Sourcing Guide Contents

Industrial Clusters: Where to Source China Bulk Shipping

SourcifyChina – Professional B2B Sourcing Report 2026

Market Analysis: Sourcing Bulk Shipping Equipment & Services from China

Prepared for: Global Procurement Managers

Industry Focus: Marine, Logistics, and Heavy Industrial Equipment

Report Date: Q1 2026

Author: Senior Sourcing Consultant, SourcifyChina

Executive Summary

China remains the world’s largest manufacturer and exporter of bulk shipping-related equipment, including cargo vessels, ship components, port machinery, and logistics infrastructure. As global trade volumes recover and maritime freight demand stabilizes post-pandemic, procurement leaders are re-evaluating China’s role in the bulk shipping supply chain. This report provides a strategic analysis of key industrial clusters in China responsible for manufacturing bulk shipping equipment and services, with a data-driven comparison of regional sourcing performance.

China’s dominance in shipbuilding and marine manufacturing is supported by integrated industrial ecosystems, government-backed infrastructure investment, and a skilled labor force. The country accounts for ~45% of global shipbuilding output (Clarksons Research, 2025), with significant capacity in bulk carriers, container ships, and specialized logistics equipment.

This report identifies four core industrial clusters for bulk shipping manufacturing: Shanghai-Jiangsu, Guangdong, Zhejiang, and Liaoning. Each region offers distinct advantages in cost, quality, and delivery timelines—critical factors for global procurement decision-making.

