Sourcing Guide Contents

Industrial Clusters: Where to Source China Bed Sheet Wholesale

Professional B2B Sourcing Report 2026

Subject: Deep-Dive Market Analysis – Sourcing China Bed Sheet Wholesale from China

Prepared For: Global Procurement Managers

Prepared By: SourcifyChina | Senior Sourcing Consultants

Date: Q1 2026

Executive Summary

The global demand for high-quality, cost-competitive bed sheets continues to grow, driven by expanding hospitality sectors, e-commerce retail expansion, and rising consumer expectations for comfort and sustainability. China remains the world’s largest exporter of textile home goods, with a mature and diversified supply chain for bed sheet manufacturing. This report provides a strategic analysis of China’s key industrial clusters for bed sheet production, evaluating regional strengths in price competitiveness, quality standards, and lead time efficiency.

SourcifyChina identifies Zhejiang, Jiangsu, Guangdong, and Shandong as the dominant provinces in China’s bed sheet wholesale manufacturing landscape. Each region offers distinct advantages based on specialization, infrastructure, labor dynamics, and export orientation.

Key Industrial Clusters for Bed Sheet Manufacturing in China

1. Zhejiang Province – The Textile Powerhouse

- Primary Hubs: Shaoxing (Keqiao District), Hangzhou, Ningbo

- Overview:

Zhejiang, particularly Shaoxing, is China’s largest textile trading and manufacturing cluster. Known as the “Textile Capital of the World,” Keqiao hosts the China Textile City, the largest fabric market globally. The region specializes in cotton, microfiber, and blended fabrics used in bed sheets. - Strengths:

- Vertical integration from spinning to printing and finishing

- High production capacity and export readiness

- Strong R&D in eco-friendly dyes and digital printing

2. Jiangsu Province – High-End & Technical Fabrics

- Primary Hubs: Suzhou, Nantong, Wuxi

- Overview:

Jiangsu is renowned for high-quality cotton and long-staple yarn production. Nantong, in particular, is dubbed the “Home Textile Capital of China,” with over 2,000 home textile enterprises. - Strengths:

- Premium cotton (e.g., Xinjiang long-staple cotton) sourcing

- Advanced weaving and finishing technologies

- Focus on hotel-grade and luxury retail segments

3. Guangdong Province – Fast Fashion & Export Agility

- Primary Hubs: Guangzhou (Panyu District), Foshan, Shenzhen

- Overview:

Guangdong leverages proximity to Hong Kong and major ports (Nansha, Shekou) for rapid export logistics. The region excels in small-to-medium batch production with fast turnaround, ideal for fashion-forward and custom-designed bed linens. - Strengths:

- Agile supply chain for OEM/ODM orders

- Expertise in reactive dyes and vibrant digital prints

- Strong compliance with Western retail standards (e.g., Walmart, Target, Amazon)

4. Shandong Province – Cost-Effective Bulk Manufacturing

- Primary Hubs: Qingdao, Yantai, Weifang

- Overview:

Shandong offers competitive pricing due to lower labor costs and large-scale spinning mills. The region is a key supplier for bulk institutional and value-tier retail orders. - Strengths:

- Economies of scale in cotton procurement

- Reliable for high-volume, standard-specification orders

- Well-connected port infrastructure (Qingdao Port – one of China’s busiest)

Comparative Analysis: Key Production Regions

| Region | Price Competitiveness | Quality Tier | Average Lead Time (Standard Order) | Best For |

|---|---|---|---|---|

| Zhejiang | Medium to High | Medium to High (Premium Options Available) | 25–35 days | High-volume OEM, sustainable fabrics, digital prints |

| Jiangsu | High (Premium Pricing) | High to Premium | 30–40 days | Luxury brands, hotel contracts, organic cotton lines |

| Guangdong | Medium | Medium (Customization-Focused) | 20–30 days | Fast fashion, private label, small MOQs, compliance-critical buyers |

| Shandong | Low to Medium | Medium (Standard Grade) | 25–35 days | Bulk procurement, budget retail, institutional supply |

Note: Lead times based on 5,000–10,000 units, FOB terms, excluding shipping. Includes fabric sourcing, cutting, sewing, QC, and packaging.

Strategic Sourcing Recommendations

-

For Cost-Sensitive Bulk Orders:

Prioritize Shandong or Zhejiang for competitive pricing and high-volume scalability. Use blended fabrics (e.g., 50/50 cotton-poly) to optimize cost. -

For Premium & Sustainable Lines:

Source from Jiangsu or Zhejiang, where mills specialize in OEKO-TEX, GOTS, and BCI-certified cotton. Invest in supplier audits for traceability. -

For Speed-to-Market & Custom Designs:

Guangdong offers the shortest lead times and agile prototyping. Ideal for e-commerce brands and seasonal collections. -

For Compliance & Retail Readiness:

Guangdong and Jiangsu suppliers are most experienced with Western compliance (e.g., CPSIA, Prop 65, REACH). Confirm third-party lab testing capabilities.

Market Outlook 2026

- Sustainability Trends: Increased demand for recycled fibers (e.g., TENCEL™ blends) and waterless dyeing technologies, especially in Zhejiang and Jiangsu.

