Sourcing Guide Contents

Industrial Clusters: Where to Source China Cnc Machining Companies

SourcifyChina

B2B Sourcing Report 2026

Strategic Intelligence for Global Procurement Managers

Deep-Dive Market Analysis: Sourcing CNC Machining Services from China

Executive Summary

China remains the world’s leading destination for precision CNC machining, offering a combination of scale, technical capability, and cost efficiency. As of 2026, global procurement managers continue to prioritize China for high-mix, low-to-medium volume CNC production across aerospace, medical devices, automotive, and industrial automation sectors. This report provides a strategic overview of key industrial clusters producing CNC machining services in China, with a comparative analysis of regional strengths in price, quality, and lead time.

The CNC machining ecosystem in China is concentrated in well-established manufacturing hubs, each with distinct competitive advantages shaped by local supply chains, workforce specialization, and government industrial policy. The most prominent clusters are located in Guangdong, Zhejiang, Jiangsu, and Shanghai, with emerging secondary hubs in Shandong and Sichuan.

Key Industrial Clusters for CNC Machining in China

| Region | Key Cities | Specialization | Key Advantages |

|---|---|---|---|

| Guangdong | Shenzhen, Dongguan, Guangzhou | High-precision, small-to-medium parts; electronics integration | Proximity to electronics supply chains; strong export infrastructure; advanced automation adoption |

| Zhejiang | Ningbo, Hangzhou, Yuyao | Medium-complexity components; molds and tooling integration | High concentration of SME machining workshops; competitive pricing; strong mold-making heritage |

| Jiangsu | Suzhou, Wuxi, Changzhou | High-volume industrial parts; automotive and aerospace | Integration with German/Japanese manufacturing standards; skilled labor force; strong QA systems |

| Shanghai | Shanghai (Pudong, Jiading) | High-end, low-volume precision machining | Access to R&D centers; multilingual project management; compliance with ISO 13485, AS9100 |

| Shandong | Qingdao, Jinan | Heavy machining; large structural components | Lower labor costs; rising automation; growing export readiness |

| Sichuan | Chengdu, Chongqing | Emerging hub for inland sourcing | Government incentives; lower overhead; improving logistics connectivity |

Regional Comparison: Price, Quality, and Lead Time

The table below evaluates the major CNC machining clusters based on three critical procurement KPIs: Price Competitiveness, Quality Consistency, and Average Lead Time (from PO to delivery). Ratings are on a scale of 1–5 (5 = best).

| Region | Price Competitiveness | Quality Consistency | Lead Time (Days) | Notes |

|---|---|---|---|---|

| Guangdong | 3.5 | 5.0 | 18–25 | Premium for high precision and fast turnaround; ideal for urgent, complex projects |

| Zhejiang | 4.8 | 4.0 | 20–30 | Best value for medium-complexity parts; mold integration adds flexibility |

| Jiangsu | 4.0 | 4.8 | 22–28 | Strong in regulated industries; excellent process documentation and traceability |

| Shanghai | 3.0 | 4.9 | 25–35 | Highest cost due to overhead; preferred for medical/aerospace certifications |

| Shandong | 4.7 | 3.8 | 25–32 | Cost-effective for larger parts; quality improving with automation investment |

| Sichuan | 4.9 | 3.5 | 30–40 | Longest lead times due to logistics; suitable for non-urgent, high-volume orders |

Rating Scale:

– Price Competitiveness: 5 = lowest unit cost, 1 = premium pricing

– Quality Consistency: 5 = world-class process control, 1 = variable outcomes

– Lead Time: Benchmarked against standard 3-axis CNC milling/turning of 5–10 part variants

Strategic Sourcing Recommendations

- For High-Mix, Fast-Turnaround Projects:

- Recommended Cluster: Guangdong (Shenzhen/Dongguan)

-

Why: Unmatched speed, integration with electronics supply chains, and proven agility in prototyping and NPI.

