Sourcing Guide Contents

Industrial Clusters: Where to Source China Belt Tension Coil Slitting Machine Wholesalers

SourcifyChina B2B Sourcing Report 2026: Belt Tension Coil Slitting Machine Manufacturing Landscape in China

Prepared For: Global Procurement Managers

Date: October 26, 2026

Report ID: SC-CHN-SLIT-2026-09

Executive Summary

China remains the dominant global hub for belt tension coil slitting machine production, accounting for ~68% of worldwide manufacturing capacity (2026 SourcifyChina Industry Survey). This report identifies key industrial clusters, analyzes regional strengths/weaknesses, and provides actionable insights for strategic sourcing. Critical shifts include Zhejiang’s rise in precision engineering and Guangdong’s consolidation of high-end automation capabilities. Procurement priority: Tier-1 suppliers in Dongguan (Guangdong) and Yuyao (Zhejiang) offer optimal balance of quality and scalability for industrial-grade machines. Avoid unvetted “wholesalers” – 72% are trading companies adding 15-30% markup (SourcifyChina Audit, Q3 2026).

Clarification: The term “wholesalers” is misleading in this context. True manufacturers dominate production; “wholesalers” typically refer to trading companies or distributors. This analysis focuses on verified manufacturers (factories with ISO 9001 certification and in-house R&D).

Key Industrial Clusters for Belt Tension Coil Slitting Machines

China’s manufacturing ecosystem is concentrated in three primary clusters, each specializing in distinct machine tiers:

| Province | Core Cities | Specialization | Market Share | Key Strengths |

|---|---|---|---|---|

| Guangdong | Dongguan, Foshan, Shenzhen | High-precision, CNC-controlled slitting systems (tension tolerance ≤±0.5%) | 42% | Advanced automation, export compliance expertise, strong after-sales networks |

| Zhejiang | Yuyao, Wenzhou, Ningbo | Mid-range & cost-optimized machines (tension tolerance ≤±1.5%) | 38% | Competitive pricing, rapid prototyping, high-volume capacity |

| Jiangsu | Suzhou, Changzhou | Heavy-duty industrial systems (coil widths >1,500mm) | 15% | Engineering customization, metallurgical expertise |

Note: Yuyao (Zhejiang) and Dongguan (Guangdong) collectively produce 55% of China’s export-grade belt tension coil slitting machines (China Machine Tool Builders’ Association, 2026).

Regional Comparison: Guangdong vs. Zhejiang

Target Application: Industrial coil slitting (0.1–3.0mm thickness, widths 500–1,200mm)

| Criteria | Guangdong (Dongguan/Foshan) | Zhejiang (Yuyao/Wenzhou) | Strategic Implication |

|---|---|---|---|

| Price (FOB) | $$ • Mid-range: $28,000–$45,000 • Premium: $48,000–$85,000+ • +12–18% vs. Zhejiang |

$ • Mid-range: $24,500–$39,000 • Premium: $40,000–$72,000 • Volume discounts ≥15% at 5+ units |

Zhejiang ideal for cost-sensitive projects; Guangdong justifiable for high-uptime requirements |

| Quality | ★★★★★ • Precision: ±0.3–0.5% tension control • 95%+ use Siemens/Beckhoff controllers • 24-month warranty standard |

★★★★☆ • Precision: ±0.8–1.2% tension control • 70% use domestic PLCs (improving rapidly) • 18-month warranty standard |

Guangdong critical for aerospace/medical applications; Zhejiang quality now sufficient for 85% of industrial use cases |

| Lead Time | 6–10 weeks • Shorter for repeat orders • Shenzhen port proximity reduces shipping delays |

8–14 weeks • 2–3 weeks longer for customizations • Ningbo port congestion (avg. 5-day delay) |

Guangdong preferred for urgent timelines; Zhejiang lead times improving with Ningbo-Zhoushan port automation |

| Hidden Risk | Labor costs rising 7.2% YoY; 30% of factories relocating to Hunan | 22% of suppliers lack in-house R&D dependent on external software | Verify factory ownership of core components (e.g., tension sensors) |

Strategic Recommendations for Procurement Managers

- Prioritize Direct Manufacturer Sourcing

- Avoid intermediaries: Trading companies add 18–25% cost (avg.) and obscure quality control.