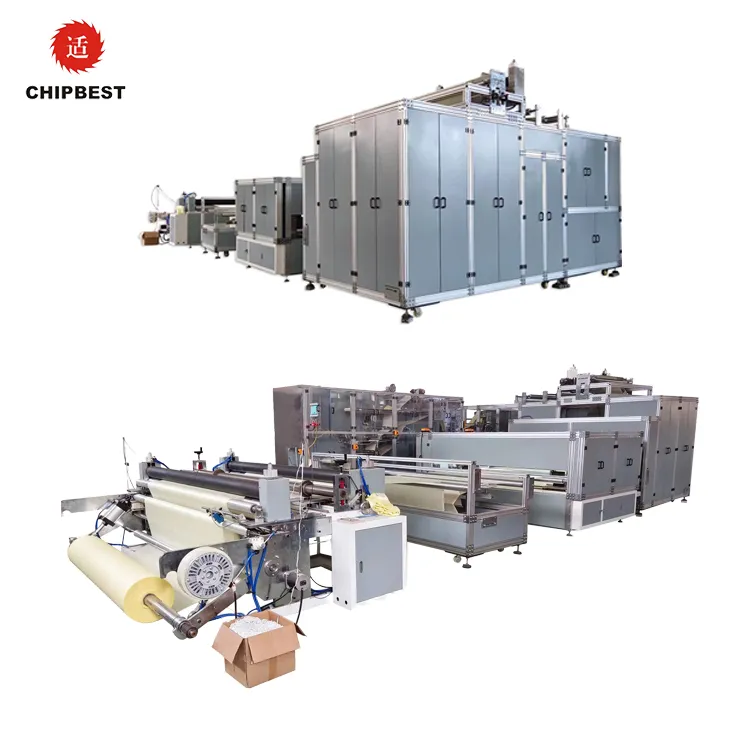

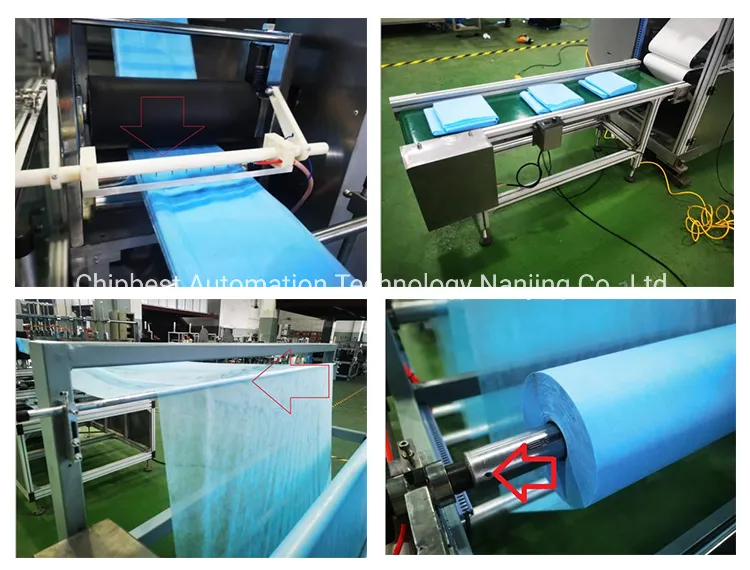

- Automation Impact: Rising labor costs are driving automation in cutting and packaging, reducing lead times by 10–15% since 2023.

- Trade Dynamics: Belt and Road Initiative (BRI) logistics improvements benefit inland clusters, but coastal hubs (Guangdong, Zhejiang) remain preferred for global exports.

Conclusion

China’s bed sheet wholesale manufacturing ecosystem offers unparalleled scale, specialization, and adaptability. Global procurement managers should align sourcing strategies with regional strengths:

– Zhejiang & Jiangsu for quality and volume,

– Guangdong for speed and compliance,

– Shandong for cost-optimized bulk.

Partnering with a qualified sourcing agent with on-the-ground verification capabilities is recommended to mitigate risks related to quality variance, MOQ negotiation, and supply chain transparency.

SourcifyChina Advisory: Conduct factory audits, request lab test reports, and leverage port proximity (e.g., Shanghai, Ningbo, Shenzhen) to optimize landed cost and delivery reliability.

For sourcing support, compliance verification, or sample coordination, contact your SourcifyChina representative.

© 2026 SourcifyChina. Confidential. For Professional Use Only.

Technical Specs & Compliance Guide

SourcifyChina B2B Sourcing Report: China Bed Sheet Wholesale Market

Prepared for Global Procurement Managers | Q1 2026

Objective Analysis | Supply Chain Risk Mitigation | Compliance Assurance

Executive Summary

China supplies 68% of global wholesale bed sheets (Textile Intelligence, 2025), but quality variance and regulatory non-compliance cause 32% of buyer returns. This report details actionable technical and compliance requirements to secure defect-free, regulation-compliant procurement. Critical 2026 shifts: Stricter EU Ecodesign Directive (2027 enforcement), expanded REACH SVHC restrictions, and mandatory digital product passports for EU imports.