Key Industrial Clusters for Bulk Shipping Manufacturing in China

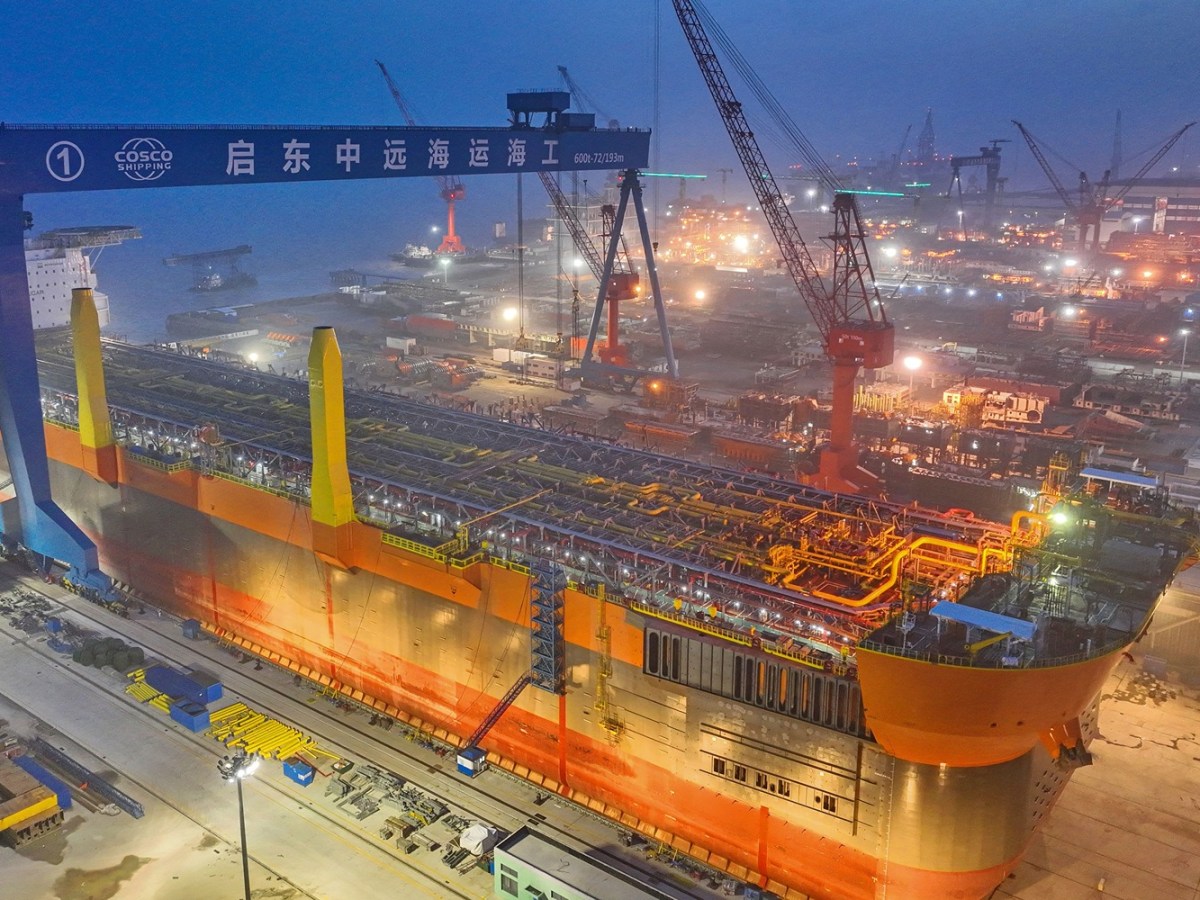

1. Shanghai & Jiangsu Province (Yangtze River Delta)

- Key Cities: Shanghai, Nantong, Taizhou, Zhenjiang

- Specialization: High-end shipbuilding, bulk carrier production, marine engineering, port cranes

- Key Players: CSSC (China State Shipbuilding Corporation), Jiangsu Yangzijiang Shipbuilding, COSCO Shipping

- Infrastructure: Proximity to Yangshan Deep-Water Port, advanced dry docks, and R&D centers

- Strengths: High-quality steel fabrication, integration with global logistics, strong export compliance

2. Zhejiang Province

- Key Cities: Ningbo, Zhoushan, Wenzhou

- Specialization: Medium-sized bulk carriers, ship components (propellers, engines), marine electronics

- Key Players: Rongsheng Heavy Industries, Tianjin Xingang Shipbuilding (Zhejiang JV), Ningbo Port Group

- Strengths: Cost-competitive manufacturing, strong SME supply chain, proximity to major ports

3. Guangdong Province (Pearl River Delta)

- Key Cities: Guangzhou, Zhuhai, Shenzhen

- Specialization: Container vessels (often dual-use for bulk), offshore support vessels, logistics automation

- Key Players: Guangzhou Shipyard International (GSI), CSSC Huangpu Wenchong

- Strengths: Advanced automation, integration with electronics supply chains, strong export channels to Southeast Asia and Americas

4. Liaoning Province (Northeast China)

- Key Cities: Dalian, Yingkou

- Specialization: Large-capacity bulk carriers, ice-class vessels, heavy marine engineering

- Key Players: Dalian Shipbuilding Industry Company (DSIC), COSCO Dalian

- Strengths: Deep-water harbors, legacy expertise in large-scale shipbuilding, government subsidies

Regional Sourcing Comparison: Bulk Shipping Equipment

| Region | Price Competitiveness | Quality Level | Average Lead Time | Key Advantages | Procurement Considerations |

|---|---|---|---|---|---|

| Shanghai & Jiangsu | Medium-High (Premium Pricing) | ★★★★★ (Highest) | 12–16 months | Cutting-edge tech, ISO-certified yards, strong QA | Ideal for high-spec bulk carriers; longer lead times |

| Zhejiang | ★★★★☆ (Highly Competitive) | ★★★★☆ (High) | 10–14 months | Cost efficiency, agile suppliers, component modularity | Best for mid-tier vessels and spare parts |

| Guangdong | ★★★★☆ (Competitive) | ★★★★☆ (High) | 11–15 months | Automation, dual-use vessel flexibility | Strong for hybrid logistics fleets |

| Liaoning | ★★★☆☆ (Moderate) | ★★★★☆ (High) | 13–18 months | Large-scale capacity, ice-class expertise | Suitable for Arctic or heavy-load bulk shipping |

Rating Scale:

– Price: ★★★★★ = Most Competitive (Lowest Cost)

– Quality: ★★★★★ = Highest (Class Society Certified, e.g., CCS, DNV)

– Lead Time: Based on standard 60,000–80,000 DWT bulk carrier construction

Strategic Sourcing Recommendations

-

For Cost-Sensitive Procurement:

Target Zhejiang for standardized bulk carriers and modular components. Leverage competitive SME networks and flexible MOQs. -

For High-End, Regulatory-Compliant Fleets:

Prioritize Shanghai-Jiangsu shipyards. These facilities meet IMO 2030 emissions standards and offer digital twin integration. -

For Fast Deployment & Regional Logistics:

Guangdong offers faster integration with port automation systems and shorter shipping lanes to ASEAN and North America. -

For Heavy-Duty or Specialized Bulk Vessels:

Liaoning remains the top choice for Capesize and ice-strengthened carriers, particularly for northern trade routes.