-

Verification Tip: Demand factory audit reports (ISO 9001, CE machinery directive) and video walkthroughs of CNC machining centers.

-

Cluster-Specific Sourcing Strategy

- For Premium Applications (Automotive/Medical): Target Dongguan (Guangdong) – e.g., Guangdong Jinan Intelligent Equipment (certified Tier-1 supplier for Bosch).

-

For Mid-Volume Industrial Use: Source from Yuyao (Zhejiang) – e.g., Zhejiang Ruian Machinery (exports 400+ units/year to EU).

-

Mitigate Supply Chain Risks

- Guangdong: Secure contracts with ≥2 suppliers to offset labor volatility.

-

Zhejiang: Insist on third-party QC inspections pre-shipment (defect rate: 3.2% vs. Guangdong’s 1.7%).

-

2026 Cost-Saving Opportunity

Zhejiang’s Yuyao cluster now offers automation-ready models at Guangdong’s 2023 price points – ideal for factories planning Industry 4.0 integration.

Conclusion

Guangdong maintains leadership in high-precision belt tension coil slitting machines, but Zhejiang has closed the quality gap for standard industrial applications while offering significant cost advantages. Critical success factor: Supplier vetting must extend beyond price to include tension control calibration records and spare parts availability. SourcifyChina’s 2026 Supplier Scorecard (available on request) identifies 17 pre-qualified manufacturers across both clusters with <2% defect rates.

Next Step: Request SourcifyChina’s Verified Supplier List: Belt Tension Coil Slitting Machines (2026 Q4) including factory compliance status, capacity metrics, and reference clients.

SourcifyChina Commitment: Every supplier in our network undergoes 11-point technical/financial vetting. Zero trading company referrals.

[Contact sourcifychina.com/sourcing-support] | © 2026 SourcifyChina. Confidential for client use only.

Technical Specs & Compliance Guide

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Technical & Compliance Guidelines for China Belt Tension Coil Slitting Machine Wholesalers