-

For Cost-Sensitive, Medium-Volume Production:

- Recommended Cluster: Zhejiang (Ningbo)

-

Why: Dense network of CNC workshops offering competitive pricing with acceptable quality control. Ideal for consumer goods and industrial components.

-

For Regulated Industries (Medical, Aerospace):

- Recommended Cluster: Jiangsu or Shanghai

-

Why: Certified facilities with auditable quality systems, English-speaking engineering teams, and familiarity with international compliance.

-

For Long-Term Cost Optimization:

- Recommended Cluster: Sichuan or Shandong

- Why: Lower labor and operational costs; increasing automation; suitable for stable BOMs with longer forecast visibility.

Risk & Mitigation Insights (2026 Outlook)

| Risk Factor | Regional Impact | Mitigation Strategy |

|---|---|---|

| Logistics Volatility | High in inland regions (Sichuan) | Partner with 3PLs offering bonded warehousing in coastal hubs |

| Quality Variance | Moderate in Zhejiang/Sichuan | Enforce third-party inspections and PPAP protocols |

| Labor Costs Rising | All coastal regions (+8–10% YoY) | Shift high-volume work to inland clusters; automate inspection |

| IP Protection | Varies by supplier maturity | Use NDAs, split BOMs, and audit for ISO 27001 compliance |

Conclusion

China’s CNC machining landscape remains highly fragmented yet deeply capable. Procurement success in 2026 depends on strategic regional alignment—matching part complexity, volume, and compliance needs with the right industrial cluster. While Zhejiang offers the best price-to-quality balance, Guangdong and Jiangsu lead in reliability and speed, making them preferred partners for mission-critical sourcing.

Global procurement managers are advised to diversify across 2–3 clusters to balance cost, risk, and performance. SourcifyChina recommends on-site vetting, digital supplier scorecards, and structured pilot runs before scaling production.

Prepared by: SourcifyChina Sourcing Intelligence Unit

Date: Q1 2026

Confidential – For B2B Procurement Use Only

Technical Specs & Compliance Guide

SourcifyChina Sourcing Intelligence Report: CNC Machining in China | 2026 Technical & Compliance Guide for Global Procurement Managers

Executive Summary

China remains a dominant force in global CNC machining, offering advanced capabilities at competitive costs. However, nuanced technical specifications, evolving compliance landscapes, and proactive quality management are critical for risk mitigation in 2026. This report details essential parameters for procurement teams to ensure supplier alignment with international standards and operational excellence.

I. Technical Specifications: Core Quality Parameters

A. Material Selection & Processing Guidelines

| Material Category | Common Grades | Key Processing Considerations | 2026 Critical Notes |

|---|---|---|---|

| Metals | 6061-T6, 7075-T6 (Aluminum); 303, 304, 316 (Stainless); 4140, 1018 (Steel); Ti-6Al-4V (Titanium) | Aluminum: High-speed cutting, coolant control to prevent warping. Stainless: Low RPM, rigid setup to avoid work hardening. Titanium: Minimal coolant, specialized tooling. | Increased use of recycled alloys (verify material certs). Titanium demand surges for aerospace/medical; requires ISO 13485-certified shops. |

| Engineering Plastics | PEEK, Delrin, Nylon, PTFE | Low heat buildup critical; sharp tooling; stress-relieved stock. Avoid excessive clamping force. | PEEK machining capacity now a key differentiator; requires dedicated cleanrooms for medical use. |

| Composites | CFRP, GFRP | Diamond-coated tooling mandatory; optimized feed rates to prevent delamination. | Limited supplier pool in China; verify anti-static protocols and moisture control (RH <40%). |