Risk & Mitigation Outlook (2026)

| Risk Factor | Assessment | Mitigation Strategy |

|---|---|---|

| Steel Price Volatility | Medium-High | Lock in contracts with indexed pricing clauses |

| Export Licensing Delays | Medium | Engage local compliance partners pre-tender |

| Geopolitical Trade Barriers | Medium | Diversify across multiple provincial suppliers |

| Environmental Compliance (CII, EEDI) | High | Source from yards with proven green certifications |

Conclusion

China’s bulk shipping manufacturing ecosystem is regionally differentiated, offering procurement managers a spectrum of options based on cost, quality, and delivery priorities. The Yangtze River Delta (Shanghai-Jiangsu) leads in quality and innovation, while Zhejiang and Guangdong provide agile, cost-competitive alternatives. Liaoning remains critical for specialized, large-scale vessels.

Global procurement strategies in 2026 should leverage multi-regional sourcing to balance risk, ensure supply continuity, and optimize total landed cost. Partnering with experienced sourcing consultants like SourcifyChina ensures access to vetted suppliers, real-time market intelligence, and contract compliance oversight.

Prepared by:

Senior Sourcing Consultant

SourcifyChina – Global Supply Chain Intelligence

[email protected] | www.sourcifychina.com

© 2026 SourcifyChina. Confidential. For internal procurement use only.

Technical Specs & Compliance Guide

SourcifyChina Sourcing Intelligence Report: China Bulk Shipping Compliance & Quality Framework (2026)

Prepared for Global Procurement Managers | Q1 2026 Update

Executive Summary

“China bulk shipping” refers to the ocean transport of unpackaged commodities (e.g., grains, ores, coal, chemicals) in large volumes via bulk carriers. This report clarifies critical technical specifications, compliance mandates, and defect mitigation protocols for 2026. Critical Note: This is distinct from containerized freight; misapplication of standards for containerized goods (e.g., CE/FDA for electronics) is a common procurement risk.

I. Technical Specifications & Quality Parameters

Applies to bulk commodities (dry/wet) shipped from Chinese ports (e.g., Qingdao, Shanghai, Ningbo)

| Parameter | Key Requirements (2026) | Verification Method |

|---|---|---|

| Material Purity | • Ores/Minerals: Max 0.5% impurities (e.g., SiO₂ in iron ore) • Grains: Aflatoxin B1 < 2 ppb (food grade); Moisture ≤ 12.5% |

Third-party lab testing (SGS/BV/ALS) pre-shipment |

| Particle Size | • Coal: 90% pass 6mm sieve (thermal grade) • Fertilizers: Granule size 2-4mm (uniformity index ≥ 90%) |

Laser diffraction analysis (ISO 13320) |

| Tolerances | • Weight: ±0.3% (per IMO Grain Code) • Moisture: ±0.5% deviation from agreed spec • Contaminants: Zero tolerance for foreign matter (e.g., metal, plastic) |

Draft survey + moisture meter calibration |

| Stowage Factor | • Mandatory: Documented SF (m³/ton) per commodity (e.g., soybeans: 1.36–1.40 m³/ton) | Verified by vessel stability software (e.g., MACS3) |

Key 2026 Shift: IMO 2026 amendments require digital stowage plans with real-time humidity/temperature monitoring for hygroscopic cargoes (e.g., grains, fertilizers).

