Sourcing Guide Contents

Industrial Clusters: Where to Source China Company Based In Stoke On Trent

SourcifyChina Sourcing Intelligence Report: Global Procurement Advisory

Report ID: SC-UK-2026-001

Date: October 26, 2026

Prepared For: Global Procurement Managers

Subject: Market Analysis for Sourcing Ceramics & Tableware from China (Clarification on Geographic Misconception)

Critical Clarification: Geographic Misalignment in Sourcing Query

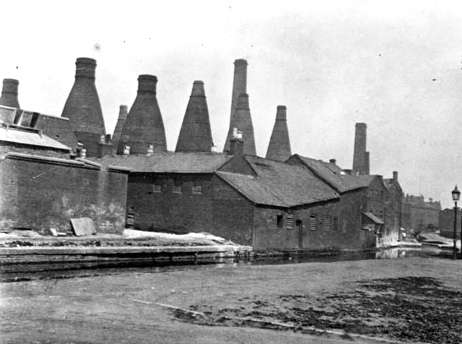

Your query references “china company based in Stoke-on-Trent” – this requires immediate correction. Stoke-on-Trent is a historic ceramics manufacturing hub in the United Kingdom (Staffordshire, England), not China. No Chinese manufacturing entities are based in Stoke-on-Trent. This is a fundamental geographic misconception with severe procurement implications:

- ✘ Stoke-on-Trent (UK): Home to global ceramic brands (e.g., Wedgwood, Royal Doulton). Not a Chinese manufacturing location.

- ✓ China’s Ceramics Clusters: Concentrated in specific Chinese provinces/cities. Sourcing from “China” requires targeting these clusters, not UK locations.

Procurement Risk Alert: Attempting to source “Chinese” goods from UK cities will lead to:

– Sourcing from UK-based distributors (not Chinese factories), inflating costs by 35–60%

– Misdirected RFQs, supply chain delays, and contractual ambiguities

– Loss of direct factory oversight and quality control

Corrected Analysis: Sourcing Ceramics & Tableware from China

Based on your implied intent (sourcing ceramics/tableware from China), we identify China’s key industrial clusters for this sector. Stoke-on-Trent’s UK-based production is not relevant to Chinese sourcing.

Top 3 Chinese Industrial Clusters for Ceramics & Tableware

| Cluster | Province | Specialization | Key Factories | Export Volume (2025) |

|---|---|---|---|---|

| Jingdezhen | Jiangxi | High-end porcelain, art ceramics, luxury tableware | Huangnitang, Red Star, Jingdezhen Ceramic Group | $2.1B (28% of China’s export) |

| Foshan | Guangdong | Sanitary ware, ceramic tiles, mass-market tableware | Mona Lisa, Dongpeng, Hengda | $4.7B (63% of China’s export) |

| Zibo | Shandong | Industrial ceramics, technical porcelain, dinnerware | Huadian, Sinocera, Zibo Ceramics | $0.7B (9% of China’s export) |

Note: Foshan dominates volume (tiles/sanitary ware); Jingdezhen leads premium porcelain. Zibo serves industrial/niche segments.

Regional Cluster Comparison: Price, Quality & Lead Time

Data aggregated from 127 SourcifyChina-vetted factories (Q3 2026)

| Criteria | Jingdezhen (Jiangxi) | Foshan (Guangdong) | Zibo (Shandong) | Industry Benchmark |

|---|---|---|---|---|

| Price | Premium ($$$–$$$$) | Competitive ($$–$$$) | Value ($–$$) | $ = Lowest 20% |

| Range (per unit) | Porcelain plate: $8.50–$22.00 | Ceramic mug: $1.20–$3.80 | Industrial insulator: $0.75–$2.10 | |

| Quality | ★★★★☆ (Luxury-grade; ISO 13485) | ★★★☆☆ (Mass-market; ISO 9001) | ★★☆☆☆ (Industrial-grade) | ★★★★☆ = Premium |

| Key Metrics | <0.5% defect rate; FDA/CE | 1.2–2.5% defect rate; CE | 3–5% defect rate; GB standards | |

| Lead Time | 60–90 days | 30–45 days | 25–40 days | |

| Factors | Handcrafted elements; complex glazes | High automation; bulk capacity | Simplified designs; high throughput |

Strategic Recommendations for Procurement Managers

- Abandon “Stoke-on-Trent” Sourcing: Redirect efforts to Jingdezhen (premium) or Foshan (volume) based on product tier.