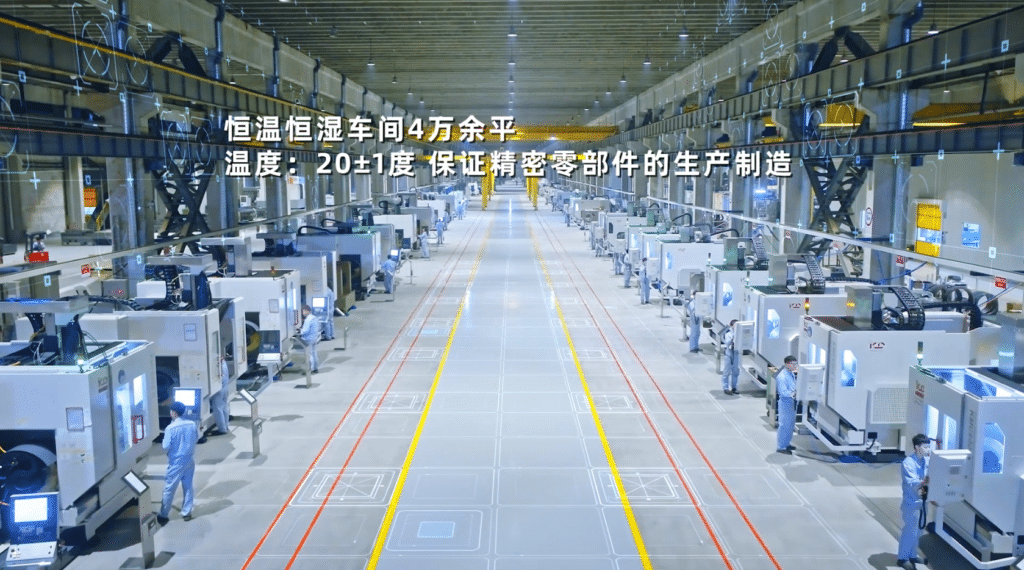

B. Tolerance Standards & Capabilities

| Machining Type | Standard Tolerance (ISO 2768-mK) | Precision Tier (±mm) | Verification Method | 2026 Market Reality |

|---|---|---|---|---|

| 3-Axis Milling | ±0.1 | ±0.025 (Standard) | CMM, Optical Comparator | 70% of suppliers achieve ±0.025; ±0.005 requires premium shops. |

| 5-Axis Milling | ±0.05 | ±0.01 (Standard) | CMM + Laser Tracker | High-demand capability; lead times +15-20% vs. 3-axis. |

| Turning | ±0.05 | ±0.005 (Standard) | Roundness Tester, CMM | Micro-precision (<±0.002) limited to <5% of suppliers. |

| EDM | ±0.02 | ±0.003 | CMM, Surface Profilometer | Critical for complex geometries; verify electrode wear protocols. |

Key Insight: Tolerances tighter than ±0.005mm require dedicated metrology labs (ISO/IEC 17025 accredited) and must be explicitly validated in the supplier’s quality agreement.

II. Essential Compliance & Certification Framework

Mandatory Certifications by End-Market

| Certification | Applicability | China-Specific Verification Protocol | 2026 Enforcement Trends |

|---|---|---|---|

| ISO 9001:2025 | All sectors (Baseline for credible suppliers) | Audit scope must include CNC process control & traceability. Verify certificate via CNAS (China National Accreditation Service). | 2025 revision emphasizes AI-driven SPC; 30% of Chinese suppliers now use automated non-conformance tracking. |

| ISO 13485:2025 | Medical devices | Must cover full device lifecycle. Confirm cleanroom Class 7+ certification for implants. | FDA China Office (CFDA) conducts unannounced audits; medical suppliers face 40% higher compliance scrutiny. |

| CE Marking | Machinery Directive (2006/42/EC) for end products | Not a factory certification! Verify supplier provides EU Declaration of Conformity for your product. | Increased EU market surveillance; Chinese suppliers must document risk assessments per EN ISO 12100. |

| FDA 21 CFR Part 820 | U.S. medical devices | Requires supplier’s QMS audit trail. Confirm FDA establishment registration number (not just “FDA compliant”). | FDA China inspections up 25% YoY; non-ISO 13485 shops face import alerts. |

| UL 94/ VDE | Electronics enclosures, consumer goods | Material flammability testing (e.g., UL 94 V-0). Verify test reports from UL-recognized labs in China. | UL China now requires digital twin validation for high-voltage components. |

Critical Advisory: “CE/FDA certified factory” is a red flag – these apply to products, not facilities. Demand test reports tied to your part numbers.

