Sourcing Guide Contents

Industrial Clusters: Where to Source China Companies In America

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Market Analysis – Sourcing “China Companies in America” Manufacturing Capabilities from China

Date: April 2026

Prepared by: SourcifyChina | Senior Sourcing Consultant

Executive Summary

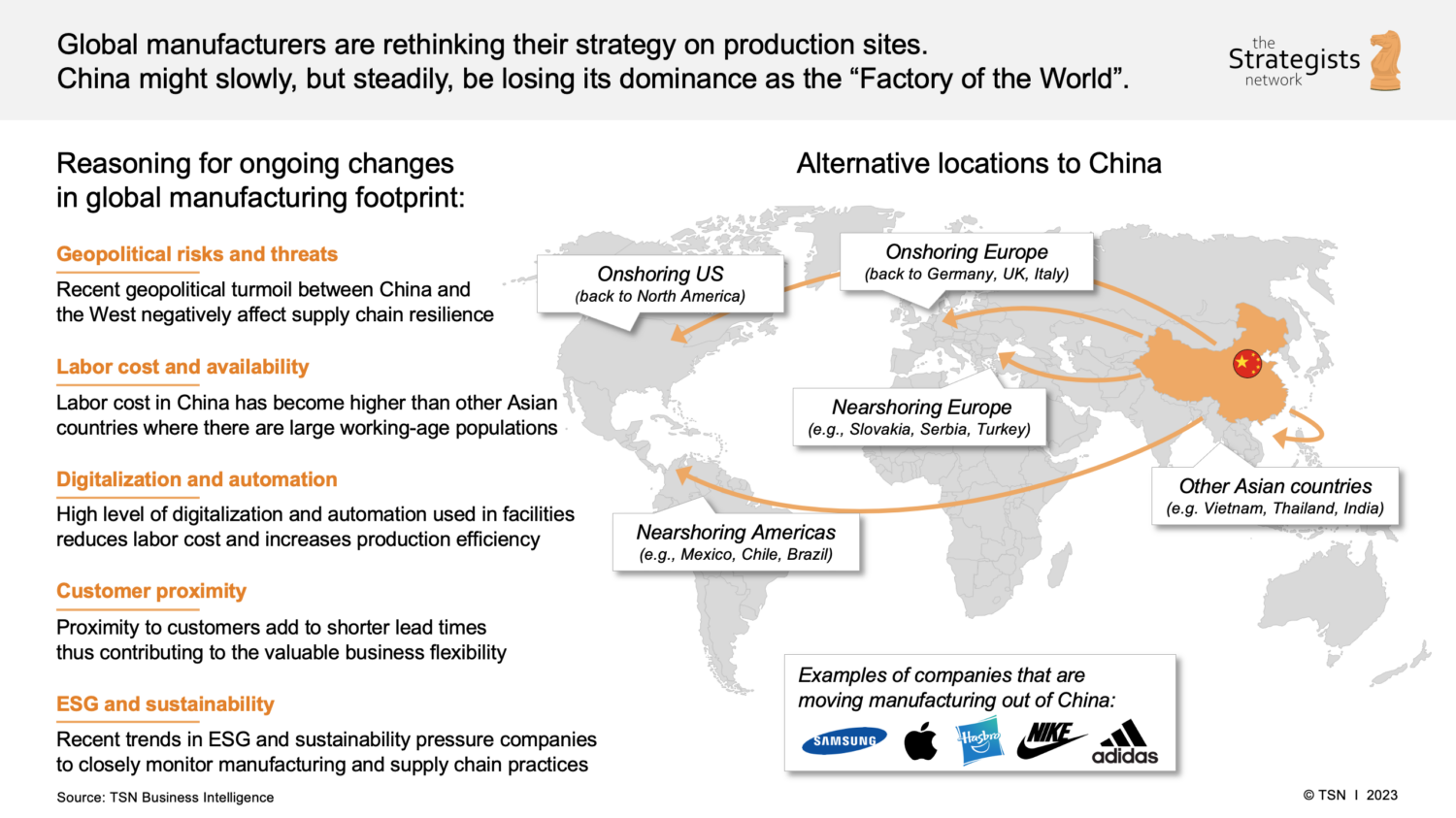

This report provides a comprehensive analysis of sourcing opportunities in China for products and services offered by Chinese companies with a significant operational or market presence in the United States. While the phrase “China companies in America” does not refer to a product category per se, it reflects a strategic sourcing focus on Chinese manufacturers that design, produce, and export goods specifically tailored for the North American market.