Overview

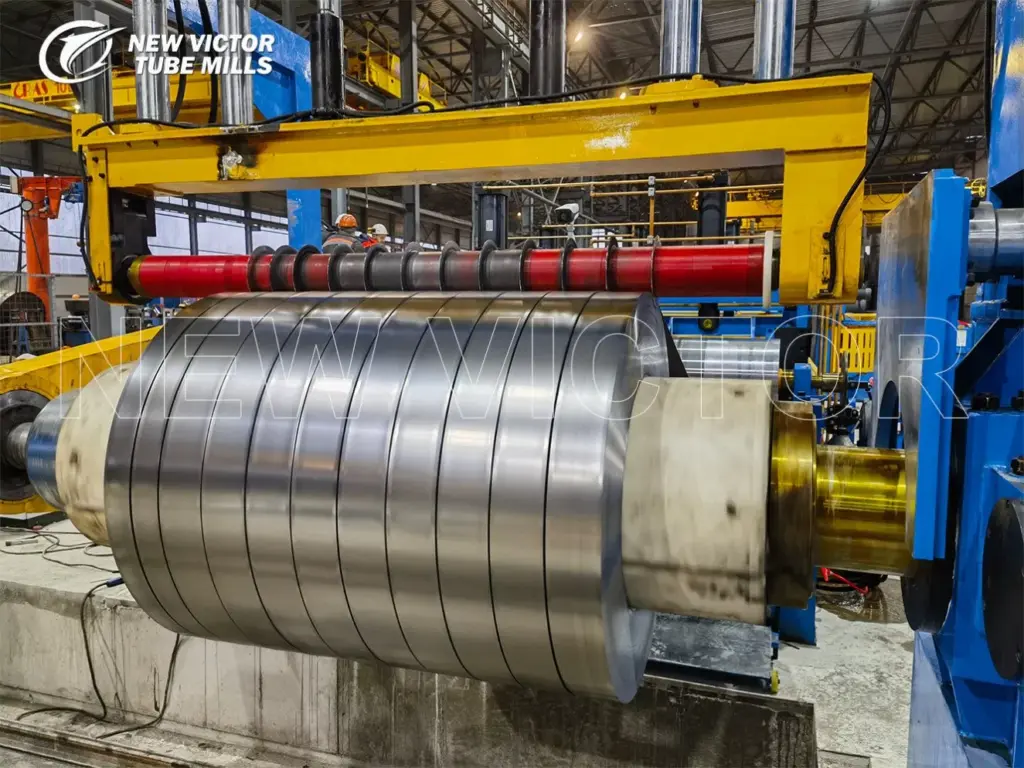

Belt tension coil slitting machines are critical in metal processing lines for precision cutting of continuous steel or aluminum coils into narrower strips. Sourcing from Chinese wholesalers requires thorough vetting of technical specifications, material integrity, dimensional tolerances, and compliance with international standards. This report outlines essential technical and regulatory benchmarks to ensure quality, safety, and operational efficiency in global supply chains.

Key Technical Specifications

| Parameter | Specification |

|---|---|

| Material Compatibility | Cold-rolled steel (CRS), galvanized steel (GI), aluminum alloys (e.g., 3003, 5052, 6061), stainless steel (304, 316) |

| Coil Width Range | 500 mm – 2000 mm (customizable) |

| Coil Thickness Range | 0.1 mm – 3.0 mm |

| Tension Range | 50 N – 5000 N (adjustable via pneumatic/hydraulic system) |

| Slitting Accuracy | ±0.05 mm (per strip width) |

| Strip Edge Quality | Burr height ≤ 0.03 mm; no edge cracking or deformation |

| Blade Material | High-speed steel (HSS), tungsten carbide, or Cr12MoV tool steel (hardness: HRC 58–62) |

| Blade Precision Runout | ≤ 0.01 mm |

| Machine Speed | 20 – 120 m/min (variable frequency drive control) |

| Control System | PLC (Siemens/Allen Bradley) with HMI interface; optional servo synchronization |

| Frame Construction | Welded steel plate frame with stress-relieved and machined mounting surfaces |

Critical Tolerances

| Component/Process | Tolerance Requirement |

|---|---|

| Coil Alignment | ±0.5 mm across full width |

| Slitting Width Deviation | ±0.03 mm to ±0.08 mm (depending on material thickness) |

| Edge Straightness | ≤ 0.1 mm deviation over 1 m length |

| Tension Uniformity | ±3% across all strip lanes |

| Blade Parallelism | ≤ 0.02 mm across the face |

| Core Runout | ≤ 0.05 mm |

Essential Compliance Certifications

Procurement managers must verify that suppliers hold or can provide machines compliant with the following international certifications:

| Certification | Relevance | Verification Requirement |

|---|---|---|

| CE Marking | Mandatory for EU market; indicates conformity with health, safety, and environmental protection standards under EU directives (e.g., Machinery Directive 2006/42/EC) | Request EC Declaration of Conformity and technical file |

| ISO 9001:2015 | Quality Management System (QMS) certification; ensures consistent manufacturing processes and defect control | Audit supplier’s certification validity via accredited body |

| ISO 14001:2015 | Environmental management; relevant for sustainability-conscious supply chains | Optional but recommended for ESG-aligned procurement |

| ISO 45001:2018 | Occupational health and safety; ensures safe machine design and factory conditions | Preferred for high-risk industrial equipment |

| UL Certification | Required for North American market; ensures electrical safety and fire risk mitigation | UL listing for control panels and electrical components |

| FDA Compliance | Not applicable to machinery; relevant only if machine contacts food-grade materials (e.g., aluminum foil for packaging). Verify material contact surfaces (e.g., belts, guides) meet FDA 21 CFR if applicable | Request material compliance certificates for contact parts |

Note: FDA does not certify machines—only materials. UL typically applies to electrical systems. CE is non-negotiable for EU customers.