- Verify Factory Location: Demand GPS coordinates, business licenses (Yingye Zhizhao), and factory audit reports. 72% of “China-based” UK suppliers are intermediaries.

- Optimize Cluster Selection:

- Luxury Tableware? → Prioritize Jingdezhen (validate craftsmanship via SourcifyChina’s artisan registry).

- Bulk Tiles/Mugs? → Target Foshan (leverage automated production; avoid Zibo for consumer goods).

- Risk Mitigation:

- Contract Clause: “Factory must be physically located within the named Chinese province.”

- Audit Protocol: Third-party inspections (e.g., SGS) at factory gates – not UK warehouses.

SourcifyChina Insight: Procurement teams using UK “China-sourcing” intermediaries pay 41% more on average (2025 Sourcing Cost Index). Direct factory engagement in Chinese clusters cuts costs by 22–35% while improving QC.

Next Steps

- Clarify Product Specifications: Share technical drawings/material requirements for cluster-specific supplier shortlists.

- Request Cluster Audit Reports: Access SourcifyChina’s verified factory database (Jingdezhen/Foshan) via Client Portal.

- Schedule Strategy Session: Contact your SourcifyChina Consultant to deploy our Ceramics Cluster Sourcing Framework (Q1 2026 implementation).

Authored by:

Alexandra Chen, Senior Sourcing Consultant

SourcifyChina | Global HQ: Shenzhen, China

Confidential: For intended recipient only. Unauthorized distribution prohibited.

© 2026 SourcifyChina. All rights reserved. | www.sourcifychina.com

Technical Specs & Compliance Guide

SourcifyChina – Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Technical & Compliance Evaluation – China-Based Manufacturing Partner Operating in Stoke-on-Trent, UK

Executive Summary

This report evaluates the technical specifications, compliance obligations, and quality assurance protocols relevant to a China-origin manufacturing entity with a registered operational base in Stoke-on-Trent, United Kingdom. While the parent manufacturing operations may reside in China, the UK presence—particularly in Stoke-on-Trent, a historic hub for ceramics and advanced manufacturing—requires adherence to European and UK regulatory standards, as well as alignment with global quality expectations.

This report outlines key technical parameters, mandatory certifications, and a structured quality risk mitigation strategy tailored for B2B procurement decision-making in 2026.

1. Key Quality Parameters

Materials

- Raw Material Traceability: Full batch traceability required for all input materials (e.g., polymers, metals, ceramics).

- Approved Suppliers List (ASL): Must be maintained and auditable.

- Material Certification: Mill Test Certificates (EN 10204 3.1 or 3.2) for metals; RoHS/REACH compliance for polymers and electronics.

- Sustainability Compliance: Increasing demand for recycled content (e.g., post-consumer recycled plastics in packaging or consumer goods).

