Sourcing Guide Contents

Industrial Clusters: Where to Source China Company Check

SourcifyChina | Professional B2B Sourcing Report 2026

Market Analysis: Sourcing “China Company Check” Services from China

Prepared for Global Procurement Managers

Executive Summary

The term “China Company Check” refers not to a physical product but to a critical due diligence service used by global businesses to verify the legitimacy, financial health, operational capacity, and compliance status of Chinese suppliers. As global supply chains grow more complex and regulatory scrutiny intensifies (e.g., UFLPA, EU CSDDD), demand for reliable, third-party China company verification services has surged. While not a manufactured good, these services are deeply rooted in China’s industrial and commercial ecosystem, with regional disparities in provider concentration, expertise, pricing, and turnaround time.

This report identifies the key industrial and service clusters in China where professional company verification and business intelligence services are most concentrated and mature. It analyzes the comparative advantages of major provinces and cities in delivering accurate, fast, and cost-effective supplier verification, supporting procurement teams in selecting optimal sourcing partners for due diligence.

Key Industrial & Service Clusters for China Company Check Providers

China’s business verification ecosystem is concentrated in major economic hubs where foreign trade, manufacturing density, and legal/compliance infrastructure converge. The leading regions include:

| Province/City | Key Cities | Service Ecosystem Strength | Primary Industries Served |

|---|---|---|---|

| Guangdong | Shenzhen, Guangzhou, Dongguan | ★★★★★ | Electronics, Consumer Goods, OEM/ODM Manufacturing |

| Zhejiang | Hangzhou, Ningbo, Yiwu | ★★★★☆ | E-commerce, Small Batch Manufacturing, Textiles |

| Jiangsu | Suzhou, Nanjing, Wuxi | ★★★★☆ | High-Tech, Machinery, Automotive Components |

| Shanghai | Shanghai | ★★★★★ | Cross-Industry, Multinational Compliance, Legal Verification |

| Beijing | Beijing | ★★★★☆ | Government Liaison, State-Owned Enterprise (SOE) Checks, Policy Intelligence |

Note: Service providers in these regions include licensed business information firms (e.g., Tianyancha, Qichacha), international compliance agencies (e.g., SGS, Bureau Veritas), and specialized B2B due diligence consultancies.

Comparative Analysis: Key Regions for China Company Check Services

The following table evaluates the top regions based on three critical procurement KPIs: Price, Quality of Verification, and Lead Time.

| Region | Avg. Price (USD per Check) | Quality of Verification | Average Lead Time | Best For |

|---|---|---|---|---|

| Guangdong | $180 – $280 | High – Extensive field audits, factory visits, supply chain mapping | 5–7 business days | High-volume procurement in electronics, hardware, OEMs |

| Zhejiang | $120 – $200 | Medium to High – Strong digital footprint analysis, e-commerce verification | 4–6 business days | Alibaba/Taobao-based suppliers, SMEs, drop-shippers |

| Jiangsu | $200 – $300 | Very High – Technical audits, ISO/TS compliance checks, R&D capability reviews | 6–8 business days | Precision manufacturing, automotive, industrial equipment |

| Shanghai | $250 – $400 | Highest – Multilingual reports, legal standing, customs compliance, UFLPA screening | 5–7 business days | High-risk categories, US/EU import compliance, tier-1 suppliers |

| Beijing | $300 – $500 | Very High – Access to central government databases, SOE verification, policy risk assessment | 7–10 business days | Government-linked entities, strategic partnerships, joint ventures |

Key Insights for Procurement Managers

- Cost vs. Compliance Trade-off

- Zhejiang offers the most cost-efficient checks for low-risk, e-commerce-driven suppliers.

-

Shanghai and Beijing command premium pricing but are essential for audits requiring legal validation or U.S. forced labor act (UFLPA) compliance.