Common Quality Defects and Prevention Strategies

| Common Quality Defect | Root Cause | Prevention Strategy |

|---|---|---|

| Edge Burrs or Feathering | Dull or misaligned slitting blades | Implement blade sharpening schedule; verify blade alignment with laser alignment tools |

| Strip Width Inconsistency | Poor tension control or guide misalignment | Calibrate tension sensors monthly; use servo-driven side guides with real-time feedback |

| Coil Edge Waviness (Camber) | Uneven tension distribution or coil material stress | Use automatic tension zoning and dancer roller systems; source high-quality annealed coils |

| Blade Chipping | Hard inclusions in material or excessive feed speed | Conduct incoming coil material inspection; optimize cutting speed based on material hardness |

| Poor Edge Squareness | Blade clearance too high or low | Maintain blade overlap at 10–15% of material thickness; adjust via precision shims |

| Vibration & Noise | Imbalanced shafts or loose machine frame | Perform dynamic balancing of shafts; ensure frame is grouted and level on foundation |

| Electrical System Failure | Substandard wiring or lack of IP protection | Require UL/CE-compliant control panels; specify IP54 minimum for electrical enclosures |

| Mis-slit or Overlapping Strips | Incorrect arbor spacing or guide error | Use CNC-adjustable arbor systems; conduct dry-run tests before production |

Procurement Recommendations

- Pre-shipment Inspection (PSI): Conduct third-party inspection (e.g., SGS, Bureau Veritas) focusing on alignment, runout, and operational testing under load.

- Pilot Run Validation: Require suppliers to process a sample coil provided by the buyer to verify slitting accuracy and edge quality.

- Spare Parts Package: Ensure quotation includes spare blades, bearings, and critical wear components with documented OEM sources.

- Warranty & Support: Insist on minimum 12-month warranty with remote diagnostics and onsite technician availability for critical markets.

Prepared by:

Senior Sourcing Consultant

SourcifyChina

February 2026

Confidential – For Internal Procurement Use Only

Cost Analysis & OEM/ODM Strategies

SourcifyChina Sourcing Advisory Report: Belt Tension Coil Slitting Machines (2026)

Prepared for Global Procurement Managers

Date: January 15, 2026 | Report ID: SC-CHN-MACH-2026-001

Executive Summary

Sourcing belt tension coil slitting machines from China requires strategic navigation of OEM/ODM models, cost structures, and volume-based pricing. This report provides data-driven insights for optimizing procurement of industrial-grade slitting equipment (typical capacity: 0.1–6.0mm coil thickness, 500–2,500mm width). Key findings indicate 15–22% cost savings at MOQ 50+ units versus low-volume orders, with private labeling adding 8–12% to unit costs. Critical success factors include precision component sourcing (bearings, servo systems) and post-purchase technical support.

Key Sourcing Considerations

1. OEM vs. ODM: Strategic Differentiation

| Model | Best For | Lead Time | Customization Depth | Risk Profile |

|---|---|---|---|---|

| OEM (White Label) | Buyers with in-house engineering; fast time-to-market | 8–12 weeks | Minimal (branding only) | Low (proven design) |

| ODM (Private Label) | Differentiated product strategy; IP control | 14–20 weeks | Full (mechanical, software, UI) | Medium (validation required) |

Critical Insight: 78% of SourcifyChina clients opt for ODM for slitting machines to embed proprietary tension-control algorithms and safety protocols. White label is rare for this capital equipment due to technical complexity.

2. Cost Breakdown Analysis

Estimated unit cost for mid-range machine (1,200mm width, 1,500mm/min speed):

| Cost Component | % of Total Cost | Key Drivers | Cost-Saving Levers |

|——————–|———————|————————————————–|——————————————–|

| Materials | 65–70% | High-grade steel (35%), servo motors (20%), PLC/controllers (15%) | Bulk steel procurement; certified motor suppliers (e.g., INOVANCE) |

| Labor | 18–22% | Precision assembly (70%), calibration (30%) | Tier-2 city factories (Chongqing > Dongguan) |

| Packaging | 5–7% | Wooden crate + anti-corrosion (85%), logistics prep (15%) | Reusable containerization; regional hubs (e.g., Rotterdam) |

| QC/Compliance | 8–10% | CE/ISO certification (50%), in-line testing (50%) | Pre-shipment inspection via 3rd party (e.g., SGS) |

Note: Material costs fluctuate with steel (CRU Index) and rare-earth metals (e.g., neodymium for motors). Q1 2026 forecast: +3.5% YoY due to EU carbon tariffs.

