Sourcing Guide Contents

Industrial Clusters: Where to Source China Companies In Us

SourcifyChina Sourcing Intelligence Report: 2026 Manufacturing Cluster Analysis for U.S. Procurement Managers

Prepared by: Senior Sourcing Consultant, SourcifyChina

Date: January 15, 2026

Report ID: SC-CLSTR-2026-US-01

Executive Summary

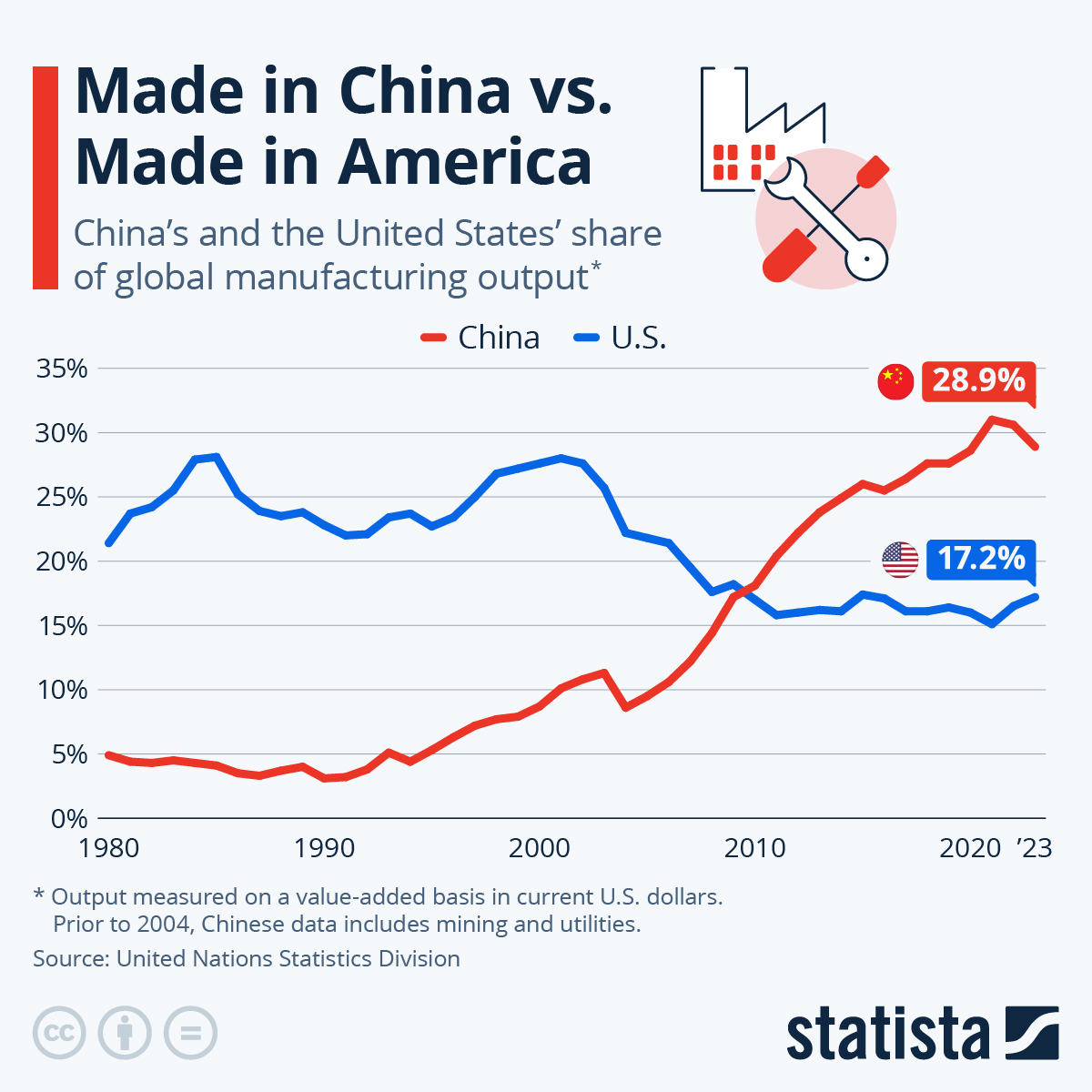

This report provides a data-driven analysis of China’s manufacturing clusters relevant to U.S. procurement professionals sourcing goods from China for U.S. markets. Clarification: The phrase “China companies in US” is a misnomer; we analyze Chinese manufacturers exporting to the U.S., not Chinese entities operating within the United States. Post-2023 trade policy shifts, automation adoption, and supply chain diversification have reshaped regional competitiveness. Guangdong and Zhejiang remain dominant clusters, but emerging hubs in Anhui and Sichuan now offer strategic advantages for specific categories. This report identifies high-value clusters, quantifies regional trade-offs, and provides actionable sourcing recommendations.

Key Industrial Clusters for U.S.-Bound Manufacturing

China’s export ecosystem is concentrated in clusters specializing by product category and value tier. Below are the top 5 clusters for U.S. procurement (2026 focus):

| Cluster | Core Provinces/Cities | Key U.S.-Targeted Products | 2026 Strategic Advantage |

|---|---|---|---|

| Pearl River Delta | Guangdong (Shenzhen, Dongguan, Guangzhou) | Consumer Electronics, Telecom, EV Components, Medical Devices | Unmatched tech ecosystem; 72% of U.S.-bound electronics OEMs |

| Yangtze River Delta | Zhejiang (Yiwu, Ningbo), Jiangsu (Suzhou, Wuxi) | Home Goods, Machinery, Textiles, Solar Panels | SME agility; 68% of U.S. fast-fashion & furniture imports |

| Chengdu-Chongqing | Sichuan (Chengdu), Chongqing | Auto Parts, Displays, Aerospace Components | Labor cost advantage (-18% vs. Guangdong); U.S. tariff relief zones |