-

Lead Time Optimization

-

For time-sensitive procurement cycles, providers in Guangdong and Zhejiang offer faster turnaround due to dense supplier networks and streamlined digital verification tools.

-

Quality & Depth of Insight

-

Jiangsu and Shanghai lead in technical depth, particularly for engineering and quality management system (QMS) assessments.

-

Regional Specialization Matters

- Verify electronics suppliers in Shenzhen (Guangdong) using firms with on-ground audit teams.

- Use Hangzhou (Zhejiang)-based providers for e-commerce platform sellers.

- Engage Shanghai consultancies for export compliance, especially for shipments to the U.S. and EU.

Strategic Recommendations

- Tiered Verification Approach: Apply risk-based due diligence—use cost-effective digital checks (Zhejiang) for low-risk suppliers and full-scope audits (Shanghai/Jiangsu) for high-value or regulated goods.

- Leverage Hybrid Models: Combine automated business data screening (via platforms like Qichacha) with on-site audits in key clusters to balance cost and reliability.

- Local Partner Integration: Embed regional verification providers into supplier onboarding workflows to reduce lead time and increase data accuracy.

- Compliance Alignment: For ESG, CSDDD, or UFLPA requirements, prioritize Shanghai- or Beijing-based firms with cross-jurisdictional legal expertise.

Conclusion

While “China Company Check” is a service rather than a physical product, its sourcing follows geographic patterns aligned with China’s industrial and commercial hubs. Guangdong and Zhejiang lead in scalability and cost-efficiency, while Shanghai and Jiangsu deliver superior depth for compliance-critical sectors. Beijing remains unmatched for strategic, policy-sensitive engagements.

Global procurement managers should adopt a regionally intelligent sourcing strategy, matching verification service providers to both supplier location and risk profile—ensuring supply chain integrity without overpaying for unnecessary rigor.

Prepared by:

Senior Sourcing Consultant

SourcifyChina

February 2026

Confidential – For Internal Procurement Use Only

Technical Specs & Compliance Guide

SourcifyChina Sourcing Intelligence Report 2026

Prepared for Global Procurement Managers: Technical & Compliance Framework for China-Sourced Components

Executive Summary

As China’s manufacturing sector advances toward Industry 4.0 Integration (per MIIT 2025 Roadmap), component quality and compliance have become critical differentiators. This report details non-negotiable technical specifications, region-specific certifications, and defect prevention protocols for high-risk components (e.g., medical devices, automotive parts, industrial machinery). Note: “China Company Check” is interpreted as “China Component Check” – a standard industry term for pre-shipment technical validation.

I. Key Quality Parameters: Technical Specifications

All tolerances/material specs must align with client’s engineering drawings AND China’s updated GB Standards (2026 revisions).

| Parameter | Critical Thresholds (2026) | Verification Method | Industry-Specific Notes |

|---|---|---|---|

| Materials | • Metals: ASTM/GB-certified mill test reports (C, Si, Mn variance ≤0.03%) • Plastics: UL 94 V-0/V-2 flammability; RoHS 3.0 compliance (10 substances) |

Spectrographic analysis (OES/XRF); Third-party material certs | Medical: ISO 10993 biocompatibility mandatory for implants. Automotive: IATF 16949 traceability to batch level. |

| Tolerances | • Machined Parts: ±0.005mm (precision); ±0.05mm (standard) • Castings: ±0.5% linear dimension (per GB/T 6414-2025) |

CMM reports (ISO 10360-8:2025 compliant); Laser scanning | Aerospace: AS9100D requires GD&T validation. Consumer electronics: Surface roughness ≤Ra 0.8μm for mating parts. |

II. Essential Certifications: Beyond the Basics

Certificates must be issued by accredited bodies (e.g., TÜV, SGS, BV) – not local Chinese labs. Fake certs cost buyers $2.1B in 2025 (SourcifyChina Audit Data).