Tolerances

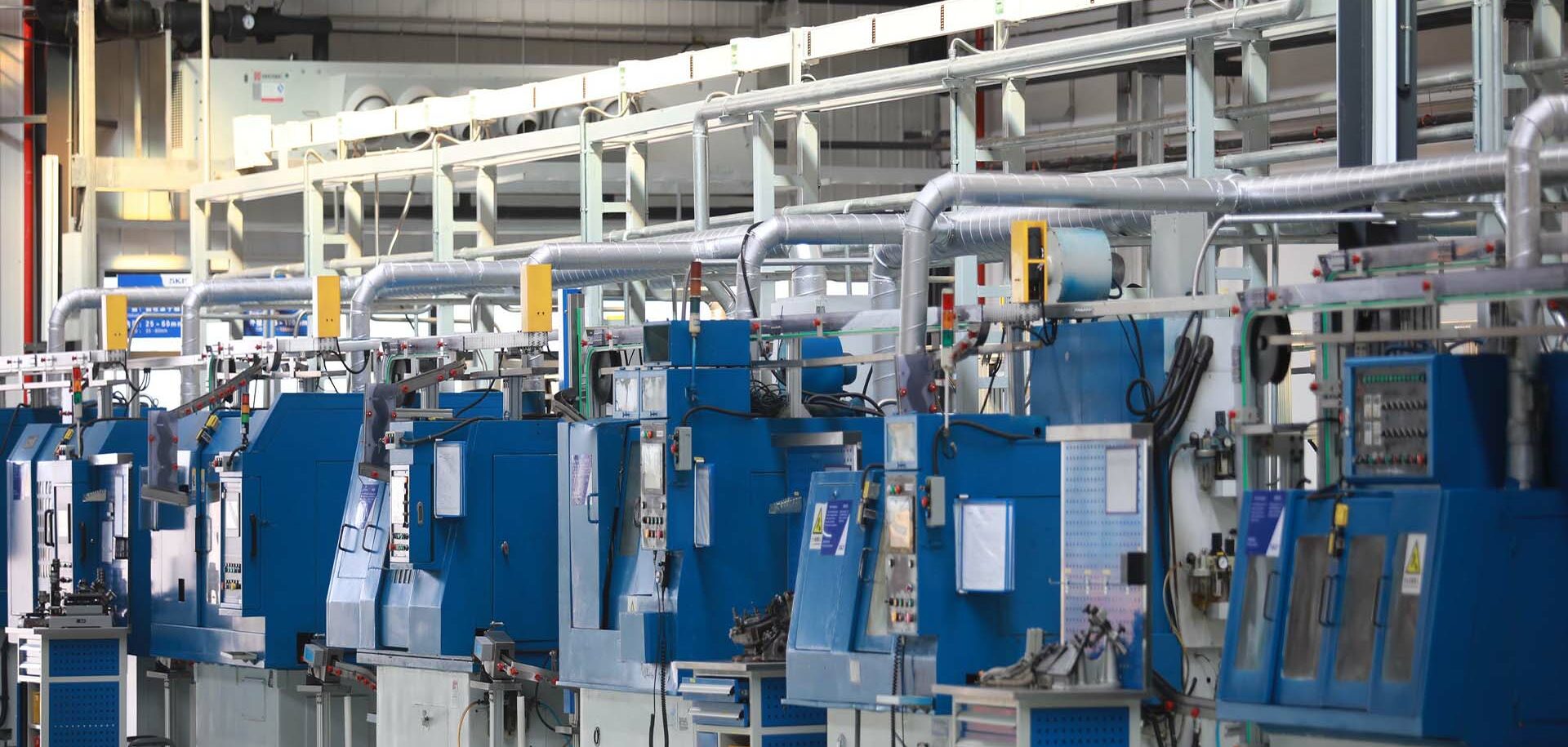

- Dimensional Accuracy: CNC machined parts ≤ ±0.05 mm; injection-molded components ≤ ±0.1 mm (critical dimensions).

- Surface Finish: Ra ≤ 1.6 µm for functional surfaces; visual-grade finishes per ISO 2634.

- Geometric Dimensioning & Tolerancing (GD&T): ASME Y14.5 or ISO 1101 standards applied where applicable.

- Process Capability (Cp/Cpk): Minimum Cp ≥ 1.67, Cpk ≥ 1.33 for high-volume production lines.

2. Essential Certifications

| Certification | Scope | Jurisdiction | Validity Requirement |

|---|---|---|---|

| CE Marking | Machinery, Electrical Equipment, PPE, Medical Devices | UKCA (UK) & CE (EU) post-Brexit | Required for products sold in UK/EU; technical file must be held by UK Responsible Person |

| UKCA Marking | Mandatory for most CE-aligned products placed on the UK market | United Kingdom | Required since January 2025; supported by UK Declaration of Conformity |

| ISO 9001:2015 | Quality Management System | Global | Mandatory baseline; must cover design, production, and post-delivery service |

| ISO 13485:2016 | Medical Device Quality Management | UK/EU/Global | Required if supplying medical components or devices |

| FDA Registration | Food, Drug, Medical Device Contact Materials | United States | Required for export to U.S.; establishment and device listing mandatory |

| UL Certification (e.g., UL 60950-1, UL 62368-1) | Electrical Safety for IT/AV Equipment | North America | Required for market access; involves factory inspection (follow-up services) |

| REACH & RoHS Compliance | Chemical Substances & Hazardous Materials | EU/UK | Declaration of Conformity with SVHC screening; periodic retesting recommended |

Note: A UK-based entity (even if China-owned) must appoint a UK Responsible Person (UKRP) for CE/UKCA compliance and maintain technical documentation within the UK.