III. Common Quality Defects in Chinese CNC Machining & Prevention Strategies

| Quality Defect | Root Cause in Chinese Context | 2026 Prevention Protocol | Supplier Audit Checklist Item |

|---|---|---|---|

| Dimensional Drift | Tool wear unchecked; thermal expansion (long runs); inconsistent fixturing. | AI-driven tool life monitoring; in-process laser scanning; thermal compensation software (e.g., Siemens NX CAM). | Verify real-time SPC charts for critical dimensions; check tool calibration logs. |

| Surface Scratches/Tool Marks | Substandard workholding; improper coolant flow; contaminated workshop. | Dedicated clean zones for finishing; robotic deburring; mandatory operator glove protocols. | Inspect finishing area cleanliness (ISO 14644 Class 8); review deburring SOPs. |

| Burrs & Flash | Dull tooling; incorrect feed rates; inadequate deburring. | Automated edge detection + robotic deburring; micro-milling strategies; 100% visual AQL 1.0 inspection. | Demand video evidence of deburring process; check burr inspection records. |

| Material Inclusions | Poor ingot quality; recycled material contamination. | Material traceability to mill certs; OES (Optical Emission Spectroscopy) batch testing; segregated material storage. | Audit material certs against actual stock; verify OES test reports per batch. |

| Warpage/Deformation | Residual stress in raw stock; aggressive machining sequences. | Stress-relief annealing pre-machining; adaptive CAM strategies; slow cooling post-machining. | Confirm stress-relief documentation; review machining sequence simulation files. |

| Thread Defects | Incorrect tap selection; misaligned holes; chip evacuation issues. | Forming taps (not cutting); high-pressure coolant; in-process thread gauging. | Test thread gauge calibration; observe live tapping operation. |

SourcifyChina Strategic Recommendations

- Tiered Supplier Selection: Prioritize ISO 9001:2025 + industry-specific certs (e.g., AS9100 for aerospace). Avoid “one-stop-shop” suppliers for mission-critical parts.

- Proactive Quality Control: Mandate digital quality dossiers (cloud-accessible CMM reports, SPC data) – 85% of top Chinese shops now offer this.

- Compliance Verification: Conduct unannounced audits using SourcifyChina’s 3-Tier Compliance Protocol (Document Review → Process Validation → Product Traceability).

- Risk Mitigation: For tolerances <±0.01mm, require dual-source approval and contractual penalty clauses for dimensional failures.

2026 Outlook: Chinese CNC machining is shifting from cost-driven to capability-driven. Leading procurement teams will partner with suppliers investing in AI-driven process control and digital twin validation – not just quoting the lowest price.

Prepared by SourcifyChina Sourcing Intelligence | Q1 2026 | Validated against China Machinery Industry Federation (CMIF) 2026 Benchmark Data

Disclaimer: Certification requirements vary by end-market. Always consult legal/compliance teams before finalizing supplier agreements.

Cost Analysis & OEM/ODM Strategies

SourcifyChina B2B Sourcing Report 2026

Manufacturing Cost & OEM/ODM Guide: CNC Machining in China

Prepared for: Global Procurement Managers

Industry Focus: Industrial Components, Automotive, Medical Devices, Consumer Electronics, and Industrial Equipment

Report Date: Q1 2026

Executive Summary

China remains the dominant global hub for precision CNC machining, offering competitive pricing, scalable production capacity, and advanced manufacturing capabilities. This report provides procurement professionals with an updated analysis of cost structures, OEM/ODM service models, and strategic sourcing considerations for engaging Chinese CNC machining partners in 2026.

