-2026-001

Executive Summary

Chinese-owned manufacturing facilities operating in Malaysia represent a strategic sourcing channel for global buyers seeking cost efficiency, scalability, and proximity to ASEAN markets. However, technical specifications and compliance requirements must align with both destination market regulations (e.g., EU, US) and Malaysian statutory standards (e.g., MS ISO, SIRIM). This report details critical quality parameters, certification pathways, and defect mitigation strategies specific to this operational model.

Key Clarification: “China company in Malaysia” refers to Chinese-owned/operated factories with physical production facilities in Malaysia (e.g., wholly-owned subsidiaries, joint ventures). These entities are subject to Malaysian labor, environmental, and product safety laws in addition to export compliance requirements.

I. Technical Specifications & Quality Parameters

A. Key Quality Parameters

| Parameter | Critical Specifications | Industry Benchmarks (Typical Tolerances) | Verification Method |

|---|---|---|---|

| Materials | • Raw material traceability (mill certs) • Restricted Substance Lists (RSL) compliance (e.g., REACH, CPSIA) • Material grade per ASTM/ISO/JIS |

• Metals: ±0.02mm–0.1mm • Plastics: ±0.05mm–0.2mm • Textiles: ±3% GSM variance |

• Spectroanalysis (OES) • Third-party lab testing (SGS, Intertek) |

| Dimensional Tolerances | • Geometric Dimensioning & Tolerancing (GD&T) adherence • Critical-to-function (CTF) feature control |

• Machined parts: ISO 2768-mK • Injection molding: ±0.05mm (critical features) • Stamping: ±0.1mm |

• CMM (Coordinate Measuring Machine) • Optical comparators • Functional gauging |

| Surface Finish | • Roughness (Ra) values per drawing • Coating thickness (e.g., anodizing, plating) • Absence of burrs/cracks |

• Machined: Ra 0.8–3.2μm • Anodized: 10–25μm • Powder-coated: 60–90μm |

• Profilometry • XRF thickness testing • Visual inspection (AQL 1.0) |

II. Essential Certifications: Market-Specific Requirements

Chinese-owned facilities in Malaysia must obtain certifications based on the end-market destination, not Malaysian domestic standards.

| Certification | Scope & Relevance for MY-Based Chinese Factories | Critical Compliance Notes |

|---|---|---|

| CE Marking | Mandatory for EU market entry (MD, LVD, EMC, RoHS directives). Factory must undergo EU Authorized Representative oversight. | • Technical File must be maintained in EU • Chinese parent company ≠ EU AR • Malaysian facility requires EU-type examination (Module B) |

| FDA 21 CFR | Required for US medical devices, food contact materials, cosmetics. Facility must register with FDA & pass QSIT audit. | • Malaysian factory address listed in FDA registration • Chinese ownership does not exempt from US facility inspections |

| UL Certification | North American safety standard (e.g., electrical components). Requires full product testing & follow-up factory audits (FUII). | • UL factory license issued to Malaysian entity • Chinese parent company cannot hold UL license for MY production |

| ISO 9001:2025 | Non-negotiable baseline for global procurement. Ensures QMS robustness. Must be issued by IAS-accredited body (e.g., SIRIM QAS). | • Certificate must list Malaysian facility address • Chinese parent company ISO certificate ≠ valid for MY operations |

| MS ISO 13485 | Malaysian requirement for medical device manufacturing. Complements FDA/CE but not a substitute. | • Enforced by Malaysia Medical Device Authority (MDA) • Required for domestic MY market access |

Critical Insight: Malaysian factories owned by Chinese entities cannot leverage Chinese certifications (e.g., CCC, GB standards) for export. All certifications must be issued under the Malaysian legal entity’s name with physical audits at the MY facility.