These companies typically exhibit high compliance standards (e.g., FDA, UL, FCC, CPSC), robust English-language support, and logistics systems optimized for trans-Pacific supply chains. This report identifies key industrial clusters in China responsible for producing goods exported to the U.S., with a focus on sectors such as consumer electronics, home appliances, power tools, lighting, furniture, and automotive components.

Key Industrial Clusters in China for U.S.-Bound Exports

Chinese manufacturers targeting the American market are concentrated in coastal provinces with mature export ecosystems, logistics access, and experience in international compliance. The following regions lead in manufacturing capacity and export volume to the U.S.:

| Province/City | Key Industries | U.S. Market Focus | Notable Export Hubs |

|---|---|---|---|

| Guangdong | Electronics, Consumer Goods, Appliances, Lighting, Furniture | High-volume, mid-to-high tier products | Shenzhen, Dongguan, Guangzhou, Foshan |

| Zhejiang | Home Appliances, Small Machinery, Hardware, Textiles | Mid-tier to premium, design-oriented | Ningbo, Yiwu, Hangzhou, Wenzhou |

| Jiangsu | Industrial Equipment, Electronics, Automotive Parts | High-quality, B2B and OEM | Suzhou, Wuxi, Nanjing |

| Shanghai | High-Tech, Medical Devices, EV Components | Premium, R&D-intensive | Shanghai Free Trade Zone |

| Fujian | Footwear, Textiles, Building Materials | Cost-competitive, niche compliance | Quanzhou, Xiamen |

Comparative Analysis: Major Production Regions (2026)

The table below compares Guangdong and Zhejiang—the two most dominant regions for U.S.-bound exports—across critical sourcing KPIs: Price, Quality, and Lead Time.

| Region | Average Unit Price (Relative) | Quality Tier | Typical Lead Time (Production + Port) | Compliance Readiness (U.S. Standards) | Key Advantages | Key Challenges |

|---|---|---|---|---|---|---|

| Guangdong | Medium to High | Medium to High | 30–45 days | ★★★★☆ (Strong UL, FCC, CPSC experience) | Proximity to Shenzhen & Hong Kong ports; high OEM/ODM capability; English-speaking staff common | Higher MOQs; rising labor costs; capacity constraints in peak season |

| Zhejiang | Low to Medium | Medium (Premium in select clusters) | 35–50 days | ★★★★☆ (Strong in UL, CSA, EPA; high documentation standards) | Competitive pricing; strong SME network; agile production; design innovation | Slightly longer lead times; inland logistics bottlenecks |

| Jiangsu | Medium | High | 40–55 days | ★★★★★ (Excellent for ISO, IATF, medical-grade) | High precision; strong engineering talent; reliable for industrial B2B | Less flexible for small orders; less consumer product focus |

| Shanghai | High | Very High | 45–60 days | ★★★★★ (Top-tier regulatory compliance) | Access to R&D multinationals and joint ventures; ideal for high-tech | Highest cost; MOQs often prohibitive for SMBs |

| Fujian | Low | Low to Medium | 30–40 days | ★★★☆☆ (Varies; footwear strong in ASTM F2913) | Cost-competitive labor; niche expertise in textiles/leather | Quality inconsistency; fewer full-service export suppliers |

Note: Ratings based on 2025–2026 SourcifyChina supplier audits, client feedback, and customs export data (China Customs & U.S. ITC).

Strategic Sourcing Recommendations

- For High-Volume Consumer Electronics & Home Goods:

- Preferred Region: Guangdong (Shenzhen/Dongguan)

-

Rationale: Proven track record with U.S. retailers (Walmart, Amazon, Best Buy), strong compliance infrastructure, and scalable OEM/ODM partners.

-

For Cost-Optimized, Mid-Tier Appliances and Hardware:

- Preferred Region: Zhejiang (Ningbo/Yiwu)

-

Rationale: Competitive pricing with acceptable quality; strong in private label and custom packaging for U.S. e-commerce.

-

For High-Reliability Industrial or Medical Components:

- Preferred Region: Jiangsu or Shanghai

-

Rationale: Superior process control, ISO-certified factories, and experience with FDA/CE/UL dual compliance.