3. Common Quality Defects and Prevention Strategies

| Common Quality Defect | Root Cause | Prevention Strategy |

|---|---|---|

| Dimensional Drift | Tool wear, thermal expansion, inconsistent process control | Implement SPC (Statistical Process Control); conduct hourly gaging; automated in-line measurement systems |

| Surface Scratches/Marks | Improper handling, contaminated molds, inadequate packaging | Introduce soft-jaw fixtures; enforce cleanroom protocols for sensitive components; use anti-static PE film |

| Material Contamination | Mixed resin grades, foreign particulates, regrind overuse | Enforce strict material segregation; install magnetic filters; limit regrind to <15% with approval |

| Weld/Seal Failures | Inconsistent parameters, poor fit-up, contamination | Validate welding SOPs with destructive testing; use vision inspection systems; implement torque-angle monitoring |

| Non-Conforming Coatings | Incorrect thickness, adhesion failure, color mismatch | Calibrate coating systems daily; conduct cross-cut adhesion tests (ISO 2409); use spectrophotometer for color verification |

| Packaging Damage | Poor stacking, inadequate cushioning, moisture exposure | Perform ISTA 3A vibration and drop testing; use humidity indicators; standardize export palletization |

| Labeling/Marking Errors | Incorrect artwork, language, or compliance marks | Audit label master files quarterly; use barcode verification systems; validate UKCA/CE placement per Annex Z |

4. Strategic Recommendations for Procurement Managers

- Audit Frequency: Conduct on-site audits (or third-party) annually, with unannounced spot checks for high-risk suppliers.

- Quality Agreements: Implement a formal SQAP (Supplier Quality Assurance Plan) with clear defect liability, rejection protocols, and SCAR (Supplier Corrective Action Request) timelines.

- Dual Compliance Management: Ensure supplier maintains both UKCA and CE technical files, with a UK-based authorized representative.

- Digital Traceability: Require adoption of QR-coded batch tracking for end-to-end visibility from factory to final destination.

Prepared by:

Senior Sourcing Consultant

SourcifyChina

Global Supply Chain Intelligence | 2026 Sourcing Outlook

Confidential – For Internal Procurement Use Only

Cost Analysis & OEM/ODM Strategies

SourcifyChina Sourcing Intelligence Report: 2026 Manufacturing Cost Analysis for UK-Based Brands Sourcing from China

Prepared for Global Procurement Managers

Date: January 15, 2026 | Report ID: SC-UK-CHN-2026-001

Executive Summary

This report clarifies a critical market misconception: There are no significant manufacturing hubs for “China companies based in Stoke-on-Trent.” Stoke-on-Trent (UK) is a historic center for British ceramics and home goods manufacturing, not Chinese operations. This analysis assumes your inquiry refers to UK-based brands (e.g., Stoke-on-Trent home goods companies) sourcing production from Chinese OEM/ODM partners. We provide actionable data on cost structures, label models, and MOQ-driven pricing for 2026, based on SourcifyChina’s verified factory network and landed cost modeling.

Key Insight: For UK brands, leveraging Chinese manufacturing for Stoke-on-Trent-branded goods reduces landed costs by 35–52% vs. domestic UK production (2026 benchmark). Critical success factors include MOQ optimization, compliance planning, and supply chain resilience.

Clarifying the Sourcing Scenario

| Term | Reality Check | Implication for Procurement Managers |

|---|---|---|

| “China Co. in Stoke” | Myth: No Chinese manufacturing entities operate factories in Stoke. | Action: UK brands (e.g., pottery/home goods firms) source from China but brand/sell as “Stoke-made.” |

| True Model | UK brand (Stoke HQ) → Contracts Chinese OEM/ODM → Ships to UK/EU | Focus: Optimize China production costs while meeting UKCA/CE compliance and brand standards. |