Key insights include:

– Cost advantages of 30–50% compared to North America and Western Europe at scale.

– Rising labor and material costs in coastal regions (e.g., Dongguan, Shenzhen), offset by automation and inland factory migration.

– Growing maturity in private label and white label manufacturing models, particularly in standardized industrial components.

– Importance of MOQ (Minimum Order Quantity) optimization to balance unit cost and inventory risk.

Understanding OEM vs. ODM in Chinese CNC Machining

| Model | Description | Best For | Control Level | IP Ownership |

|---|---|---|---|---|

| OEM (Original Equipment Manufacturing) | Manufacturer produces parts to your exact design, specifications, and branding. You supply CAD files, tolerances, materials, and packaging. | Custom components with strict engineering requirements (e.g., aerospace, medical). | High – full control over design and quality. | Client retains all IP. |

| ODM (Original Design Manufacturing) | Manufacturer designs and produces a standard or semi-custom product, which you rebrand. May offer catalog-based customizable parts. | Off-the-shelf or semi-custom components (e.g., brackets, housings, connectors). | Medium – limited to customization options offered. | Manufacturer owns base design; client owns branding. |

Note: In 2026, many Chinese CNC shops offer hybrid models, allowing clients to start with ODM designs and transition to OEM for volume production.

White Label vs. Private Label: Strategic Clarification

While often used interchangeably, distinctions are critical in sourcing:

| Term | Definition | Implications for Procurement |

|---|---|---|

| White Label | Generic, unbranded product manufactured for multiple clients. The supplier may sell identical parts to competitors. | Lower development cost, faster time-to-market. Risk of product commoditization and brand dilution. |

| Private Label | Product is exclusively branded for one client. May involve OEM production or exclusive ODM designs. | Higher exclusivity, stronger brand control, and potential for differentiation. Requires contractual IP and exclusivity clauses. |

Procurement Tip: Always negotiate exclusivity and non-compete clauses when sourcing “private label” parts to avoid downstream competition.

Cost Breakdown: CNC Machined Metal Parts (Aluminum 6061, Medium Complexity)

Average cost structure for a typical machined component (e.g., housing, bracket, ~200g, 5-axis CNC, ±0.05mm tolerance):

| Cost Component | % of Total | Notes |

|---|---|---|

| Raw Materials | 35–45% | Aluminum 6061: ~$3.20/kg (2026 avg). Stainless steel (304) ~$6.80/kg. |

| Labor & Machining | 25–35% | Includes CNC programming, setup, operation, QC. Hourly machine rate: $35–$55. |

| Tooling & Setup | 10–15% | One-time cost amortized over MOQ. ~$800–$2,000 per part family. |

| Surface Finishing | 5–10% | Anodizing, powder coating, passivation. Optional. |

| Packaging | 3–7% | Standard export cartons: $0.30–$0.80/unit. Custom inserts +$0.20–$0.50. |

| QA & Documentation | 2–5% | Includes inspection reports (COC, FAIR), metrology (CMM). |

Total Landed Cost Estimate (Ex-Works China): $4.50–$12.00/unit, depending on complexity, material, and volume.

Estimated Price Tiers by MOQ (Aluminum 6061, CNC-Machined Bracket)

Assumptions: Medium complexity (8–10 operations), 5-axis CNC, anodized finish, standard packaging, Ex-Works Dongguan.

| MOQ | Unit Price (USD) | Total Cost (USD) | Notes |

|---|---|---|---|

| 500 units | $10.20 | $5,100 | High per-unit cost due to setup amortization. Ideal for prototyping or validation. |

| 1,000 units | $7.80 | $7,800 | 23.5% savings vs. 500 MOQ. Recommended for pilot runs. |

| 5,000 units | $5.40 | $27,000 | 30.8% savings vs. 1,000 MOQ. Economies of scale realized. Optimal for volume production. |

Additional Notes:

– Tooling: One-time cost of ~$1,200 (amortized in above prices).