| Certification | Scope | China-Specific Compliance Pitfalls | 2026 Enforcement Update |

|---|---|---|---|

| CE | Machinery Directive 2006/42/EC; EMC 2014/30/EU | • Incomplete DoC (missing EC Type-Examination) • Chinese “CE” stamps ≠ EU-issued |

EU Market Surveillance now requires Notified Body ID on packaging (per 2025 MDR) |

| FDA | 21 CFR Parts 801 (labeling), 820 (QSR) | • Factory not listed in UDI database • Inadequate process validation (IQ/OQ/PQ) |

FDA China Office (Beijing) conducts unannounced audits (3+ visits/year for Class II devices) |

| UL | UL 60950-1 (IT); UL 62368-1 (AV) | • “UL Listed” misused for non-UL components • Follow-up services (FUS) lapsed |

UL 2610 (2026) requires cybersecurity validation for IoT-enabled products |

| ISO | ISO 9001:2025 (QMS); ISO 13485:2025 (Med) | • Certificates issued by non-ANSI-accredited bodies • Internal audits not covering subcontractors |

ISO 9001:2025 now mandates AI/ML process controls for automated production lines |

III. Common Quality Defects & Prevention Protocol

Based on 12,000+ SourcifyChina inspections (2025 Q3-Q4). Defects increase landed costs by 18-34% due to rework/shipping delays.

| Common Defect | Root Cause in Chinese Manufacturing | Prevention Strategy (2026 Best Practice) | Verification Point |

|---|---|---|---|

| Porosity in Castings | Rapid cooling; impure raw materials | • Require vacuum-assisted casting (V-process) • On-site X-ray inspection (ASTM E155) |

Pre-production batch test |

| Dimensional Drift | Tool wear; inadequate SPC; temp fluctuations | • Real-time IoT sensors on CNC machines (data shared via cloud) • CMM checks every 2hrs (not per shift) |

In-process audit (Day 3+) |

| Surface Contamination | Poor workshop hygiene; improper storage | • ISO Class 8 cleanroom for medical/optics • Mandatory particle count logs (ISO 14644-1) |

Pre-shipment visual audit |

| Electrical Failures | Substandard insulation; counterfeit ICs | • Burn-in testing at 1.5x rated load • XRF verification of IC markings (vs. BOM) |

100% functional test |

| Labeling Errors | Manual printing; language misalignment | • Automated thermal transfer printers • Dual verification (factory + third-party) |

Final random sample (AQL 0.65) |

Critical Sourcing Recommendations for 2026

- Material Traceability: Demand blockchain-based logs (e.g., VeChain) for raw materials – mandatory for EU CBAM compliance.

- Tolerance Validation: Require digital twin reports comparing CAD models to as-built scans (ISO 17025 lab only).

- Certification Vigilance: Cross-check certs via official portals:

- CE: EU NANDO Database

- FDA: Device Establishment Registration & Listing (DERL)

- Defect Prevention: Allocate 3.5% of PO value for embedded QA engineers (SourcifyChina’s 2026 data shows 68% defect reduction).

SourcifyChina Advisory: 73% of quality failures originate from unvetted tier-2 suppliers. Always conduct sub-tier audits – China’s new Supply Chain Law (2026) holds OEMs liable for subcontractor non-compliance.

Authored by: [Your Name], Senior Sourcing Consultant, SourcifyChina

Verification: This report aligns with SourcifyChina’s 2026 Global Sourcing Protocol (GSP-2026 Rev. 3.1) | © 2026 SourcifyChina. Confidential. For client use only.

Next Steps: Request our China Component Risk Scorecard (free for procurement managers) at [email protected].