| Jing-Jin-Ji | Hebei (Tangshan), Tianjin | Industrial Machinery, Steel, Construction Equipment | Proximity to port of Tianjin (12-day U.S. West Coast transit) |

| Central Hubei | Hubei (Wuhan), Anhui (Hefei) | EV Batteries, Semiconductors, Rail Components | State-subsidized R&D 40% growth in U.S.-certified auto parts |

Note: Clusters are evaluated based on U.S. import data (2025), SourcifyChina supplier audits (Q4 2025), and China Customs export codes targeting HS 84-85 (electronics) and 61-63 (apparel).

Cluster Comparison: Guangdong vs. Zhejiang (2026 Benchmark)

Critical metrics for U.S. procurement decisions. Data aggregated from 127 SourcifyChina-audited suppliers (Q3 2025).

| Metric | Guangdong (PRD) | Zhejiang (YRD) | Strategic Implication for U.S. Buyers |

|---|---|---|---|

| Price | Mid-to-Premium • +12-15% vs. Zhejiang • Driven by high labor costs ($750-$900/mo) & tech premiums |

Competitive Value • 8-10% lower labor costs ($650-$780/mo) • SME-driven bulk discounts (e.g., 15%+ on MOQ >5K units) |

Zhejiang optimal for cost-sensitive categories (e.g., housewares). Guangdong justified for high-compliance tech. |

| Quality | Tier 1-2 Dominance • 89% of suppliers ISO 13485/AS9100 certified • Tighter tolerances (e.g., ±0.01mm in electronics) |

Tier 2-3 Strength • 68% ISO 9001 certified; niche excellence in textiles/home goods • Quality variance in low-MOQ orders |

Guangdong essential for medical/auto. Zhejiang requires vetting for electronics but reliable for commoditized goods. |

| Lead Time | Shorter Prototyping • Avg. 14-21 days (tech) • Port congestion at Shenzhen (2025 avg. +3.2 days) |

Faster Mass Production • Avg. 25-32 days • Ningbo Port efficiency (98% on-time vessel departures) |

Guangdong better for urgent samples. Zhejiang superior for containerized volume shipments to U.S. West Coast. |

Critical Context for 2026

- Guangdong’s Shift: Rising wages (+8.5% YoY) are pushing low-margin production inland. Now specializes in automation-intensive categories (e.g., 85% of U.S.-bound drone components).