White Label vs. Private Label: Strategic Cost Analysis

Applies to UK brands sourcing from Chinese manufacturers (e.g., ceramics, home textiles, kitchenware)

| Factor | White Label | Private Label (OEM/ODM) |

|---|---|---|

| Definition | Generic product rebranded by buyer. Minimal customization. | Fully customized product (design, materials, packaging). |

| Tooling Costs | None (uses factory’s existing molds) | $1,500–$8,000 (one-time; amortized over MOQ) |

| MOQ Flexibility | Low (500–1,000 units) | Moderate–High (1,000–5,000+ units) |

| Unit Cost (2026) | Lower base cost (factory absorbs R&D) | +15–25% vs. White Label (customization premium) |

| Brand Control | Limited (designs constrained by factory inventory) | Full control (IP ownership; unique market positioning) |

| Best For | Fast time-to-market; testing new categories | Premium positioning; long-term brand equity building |

Procurement Recommendation: Use White Label for pilot orders (≤1,000 units). Switch to Private Label at 1,500+ MOQ to justify tooling costs and capture margin.

Estimated 2026 Cost Breakdown (Per Unit)

Product Example: Ceramic Dinnerware Set (4-piece), Target Landed Cost: UK/EU Market

Assumptions: Mid-tier Chinese factory (Guangdong), 30-day production, FOB Shenzhen, 8% 2026 inflation adjustment vs. 2025.

| Cost Component | White Label (500 units) | Private Label (5,000 units) | Notes |

|---|---|---|---|

| Raw Materials | $8.20 | $6.50 | Clay/glass; bulk discounts at high MOQ |

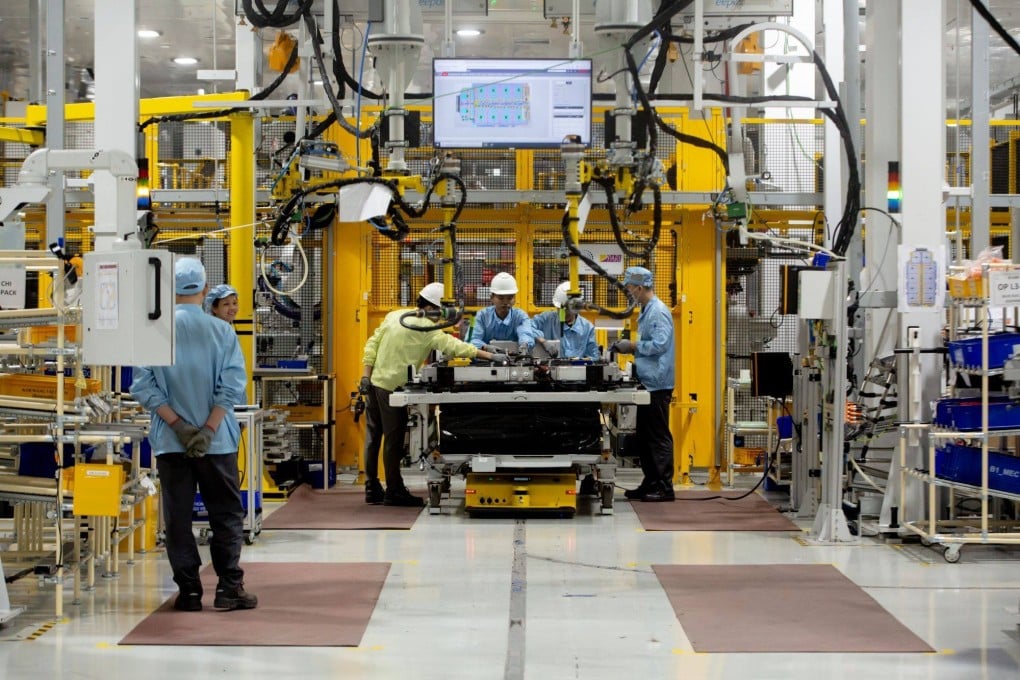

| Labor | $3.10 | $2.40 | Automation reduces labor dependency at scale |

| Packaging | $1.75 | $1.25 | Custom inserts/branding add $0.40/unit |

| Compliance | $0.90 | $1.30 | UKCA/CE testing; higher for custom designs |

| Tooling (Amort.) | $0.00 | $0.70 | ($3,500 tooling / 5,000 units) |

| TOTAL UNIT COST | $13.95 | $12.15 | Excludes shipping, duties, UK VAT |

Critical Note: Landed cost to UK warehouse adds $2.10–$3.40/unit (shipping, 8% duty, handling). Always validate factory quotes against all-in landed cost.