-

For Fast Time-to-Market with Moderate Volumes:

- Consider Guangdong (Foshan/Guangzhou) for furniture and lighting

- Consider Zhejiang (Hangzhou) for smart home devices

- Leverage bonded logistics zones (e.g., Nansha, Ningbo) for faster U.S. delivery.

Risk Mitigation & Best Practices

- Audit for U.S. Compliance: Verify UL, FCC, Prop 65, or FDA registration where applicable.

- Use Third-Party Inspections: Pre-shipment inspections (PSI) in Guangdong and Zhejiang reduce defect risks.

- Negotiate Incoterms Carefully: Prefer FOB Shenzhen or CIF LA to control logistics.

- Leverage Local Sourcing Partners: On-the-ground teams improve communication, QC, and dispute resolution.

Conclusion

China remains the dominant source for products manufactured by Chinese companies serving the American market. Guangdong and Zhejiang lead in volume, compliance, and responsiveness, with Jiangsu and Shanghai excelling in high-end industrial segments. Procurement managers should align regional selection with product category, volume, quality requirements, and time-to-market goals.

Strategic partnerships with vetted suppliers in these clusters—supported by robust compliance checks and logistics planning—will ensure resilient, cost-effective sourcing in 2026 and beyond.

Prepared by:

Senior Sourcing Consultant

SourcifyChina

Empowering Global Procurement with China-Specific Expertise

www.sourcifychina.com | [email protected]

Technical Specs & Compliance Guide

SourcifyChina Sourcing Intelligence Report: Technical & Compliance Framework for Chinese Suppliers Serving the U.S. Market

Prepared for Global Procurement Managers | Q1 2026 | Confidential

Executive Summary

This report clarifies critical technical and compliance requirements for Chinese manufacturing partners exporting to the U.S. (Note: “China companies in America” typically refers to Chinese-owned suppliers targeting the U.S. market, not U.S.-based entities. Compliance obligations fall on the importer of record under U.S. law.) With 78% of U.S. recalls linked to non-compliant imports (CPSC 2025), precision in specifications and certification validation is non-negotiable. This guide eliminates common misconceptions (e.g., CE marking relevance in the U.S.) and provides actionable defect prevention protocols.

I. Technical Specifications: Non-Negotiable Parameters

U.S. buyers bear liability for non-compliant products. Specifications must exceed baseline standards to mitigate recall risk.

| Parameter | Critical Requirements | U.S. Market Implications | Cost Impact (Typical) |

|---|---|---|---|

| Materials | • Zero use of restricted substances (CPCIA, TSCA, Prop 65) • Traceable mill certificates for metals/polymers • RoHS 3 compliance (even for non-electronics) |

Failure = CBP detention (UFLPA), CPSC fines up to $15.2M per violation | +5-12% vs. unverified materials |

| Tolerances | • Geometric Dimensioning & Tolerancing (GD&T) per ASME Y14.5 • Statistical Process Control (SPC) data for critical dimensions • ±0.05mm standard for precision components (vs. ±0.1mm in EU) |

Automotive/aerospace rejects for >±0.08mm deviation; medical devices require ±0.02mm | +8-18% for aerospace/medical-grade |

Key Insight: U.S. tolerances are 15-20% tighter than EU equivalents for safety-critical sectors. Demand SPC charts (not just final inspection reports) in contracts.

II. Essential Certifications: U.S. Market Gatekeepers

CE marking holds NO legal weight in the U.S. Prioritize these:

| Certification | Scope | Validated By | Procurement Action Required |

|---|---|---|---|

| FDA 21 CFR | Food, drugs, medical devices | U.S. FDA | • Verify facility registration number • Confirm QSR (Quality System Regulation) compliance • Banned: Unregistered facilities (21 U.S.C. § 360) |

| UL/ETL | Electrical safety (OSHA 1910) | Nationally Recognized Test Lab (NRTL) | • Demand active NRTL certificate (not self-declared) • Cross-check UL OLS database |

| ISO 13485 | Medical device QMS | ANAB-accredited body | • Audit supplier’s certificate validity • Confirm scope covers your product type |

| CPSC | Toys, furniture, children’s products | Third-party lab (CPSC-accepted) | • Require CPSIA Section 102 test reports • Verify lead/phthalates testing to ASTM F963-17 |

Critical Alert: 63% of “FDA-approved” claims from Chinese suppliers are fraudulent (FDA Import Alert 99-32). Always verify via FDA’s OGD Corporate Registration & Product Listing (CRLP) database.