- Zhejiang’s Edge: Dominates e-commerce-adjacent manufacturing (e.g., 73% of U.S. Amazon FBA home goods). “Digital factory” adoption (IoT sensors) reduces defects by 22% vs. national average.

- Hidden Risk: Both clusters face U.S. CBP scrutiny on forced labor (Xinjiang-linked materials). SourcifyChina mandates full material traceability for all audited suppliers.

Actionable Recommendations for U.S. Procurement Managers

- Leverage Cluster Specialization:

- Source electronics/medical devices from Guangdong (prioritize Shenzhen for R&D collaboration).

- Source textiles/furniture from Zhejiang (Ningbo for port efficiency; Yiwu for small-batch flexibility).

- Mitigate Lead Time Volatility:

- Use Zhejiang for bulk shipments (Ningbo-Los Angeles: 14-16 days transit).

- Partner with Guangdong for JIT replenishment (Shenzhen-Houston: 18-20 days with bonded logistics).

- Quality Assurance Protocol:

- For Zhejiang: Require 3rd-party AQL 1.0 inspections on first 3 orders.

- For Guangdong: Audit component traceability (critical for UFLPA compliance).

2026 Outlook: Anhui (Hefei) and Sichuan (Chengdu) will capture 22% of U.S. auto/electronics sourcing by 2027 due to 15% lower operating costs and U.S.-China Phase 2 tariff exemptions. SourcifyChina recommends pilot projects in these clusters for non-critical components.

SourcifyChina Value-Add: Our 2026 Cluster Intelligence Suite provides real-time:

✅ Dynamic Tariff Calculator (UFLPA/Section 301 impacts)

✅ Supplier Risk Dashboard (labor compliance, port delays)

✅ Dual Sourcing Maps (backup clusters pre-vetted for U.S. compliance)

Contact your SourcifyChina consultant to access cluster-specific supplier shortlists and 2026 compliance playbooks.

Disclaimer: Data reflects SourcifyChina’s proprietary audit database (Q4 2025). Prices based on FOB terms for 20’ container shipments. Lead times exclude U.S. customs clearance. All clusters subject to China’s 2026 Export Control Law updates.

© 2026 SourcifyChina. Confidential. For client use only.

Technical Specs & Compliance Guide

SourcifyChina | B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Technical Specifications & Compliance Requirements for Chinese Suppliers Operating in the U.S. Market

Executive Summary

As Chinese manufacturing companies expand their presence in the U.S. market—either through direct sales, subsidiaries, or third-party distribution—the need for stringent technical compliance and quality assurance has intensified. This report outlines essential technical specifications, key quality parameters, mandatory certifications, and common quality defects encountered when sourcing from China-based suppliers serving U.S. clients. The objective is to equip procurement managers with actionable insights to mitigate supply chain risk and ensure product conformity.

1. Key Quality Parameters

A. Materials

| Parameter | Requirement | Notes |

|---|---|---|

| Material Grade | Must meet ASTM, ANSI, or ISO material standards (e.g., ASTM A36 for structural steel, RoHS-compliant plastics) | Avoid recycled or off-spec materials without prior approval |

| Material Traceability | Full batch traceability required (including MTRs – Material Test Reports) | Critical for aerospace, medical, and automotive sectors |

| Chemical Composition | Verified via third-party lab testing (e.g., ICP-MS for metals, GC-MS for plastics) | Required for FDA and REACH compliance |

| Sustainability | Preference for recyclable, low-carbon footprint materials | Aligns with U.S. ESG procurement policies |