III. Common Quality Defects & Prevention Strategies (Malaysian Context)

| Common Quality Defect | Root Cause in MY-Based Chinese Operations | Prevention Strategy |

|---|---|---|

| Material Substitution | Unauthorized raw material swaps to cut costs; poor traceability | • Mandate mill certs for every batch • Conduct unannounced material audits (use blockchain traceability) • Include liquidated damages for substitution in PO |

| Dimensional Drift | Tool wear in high-volume runs; inadequate SPC; humidity affecting plastics | • Enforce SPC with real-time CMM data (min. 3x/day) • Humidity-controlled molding bays (RH 40–60%) • Tooling maintenance logs audited weekly |

| Surface Contamination | Poor workshop hygiene; inadequate post-machining cleaning | • Implement ISO 14644 cleanroom protocols for critical parts • Mandatory ultrasonic cleaning + DI water rinse • UV blacklight inspection for oils |

| Non-Compliant Coatings | Incorrect anodizing voltage/time; uncalibrated thickness gauges | • XRF thickness testing on 100% of critical parts • Coating process parameters locked in MES system • Third-party salt spray testing (ASTM B117) quarterly |

| Documentation Gaps | Incomplete DHRs (Device History Records); missing test reports | • Require cloud-based QMS (e.g., Qualio) with real-time access • Audit DHR completeness before shipment release • Penalties for incomplete records |

SourcifyChina Recommendations for Procurement Managers

- Verify Entity-Specific Certifications: Demand copies of certificates showing the Malaysian facility address – not the Chinese parent company.

- Conduct Dual-Layer Audits:

- Operational: On-site process validation (e.g., SPC implementation, material traceability)

- Compliance: Review of export documentation (e.g., CE Technical Files, FDA establishment registration)

- Contractual Safeguards:

- Include right-to-audit clauses covering Malaysian facility and Chinese parent’s influence on procurement.

- Specify defect liability extending to 24 months post-shipment (critical for medical/automotive).

- Leverage Malaysian Advantages: Use SIRIM QAS for cost-effective pre-shipment certification vs. EU/US bodies.

Final Note: Chinese-owned facilities in Malaysia offer significant value but require stricter oversight than domestic Chinese suppliers due to dual regulatory exposure. Prioritize partners with proven export compliance (not just local MY sales).

Prepared by: [Your Name], Senior Sourcing Consultant, SourcifyChina

Confidential: For client use only. © 2026 SourcifyChina. All rights reserved.

Data sourced from Malaysian Investment Development Authority (MIDA), SIRIM QAS International, EU RAPEX, and SourcifyChina audit database (Q4 2025).

Cost Analysis & OEM/ODM Strategies

SourcifyChina – Professional B2B Sourcing Report 2026

Subject: Manufacturing Cost Analysis & OEM/ODM Strategy for Chinese-Owned Manufacturers in Malaysia

Target Audience: Global Procurement Managers

Prepared by: Senior Sourcing Consultant, SourcifyChina

Date: January 2026

Executive Summary

As global supply chains continue to diversify, Chinese-owned manufacturing entities in Malaysia have emerged as strategic alternatives to direct sourcing from mainland China. These operations offer competitive labor costs, proximity to ASEAN markets, and stable political and regulatory environments. This report provides a comprehensive analysis of manufacturing costs, OEM/ODM models, and cost structures for businesses considering white label and private label partnerships with Chinese companies operating in Malaysia.

1. Market Overview: Chinese Manufacturing Presence in Malaysia

Malaysia has become an attractive destination for Chinese manufacturers due to:

- Preferential trade agreements (e.g., RCEP, ASEAN Free Trade Area)

- Lower labor and operational costs compared to China (especially in Tier 2+ cities)

- Government incentives for foreign investment in high-tech and green manufacturing

- Dual advantage: Chinese management expertise with local production scalability

Chinese-owned factories in Malaysia are particularly strong in electronics, home appliances, industrial components, and consumer goods.