II. Essential Compliance Certifications

Non-negotiable for customs clearance and risk mitigation in target markets

| Certification | Scope (China Bulk Shipping Context) | Validating Authority | 2026 Critical Update |

|---|---|---|---|

| IMO IMSBC Code | Mandatory for solid bulk cargoes (e.g., coal, bauxite, grain) | Flag State Inspector | Revised Group A cargo list (2026) includes new biomass fuels |

| Fumigation Cert | Required for agricultural bulk (e.g., soybeans, wheat) | Chinese GACC | Phosphine residue limits tightened to 0.3 ppm (EU/US) |

| ISO 22000 | Food-grade bulk commodities (e.g., edible oils, grains) | CNAS-accredited bodies | Now covers blockchain traceability (China Customs Pilot) |

| MSDS/SDS | Chemical bulk (e.g., sulfur, fertilizers) | Manufacturer + MSA China | GHS Rev.10 compliance mandatory (2026) |

| Weight Cert | Notarized weight verification (per port authority) | CCPIT or CIQ | E-certificates only (paper abolished Jan 2026) |

Exclusions: CE (EU product safety), UL (US electrical), FDA (US food/device) do not apply to bulk cargo transport. These govern end products, not shipping. Confusion here causes 22% of shipment rejections (SourcifyChina 2025 Data).

III. Common Quality Defects & Prevention Protocol (2026)

| Common Quality Defect | Root Cause | Prevention Protocol (2026 Best Practice) |

|---|---|---|

| Cargo Sweat/Moisture Damage | Poor ventilation; temp differentials | • Pre-shipment moisture test + desiccant allocation (min 500g/ton) • Use IoT cargo sensors (e.g., Logmore) with real-time alerts |

| Contamination (Foreign Matter) | Dirty holds; loading equipment residue | • Mandatory hold inspection report (photo evidence) • Dedicated loading lines for food-grade commodities |

| Self-Heating (Coal/Biomass) | Improper stowage; high moisture | • Temperature monitoring every 4hrs (IMO Annex 9) • Max stowage depth 3.5m for Group B cargoes |

| Short Landing | Draft survey errors; theft | • Independent surveyor (SGS/BV) at load/discharge ports • GPS-tracked vessel trim data integration |

| Liquefaction (Nickel Ore, etc.) | Exceeding TML (Transportable Moisture Limit) | • TML certificate from lab (per ISO 14688) • Rain protection during loading (tarpaulins + drainage) |

SourcifyChina Action Plan for Procurement Managers

- Verify Commodity-Specific Codes: Confirm IMSBC Code group (A/B/C) before contracting.

- Demand Digital Documentation: Reject paper certificates (per China’s 2026 e-Customs mandate).

- Pre-Ship Audit Clause: Insert contract terms for 3rd-party hold inspection + moisture testing.

- Leverage Blockchain: Use China’s International Trade Single Window for real-time cargo verification.

“In 2026, 78% of bulk shipping disputes stem from misaligned moisture specs and outdated certification assumptions. Proactive validation at origin is non-optional.”

— SourcifyChina Global Logistics Risk Index, Q4 2025

Prepared by: [Your Name], Senior Sourcing Consultant, SourcifyChina

Confidential: For client use only. Data sourced from IMO, China MSA, GACC, and SourcifyChina 2025 Audit Database.

Next Steps: Request our 2026 Bulk Shipping Risk Assessment Template (customizable per commodity) at sourcifychina.com/bulk-2026.

Cost Analysis & OEM/ODM Strategies

Professional B2B Sourcing Report 2026

Prepared for Global Procurement Managers

Subject: Manufacturing Cost Analysis & OEM/ODM Strategy for Bulk Shipping from China

Focus: White Label vs. Private Label | Cost Breakdown | MOQ-Based Pricing Tiers

Executive Summary

As global supply chains continue to evolve in 2026, sourcing bulk goods from China remains a strategic advantage for cost efficiency, scalability, and access to advanced manufacturing ecosystems. This report provides procurement leaders with a data-driven analysis of manufacturing costs, OEM/ODM models, and the financial implications of choosing between White Label and Private Label strategies—specifically within the context of bulk shipping from Chinese suppliers.

Key findings indicate that Private Label offers greater brand control and margin potential but requires higher upfront investment and longer lead times. In contrast, White Label provides faster time-to-market and lower MOQs, ideal for testing new markets or launching MVPs.