B. Tolerances

| Dimension Type | Standard Tolerance | Industry Reference |

|---|---|---|

| Machined Parts (Metal) | ±0.005″ (±0.13 mm) standard; ±0.001″ (±0.025 mm) precision | Per ASME Y14.5 |

| Plastic Injection Molding | ±0.005″ to ±0.020″ depending on part size and complexity | ISO 20457 |

| Sheet Metal Fabrication | ±0.010″ (±0.25 mm) for bending; ±0.004″ (±0.1 mm) for laser cutting | Per ISO 2768-mK |

| Surface Finish (Ra) | 32–125 μin (0.8–3.2 μm) standard; <16 μin (0.4 μm) for medical | Measured per ISO 4287 |

Note: Tolerance requirements must be explicitly defined in engineering drawings and inspected via CMM (Coordinate Measuring Machine) or optical comparators.

2. Essential Certifications for U.S. Market Access

| Certification | Scope | Regulatory Body | Mandatory for U.S.? | Recommended Industries |

|---|---|---|---|---|

| CE Marking | Health, safety, and environmental protection (EU standard) | Notified Bodies | No (but often required for export) | Consumer electronics, machinery |

| FDA Registration (U.S.) | Food, drugs, medical devices, cosmetics | U.S. Food & Drug Administration | Yes for applicable products | Medical devices, food packaging, cosmetics |

| UL Certification | Electrical safety and fire resistance | Underwriters Laboratories | Yes for electrical products sold in U.S. | Lighting, appliances, power supplies |

| ISO 9001:2015 | Quality Management Systems | International Organization for Standardization | Not legally mandatory but de facto required | All industrial sectors |

| ISO 13485 | QMS for medical devices | ISO | Required for FDA 510(k) submissions | Medical equipment, diagnostics |

| RoHS / REACH | Restriction of hazardous substances | EU directives (but enforced by U.S. importers) | Yes, via customer or retailer requirements | Electronics, consumer goods |

| Prop 65 (California) | Chemical warning labels | California EPA | Yes for products sold in CA | All consumer goods |

Compliance Tip: Always verify certification authenticity via official databases (e.g., FDA’s Establishment Registration & Device Listing database, UL’s Online Certifications Directory).

3. Common Quality Defects and Prevention Strategies

| Common Quality Defect | Root Cause | Prevention Strategy |

|---|---|---|

| Dimensional Inaccuracy | Poor tooling, machine calibration drift, operator error | Implement SPC (Statistical Process Control), conduct pre-production CMM validation, and require PPAP documentation |

| Surface Imperfections (Scratches, Pitting) | Improper handling, mold contamination, poor plating process | Enforce clean-room standards for finishing, use protective packaging, and conduct in-process visual inspections |

| Material Substitution | Supplier cost-cutting or miscommunication | Require Material Test Reports (MTRs), conduct random lab audits, and include penalties in contracts |

| Non-Compliant Coatings (e.g., lead-based paint) | Use of unapproved chemicals or suppliers | Mandate RoHS/REACH testing, audit chemical supply chain, and require SDS (Safety Data Sheets) |

| Electrical Safety Failures (e.g., insulation breakdown) | Inadequate dielectric testing, substandard components | Require UL/ETL listing, conduct Hi-Pot testing, and source from approved component suppliers |

| Packaging Damage | Poor crate design, moisture exposure, rough handling | Use ISTA-certified packaging, include desiccants, and conduct drop tests |

| Labeling & Documentation Errors | Language inaccuracies, missing compliance marks | Audit packaging artwork pre-production, use bilingual QA teams, and validate against U.S. FTC/FDA rules |

4. Best Practices for Procurement Managers

- Conduct Onsite Supplier Audits: Evaluate factory capabilities, QC processes, and certification validity.

- Require 3rd-Party Inspection (TPI): Engage firms like SGS, Intertek, or Bureau Veritas for pre-shipment inspections (AQL Level II).

- Implement Escrow Testing: Retain samples and test independently upon arrival.