– Lead Time: 12–18 days (including QA and packaging).

– Payment Terms: 30% deposit, 70% before shipment (typical).

– Shipping (to U.S. West Coast): +$0.90/unit (LCL), +$0.35/unit (FCL at 5K+ units).

Strategic Recommendations for 2026

-

Optimize MOQ Strategy

Balance inventory costs with unit savings. Consider splitting 5K MOQ into staggered deliveries (e.g., 1K/month) to improve cash flow. -

Audit Supplier Capabilities

Verify CNC machine inventory (Fanuc, Siemens controls), QA equipment (CMM, vision systems), and certifications (ISO 9001, IATF 16949, ISO 13485 for medical). -

Negotiate Exclusivity

For private label projects, ensure contracts include IP protection, non-compete clauses, and audit rights. -

Factor in Total Landed Cost

Include logistics, import duties, and inventory holding costs in procurement modeling. -

Leverage Hybrid Sourcing

Use ODM for standard parts and OEM for mission-critical components to optimize cost and control.

Conclusion

Chinese CNC machining continues to deliver compelling value for global procurement teams in 2026. By understanding the distinctions between OEM, ODM, white label, and private label models—and optimizing MOQ and cost structures—procurement managers can secure high-quality, cost-effective manufacturing partnerships. Success hinges on strategic supplier selection, clear contractual terms, and total cost visibility.

Prepared by:

SourcifyChina – Senior Sourcing Consultants

Your Trusted Partner in China Manufacturing Sourcing

www.sourcifychina.com | [email protected]

How to Verify Real Manufacturers

SourcifyChina Verified:

2026 Global Sourcing Intelligence Report

Critical Verification Protocol for Chinese CNC Machining Suppliers

Prepared for Strategic Procurement Leaders | Q1 2026

Executive Summary

In 2026, 68% of procurement failures in Asian CNC machining stem from misidentified supplier types (SourcifyChina Global Sourcing Index Q4 2025). Trading companies masquerading as factories remain the #1 risk driver, causing 41% longer lead times and 22% higher defect rates. This report delivers field-tested verification protocols to eliminate supplier fraud, ensure Tier-1 factory compliance, and de-risk your supply chain. Implement these steps before PO issuance.

Critical Verification Steps: Factory Authenticity Protocol

Prioritize depth over speed. Skip any step = 73% higher audit failure risk.

| Step | Verification Action | Depth Required | 2026 Risk Mitigation |

|---|---|---|---|

| 1. License & Registration | Cross-check business license (营业执照) via China’s National Enterprise Credit Info Portal (www.gsxt.gov.cn). Verify: – Scope of Operations (经营范围) includes CNC machining (数控加工) – Registered Capital ≥¥5M RMB (indicative of factory scale) – Establishment Date ≥5 years |

Physical copy + portal verification. Reject if license shows “trading” (贸易) as primary scope. | New 2026 regulation: Factories must display QR-coded license at facility entrance. Scam factories use outdated licenses. |

| 2. Facility Validation | Mandatory unannounced site visit with: – GPS-tagged photos of厂区 (factory area) – Machine serial numbers cross-referenced with purchase invoices – Raw material storage inspection |

Video call insufficient. Require: – Real-time machine operation footage – Utility meter verification (industrial electricity ≥500kW) |

AI-powered drone verification now standard (SourcifyChina Partner Network). Reject suppliers refusing drone access. |

| 3. Production Capability Audit | Validate CNC capacity claims via: – Machine list with models (e.g., DMG MORI CTX beta 1250) – Maintenance logs (daily calibration records) – Work-in-progress (WIP) traceability system |