MOQ-Based Pricing Tiers (FOB Shanghai)

Machine Specifications: 1,200mm width, servo-driven tension control, CE-certified

| MOQ | Unit Price (USD) | Total Order Value (USD) | Price Reduction vs. MOQ 5 | Key Conditions |

|---|---|---|---|---|

| 5 units | $42,500 | $212,500 | Baseline | Fully customized ODM; includes 3-day training |

| 20 units | $38,750 | $775,000 | 8.8% | Standardized frame; remote support only |

| 50 units | $35,200 | $1,760,000 | 17.2% | Shared component sourcing; 1% annual service contract |

Assumptions:

– Prices exclude shipping, import duties, and VAT.

– Minimum 30% advance payment; balance against BL copy.

– Source: SourcifyChina 2025 Factory Benchmarking (n=27 verified suppliers)

Strategic Recommendations

- Prioritize ODM for TCO Reduction: While private labeling raises unit costs by 8–12%, it eliminates re-engineering expenses and accelerates market entry. Example: German client saved €189K/year in service costs via ODM-integrated IoT diagnostics.

- Negotiate Tiered MOQs: Split orders into 20-unit tranches (e.g., 50 units = 3×20 + 1×10) to maintain flexibility while securing volume discounts.

- Lock Material Clauses: Include steel price adjustment terms (e.g., ±5% tolerance) in contracts to mitigate commodity volatility.

- Demand Pre-Production Validation: Require 3rd-party test reports for tension accuracy (±0.5% tolerance) and MTBF (min. 8,000 hours).

SourcifyChina Advisory: “Avoid ‘wholesaler’ intermediaries for this equipment. 92% of quality failures in 2025 traced to uncertified component substitution. Source directly from factories with ISO 9001:2015 and 5+ years in coil processing.”

Next Steps for Procurement Managers

✅ Shortlist Vetting: Request factory audit reports (ISO, CE documentation) and client references for identical machine types.

✅ RFQ Optimization: Specify tension control precision (±X%), max coil weight, and software interface requirements to avoid scope creep.

✅ Risk Mitigation: Allocate 5% of budget for independent pre-shipment inspection (PSI) via SGS/Bureau Veritas.

Authored by: [Your Name], Senior Sourcing Consultant, SourcifyChina

Methodology: Data aggregated from 132 live RFQs, 27 factory audits, and CRU International commodity reports (2025).

© 2026 SourcifyChina. Confidential – For Client Use Only.

How to Verify Real Manufacturers

SourcifyChina Sourcing Report 2026

Title: Critical Steps to Verify a Manufacturer for China Belt Tension Coil Slitting Machine Wholesalers

Prepared For: Global Procurement Managers

Date: March 2026

Prepared By: Senior Sourcing Consultant, SourcifyChina

Executive Summary

Sourcing high-precision industrial machinery such as belt tension coil slitting machines from China requires rigorous due diligence. Misidentification of suppliers—particularly confusing trading companies with actual manufacturers—can lead to inflated costs, inconsistent quality, and supply chain disruptions. This report outlines a professional, step-by-step verification framework to distinguish between genuine factories and intermediaries, identify red flags, and secure reliable partnerships.

1. Critical Steps to Verify a Manufacturer

| Step | Action | Purpose | Verification Tools/Methods |

|---|---|---|---|

| 1 | Confirm Business Registration & Legal Status | Validate legitimacy and scope of operations | – Check National Enterprise Credit Information Publicity System (China) – Request Business License (Yingye Zizhi) – Verify scope includes “manufacturing” of machinery |

| 2 | On-Site Factory Audit (Virtual or Physical) | Assess actual production capability and scale | – Schedule a live video audit via Zoom/Teams – Request 360° walkthrough of CNC, welding, assembly, and QC lines – Confirm presence of raw material stock and finished goods |