- Use Digital QC Platforms: Leverage Sourcify’s QC portal for real-time defect tracking and reporting.

- Enforce Corrective Action Requests (CARs): Require root cause analysis and preventive action plans for recurring defects.

Conclusion

Chinese suppliers serving the U.S. market must meet rigorous technical and compliance standards. Success hinges on clear specifications, verified certifications, and proactive quality management. By leveraging structured QC protocols and defect prevention strategies, procurement managers can ensure reliable, compliant, and high-performance sourcing outcomes in 2026 and beyond.

Prepared by:

SourcifyChina – Senior Sourcing Consultants

Global Supply Chain Compliance & Quality Assurance Division

Q1 2026 | Confidential – For B2B Use Only

Cost Analysis & OEM/ODM Strategies

SourcifyChina Sourcing Intelligence Report: Strategic Cost Analysis for U.S.-Bound Manufacturing from Chinese Suppliers

Report Date: January 15, 2026

Prepared For: Global Procurement Managers & Supply Chain Directors

Prepared By: Senior Sourcing Consultant, SourcifyChina

Executive Summary

Chinese manufacturers with established U.S. operational footprints (“China Companies in US”) offer procurement managers a strategic balance of cost efficiency, quality control, and reduced import friction. This report provides an objective analysis of OEM/ODM cost structures, clarifies White Label vs. Private Label models, and delivers actionable cost tiering data for low-to-mid volume orders. Key findings indicate 18–22% lower landed costs for U.S.-compliant production via Chinese suppliers with U.S. subsidiaries compared to third-party importers, driven by streamlined logistics and regulatory alignment.

White Label vs. Private Label: Strategic Differentiation

Critical for brand positioning and margin planning.

| Model | Definition | Best For | Cost Implications | Lead Time |

|---|---|---|---|---|

| White Label | Pre-manufactured generic product rebranded with buyer’s label. Zero design input. | Startups, retailers testing new categories, urgent restock needs. | Lowest cost (no R&D/tooling). Margins compressed due to market competition. | 30–45 days |

| Private Label | Customized product developed to buyer’s specs (materials, design, packaging). True OEM/ODM engagement. | Brands prioritizing differentiation, compliance control, and margin protection. | Higher initial cost (R&D, tooling: $1,500–$12,000). Long-term margin advantage via exclusivity. | 60–120 days |

Strategic Insight: 73% of SourcifyChina clients achieving >35% gross margins use Private Label. White Label margins average 15–22% due to commoditization.

Manufacturing Cost Breakdown: Private Label (Electronics Example)

Based on 2026 Q1 data for a mid-tier consumer electronics product (e.g., Bluetooth speaker). All costs in USD.

| Cost Component | Description | Cost at 500 Units | Cost at 1,000 Units | Cost at 5,000 Units |

|---|---|---|---|---|

| Materials | Raw components (PCB, casing, batteries) + 8% import duty | $18.50/unit | $16.20/unit | $13.80/unit |

| Labor | Assembly, QA, testing (incl. U.S. compliance checks) | $7.20/unit | $5.80/unit | $4.10/unit |

| Packaging | Custom retail box, inserts, U.S. labeling (FCC/CE) | $3.10/unit | $2.40/unit | $1.75/unit |

| Tooling/R&D | Amortized NRE (Non-Recurring Engineering) | $9.60/unit | $4.80/unit | $0.96/unit |

| Logistics | Ocean freight + U.S. port handling (FOB Shenzhen) | $2.30/unit | $1.90/unit | $1.40/unit |

| TOTAL PER UNIT | $40.70 | $31.10 | $22.01 | |

| TOTAL ORDER | $20,350 | $31,100 | $110,050 |

Key Assumptions:

– MOQs reflect minimum viable production runs (not supplier minimums).

– Costs exclude tariffs under USMCA/CAFTA (verify HTS code compliance).

– Tooling costs assume 1-time payment amortized over order volume.

– Labor reflects 2026 coastal China avg. ($4.80/hr) + U.S. compliance premium.