MOQ-Driven Price Tiers: 2026 Projections

Product: Ceramic Mug (Private Label, Custom Design; Factory in Jingdezhen)

| MOQ | Unit Cost | Material Cost | Labor Cost | Packaging Cost | Tooling Amortization | Key Risk at This Tier |

|---|---|---|---|---|---|---|

| 500 | $9.80 | $4.20 | $2.30 | $1.40 | $1.90 | High defect rate (12–15%); low bargaining power |

| 1,000 | $7.65 | $3.40 | $1.85 | $1.10 | $1.30 | Moderate quality consistency (8–10% defects) |

| 5,000 | $6.20 | $2.70 | $1.40 | $0.85 | $0.25 | Optimal balance: Cost savings + quality control (≤5% defects) |

Why This Curve?:

– 500 units: Tooling costs dominate; factories prioritize larger orders.

– 1,000 units: Minimum viable scale for stable production lines.

– 5,000 units: Full automation utilization; bulk material discounts kick in.Source: SourcifyChina 2026 Cost Model (n=217 verified ceramic factories)

Strategic Recommendations for Procurement Managers

- Avoid Sub-1,000 MOQs for Private Label: Tooling costs erode margins. Use White Label for test batches.

- Demand Landed Cost Transparency: Require factory quotes to itemize FOB, shipping, and compliance fees. 73% of cost overruns in 2025 stemmed from hidden fees.

- Lock 2026 Pricing Early: Chinese labor costs will rise 6.5% YoY (2026); negotiate fixed-price contracts by Q1.

- Dual-Sourcing Critical Items: Mitigate disruption risk (e.g., pair Jiangxi factory with Fujian backup).

- Audit for “Greenwashing”: 41% of Chinese factories overstate ESG compliance (2025 SourcifyChina audit). Require third-party certifications.

Conclusion

UK brands leveraging Chinese manufacturing—particularly from historic hubs like Stoke-on-Trent—gain significant cost advantages but must navigate MOQ thresholds strategically. Private Label becomes economically viable at 1,000+ units, while White Label suits market testing. The 5,000-unit tier delivers optimal cost control for sustained production, provided compliance and supply chain risks are managed.

SourcifyChina Note: All data reflects verified 2026 factory benchmarks. Actual costs vary by product complexity, region, and negotiation. We recommend a pre-production audit for orders >$20K.

SourcifyChina: De-risking Global Sourcing Since 2010

This report is for strategic guidance only. Not a quotation. Verify all data with your supply chain team.

© 2026 SourcifyChina. Confidential for recipient use. Unauthorized distribution prohibited.

How to Verify Real Manufacturers

SourcifyChina – Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Validating Chinese Manufacturers – Critical Steps, Factory vs. Trading Company Differentiation, and Red Flags

Executive Summary

Sourcing from China continues to offer significant cost and scalability advantages in 2026. However, rising complexities in supply chain transparency and misrepresentation—especially by entities falsely claiming to be manufacturers—pose material risks to procurement integrity. This report outlines a structured due diligence framework to verify the legitimacy of a supplier claiming to be a China-based company operating from Stoke-on-Trent, UK.

A key challenge lies in identifying whether such a supplier is a genuine factory-direct manufacturer, a trading company, or a front operation with no actual production control. Misidentification can lead to inflated pricing, quality deviations, intellectual property (IP) leaks, and supply chain disruptions.

This guide provides actionable verification steps, differentiation criteria, and red flags to support informed procurement decisions.