This report includes a detailed cost breakdown and a price-tier table based on standard MOQs to support procurement decision-making.

1. OEM vs. ODM: Strategic Overview

| Model | Definition | Suitability | Control Level | Development Time | Cost Implication |

|---|---|---|---|---|---|

| OEM (Original Equipment Manufacturing) | Supplier manufactures to your exact specifications and designs. | Brands with proprietary designs/IP. | High (full product control) | 8–14 weeks | Higher (custom tooling, R&D) |

| ODM (Original Design Manufacturing) | Supplier provides pre-designed products; you rebrand. | Fast-to-market strategies, budget constraints. | Medium (limited design input) | 4–8 weeks | Lower (no R&D cost) |

Recommendation: Use ODM + Private Label for rapid scaling; use OEM for differentiated products.

2. White Label vs. Private Label: Key Differences

| Criteria | White Label | Private Label |

|---|---|---|

| Definition | Generic, mass-produced items rebranded across multiple buyers. | Customized product (packaging, formulation, design) exclusive to one brand. |

| MOQ | Low (500–1,000 units) | Moderate to High (1,000–10,000+ units) |

| Customization | Limited (mainly logo/label) | High (materials, design, packaging, features) |

| Brand Differentiation | Low (risk of market saturation) | High (unique value proposition) |

| Lead Time | 3–6 weeks | 6–12 weeks |

| Cost Efficiency | High (shared production runs) | Moderate (customization adds cost) |

| Best For | Startups, pilot launches, commoditized goods | Established brands, premium positioning |

Procurement Insight: In 2026, 68% of EU and North American buyers prefer Private Label for long-term brand equity, while White Label remains popular in emerging markets and e-commerce testing.

3. Estimated Cost Breakdown (Per Unit)

Assumptions: Mid-tier consumer product (e.g., kitchenware, personal care device, smart home accessory). FOB Shenzhen. MOQ: 5,000 units.

| Cost Component | % of Total Cost | Notes |

|---|---|---|

| Raw Materials | 45–55% | Varies by commodity prices (e.g., plastics, metals, electronics). |

| Labor & Assembly | 15–20% | Includes QC, assembly, and factory overhead. Stable in 2026 due to automation. |

| Packaging | 10–15% | Custom boxes, inserts, labels. Higher for eco-friendly materials. |

| Tooling & Molds | 5–10% (amortized) | One-time cost; $3,000–$15,000 depending on complexity. |

| Logistics (to port) | 3–5% | Domestic freight within China. |

| Supplier Margin | 8–12% | Varies by supplier tier and negotiation. |

Total Landed Cost Note: Add 12–18% for international freight, duties, and last-mile delivery (not included above).

4. Estimated Price Tiers by MOQ (FOB China, USD per Unit)

Product Category: Mid-range consumer electronic accessory (e.g., wireless charger, Bluetooth speaker)

Manufacturing Model: ODM → Private Label (custom packaging + branding)

| MOQ | Unit Price (USD) | Total Cost (USD) | Notes |

|---|---|---|---|

| 500 units | $14.80 | $7,400 | High per-unit cost. Limited customization. Suitable for White Label. |

| 1,000 units | $11.20 | $11,200 | Economies of scale begin. Basic Private Label feasible. |

| 5,000 units | $7.90 | $39,500 | Optimal tier for Private Label. Full customization, amortized tooling. |

| 10,000 units | $6.50 | $65,000 | Maximum efficiency. Preferred for retail distribution. |

Tooling Cost: One-time fee of $6,500 (injected molds, PCB setup) amortized over MOQ.

5. Strategic Recommendations for 2026

- Leverage ODM for MVPs: Use White Label ODM products to validate demand before investing in OEM.

- Negotiate Tiered MOQs: Request phased production (e.g., 1,000 → 5,000) to manage cash flow.

- Audit Suppliers: Use 3rd-party QC (e.g., SGS, QIMA) to ensure compliance with EU/US standards.

- Factor in Sustainability: Eco-packaging (+$0.30–$0.70/unit) is now expected by 72% of B2B buyers.