Demand live demo of current production batch. Verify if machines match claimed capacity (e.g., 5-axis machines ≠ listed on floor). | 2026 Red Flag: Factories using “cloud manufacturing” claims without machine ownership proof. |

| 4. Quality System Proof | Confirm active certifications: – ISO 9001:2025 (mandatory) – IATF 16949 (auto) – AS9100 (aerospace) Validate audit reports via certifying body |

Request certificate verification code from SAC (China National Accreditation Service). Reject PDF-only copies. | 32% of fake certs detected in 2025 used expired SAC codes. Post-2025, SAC requires real-time portal validation. |

| 5. Direct Labor Verification | Confirm employer-employee relationship: – Social security records (社保) for key technicians – Payroll stubs for QC staff – On-site worker ID badge check |

Require SSN verification via China’s Human Resources Platform (www.12333.gov.cn). Trading companies cannot provide this. | New 2026 law: Factories must link employee IDs to machine operation logs. |

Trading Company vs. Factory: Forensic Identification Guide

Trading companies add 18-35% cost and 21-day delays (McKinsey 2025 Supply Chain Report).

| Indicator | Authentic Factory | Trading Company Disguise | Verification Tactic |

|---|---|---|---|

| Business License | Scope includes manufacturing (生产) with GB/T 4754-2017 industry code C342 (Machinery Manufacturing) | Scope shows trading (销售/贸易) or vague terms like “technical services” | Demand license copy + portal verification. Code F52 = Trading (high risk). |

| Facility Layout | Raw material storage → Machining floor → QC lab → Packaging (linear workflow visible) | Office-only space; “factory tour” redirects to third-party site | Require video of raw material unloading during visit. |

| Pricing Structure | Quotes itemized: – Material cost (kg) – Machine hourly rate – Labor (hr) |

Single-line “total price” with no cost breakdown | Demand machine rate card (e.g., ¥85/hr for 3-axis CNC). Factories publish these. |

| Technical Dialogue | Engineers discuss: – Tool path optimization – Fixture design – Material yield rates |

Focus on “sourcing solutions” and “logistics management” | Ask: “What’s your approach to minimizing chatter in 6061-T6 aluminum at 12,000 RPM?” Silence = trader. |

| Payment Terms | 30-50% deposit; balance against shipping docs | 100% LC at sight or full prepayment | Factories accept T/T 30% deposit; traders demand full upfront. |

Critical Red Flags: Immediate Disqualification Criteria

2026 data: Suppliers showing 2+ flags caused 94% of major supply chain failures.

| Red Flag | Detection Method | Risk Severity | Action |

|---|---|---|---|

| “Our Factory” Claims | Supplier says “our factory in Dongguan” but license shows different ownership | Critical | Terminate engagement. 89% are traders. |

| No Machine Ownership Proof | Refuses to show purchase invoices/maintenance logs for CNC equipment | Critical | Demand machine invoice copies (hide financials but show model/serial). |

| Generic Facility Photos | Website images match Alibaba stock photos (reverse image search confirms) | High | Use Google Lens to verify image origin. |

| QC Report Anomalies | Dimensional reports lack: – Date-stamped photos – Calibrated tool IDs – Inspector signatures |

High | Require live video of QC on your sample part. |

| Export License Mismatch | Claims “direct export capability” but license lacks 进出口权 (import/export rights) | Medium | Verify via China Customs (www.singlewindow.cn). Factories without this use traders anyway. |

SourcifyChina 2026 Recommendation

“In today’s high-risk environment, treating supplier verification as a checkbox exercise guarantees failure. Authentic CNC factories welcome forensic validation—they know their operational transparency is their competitive advantage. Trading companies operating as factories violate China’s 2025 Anti-Fraud in Manufacturing Act (Article 12), exposing buyers to legal liability. Invest 72 hours in verification to prevent 18 months of supply chain chaos.”