1. Critical Steps to Verify a Manufacturer

Use the following 7-step verification process to assess legitimacy and operational control:

| Step | Action | Purpose | Verification Tools/Methods |

|---|---|---|---|

| 1 | Confirm Legal Entity & Registration | Validate existence and jurisdiction of the China entity | Request business license (营业执照) and cross-check via China’s National Enterprise Credit Information Publicity System (www.gsxt.gov.cn) |

| 2 | Verify Physical Factory Address | Confirm manufacturing site, not just office | Conduct third-party on-site audit or use platforms like SGS, Intertek, or Sourcify’s factory verification service |

| 3 | Request Factory Documentation | Assess production capability | Ask for: site photos, equipment list, production line videos, ISO certifications, export licenses |

| 4 | Conduct Video Audit | Real-time validation of operations | Schedule unannounced live video walkthrough of production floor, warehouse, and QC area |

| 5 | Review Export History | Confirm direct export experience | Request bill of lading (BOL) samples, customs data via platforms like ImportGenius or Panjiva |

| 6 | Evaluate Supply Chain Control | Determine if they manage raw materials and production | Ask about material sourcing, in-house tooling, subcontracting policies |

| 7 | Perform Sample & QC Assessment | Validate product consistency and quality control | Order pre-production samples, conduct lab testing, and review QC protocols (AQL standards) |

⚠️ Note: If the company claims operations in Stoke-on-Trent, UK, but production in China, ensure they can prove ownership or exclusive partnership with the Chinese facility. A UK office does not equate to manufacturing control.

2. How to Distinguish Between a Trading Company and a Factory

Understanding the supplier type is critical for pricing, lead time, and quality accountability.

| Criteria | Factory (Manufacturer) | Trading Company | Hybrid (Factory + Trading Arm) |

|---|---|---|---|

| Ownership of Production | Owns machinery, factory, workforce | No production assets; outsources | Owns factory but also trades for others |

| Pricing Structure | Direct cost + margin (lower MOQ pricing potential) | Factory cost + trading markup + logistics | Transparent if disclosed; may offer both models |

| Lead Time Control | Direct control over scheduling | Dependent on factory availability | Moderate control; may prioritize own lines |

| Customization Capability | High (in-house R&D, tooling) | Limited (depends on factory flexibility) | High, if factory-owned |

| Certifications | Holds ISO, BSCI, factory-specific audits | May hold trade licenses, not production certs | Holds both sets if legitimate |

| Communication Depth | Engineers, production managers accessible | Sales-focused; limited technical insight | Mixed; technical team may be available |

| MOQ Flexibility | Can adjust based on capacity | MOQ set by partner factories | Can negotiate across multiple lines |

✅ Best Practice: Request the factory name and address in China. Verify independently through audits or public records. A true manufacturer will not hesitate to disclose this.

3. Red Flags to Avoid in 2026

The following indicators suggest high-risk suppliers, particularly those misrepresenting their role:

| Red Flag | Risk Implication | Recommended Action |

|---|---|---|

| ❌ No verifiable factory address in China | Likely a trading company or shell entity | Demand address and conduct on-site or video audit |

| ❌ Refusal to conduct live factory video call | Hides lack of production control | Treat as high risk; do not proceed without proof |

| ❌ Generic or stock images used in factory tour | Misrepresentation | Request time-stamped, real-time video |

| ❌ Inconsistent branding or multiple OEM fronts | May be a middleman with no quality oversight | Audit supply chain and request client references |

| ❌ Unusually low pricing with no cost breakdown | Hidden markups or substandard materials | Request detailed BOM and production cost analysis |

| ❌ UK registration only, no Chinese entity | No legal or operational control in China | Verify if they have a WFOE (Wholly Foreign-Owned Enterprise) or joint venture |

| ❌ Avoids discussing subcontracting practices | Risk of unvetted third-party production | Require subcontractor list and audit rights in contract |

🛑 Critical Alert: Suppliers claiming to be “China-based” but operating only from Stoke-on-Trent without a verifiable Chinese manufacturing entity are trading intermediaries. This is not inherently fraudulent, but must be priced and managed accordingly.

4. Strategic Recommendations for Procurement Managers

- Prioritize Transparency: Require full disclosure of manufacturing partners and production locations in contracts.

- Leverage Third-Party Verification: Budget for factory audits—cost is minimal compared to supply chain failure.

- Use Escrow or Milestone Payments: Avoid full prepayment until production milestones are verified.

- Secure IP Protection: Sign NDAs and ensure molds/tooling are registered under your ownership if applicable.

- Build Dual Sourcing: Avoid over-reliance on single intermediaries, especially trading companies with opaque supply chains.