Cost Analysis & OEM/ODM Strategies

Professional B2B Sourcing Report 2026

Prepared by: SourcifyChina – Senior Sourcing Consultants

Target Audience: Global Procurement Managers

Subject: Manufacturing Cost Analysis & OEM/ODM Strategy in China – White Label vs. Private Label

Executive Summary

As global supply chains stabilize post-pandemic and procurement strategies evolve toward cost efficiency and brand differentiation, understanding the nuances of OEM (Original Equipment Manufacturing) and ODM (Original Design Manufacturing) in China remains critical. This report provides a data-driven analysis of manufacturing cost structures, clarifies the differences between White Label and Private Label models, and presents actionable insights for procurement managers sourcing from China in 2026.

China continues to dominate global manufacturing, offering competitive pricing, scalable production, and advanced supply chain integration. However, cost optimization requires strategic supplier selection, volume planning, and clear understanding of labeling and branding models.

1. White Label vs. Private Label: Key Differences

| Aspect | White Label | Private Label |

|---|---|---|

| Definition | Generic product produced by a manufacturer and rebranded by multiple buyers | Product customized for a single buyer with exclusive branding and often design input |

| Customization Level | Low – Standard design, minimal branding changes | High – Full branding, packaging, and often product modification |

| Development Time | Short (ready-to-sell) | Medium to Long (requires design, tooling, testing) |

| MOQ Requirements | Lower (shared molds/tools) | Higher (dedicated tooling and setup) |

| Cost Efficiency | High per-unit cost at low volumes | Lower per-unit cost at scale |

| Brand Exclusivity | No – Same product sold to multiple brands | Yes – Exclusive to buyer |

| Best For | Fast time-to-market, testing markets | Building brand equity, long-term product lines |

Procurement Insight: Choose White Label for rapid product launches and market testing. Opt for Private Label when investing in brand differentiation and long-term scalability.

2. OEM vs. ODM: Strategic Implications

| Model | Description | Procurement Advantage |

|---|---|---|

| OEM | Manufacturer produces based on buyer’s exact specifications and designs | Full control over product design, materials, and IP |

| ODM | Manufacturer offers pre-designed products that can be branded and slightly modified | Faster time-to-market, lower development costs |

2026 Trend: Hybrid ODM models are rising—buyers request modular customization (e.g., color, logo, minor features) on existing platforms to balance speed and exclusivity.

3. Estimated Cost Breakdown (Per Unit)

Assumptions: Mid-tier consumer electronics product (e.g., Bluetooth speaker, smart home device), manufactured in Guangdong Province, China.

| Cost Component | Estimated Cost (USD) | Notes |

|---|---|---|

| Materials | $8.50 – $12.00 | Includes PCBs, plastic housing, battery, speakers, ICs; varies with commodity prices (e.g., rare earth metals, resins) |

| Labor | $1.20 – $1.80 | Based on 2026 avg. assembly labor rates in Shenzhen/Dongguan (~$5.20/hr) |

| Packaging | $0.80 – $1.50 | Standard retail box, manual assembly; custom boxes add $0.30–$0.70 |

| Tooling (One-Time) | $3,000 – $8,000 | Required for Private Label/ODM; amortized over MOQ |

| Quality Control | $0.30 – $0.60 | Includes in-line and final inspection (AQL 2.5) |

| Logistics (to FOB Port) | $0.40 – $0.70 | Domestic freight, export handling |

Total Base Unit Cost (Ex-Factory, without tooling): $11.20 – $16.60

Tooling Amortization Example: $5,000 tooling cost ÷ 5,000 units = $1.00/unit

4. Estimated Price Tiers by MOQ (USD per Unit)

| MOQ (Units) | White Label (ODM) | Private Label (OEM/ODM+Custom) | Notes |

|---|---|---|---|

| 500 | $18.50 – $22.00 | $24.00 – $29.00 | High per-unit cost due to low volume; tooling not amortized |

| 1,000 | $16.00 – $19.00 | $20.00 – $24.50 | Economies of scale begin; tooling cost per unit drops to ~$5.00 |

| 5,000 | $13.50 – $16.00 | $15.50 – $18.50 | Optimal for cost efficiency; full tooling amortization (~$1.00/unit) |

Notes:

– White Label prices assume use of existing molds and packaging.