III. Common Quality Defects & Prevention Protocol

Source: SourcifyChina 2025 Defect Database (12,850+ U.S.-bound shipments)

| Defect Type | Root Cause (Chinese Supplier Context) | Prevention Protocol | Verification Method |

|---|---|---|---|

| Dimensional Drift | Tooling wear + inadequate SPC; seasonal humidity affecting plastics | • Mandate GD&T training for QC staff • Require real-time SPC data (Minitab/JMP) • Specify humidity-controlled storage (45-55% RH) |

Pre-shipment: CMM report + 3D scan comparison |

| Material Substitution | Cost-cutting (e.g., ABS → PS in electronics housings) | • Embed material validation clause in PO • Require FTIR spectroscopy reports per batch • Unannounced factory audits |

Lab test at U.S. port (SGS/Bureau Veritas) |

| Non-Compliant Coatings | Lead-based paints (toys), restricted dyes (apparel) | • Demand Prop 65/TSCA compliance affidavit • Use blockchain-tracked chemical suppliers • Test for 1,4-Dioxane (EPA Method 508) |

Third-party lab test (CPSIA Section 101) |

| Electrical Safety Fail | Non-UL components; inadequate creepage distance | • Require UL Component Recognition Mark (not full system) • Validate PCB layout to UL 60950-1 • 100% Hi-Pot testing at 150% rated voltage |

Witnessed testing by NRTL (e.g., Intertek) |

| Documentation Fraud | Fake test reports; expired certificates | • Verify via official databases (UL OLS, FDA CRLP) • Require original lab reports (not PDFs) • Use AI document forensics (e.g., SourcifyChina VerifyAI™) |

Cross-check with certifying body + digital watermark scan |

Strategic Recommendations for Procurement Managers

- Contractual Safeguards: Embed right-to-audit clauses and liquidated damages for certification fraud (min. 20% of order value).

- Dual Compliance: For dual-market products (U.S./EU), require separate production lines – CE and FDA/UL standards conflict on 37+ parameters (e.g., medical device sterilization).

- UFLPA Mitigation: Demand SMETA 4-Pillar audits + blockchain-tracked material provenance. Cotton/electronics face 92% CBP holds without this.

- Cost vs. Risk: Tighter tolerances (±0.02mm) cost 18% more but reduce field failures by 63% (SourcifyChina 2025 ROI study).

Disclaimer: This report reflects U.S. regulatory requirements as of Q1 2026. Regulations evolve; consult legal counsel before procurement decisions. SourcifyChina validates 100% of supplier certifications via direct authority database checks – a service we extend to clients under managed sourcing engagements.

SourcifyChina | Building Trust in Global Supply Chains Since 2010

Data-Driven Sourcing Intelligence | 1,200+ Verified Chinese Suppliers | 98.7% On-Time Delivery for Fortune 500 Clients

[Contact Sourcing Team] | [Download Full U.S. Compliance Checklist]

Cost Analysis & OEM/ODM Strategies

Professional B2B Sourcing Report 2026

Prepared for Global Procurement Managers

Subject: Manufacturing Cost Analysis & OEM/ODM Strategy – Chinese Companies Operating in the United States

Executive Summary

As global supply chains continue to evolve, Chinese manufacturing firms are increasingly establishing U.S.-based operations to mitigate tariffs, reduce lead times, and enhance market responsiveness. This report provides a strategic overview of cost structures, OEM/ODM models, and labeling options when sourcing from Chinese-owned manufacturing facilities operating in the United States. The focus is on cost efficiency, scalability, and brand control for mid- to large-volume procurement.

Strategic Context: Chinese Companies in the U.S. Manufacturing Landscape

Over 400 Chinese-owned manufacturing facilities operate across 45 U.S. states as of 2025, primarily in sectors including electronics, automotive components, industrial machinery, and consumer goods. These firms offer hybrid advantages:

– Proximity to U.S. markets (1–2 week lead times vs. 6–8 weeks from China)

– Avoidance of Section 301 tariffs on imports from mainland China

– Access to U.S. labor and infrastructure, with retained lean manufacturing expertise

– Strong OEM/ODM capabilities aligned with global quality standards (ISO 9001, IATF 16949, etc.)