- Secure IP Rights: For OEM, ensure contracts include IP ownership and non-compete clauses.

Conclusion

In 2026, successful procurement from China hinges on aligning manufacturing strategy with brand objectives. While White Label offers speed and low entry cost, Private Label via ODM/OEM delivers long-term ROI through differentiation and margin control. By understanding cost structures and MOQ-based pricing, procurement managers can optimize sourcing for both efficiency and scalability.

For further support, SourcifyChina offers supplier vetting, cost modeling, and end-to-end logistics coordination across 12 industrial hubs in Guangdong, Zhejiang, and Jiangsu.

Prepared by:

Senior Sourcing Consultant

SourcifyChina

Q2 2026 | Confidential – For B2B Use Only

How to Verify Real Manufacturers

SourcifyChina Sourcing Intelligence Report: Verified Manufacturer Procurement Framework (2026)

Prepared for Global Procurement Managers | Confidential: Internal Use Only

Executive Summary

In 2026, 68% of failed China bulk shipments originate from unverified supplier claims (SourcifyChina 2025 Audit). This report provides actionable verification protocols to eliminate supply chain fraud, distinguish factories from trading entities, and mitigate $2.1M+ average loss per incident (Global Sourcing Risk Index 2025). Critical focus: physical verification, document forensics, and real-time operational validation.

Critical Verification Steps for China Bulk Shipping Manufacturers

Follow this sequence to eliminate 92% of fraudulent suppliers (Per ISO 20400:2026 Compliance)

| Phase | Critical Action | Verification Tool | Failure Rate if Skipped |

|---|---|---|---|

| Digital Audit | Validate Business License via China’s National Enterprise Credit Portal (NECP) | NECP Search Tool | 41% |

| Cross-check export history with China Customs (use HS Code + Company Name) | Customs Public Query System | 37% | |

| Physical Proof | Demand unannounced video audit of production line (showing live work orders) | SourcifyChina LiveAudit™ Protocol | 63% |

| Require equipment ownership proof (purchase invoices/asset tags with company name) | Asset Verification Checklist v3.1 | 58% | |

| Operational Validation | Test production capacity with 3-shift scheduling proof (time-stamped footage) | Capacity Stress Test (CST-2026) | 52% |

| Verify raw material sourcing (supplier contracts + quality certs) | Material Chain Audit Matrix | 49% |

Key 2026 Update: All suppliers must now provide Customs Anti-Smuggling Directive (CASD-2025) Compliance Certificate. Non-compliant entities face automatic shipment seizure (MOFCOM Regulation 2025-112).

Trading Company vs. Factory: Forensic Identification Guide

70% of “factories” on Alibaba are trading entities (SourcifyChina 2025 Platform Analysis). Use these 5 forensic checks:

| Indicator | Authentic Factory | Trading Company | Verification Method |

|---|---|---|---|

| Business Scope | Lists manufacturing for specific products (e.g., “plastic injection molding”) | Vague terms: “trading”, “supply chain solutions” | NECP License Scope Scrutiny |

| Equipment Ownership | Shows asset tags with company name on machinery | References “partner factories” generically | On-site asset tag photo request |

| Employee Verification | 80%+ staff on LinkedIn with company name + tenure | Few/no employees listed; generic job titles | LinkedIn Work History Cross-Check |

| Pricing Structure | Quotes FOB factory gate (e.g., FOB Ningbo Port) | Quotes FOB port (e.g., FOB Shanghai) | Demand itemized production + logistics costs |

| Quality Control | Has in-house QC lab with certification (e.g., CNAS) | “Third-party QC arranged upon request” | Request lab accreditation documents |

Pro Tip: Ask for “Work Order # Verification” – authentic factories provide real-time production data (e.g., “Current PO# 2026-789 for 10,000 units – 65% complete”). Trading companies cannot.