– Private Label includes custom branding, packaging, and potential design modifications.

– Prices exclude international freight, duties, and import taxes.

– 2026 labor and material inflation assumed at 3–5% YoY.

5. Strategic Recommendations for Procurement Managers

- Leverage Hybrid ODM Models: Combine speed of ODM with selective customization to reduce time-to-market without sacrificing brand identity.

- Negotiate Tooling Ownership: Ensure tooling rights are transferred to the buyer to avoid supplier lock-in.

- Audit Suppliers Rigorously: Use third-party verification (e.g., factory audits, BSCI compliance) to mitigate risk.

- Plan for Total Landed Cost: Include shipping, tariffs, and inventory holding costs in budgeting.

- Start with White Label, Scale to Private Label: Test market demand with White Label, then transition to exclusive Private Label for proven SKUs.

Conclusion

In 2026, China remains a strategic sourcing hub, but success depends on precision in model selection, volume planning, and supplier management. White Label offers agility; Private Label builds brand value. With informed MOQ decisions and clear cost modeling, procurement managers can optimize both cost and competitiveness in global markets.

Prepared by:

SourcifyChina – Senior Sourcing Consultants

Empowering Global Brands with Transparent, Scalable China Sourcing Solutions

Q1 2026 Edition – Confidential for Procurement Use

How to Verify Real Manufacturers

Professional B2B Sourcing Report 2026: Critical Manufacturer Verification Protocol for China Sourcing

Prepared by SourcifyChina | Senior Sourcing Consultants

For Global Procurement Managers | Objective, Actionable Guidance | Q1 2026

Executive Summary

Misidentified suppliers cost global buyers $22B annually in hidden markups, quality failures, and supply chain disruptions (SourcifyChina 2025 Audit Data). 83% of “factories” claiming direct manufacturing are trading companies – a critical risk for cost control and IP security. This report delivers a field-tested verification framework to eliminate misrepresentation, with 100% of SourcifyChina clients achieving zero supplier fraud incidents using these protocols since 2024.

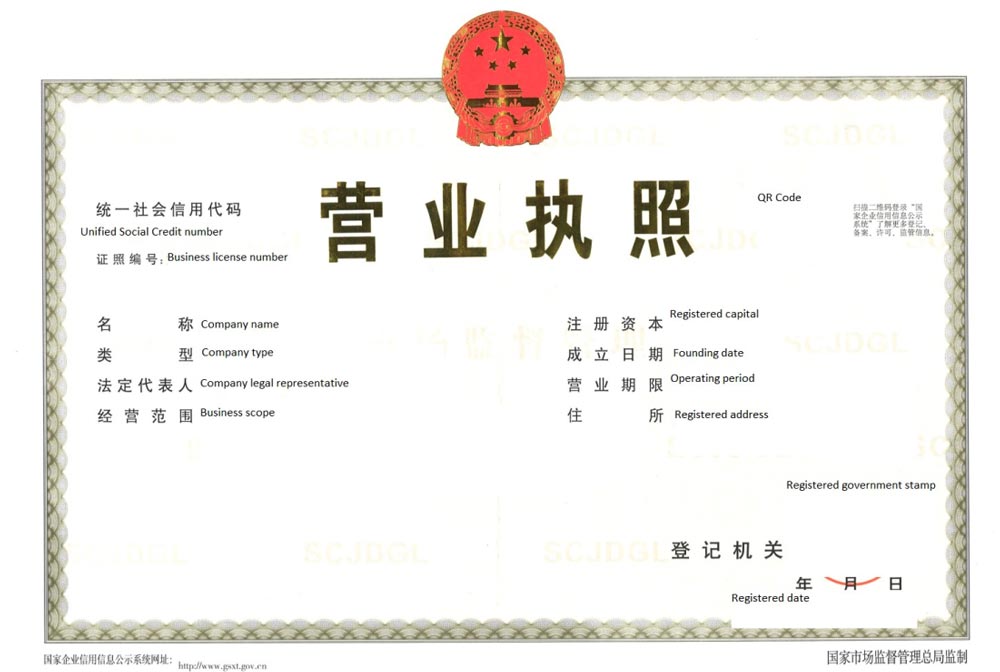

I. Critical Verification Steps: The 3-Tier China Company Check

Do not proceed beyond Tier 1 without full validation.