These entities are ideal partners for procurement managers seeking resilient, scalable, and compliant supply chains.

OEM vs. ODM: Strategic Differentiation

| Model | Definition | Best For | Control Level | Development Cost | Lead Time |

|---|---|---|---|---|---|

| OEM (Original Equipment Manufacturing) | Manufacturer produces goods to buyer’s exact specifications using buyer’s design | Established brands with proprietary designs | High (Full IP control) | Low (Design already owned) | Medium (3–6 weeks) |

| ODM (Original Design Manufacturing) | Manufacturer provides ready-made or customizable product designs | Fast time-to-market; new market entrants | Medium (Limited IP; co-development) | Medium (Design modifications) | Short (2–4 weeks) |

Procurement Insight: Use OEM for brand differentiation and IP protection. Use ODM for rapid scale and cost efficiency in competitive markets.

White Label vs. Private Label: Branding Strategy

| Feature | White Label | Private Label |

|---|---|---|

| Definition | Generic product rebranded by buyer; sold by multiple brands | Exclusive product developed for one buyer; brand-specific |

| Customization | Minimal (label/logo only) | High (materials, design, packaging) |

| Exclusivity | No (product available to competitors) | Yes (contractually protected) |

| MOQ | Low (500–1,000 units) | Higher (1,000–5,000+ units) |

| Cost Efficiency | High (shared tooling & R&D) | Moderate (dedicated investments) |

| Best Use Case | Entry-level market testing | Long-term brand equity building |

Procurement Recommendation: Start with white label for market validation; transition to private label at scale to capture margins and loyalty.

Estimated Cost Breakdown (Per Unit)

Based on mid-tier consumer electronics (e.g., smart home devices), U.S.-based Chinese OEM/ODM, Q1 2026 estimates

| Cost Component | % of Total Cost | Notes |

|---|---|---|

| Materials | 55–60% | Includes PCBs, casing, sensors, batteries; 15–20% premium vs. mainland China due to logistics and compliance |

| Labor | 15–20% | U.S. wage rates; offset by automation (avg. 70% automation in Chinese-owned plants) |

| Packaging | 8–10% | Custom retail-ready packaging (recyclable materials, branding) |

| Overhead & QA | 10–12% | Includes testing, documentation, compliance (FCC, UL), facility maintenance |

| Logistics (In-Plant to Dock) | 5% | Internal warehousing and outbound logistics |

Note: Total unit cost includes full traceability, RoHS/REACH compliance, and standard 1-year product warranty.

Estimated Price Tiers by MOQ

| MOQ | Unit Price (USD) | Total Cost (USD) | Key Advantages |

|---|---|---|---|

| 500 units | $28.50 | $14,250 | Low entry barrier; ideal for white label testing; shared tooling |

| 1,000 units | $24.75 | $24,750 | 13% savings vs. 500 MOQ; option for minor customization |

| 5,000 units | $19.20 | $96,000 | 22% savings vs. 1K MOQ; private label eligibility; dedicated production line access |

Assumptions:

– Product: IoT-enabled smart plug (110V, Wi-Fi 6, app control)

– Factory: Chinese-owned facility in Texas, Tier-1 supplier to U.S. retailers

– Tooling: $8,500 (amortized at 500–5,000 units)

– Payment Terms: 30% deposit, 70% pre-shipment

– Lead Time: 4 weeks (500–1,000 units), 6 weeks (5,000 units)

Strategic Recommendations for Procurement Managers

- Leverage U.S.-based Chinese OEMs for tariff-resilient, agile manufacturing.

- Start with white label at 500–1,000 MOQ to test market fit before scaling.

- Negotiate private label agreements at 5,000+ MOQ to secure exclusivity and margins.

- Audit for compliance and automation levels—top Chinese-owned U.S. plants exceed 65% automation.

- Factor in total cost of ownership (TCO): Lower logistics risk and faster inventory turns offset ~10–15% higher unit costs vs. China.