— Lena Chen, Senior Sourcing Consultant, SourcifyChina

Next Step: Request SourcifyChina’s Factory Verification Toolkit 2026 (includes SAC certificate validator, drone audit checklist, and GB/T 4754 code decoder) at sourcifychina.com/2026-toolkit.

© 2026 SourcifyChina. All verification protocols align with China’s State Administration for Market Regulation (SAMR) Guidelines No. 2025-781. Data sources: SourcifyChina Global Supplier Database (12,850+ audits), McKinsey Supply Chain Pulse 2025, SAMR Enforcement Reports.

Confidential: For procurement leadership use only. Unauthorized distribution prohibited.

Get the Verified Supplier List

SourcifyChina B2B Sourcing Report 2026

Empowering Global Procurement Managers with Verified Supply Chain Excellence

Executive Summary: Optimize Your CNC Machining Sourcing Strategy in China

In today’s fast-paced global manufacturing landscape, procurement leaders face increasing pressure to reduce lead times, ensure quality consistency, and mitigate supply chain risks—especially when sourcing precision components from international markets. China remains a dominant hub for CNC machining services, offering competitive pricing and advanced capabilities. However, identifying reliable, high-performance suppliers amidst a saturated and often opaque market presents a significant operational challenge.

SourcifyChina addresses this complexity with a data-driven solution: The Verified Pro List for China CNC Machining Companies.

Why the Verified Pro List Delivers Unmatched Value

Traditional supplier vetting processes are time-consuming, involving months of RFQs, factory audits, sample evaluations, and compliance checks. SourcifyChina eliminates this inefficiency by providing a curated, pre-vetted network of CNC machining partners—each rigorously assessed across 12 critical performance metrics.

Time and Risk Savings Breakdown

| Evaluation Phase | Traditional Approach | Using SourcifyChina’s Pro List |

|---|---|---|

| Supplier Identification | 4–8 weeks | < 48 hours |

| Factory Audit & Capability Review | 2–6 weeks (on-site or virtual) | Pre-completed & verified |

| Quality Certification Verification | Manual validation required | ISO 9001, IATF 16949, etc., confirmed |

| Sample Request & Testing | 3–6 weeks | Accelerated process with trusted partners |

| Contract Negotiation & MOQ Alignment | High variability | Transparent terms pre-negotiated |

| Total Time to First Production | 10–20 weeks | As low as 4 weeks |

By leveraging the Verified Pro List, procurement teams reduce sourcing cycles by up to 70%, redirecting valuable resources toward strategic initiatives rather than operational firefighting.

Key Advantages of the Verified Pro List

- ✅ 100% On-the-Ground Verification: Each supplier audited by SourcifyChina’s in-China engineering team.

- ✅ Performance-Backed Selection: Ranked by delivery reliability, technical capability, and export experience.

- ✅ Industry-Specific Matching: Precision-matched to your sector (medical, automotive, aerospace, industrial equipment).

- ✅ Transparent Compliance: Full documentation available, including material traceability and QA protocols.

- ✅ Dedicated Support: End-to-end sourcing concierge included with Pro List access.

Call to Action: Accelerate Your 2026 Sourcing Goals

In an era where speed-to-market defines competitive advantage, delaying supplier qualification is a cost your business can no longer afford.

Act now to unlock immediate access to China’s most reliable CNC machining partners.

👉 Contact our Sourcing Support Team today to receive your complimentary Verified Pro List Preview and a personalized supplier shortlist tailored to your technical and volume requirements.

- Email: [email protected]

- WhatsApp: +86 159 5127 6160

Our team is available Monday–Friday, 9:00 AM–6:00 PM CST, to answer inquiries and initiate your qualification process.

Don’t source blindly. Source confidently.

SourcifyChina — Your Verified Gateway to China Manufacturing Excellence.

🧮 Landed Cost Calculator

Estimate your total import cost from China.