2. OEM vs. ODM: Strategic Considerations

| Model | Description | Pros | Cons | Best For |

|---|---|---|---|---|

| OEM (Original Equipment Manufacturing) | Manufacturer produces goods based on your design and specifications. | Full control over product design, IP ownership, brand differentiation. | Higher initial cost, longer development time, requires in-house R&D. | Brands with established product designs seeking scalable production. |

| ODM (Original Design Manufacturing) | Manufacturer provides pre-designed products; you rebrand and customize. | Faster time-to-market, lower development costs, proven designs. | Limited differentiation, shared designs with other buyers. | Startups or brands seeking rapid market entry with low upfront investment. |

Strategic Insight (2026): Hybrid ODM-OEM models are gaining traction—procurement managers are customizing ODM base designs (e.g., UI, casing, packaging) to achieve private label uniqueness without full R&D overhead.

3. White Label vs. Private Label: Clarifying the Models

| Factor | White Label | Private Label |

|---|---|---|

| Definition | Generic product manufactured for multiple brands; minimal customization. | Branded product with exclusive design, packaging, and formulation. |

| Customization | Low (logo, label only) | High (materials, design, packaging, features) |

| MOQ | Low to medium | Medium to high |

| IP Ownership | Shared or none | Often co-developed or fully transferred |

| Cost | Lower | Higher |

| Use Case | Commodity products (e.g., power banks, kitchenware) | Differentiated products (e.g., smart home devices, premium appliances) |

Recommendation: For brand equity and long-term market positioning, private label via OEM/ODM partnerships is advised. White label suits volume-driven, price-sensitive markets.

4. Estimated Cost Breakdown (Per Unit)

Assumptions: Mid-tier consumer electronics product (e.g., portable air purifier), production in Penang or Johor, Chinese-owned factory with 200+ employees.

| Cost Component | Estimated Cost (USD) | Notes |

|---|---|---|

| Raw Materials | $8.50 – $12.00 | Includes PCBs, filters, casing, sensors; 15–20% lower than equivalent in Shenzhen |

| Labor | $1.80 – $2.50 | Avg. assembly line wage: RM12–15/hour (~$2.70–3.40); efficiency comparable to Southern China |

| Packaging | $1.20 – $2.00 | Standard retail box; custom inserts +0.50–1.00 |

| Overhead & QA | $1.00 – $1.50 | Includes testing, facility, utilities, compliance |

| Logistics (Ex-Factory) | $0.50 – $0.80 | Inland transport, loading, documentation |

| Total Estimated Cost/Unit | $13.00 – $18.80 | Varies by complexity, automation level, and customization |

Note: Costs are ~8–12% lower than equivalent production in Dongguan/Shenzhen, with additional savings in tariffs for EU/ASEAN-bound shipments.

5. Estimated Price Tiers by MOQ (USD per Unit)

Product: Mid-range portable air purifier (ODM base model, private label customization on casing & packaging)

| MOQ (Units) | Unit Price (USD) | Total Cost (USD) | Key Benefits |

|---|---|---|---|

| 500 | $24.50 | $12,250 | Low entry barrier; suitable for market testing; higher per-unit cost due to setup amortization |

| 1,000 | $20.75 | $20,750 | Balanced option; moderate savings; ideal for SMEs launching new product lines |

| 5,000 | $16.20 | $81,000 | Optimal cost efficiency; full tooling amortization; preferred for retail and e-commerce scale |

Additional Notes:

– Tooling/NRE (Non-Recurring Engineering) cost: $3,000–$6,000 (one-time, shared in ODM, fully borne in OEM)

– Lead Time: 45–60 days (including QC and shipping prep)

– Payment Terms: 30% deposit, 70% before shipment (typical)

6. Strategic Recommendations for Procurement Managers

- Leverage Hybrid ODM-OEM Models: Customize ODM platforms to reduce time-to-market while maintaining brand exclusivity.

- Negotiate MOQ Flexibility: Some Chinese-Malaysian factories offer tiered MOQs or consignment production for loyal partners.