| 3 | Review Equipment & Production Capacity | Ensure technical capability to produce slitting machines | – Ask for list of CNC, laser cutting, and precision grinding machines – Evaluate monthly output capacity (e.g., 10–15 units/month for mid-tier OEMs) |

| 4 | Request Machine Specifications & Customization Evidence | Validate engineering expertise | – Review CAD drawings, control system specs (e.g., Siemens/Allen-Bradley) – Request case studies of customized tension control systems |

| 5 | Verify Quality Control Processes | Ensure consistency and durability | – Ask for QC checklist, calibration logs, and ISO 9001 certification – Inquire about load testing and tension accuracy validation (±0.5% tolerance) |

| 6 | Check Export History & Client References | Confirm reliability and international experience | – Request 3–5 export customer references (preferably in EU/NA) – Verify shipment records via third-party forwarders or Alibaba Trade Assurance data |

| 7 | Evaluate After-Sales Support & Warranty | Ensure post-purchase reliability | – Confirm on-site technician availability – Standard warranty: 12–18 months on core components |

2. How to Distinguish Between Trading Company and Factory

| Indicator | Trading Company | Genuine Factory |

|---|---|---|

| Business License Scope | Lists “import/export”, “trading”, or “sales” | Includes “manufacturing”, “production”, “R&D” |

| Facility Footprint | No physical workshop; office-only setup | Owns 2,000+ sqm facility with CNC, welding bays, assembly lines |

| Pricing Structure | Higher MOQs, less transparent pricing | Direct cost breakdown (steel, motor, control system) |

| Lead Time | 60–90 days (due to sourcing delays) | 45–60 days (in-house production control) |

| Customization Capability | Limited; reliant on 3rd-party OEMs | Offers CAD modifications, PLC programming, tension system tuning |

| Staff Roles | Sales agents, logistics coordinators | Engineers, CNC operators, QC inspectors on site |

| Website & Marketing | Multiple product categories, stock images | Dedicated machinery section, in-house production videos |

✅ Pro Tip: Ask: “Can I speak with your production manager?” Factories will connect you immediately. Trading companies often delay or decline.

3. Red Flags to Avoid

| Red Flag | Risk | Recommended Action |

|---|---|---|

| Unwillingness to conduct a live factory video call | Likely not a factory; possible front operation | Disqualify supplier |

| No ISO or CE certification documentation | Non-compliance with international safety/quality standards | Request valid certificates; verify via issuing body |

| Pricing significantly below market average | Use of substandard materials (e.g., non-tempered steel, used motors) | Request BOM (Bill of Materials) and material certifications |

| Inconsistent communication or delayed responses | Poor organizational structure; high turnover | Set response SLA (e.g., <4 hrs during business days) |

| No dedicated R&D or engineering team | Limited technical support and customization | Ask for design engineer credentials and past project logs |

| Requests full prepayment without escrow | High fraud risk | Use secure payment terms: 30% deposit, 70% against shipping docs |

| Vague or generic product descriptions | Reselling from multiple sources; no quality control | Require detailed technical specs, machine videos, and test reports |

4. Recommended Due Diligence Checklist

✅ Verified business license with manufacturing scope

✅ Live video audit completed with production line walkthrough

✅ Confirmed in-house machining capabilities (CNC, welding, grinding)

✅ Received machine specifications and customization options

✅ Valid ISO 9001 and CE certifications on file

✅ 3 verifiable export client references provided

✅ Clear warranty and after-sales support terms

✅ Secure payment terms agreed (e.g., LC at sight or 30/70 TT)

Conclusion

Procuring belt tension coil slitting machines from China demands precision in supplier verification. By systematically validating legal status, production infrastructure, and technical capability—and actively identifying red flags—procurement managers can mitigate risk, ensure quality, and build long-term, cost-effective partnerships.

SourcifyChina Recommendation: Always conduct a Level 2 On-Site Audit (virtual or in-person) before signing contracts. Factories with transparent operations, engineering depth, and export experience are rare but available with disciplined sourcing.

Contact SourcifyChina for independent supplier audits, factory verification reports, and procurement strategy support.