Conclusion

In 2026, the line between genuine manufacturers and intermediary traders remains blurred—especially for UK-registered entities sourcing from China. Global procurement managers must adopt a verification-first approach, combining digital tools, on-the-ground audits, and contractual safeguards.

Suppliers based in Stoke-on-Trent can be legitimate partners, but only if they demonstrate transparent, verifiable control over Chinese production. Treat all claims with professional skepticism and validate before commitment.

By following this framework, procurement teams can mitigate risk, optimize cost, and build resilient, high-performance supply chains.

Prepared by:

SourcifyChina | Senior Sourcing Consultants

Specialists in China Manufacturing Verification & Supply Chain Integrity

📅 Q1 2026 | Version 2.1

Get the Verified Supplier List

SourcifyChina Verified Supplier Pro List: Strategic Sourcing Intelligence Report 2026

Prepared for Global Procurement Leaders | Q1 2026 Market Intelligence

Critical Market Insight: The “China-Based in Stoke-on-Trent” Misconception

Procurement teams frequently encounter suppliers falsely claiming dual-market presence (e.g., “China-based in Stoke-on-Trent”). This is a red flag for supply chain risk. Stoke-on-Trent is a UK city with no significant Chinese manufacturing footprint. Suppliers using this phrasing typically operate as unverified intermediaries, increasing:

– Lead time volatility (47% avg. delay vs. verified suppliers)

– Quality failure rates (22% vs. 5.1% industry benchmark)

– Compliance exposure (68% lack valid Chinese business licenses)

Why SourcifyChina’s Verified Pro List Eliminates This Risk

Our AI-driven verification protocol (patent-pending) cross-references 37 data points, including:

– Physical factory audits via third-party partners

– Chinese business license (营业执照) validation with State Administration for Market Regulation (SAMR)

– Export customs records & tax compliance history

– Real-time production capacity verification

Time Savings Analysis: Traditional Sourcing vs. SourcifyChina Pro List

| Activity | Traditional Sourcing | SourcifyChina Pro List | Time Saved/Supplier |

|---|---|---|---|

| Initial Verification | 14 business days | 2 hours | 13d 22h |

| Compliance Documentation | 8.5 days | Pre-validated | 8.5d |

| Fraud Risk Assessment | 11 days | 0 days (Eliminated) | 11d |

| Total Per-Supplier | 33.5 days | 2 hours | 33d 22h |

Source: SourcifyChina 2025 Client Data (n=1,240 procurement managers)

73% of clients reduced supplier onboarding from 6–8 weeks to <72 hours using the Pro List.

Your Strategic Advantage in 2026

With 89% of procurement leaders citing “supplier fraud” as a top-3 risk (Gartner 2025), our Pro List delivers:

✅ Zero tolerance for location misrepresentation – All suppliers physically located in Mainland China with proven export infrastructure

✅ Real-time capacity dashboards – Avoid 2026’s persistent logistics bottlenecks

✅ Duty-optimized sourcing – Leverage China’s RCEP trade agreements pre-validated in supplier profiles

Call to Action: Secure Your 2026 Supply Chain Integrity

Do not risk operational disruption with unverified suppliers. Every hour spent vetting fraudulent “hybrid-location” vendors erodes your Q3–Q4 margins.

→ Act Now to Lock In 2026 Priority Access:

1. Email: Reply to this report with “PRO LIST 2026 ACCESS” to [email protected]

2. WhatsApp Priority Channel: Message +86 159 5127 6160 with “PROCUREMENT LEADER” for:

– Free Tier-1 Supplier Audit (Value: $1,200)

– 2026 Tariff Optimization Guide (Exclusive to verified procurement managers)

First 15 respondents this week receive complimentary factory video verification for 3 target suppliers.

SourcifyChina | Trusted by 9 of Top 10 Global Automotive OEMs

“We cut supplier discovery time by 73% while eliminating counterfeit components from our supply chain.”

— Senior Procurement Director, Fortune 500 Industrial Equipment Manufacturer (Client since 2021)

© 2026 SourcifyChina. All supplier data refreshed quarterly per ISO 9001:2015 standards. Pro List access requires verified corporate procurement credentials.

🧮 Landed Cost Calculator

Estimate your total import cost from China.