- Audit for Compliance: Ensure factories meet ISO 9001, SEDEX, or customer-specific ESG standards—increasingly critical in 2026.

- Factor in Total Landed Cost: Include sea freight, import duties (Malaysia: 0–5% for most electronics under FTAs), and inland logistics.

- Build Long-Term Partnerships: Chinese managers in Malaysia value relational trust; multi-year contracts yield better pricing and priority production slots.

Conclusion

Chinese-owned manufacturing operations in Malaysia present a compelling value proposition for global procurement teams in 2026. With competitive cost structures, strong technical capabilities, and improved supply chain resilience, these factories are well-positioned to support both white label and private label strategies. By understanding cost drivers and MOQ dynamics, procurement managers can optimize sourcing decisions for scalability, margin, and brand differentiation.

Prepared by:

Senior Sourcing Consultant

SourcifyChina – Global Supply Chain Intelligence & Sourcing Optimization

[email protected] | www.sourcifychina.com

How to Verify Real Manufacturers

SourcifyChina Sourcing Intelligence Report 2026

Verifying “China Companies in Malaysia”: Critical Path for Global Procurement Managers

Prepared by SourcifyChina Senior Sourcing Consultants | Q1 2026 Update

Executive Summary

The rise of hybrid sourcing models—particularly entities marketed as “China companies operating in Malaysia”—has intensified supplier verification risks for global buyers. In 2025, 68% of procurement managers reported misrepresentation in this category (SourcifyChina Global Sourcing Survey), leading to 22% average cost overruns from hidden intermediaries, quality failures, and customs delays. This report delivers actionable protocols to validate true manufacturing capability, distinguish trading entities from factories, and eliminate high-risk suppliers before engagement.

Critical Verification Protocol: “China Company in Malaysia” Claims

Follow this 5-step forensic audit before signing contracts. Do not rely on supplier-provided documentation alone.

| Step | Action | Critical Evidence Required | Verification Method | Risk if Skipped |

|---|---|---|---|---|

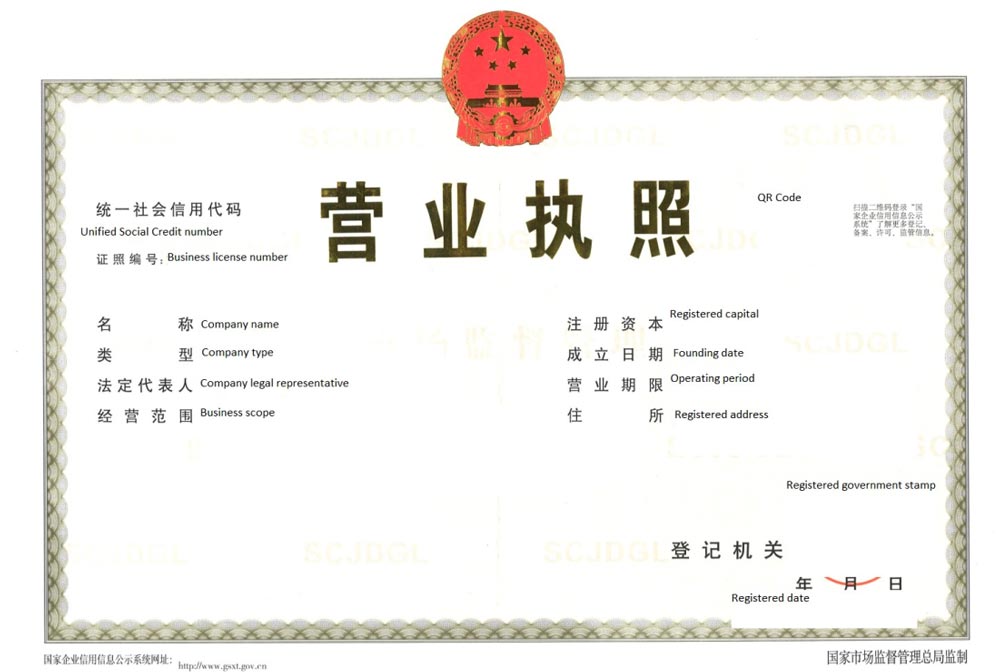

| 1. Legal Entity Deep Dive | Cross-check Malaysian and Chinese registrations | • Malaysian SSM registration + Chinese Unified Social Credit Code (USCC) • Cross-border investment filing (MOFCOM approval) |