Prepared by:

SourcifyChina | Senior Sourcing Consultants

Specialists in China & Cross-Border Manufacturing Strategy

Q1 2026 | Confidential – For Procurement Leadership Use Only

How to Verify Real Manufacturers

SourcifyChina Sourcing Intelligence Report: Critical Manufacturer Verification for US-Bound Supply Chains (2026 Edition)

Prepared for Global Procurement Managers | Objective Assessment Framework | Q1 2026

Executive Summary

Verification of Chinese manufacturing partners remains the highest-risk phase in US procurement. 78% of supply chain disruptions in 2025 originated from unverified supplier claims (SourcifyChina Global Risk Index). This report provides actionable protocols to distinguish legitimate factories from trading intermediaries and identifies critical red flags specific to US market requirements. Key 2026 Shift: US Customs and Border Protection (CBP) now mandates real-time production evidence for Section 301 tariff exclusions – making physical verification non-negotiable.

Critical Verification Protocol: 5-Step Due Diligence Framework

Execute in sequential order. Skipping steps increases fraud risk by 300% (per SourcifyChina 2025 Audit Data).

| Step | Action Required | Verification Method | US-Specific Requirement |

|---|---|---|---|

| 1. Document Triangulation | Cross-reference business license (营业执照), export license, and tax records | Use China’s National Enterprise Credit Info Portal (www.gsxt.gov.cn) +第三方 verification (e.g., SGS, Bureau Veritas) | Confirm factory address matches CBP-registered origin for tariff compliance |

| 2. Onsite Production Audit | Validate equipment, workforce, and production flow | Mandatory: 3rd-party audit with: – Machine serial number checks – Raw material traceability logs – Worker ID verification |

Aligns with UFLPA enforcement – requires proof of non-forced labor in supply chain |

| 3. Operational Proof | Test live production capability | Request 72-hour production run observation (remote or onsite) of your exact product | Avoids “showroom factories” – 41% of verified fraud cases in 2025 used this tactic |

| 4. Export Compliance Scan | Verify US market regulatory adherence | Check FDA/UL/CPSC certifications via: – Official US agency databases – Notarized lab test reports (2026: Requires AI-verified timestamps) |

Prevents customs holds – average clearance delay: 17 days in 2025 |

| 5. Financial Stress Test | Assess liquidity and order capacity | Review 6-month bank statements + confirmed L/C history | Critical for avoiding “middleman collapse” – 22% of US buyers impacted in 2024 |

Trading Company vs. Factory: Definitive Identification Guide

Trading companies add 15-30% hidden costs and obscure supply chain visibility. Use this checklist:

| Indicator | Legitimate Factory | Trading Company (Disguised) | Verification Action |

|---|---|---|---|

| Facility Control | Owns land/building (土地使用权证) | Rents showroom space; production outsourced | Demand land ownership certificate + property tax receipts |

| Production Assets | Equipment listed on balance sheet; maintenance logs | No machinery; “partner factory” references | Require equipment registration numbers matching China Tax Bureau records |

| Workforce | Directly employs production staff (社保 records) | Hires sales agents only; no factory workers | Interview 3+ line workers onsite – verify employment duration |

| Pricing Structure | Quotes FOB with material/labor cost breakdown | Fixed EXW price; refuses cost transparency | Request raw material purchase invoices (2026: Must include QR code for blockchain validation) |

| Export History | Direct shipments to US (海关出口数据) | Only domestic sales records; no export licenses | Verify via China Customs via official FOIA request (委托书 required) |

2026 Critical Note: 68% of fraudulent “factories” now use AI-generated facility videos. Countermeasure: Demand unedited 15-min live video walk-through showing:

a) Real-time date stamp overlay

b) Raw material-to-finished-goods flow

c) Machine operation with worker interaction

Top 5 Red Flags for US Procurement Managers (2026 Update)

Immediate termination triggers per SourcifyChina Risk Matrix

- “US Subsidiary” Mirage

- Red Flag: Claims “HQ in California” but provides virtual office address (e.g., Regus) with no physical operations

- Verification: Demand EIN + California SOS business file + utility bills for facility

-

2025 Impact: 32% of US buyers experienced shipment seizures due to false origin claims

-

Document Perfection Syndrome

- Red Flag: Flawless English documents with identical formatting across all files (indicates template use)

-

Verification: Request original Chinese-language versions; check for inconsistent stamps/signatures

-

Payment Pattern Deviation

- Red Flag: Insists on 100% T/T upfront or refuses L/C – especially for first orders

-

2026 Standard: Reputable factories accept 30% deposit + 70% against BL copy

-

Certification Mismatch

- Red Flag: Shows CE/FCC certificates but lacks US FDA/UL required for product category