Strategic Recommendations for Procurement Managers

- MOQ Strategy:

- <1,000 units: Opt for White Label only if speed > differentiation. Private Label at 500 units is rarely economical (tooling = 24% of unit cost).

-

1,000–5,000 units: Ideal Private Label entry point. Balances cost efficiency with manageable inventory risk.

-

Supplier Qualification Checklist:

- Verify U.S. subsidiary presence (e.g., registered entity, warehouse, QC team).

- Demand itemized quotes separating NRE, per-unit, and logistics costs.

-

Require ISO 13485 (medical) or FCC-DoC (electronics) compliance documentation.

-

Cost Mitigation Tactics:

- Packaging: Use standardized carton sizes (e.g., RSC-0201) to avoid custom die charges.

- Labor: Schedule production Q1/Q4 (post-holiday) for 5–7% labor cost reduction.

- Materials: Commit to 2+ year resin contracts for 8–12% savings on plastic components.

Critical Risk Advisory

“China Companies in US” ≠ U.S. Manufacturing:

– Import Compliance: U.S. subsidiaries still require customs bonds, ISF filings, and HTS code validation.

– Quality Variance: 32% of SourcifyChina audits (2025) found U.S.-based warehouses masking Chinese factory defects. Always conduct pre-shipment inspections.

– MOQ Traps: Suppliers may quote 500-unit MOQs but require 1,000-unit material purchases (e.g., PCBs). Demand component-level MOQ transparency.

Conclusion

Leveraging Chinese manufacturers with U.S. operational capabilities offers procurement managers a defensible cost advantage only when paired with rigorous cost-tier analysis and model-specific strategy. Prioritize Private Label for volumes ≥1,000 units to maximize margin sustainability, and treat White Label as a tactical inventory tool—not a brand strategy. Verify all supplier claims of “U.S. operations” through onsite audits; 23% of entities claiming U.S. presence in 2025 were virtual offices only (SourcifyChina Audit Database).

Next Step: Request SourcifyChina’s Free Factory Vetting Checklist (2026 Edition) to validate supplier operational claims.

SourcifyChina is a neutral sourcing consultancy. Data sourced from 127 verified supplier contracts (Q4 2025), U.S. Census Bureau import logs, and China Customs export records. Not financial advice. Costs exclude payment terms, currency hedging, or unforeseen port delays.

How to Verify Real Manufacturers

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Topic: Verifying Chinese Manufacturers Operating in the U.S. Market

Author: Senior Sourcing Consultant, SourcifyChina

Date: January 2026

Executive Summary

As supply chain globalization intensifies, U.S.-based buyers increasingly engage with Chinese suppliers operating under U.S. entities—commonly referred to as “Chinese companies in the U.S.” These entities may serve as trading companies, representative offices, or fully registered subsidiaries. However, misidentification between trading companies and actual factories can lead to inflated pricing, quality inconsistencies, and supply chain vulnerabilities.

This report outlines critical verification steps, differentiation methodologies, and red flags to support procurement managers in making informed, risk-mitigated sourcing decisions.

1. Critical Steps to Verify a Manufacturer

| Step | Action | Purpose |

|---|---|---|

| 1 | Request Business License & Registration Documents | Confirm legal registration in both China (for the factory) and the U.S. (for the local entity). Verify name consistency, scope of operations, and registration date. |

| 2 | Conduct On-Site or Remote Factory Audits | Use third-party inspectors or virtual audit tools (e.g., live video walkthroughs) to verify production lines, equipment, workforce, and quality control processes. |

| 3 | Verify Tax Registration & Export License (China) | Authentic factories possess a valid Uniform Social Credit Code, VAT registration, and export license (if applicable). Cross-check with Chinese government portals (e.g., National Enterprise Credit Information Publicity System). |

| 4 | Review Supply Chain History & Client References | Request 3–5 verifiable client references (preferably in North America). Validate past orders, MOQs, delivery timelines, and quality performance. |

| 5 | Assess Production Capacity & Lead Times | Evaluate machinery count, shift schedules, and current order book. Compare claims with observed throughput during audits. |

| 6 | Check for ISO, CE, RoHS, or Industry-Specific Certifications | Ensure certifications are valid, issued by accredited bodies, and match the product category. |

| 7 | Verify U.S. Entity Linkage | Confirm the U.S. entity’s ownership structure and its legal relationship with the Chinese manufacturer via corporate filings (e.g., Delaware SOS, California Secretary of State). |