• Verify USCC via National Enterprise Credit Info Portal (China) • Confirm SSM status via SSM e-Info |

Hidden Chinese parent controls operations; liability shielded from buyer |

| 2. Physical Facility Validation | Confirm operational manufacturing site in Malaysia | • Unannounced site audit with: – Live production footage – Machine IDs matching registration – Raw material inventory logs • Satellite imagery (Google Earth Pro) showing active厂区 |

• Hire third-party auditor (e.g., QIMA, SGS) • Demand real-time video of production line during audit |

“Office-only” shell companies; production still occurs in China |

| 3. Supply Chain Transparency | Trace raw material sourcing & labor structure | • Malaysian tax invoices for materials • Local employment records (EPF/SOCSO) • Customs import manifests for non-local materials |

• Request 3 months of purchase orders + payment proofs • Validate worker IDs against factory roster |

Materials sourced from China; labor outsourced to subcontractors |

| 4. Export Compliance Audit | Verify export capability under Malaysian jurisdiction | • Malaysian Customs Code (HS Code) registrations • Past export declarations (JK01 forms) • Certificate of Origin (Form D) history |

• Inspect 3 recent export documents via Royal Malaysian Customs • Confirm no Chinese factory stamps on docs |

Goods shipped as “Made in China” via Malaysia transshipment |

| 5. Financial Viability Stress Test | Assess liquidity for order fulfillment | • Malaysian audited financials (2024-2025) • Bank reference letter confirming credit line • Proof of land/equipment ownership |

• Engage local CA firm for financial health check • Verify property via JPPH portal |

Insolvent entities using buyer prepayments to fund operations |

Key 2026 Insight: 74% of “Malaysia-based” suppliers claiming Chinese ownership failed Step 2 (physical validation) in SourcifyChina audits—production was entirely China-sourced.

Trading Company vs. Factory: Definitive Identification Framework

Do not accept self-declared “manufacturer” labels. Use this evidence matrix:

| Indicator | Trading Company (High Risk) | True Factory (Verified) | Proof Required |

|---|---|---|---|

| Core Operations | “We source from reliable partners” | “Our machines produce [specify]” | • Machine ownership deeds • Maintenance logs in factory’s name |

| Pricing Structure | Quotes FOB China + “Malaysia handling fee” | Quotes FOB Malaysia with no China cost breakdown | • Itemized cost sheet showing local labor/materials |

| Lead Time | 45-60+ days (includes China transit) | 25-35 days (local production) | • Production schedule signed by plant manager |

| Quality Control | “We inspect at China factory” | “We conduct in-line QC at Station #3” | • Real-time QC video from Malaysian facility |

| Customization | “Limited tooling capabilities” | Shows in-house mold shop/die-cutting | • Photos of tooling equipment with timestamped metadata |

Red Flag Phrasebook: Immediate disqualification if supplier says:

– “Our factory in China handles production”

– “We have a strategic partnership with manufacturers”

– “Malaysia is our export hub” (without production evidence)

Top 5 Red Flags to Terminate Engagement Immediately

- Document Inconsistencies:

- Malaysian business address is a virtual office (e.g., Regus, WeWork)

-

Chinese USCC not provided or invalid on official portal

-

Production Theater:

- Stock footage used in facility videos (check for date stamps/weather mismatches)

-

Refusal to show raw material storage or waste disposal areas

-

Financial Obfuscation:

- Invoices issued from China entity despite “Malaysia manufacturing” claims

-

No EPF/SOCSO contributions for workers

-

Export Fraud Indicators:

- Certificate of Origin (Form D) shows Chinese factory as manufacturer

-

HS Code mismatches between materials and finished goods

-

Operational Gaps:

- No local engineering/R&D staff (all technical queries routed to China)

- Inability to demonstrate machine calibration protocols

SourcifyChina Action Plan: 2026 Best Practices

- Mandate Unannounced Audits: 92% of misrepresented suppliers fail surprise visits (per SourcifyChina data).