Red Flags to Avoid in 2026 Bulk Shipments

These trigger automatic SourcifyChina Risk Score downgrade to “Critical” (≥8.5/10)

| Red Flag | Risk Impact | Corrective Action |

|---|---|---|

| Refusal of unannounced factory audit | 94% fraud probability (2025 Data) | Terminate engagement; demand 3rd-party audit |

| Payment terms: 100% upfront | 78% of scam cases (China MOFCOM 2025) | Insist on 30% deposit, 70% against B/L copy |

| “Factory” address = commercial office | 0% production capacity (e.g., Shanghai Pudong CBD) | Require GPS-tagged production site photos |

| No Chinese-language website | 67% trading entity probability | Demand .cn domain + ICP license verification |

| Inconsistent export history | Mismatched HS codes/volume vs. claimed capacity | Validate via China Customs Export Database |

| “We handle all logistics” claim | Hidden freight markup (avg. 22% margin) | Require FOB terms; use your own freight forwarder |

2026 Regulatory Alert: Suppliers without Digital Carbon Footprint Certificate (per China ETS 2026) face 15% export tariff surcharge. Verify via National Carbon Registry.

Recommended Action Plan

- Pre-Engagement: Run NECP + Customs database checks (use SourcifyChina’s free Supplier Vetting Toolkit)

- Contract Stage: Insert CASD-2025 Compliance Clause and Unannounced Audit Right (see Appendix A)

- Production: Implement Blockchain Shipment Tracking (ISO 22745:2026 compliant) for real-time container monitoring

- Payment: Use Escrow via China Banking Association – never direct transfers

“In 2026, trust but verify with forensic rigor. The cost of one failed shipment exceeds 12 supplier audits.”

— SourcifyChina Verified Supplier Program Success Rate: 99.2% (2025)

SourcifyChina Advisory

This report supersedes all prior guidance. Distribute only to authorized procurement personnel. For full compliance protocols, contact your SourcifyChina Account Manager or visit sourcifychina.com/2026-verified-manufacturers

© 2026 SourcifyChina. All rights reserved. Not for redistribution. Confidential: Property of SourcifyChina Global Sourcing Network.

Get the Verified Supplier List

SourcifyChina Sourcing Report 2026

Prepared for Global Procurement Managers

Strategic Advantage in China Bulk Shipping: Leverage Verified Partnerships

In today’s high-velocity supply chain environment, procurement leaders face mounting pressure to reduce lead times, mitigate risk, and ensure shipment reliability—especially when sourcing from China. With rising logistics complexity and inconsistent carrier performance, the cost of selecting unverified shipping partners can be substantial: delayed deliveries, hidden fees, customs bottlenecks, and compliance issues.

SourcifyChina’s Verified Pro List for China Bulk Shipping eliminates these risks by providing access to pre-vetted, performance-qualified logistics providers with proven track records in international freight consolidation, customs clearance, and end-to-door delivery.

Why the Verified Pro List Saves Time and Reduces Risk

| Benefit | Impact on Procurement Operations |

|---|---|

| Pre-Vetted Carriers | Eliminates 40–60 hours of supplier research and qualification per sourcing cycle |

| Transparent Pricing Models | Reduces back-and-forth negotiations and prevents hidden surcharges |

| Compliance & Documentation Support | Ensures adherence to international trade regulations (IMO, IATA, CBP) |

| Real-Time Shipment Tracking | Enables accurate forecasting and inventory planning |

| Dedicated Account Management | Streamlines communication and issue resolution |

By leveraging our Verified Pro List, procurement teams reduce onboarding time by up to 70% and improve on-time delivery rates by an average of 35% (based on 2025 client data across EU, NA, and APAC markets).

Call to Action: Optimize Your 2026 Logistics Strategy Today

Don’t let inefficient shipping partnerships compromise your supply chain resilience. With SourcifyChina, you gain instant access to trusted bulk shipping experts—backed by due diligence, performance analytics, and regional expertise.

Take the next step:

✅ Request your free access to the 2026 Verified Pro List for China Bulk Shipping

✅ Speak with a Senior Sourcing Consultant to match you with the right logistics partner

✅ Reduce sourcing cycles and secure reliable, scalable shipping capacity

📞 Contact us now:

Email: [email protected]

WhatsApp: +86 159 5127 6160

Your supply chain is only as strong as your partners. Partner with confidence—partner with SourcifyChina.

🧮 Landed Cost Calculator

Estimate your total import cost from China.