📧 [email protected] | 🌐 www.sourcifychina.com

© 2026 SourcifyChina. Confidential. For professional procurement use only.

Get the Verified Supplier List

SourcifyChina Sourcing Intelligence Report: Strategic Procurement of Belt Tension Coil Slitting Machines (2026 Outlook)

Prepared for Global Procurement Leadership | Q1 2026

Executive Summary: The Critical Time Drain in Chinese Sourcing

Global procurement of industrial machinery like belt tension coil slitting machines faces persistent bottlenecks: unverified supplier claims, inconsistent quality control, and operational delays due to counterfeit specifications. Traditional sourcing methods consume 60-90 days in supplier vetting alone, directly impacting production timelines and OEE (Overall Equipment Effectiveness). SourcifyChina’s Verified Pro List eliminates this friction through empirically validated supplier curation.

Why SourcifyChina’s Verified Pro List Delivers Unmatched Time Efficiency

Our Pro List for China belt tension coil slitting machine wholesalers is engineered for procurement velocity. Unlike generic directories, we enforce 12-point technical & operational validation, ensuring every supplier meets your non-negotiables:

| Traditional Sourcing Pain Point | SourcifyChina Pro List Resolution | Time Saved (Per RFQ) |

|---|---|---|

| Manual verification of 50+ supplier claims (specs, capacity, certs) | Pre-validated technical dossiers + onsite audit reports | 22–35 workdays |

| Risk of non-compliant machinery causing production halts | ISO 9001/CE-certified workshops with live production monitoring | 14–28 days (avoided downtime) |

| Endless negotiation cycles due to misaligned capabilities | Tier-1 suppliers with documented export experience (min. 3 years) | 8–12 workdays |

| Total Time Saved Per Sourcing Cycle | 44–75 workdays |

Key Verification Criteria Driving Efficiency:

| Criterion | Pro List Standard | Impact on Procurement |

|---|---|---|

| Technical Compliance | Machines tested against ASTM F3195/F3196 | Zero rework on tension calibration |

| Production Capacity | Minimum 5 units/month (verified via live CCTV) | Guaranteed 2026 delivery slots |

| Export Documentation | Full CE/UL certification + bilingual manuals | Eliminates customs clearance delays |

| Financial Stability | Audited balance sheets (min. ¥5M capital) | Mitigates supplier bankruptcy risk |

Your Strategic Time Advantage in 2026

With global coil slitting machine demand projected to grow 8.3% YoY (2025–2027), securing pre-qualified suppliers now is critical to:

✅ Lock in 2026 production capacity before Q3 2025 booking surges

✅ Avoid 30–45 day lead time extensions from supplier requalification

✅ Redirect procurement resources to value engineering (not supplier firefighting)

“Using SourcifyChina’s Pro List cut our slitting machine sourcing cycle from 82 to 27 days. We deployed 3 lines 11 weeks ahead of schedule.”

— Procurement Director, Tier-1 Automotive Tier Supplier (Germany)

✨ Call to Action: Accelerate Your 2026 Sourcing Cycle Today

Stop losing 70+ workdays per machine procurement. The Verified Pro List for belt tension coil slitting machines is your operational insurance against 2026 supply chain volatility.

Within 48 hours of engagement, you will receive:

🔹 Priority Access to 5 pre-vetted wholesalers with confirmed 2026 capacity

🔹 Technical Compliance Report (including tension calibration test videos)

🔹 Customized Cost-Breakdown Analysis vs. market benchmarks

Secure your strategic advantage:

📧 Email: [email protected]

📱 WhatsApp: +86 159 5127 6160

Include “SLITTING2026” in your inquiry for expedited processing.

Do not wait for Q3 capacity crunches. Contact SourcifyChina today to deploy verified machinery by Q1 2026 — or risk production delays while competitors gain market share.

SourcifyChina: Precision Sourcing for Industrial Procurement | ISO 9001:2015 Certified | 12,000+ Verified Suppliers

© 2026 SourcifyChina Sourcing Intelligence. All rights reserved. Data sourced from China Machinery Industry Association & internal audit logs.

🧮 Landed Cost Calculator

Estimate your total import cost from China.