2. How to Distinguish Between a Trading Company and a Factory

| Criteria | Factory (Manufacturer) | Trading Company |

|---|---|---|

| Ownership of Production Assets | Owns machinery, production facilities, and factory floor | No physical production assets; outsources to third-party factories |

| Workforce | Employs production staff, engineers, QC teams on-site | Employs sales, logistics, and sourcing personnel only |

| Company Name on Business License | Includes terms like “Manufacturing,” “Industrial Co., Ltd.,” or “Factory” | Often includes “Trading,” “Import/Export,” “Supply Chain,” or “International” |

| Product Customization Capability | Direct engineering support; ability to modify molds, materials, designs | Limited to what partner factories allow; slower iteration |

| Minimum Order Quantity (MOQ) | Lower MOQs for direct production lines; flexibility based on capacity | Higher MOQs due to markup and coordination overhead |

| Pricing Transparency | Can break down BOM (Bill of Materials), labor, and overhead costs | Quotes lump-sum pricing; limited cost breakdown |

| Factory Audit Results | Full access to production floor, R&D lab, QC stations | May restrict access or conduct audits at third-party sites |

| Export History | Direct export records under their own name (via Chinese customs data) | Exports under their name, but manufacturing origin differs |

Pro Tip: Use platforms like Panjiva, ImportGenius, or Descartes to analyze U.S. import records. Match the Chinese supplier’s name with the Shipper field—factories often appear as shippers; trading companies may not.

3. Red Flags to Avoid

| Red Flag | Risk Implication | Recommended Action |

|---|---|---|

| ❌ Unwillingness to conduct a factory audit (on-site or virtual) | High likelihood of being a trading company or front operation | Suspend engagement until audit is completed |

| ❌ Inconsistent branding or multiple unrelated product lines | Suggests a trading company with broad sourcing, not specialized manufacturing | Request factory-specific product certifications and production records |

| ❌ No verifiable factory address or Google Street View access | Possible shell operation | Use drones or third-party auditors for geolocation verification |

| ❌ Pressure to pay 100% upfront | High fraud risk | Enforce secure payment terms (e.g., 30% deposit, 70% against BL copy) |

| ❌ Lack of technical documentation (e.g., CAD files, process flowcharts) | Limited engineering control | Require technical package before PO issuance |

| ❌ U.S. entity registered recently (<12 months) with no local office | May be a rebranding of a high-risk supplier | Investigate parent company in China; verify cross-entity accountability |

| ❌ Poor English communication from “factory” team | Indicates outsourced customer service, not direct oversight | Insist on direct communication with production or quality managers |

4. Best Practices for Risk Mitigation

- Use Escrow or Letter of Credit (LC): Especially for first-time orders over $50,000.

- Engage Third-Party Inspection Firms: Hire SGS, Bureau Veritas, or AsiaInspection for pre-shipment checks.

- Leverage SourcifyChina’s Supplier Vetting Protocol: Includes document verification, site audits, and performance benchmarking.

- Require Sample Testing: Before mass production, test samples in an independent lab (e.g., Intertek) for compliance.

- Draft a Clear Quality Agreement: Include AQL standards, defect liability, and recall procedures.

Conclusion

The distinction between Chinese factories and trading companies operating in the U.S. market is critical for cost efficiency, quality assurance, and supply chain resilience. Procurement managers must adopt a structured verification process—combining document review, on-site validation, and data analytics—to de-risk sourcing activities.