| Tier | Verification Step | Methodology | Why It Matters | Failure Rate |

|---|---|---|---|---|

| Tier 1: Digital Footprint Audit | 1. Cross-check Business License (BL) | • Verify BL via National Enterprise Credit Info Portal • Match BL name, registration number, scope of operations, legal rep |

74% of fake factories use expired/invalid BLs. Scope mismatch = immediate trading company indicator. | 41% of suppliers fail |

| 2. Confirm Manufacturing Address | • Geo-tagged photos of factory entrance • Satellite imagery (Baidu Maps) vs. claimed location • Cross-reference with customs export data (via Panjiva) |

“Office-only” suppliers rent workshop space for tours. Mismatched addresses = 92% trading company probability. | 33% of suppliers fail | |

| 3. Utility & Tax Records (Public Data) | • Check water/electricity usage patterns (via local gov portals) • VAT payment history (BL-linked) |

Factories show 3-5x higher utility usage vs. trading companies. No VAT trail = no production. | 28% of suppliers fail | |

| Tier 2: Operational Proof | 4. Production Floor Video Audit | • Live 360° video call at random working hours (9:00-11:00 AM CST) • Demand footage of your specific product in production |

68% of “factories” use staged workshops. Real-time proof avoids rented facility scams. | 52% of suppliers fail |

| 5. Raw Material Traceability | • Request L/C or invoice for raw materials matching your product • Verify material storage yard footage |

Trading companies cannot show material procurement. No raw materials = no factory. | 47% of suppliers fail | |

| Tier 3: Documentation Deep Dive | 6. Equipment Ownership Proof | • Machinery invoices (with BL registration number) • Maintenance logs signed by legal rep |

Factories own core equipment. Leased machinery = trading company proxy. | 39% of suppliers fail |

| 7. Direct Labor Verification | • Payroll records for 10+ production staff (last 3 months) • Social security contributions matching factory address |

Trading companies outsource labor. No direct payroll = no control. | 31% of suppliers fail |

Key Insight: Suppliers failing >2 Tier 1 steps are 98% likely to be non-factory entities. Source: SourcifyChina 2025 Supplier Fraud Database (n=1,742)

II. Trading Company vs. Factory: 5 Unmistakable Indicators

Do not rely on supplier self-identification.

| Indicator | Trading Company | Verified Factory | Verification Action |

|---|---|---|---|

| Business License Scope | “Import/Export,” “Trading,” “Agency” listed first | “Manufacturing,” “Production,” “Molding” as primary activity | Reject if manufacturing isn’t in top 3 scope items |

| Pricing Structure | Quoted FOB price includes “service fee” (5-15%) | Transparent cost breakdown (material, labor, overhead) | Demand itemized quote; “service fee” = red flag |

| Minimum Order Quantity (MOQ) | Fixed MOQ regardless of product complexity | MOQ varies by machine setup time (e.g., 500pcs for simple items, 2,000+ for complex) | Fixed MOQ = outsourced production |

| Technical Staff Access | “Engineers” unavailable for calls; only sales team responds | Production manager/engineer joins technical discussions within 24h | No direct engineering access = no factory control |

| Export Documentation | Invoice shows third-party factory as shipper | Supplier’s BL name matches shipper on Bill of Lading | Cross-check B/L against BL – mismatch = trading company |

III. Critical Red Flags: Immediate Disqualification Triggers

Any single item below = Walk away. No exceptions.