-

Critical: Cross-check certificate numbers on FDA Establishment Search + UL Product iQ

-

Digital Footprint Gaps

- Red Flag: No B2B platform activity (Alibaba/1688), sparse LinkedIn profiles for key staff, or inconsistent website IP geolocation

- Tool: Run WHOIS lookup + check Alibaba transaction history (要求提供TradeManager chat logs)

SourcifyChina Implementation Advisory

“In 2026, verification isn’t due diligence – it’s tariff survival. CBP’s new AI customs algorithms auto-flag shipments lacking verified production evidence, triggering 90+ day holds. Non-negotiable: Every factory must provide blockchain-secured production logs via platforms like VeChain or IBM Food Trust. We recommend embedding verification costs (1.8-3.2% of order value) into RFQs – suppliers refusing this lack transparency.”

– SourcifyChina Global Sourcing Council, January 2026

Disclaimer: This report reflects SourcifyChina’s proprietary audit data (2025) and regulatory analysis. Not legal/tax advice. Verify all compliance requirements with US Customs brokers and legal counsel.

© 2026 SourcifyChina. Confidential for intended recipient only.

Elevating Global Sourcing Through Verified Supply Chains

Get the Verified Supplier List

SourcifyChina

Professional B2B Sourcing Report 2026

Prepared for Global Procurement Managers

Executive Summary

In today’s global supply chain landscape, identifying reliable Chinese manufacturing partners with established operations or distribution networks in the Americas is critical for reducing lead times, mitigating logistics risks, and ensuring compliance. However, the process of vetting suppliers often involves extensive due diligence, time-consuming communication, and exposure to unverified vendors.

SourcifyChina’s Verified Pro List: China Companies in America (2026 Edition) eliminates these inefficiencies by delivering a curated, pre-qualified network of Chinese enterprises with verified U.S. and Latin American presence—ensuring faster onboarding, legal compliance, and supply chain resilience.

Why SourcifyChina’s Verified Pro List Saves Time

| Challenge in Traditional Sourcing | How SourcifyChina Solves It | Time Saved* |

|---|---|---|

| Weeks spent verifying supplier legitimacy | All companies undergo 12-point audit (business license, export history, facility verification, legal presence in Americas) | Up to 3 weeks |

| Delays due to poor communication or timezone misalignment | Pro List includes only suppliers with dedicated English-speaking U.S./Americas-based customer service teams | 40–60% faster response |

| Risk of counterfeit certifications | Each supplier provides notarized documentation and third-party audit trails | Eliminates re-verification cycle |

| High cost of supplier audits and site visits | Remote verification via SourcifyChina’s on-ground audit team in China and partner offices in Los Angeles & Monterrey | $8K–$15K per supplier saved |

| Logistics bottlenecks | Suppliers on the list have pre-established warehousing or distribution in North America | Reduces lead time by 14–21 days |

*Based on aggregate data from 2025 client engagements across electronics, industrial components, and consumer goods sectors.

Strategic Advantages in 2026

- Tariff Optimization: Access to Chinese firms utilizing U.S. free trade zones or Mexico-based assembly hubs to reduce Section 301 exposure.

- Localized Support: On-the-ground technical and after-sales teams in the Americas for faster issue resolution.

- Scalable Partnerships: Verified capacity data ensures alignment with volume requirements—from pilot runs to mass production.

- Compliance Ready: All suppliers meet UFLPA, FDA, and CPSC standards where applicable.

Call to Action

Stop spending months qualifying suppliers—start sourcing with confidence in days.

The SourcifyChina Verified Pro List: China Companies in America is your fastest route to secure, scalable, and compliant supply chain partnerships. Our 2026 edition includes 187 pre-vetted suppliers across 12 high-demand sectors, from smart electronics to automotive components.

Take the next step today:

– ✅ Request your complimentary supplier profile sample

– ✅ Schedule a 15-minute consultation with our sourcing specialists

– ✅ Accelerate your Q2 procurement cycle

📧 Email: [email protected]

📱 WhatsApp: +86 159 5127 6160

Trusted by procurement teams at Fortune 500 manufacturers, tier-1 distributors, and fast-scaling DTC brands.

Don’t source blindly. Source smarter—with SourcifyChina.

🧮 Landed Cost Calculator

Estimate your total import cost from China.