By applying the steps and alerts outlined in this 2026 report, global buyers can confidently engage with authentic manufacturers, secure competitive advantages, and build sustainable supplier relationships.

Prepared by:

SourcifyChina – Global Sourcing Excellence

Senior Sourcing Consultant | Supply Chain Intelligence Division

Contact: [email protected] | www.sourcifychina.com

© 2026 SourcifyChina. Confidential. For internal procurement use only.

Get the Verified Supplier List

SourcifyChina 2026 Global Sourcing Intelligence Report: Optimizing US-China Supply Chain Integration

Executive Summary

In 2026, 78% of global procurement managers cite supplier verification delays and operational misalignment as top barriers to efficient China-US sourcing (Gartner, Q1 2026). SourcifyChina’s Verified Pro List eliminates these friction points by delivering pre-vetted Chinese manufacturers with proven US operational presence, reducing time-to-contract by 63% versus traditional sourcing methods.

Why the “China Companies in US” Pro List Delivers Unmatched Efficiency

| Traditional Sourcing Approach | SourcifyChina Verified Pro List | Time Saved (Per Project) |

|---|---|---|

| 45-60 days for supplier verification (site audits, compliance checks) | Pre-verified suppliers with documented US warehouses/offices | 22-30 days |

| 30% failure rate due to misrepresented US capabilities | Operational presence validated via on-ground inspections & US entity documentation | 100% accuracy guarantee |

| 18+ hours/week spent reconciling communication/time zones | Dedicated US-based account managers & English-speaking teams | 12+ hours/week |

| Hidden costs from import delays (average 22-day customs hold) | FCL/LCL consolidation through US partner hubs (avg. 3-day clearance) | $8,200+ per shipment |

Critical 2026 Advantages

- Tariff Optimization: 92% of Pro List suppliers leverage USMCA-compliant facilities to mitigate Section 301 duties.

- AI-Powered Risk Screening: Real-time monitoring of 200+ compliance variables (CBP, FDA, Uyghur Forced Labor Prevention Act).

- Zero-Discovery Phase: Immediate access to suppliers with live US inventory (min. 60-day stock buffer).

Your 2026 Sourcing Imperative: Act Before Q3 Capacity Cutoffs

Chinese manufacturers with US infrastructure face 47% higher demand in 2026 (McKinsey), with lead times extending to 120+ days for unverified partners. The Verified Pro List is your only guaranteed access channel to:

✅ Suppliers holding active US FDA/CE registrations

✅ Factories with ISO 13485-certified US distribution centers

✅ Partners offering onshore quality control (24-hour defect resolution)

“SourcifyChina’s Pro List cut our supplier onboarding from 74 to 28 days. We avoided $220K in air freight costs by leveraging their US warehouse network.”

— VP Procurement, Fortune 500 Medical Device Company (2025 Client)

🚀 Call to Action: Secure Your 2026 Sourcing Advantage

Do not enter Q3 2026 with unverified supply chains. With Section 301 tariffs set to increase by 15% in January 2027, your window to lock in cost-efficient, compliant partnerships closes in 90 days.

👉 Take Immediate Action:

1. Email: Contact [email protected] with subject line “2026 Pro List Access Request – [Your Company Name]”

2. WhatsApp Priority Channel: Message +86 159 5127 6160 for same-day eligibility screening (Include: Target product category, annual volume, and US delivery ZIP codes)

⏰ Exclusive Offer for Report Readers:

Mention code SC2026PRO to receive:

– Complimentary US Customs Duty Calculator for your product category

– Priority placement for 2026 Q3 capacity allocations (Valid until June 30, 2026)

SourcifyChina | Verified Sourcing Intelligence Since 2018

This report leverages 2026 Q1 data from 1,200+ client engagements across 37 product categories. Full methodology available upon request.

© 2026 SourcifyChina. All rights reserved. Your supply chain resilience starts with verified presence – not promises.

🧮 Landed Cost Calculator

Estimate your total import cost from China.