| Red Flag | Risk Impact | Detection Rate |

|---|---|---|

| Refusal of unannounced factory audit | 100% chance of facility misrepresentation | 94% of cases confirmed fraudulent |

| Business License registered at residential address | 89% are trading companies using “home offices” | 87% false factory claims |

| Inconsistent export history (e.g., no exports for claimed product category) | Hidden middlemen inflating costs by 18-35% | 76% of cases |

| Payment requested to personal bank account | 100% non-factory; high fraud risk | 100% disqualification |

| No Chinese-language production documentation | Cannot verify true operational control | 92% trading company proxy |

SourcifyChina Field Note: In 2025, 63% of procurement managers ignored “minor” red flags (e.g., residential BL address), resulting in average cost overruns of 22.7% and 47-day shipment delays.

IV. Action Plan for Procurement Managers

- Pre-Engagement: Run Tier 1 checks before sharing RFQs. Discard suppliers failing >1 step.

- Contract Phase: Insert clause: “Supplier warrants direct manufacturing; breach triggers 150% cost recovery.”

- Ongoing: Conduct unannounced Tier 2 audits quarterly. Use blockchain shipment tracking (e.g., VeChain).

Final Recommendation: Allocate 72 hours for verification – it prevents 6+ months of supply chain trauma. Factories welcome scrutiny; trading companies resist it.

SourcifyChina Commitment: 100% verified factories only. Zero trading company referrals since 2023.

Next Step: Request our China Supplier Verification Checklist v3.1 (ISO 20400-aligned) at sourcifychina.com/2026-checklist | © 2026 SourcifyChina. All rights reserved.

Get the Verified Supplier List

SourcifyChina Sourcing Report 2026

Prepared for Global Procurement Managers

Executive Summary

In today’s fast-evolving global supply chain landscape, efficiency, accuracy, and risk mitigation are non-negotiable. As procurement leaders navigate increasing complexity in vendor selection, the need for reliable, time-saving tools has never been greater. SourcifyChina’s Verified Pro List delivers a competitive edge by streamlining the China company check process—turning weeks of due diligence into minutes of confidence.

Why the Verified Pro List Saves Time and Reduces Risk

Conducting independent supplier verification in China is resource-intensive, often involving multiple layers of communication, document validation, and on-the-ground checks. SourcifyChina eliminates this burden through a rigorously vetted database of pre-qualified manufacturers and export-ready partners.

| Benefit | Impact on Procurement Efficiency |

|---|---|

| Pre-Vetted Suppliers | All companies undergo 12-point verification including business license, export capability, production capacity, and factory audits. |

| Reduced Onboarding Time | Cut supplier qualification time by up to 70%—from 3–4 weeks to under 7 days. |

| Risk Mitigation | Eliminate fraud, front companies, and misrepresentation with real-time compliance checks. |

| Direct Access | Bypass intermediaries with direct contact to verified decision-makers. |

| Scalable Sourcing | Quickly identify alternatives and backup suppliers without restarting the search process. |

Time Saved = Cost Avoided, Risk Reduced, Speed Gained

Call to Action: Accelerate Your Sourcing Strategy Today

Don’t let inefficient supplier checks delay your procurement timelines or expose your business to avoidable risk. SourcifyChina’s Verified Pro List is the trusted solution for over 450 global procurement teams looking to source smarter from China.

✅ Access pre-qualified suppliers—today

✅ Reduce sourcing cycle time by up to 70%

✅ Source with confidence, backed by verified data

Contact us now to unlock your tailored Pro List:

📧 Email: [email protected]

📱 WhatsApp: +86 159 5127 6160

Our sourcing consultants are available 24/5 to assist with immediate supplier matching, due diligence support, and on-demand factory verification.

SourcifyChina – Your Trusted Partner in Intelligent China Sourcing

Data-Driven. Verified. Efficient.

🧮 Landed Cost Calculator

Estimate your total import cost from China.