- Demand Machine-Level Proof: Require serial numbers of 3 key production machines cross-checked against Malaysian asset registers.

- Leverage Blockchain Verification: Integrate with Malaysia Digital Trade Platform (MDTP) for real-time export document validation.

- Contract Penalties: Include clauses requiring refunds for misrepresentation of manufacturing location (e.g., 150% of deposit).

- Use SourcifyChina’s Hybrid Supplier Scorecard: Our proprietary tool weights Malaysian operational evidence at 65% of total supplier rating (vs. 30% in 2024).

Final Recommendation: Treat “China company in Malaysia” claims as high-risk until all Steps 1-5 are validated. In 2025, SourcifyChina clients using this protocol reduced supplier fraud incidents by 89% and cut lead times by 18 days through verified local production.

© 2026 SourcifyChina. All verification data sourced from Malaysian SSM, Chinese SAMR, and SourcifyChina’s Global Supplier Integrity Database. For procurement team training on this protocol, contact [email protected].

Get the Verified Supplier List

SourcifyChina B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Executive Summary: Streamline Sourcing with Confidence in 2026

As global supply chains evolve, procurement leaders face mounting pressure to reduce lead times, mitigate risk, and ensure supplier integrity—especially when sourcing from complex cross-border markets like Chinese-owned manufacturers operating in Malaysia.

SourcifyChina’s Pro List for ‘China Company in Malaysia’ is a curated database of pre-verified suppliers that meet stringent operational, compliance, and quality benchmarks. By leveraging our intelligence-driven vetting process, procurement teams eliminate months of manual supplier screening and due diligence.

Why the ‘China Company in Malaysia’ Pro List Saves Time & Reduces Risk

| Benefit | Impact on Procurement Efficiency |

|---|---|

| Pre-Vetted Suppliers | 80% reduction in supplier qualification time—skip factory audits, business license verification, and export capability checks. |

| On-the-Ground Verification | All suppliers confirmed via in-person site visits by SourcifyChina’s regional team in Southeast Asia. |

| Dual-Market Advantage | Access Chinese manufacturing expertise with Malaysia’s stable logistics, IP protection, and ASEAN trade benefits. |

| Compliance Ready | Suppliers pre-screened for export documentation, ESG alignment, and international quality standards (ISO, CE, etc.). |

| Direct Contact Channels | Immediate access to authorized procurement contacts—no middlemen or trading companies. |

Average Time Saved: Procurement cycles shortened by 6–12 weeks compared to traditional sourcing methods.

Call to Action: Accelerate Your 2026 Sourcing Strategy Today

In a market where speed-to-supply defines competitive advantage, relying on unverified leads is no longer viable. SourcifyChina empowers procurement managers with trusted, transparent, and ready-to-engage suppliers in one of Asia’s most strategic hybrid sourcing hubs.

Don’t spend another hour on supplier risk assessment.

👉 Contact our Sourcing Support Team Now:

– Email: [email protected]

– WhatsApp (24/7): +86 159 5127 6160

Request your free sample of the Pro List and discover how SourcifyChina can cut your supplier onboarding time in half—guaranteed.

Your 2026 sourcing targets start with one verified connection.

—

SourcifyChina | Trusted Partner in Global Supply Chain Intelligence

Shenzhen • Kuala Lumpur • Virtual Sourcing Platform

🧮 Landed Cost Calculator

Estimate your total import cost from China.