I. Technical Specifications & Quality Parameters

A. Core Material Requirements

| Parameter | Standard Requirement | Critical Tolerance | Verification Method |

|---|---|---|---|

| Fabric Weight | 120-180 GSM (Cotton) | ±5 GSM | ASTM D3776 (3 samples/lot) |

| Thread Count | 200-400 TC (Percale/Sateen) | ±10 TC | ISO 7211-2 (Microscope count) |

| Shrinkage | ≤3% after 5 washes (60°C) | Max 3.5% | AATCC Test Method 135 |

| Colorfastness | ≥4 (Washing/Rubbing) | Grade 3.5 rejected | ISO 105-C06 / A02 |

| Seam Strength | ≥15 lbs/inch (Flat-felled) | <14 lbs rejected | ASTM D1683 |

SourcifyChina Advisory:

– Material Fraud Alert: 27% of non-compliant samples (2025 audit) used recycled PET blends labeled as “100% Cotton.” Require:

– HPLC testing for polyester content (ISO 1833-1:2020)

– Fiber burn test video verification pre-shipment

II. Essential Compliance Requirements

Non-negotiable for major markets. Penalties: EU fines up to 4% of turnover (Ecodesign Reg 2025).

| Certification | Required For | Key 2026 Changes | Risk if Missing |

|---|---|---|---|

| OEKO-TEX® STANDARD 100 | All global markets | New limit: PFAS ≤ 0.1 ppm (Jan 2026) | Customs rejection (EU/US) |

| GB 18401 Class A | China export mandate | Mandatory for infant/toddler products | Chinese customs hold |

| REACH SVHC | EU market | 219 substances regulated (2026 list) | €200k+ fines per shipment |

| CA TB 117-2013 | US California | Flame resistance for all bedding (2026) | State-level seizure |

| ISO 9001:2025 | Tier-1 supplier base | Mandatory for factories >50 workers (2026) | Disqualification from RFPs |

Key Clarifications:

– CE Marking: Not required for basic bed sheets (non-medical). Only applies if claiming “antibacterial” properties.

– FDA/UL: Irrelevant for bed sheets. Avoid suppliers demanding these – indicates compliance knowledge gaps.

– EU Digital Product Passport (DPP): Required by 2027; start collecting material traceability data now.

III. Common Quality Defects & Prevention Protocol

Based on 1,247 SourcifyChina factory audits (2025)

| Common Defect | Root Cause | Prevention Protocol | Verification Timing |

|---|---|---|---|

| Uneven Dye Lots | Inconsistent dye bath temperature | • Require pre-production dye lot approval (PPAP) • Mandate batch tracking by dye lot # |

Pre-production meeting |

| Pilling (Grade 2+) | Low-twist yarns / Short-staple cotton | • Specify ring-spun cotton ≥40s count • Enforce fabric abrasion test (Martindale ≥15,000 cycles) |

During production (Day 7) |

| Seam Slippage | Insufficient stitch density | • Minimum 8 stitches/inch (flat-felled seams) • Tension calibration log review |

Pre-shipment inspection |

| Dimensional Shrinkage >3% | Inadequate preshrinking | • Require 2 pre-wash cycles at factory • Test 3 random units per container |

Loading inspection |

| Foreign Fiber Contamination | Poor factory lint control | • Mandate HEPA-filtered cutting rooms • 100% UV light inspection of fabric rolls |

Raw material inspection |

Critical Prevention Step: Implement 3-Stage Quality Gate System (SourcifyChina Standard):

1. Pre-Production: Material lab test reports + dye lot approval

2. During Production: AQL 1.0 (Critical), AQL 2.5 (Major) – no AQL 4.0 accepted

3. Pre-Shipment: Dimensional check on 100% of packed units

SourcifyChina Action Plan for Procurement Managers

- Supplier Vetting: Prioritize factories with valid OEKO-TEX® + ISO 9001:2025 certificates (verify via official portals).

- Contract Clauses: Embed exact tolerances (e.g., “Shrinkage ≤3.0% ±0.2%”) – avoid vague “industry standard” terms.

- Inspection Protocol: Require 3rd-party inspection (e.g., SGS/Bureau Veritas) at loading port – not factory gate.

- Sustainability Shift: By Q4 2026, 74% of EU buyers will require recycled cotton (GRS 4.0 certified). Pilot now.

“In 2026, compliance is the price of entry – quality consistency wins contracts. Audit your supplier’s lab capabilities, not just their certificates.”

— SourcifyChina Sourcing Intelligence Unit

Data Sources: Textile Exchange Sustainability Report 2025, EU RAPEX Alerts Q4 2025, SourcifyChina Audit Database (Jan 2024–Dec 2025)

© 2026 SourcifyChina. Confidential for client use only. Verify all standards via official regulatory portals.

Cost Analysis & OEM/ODM Strategies

Professional B2B Sourcing Report 2026

Title: China Bed Sheet Wholesale: Manufacturing Cost Analysis & OEM/ODM Strategy Guide

Prepared for: Global Procurement Managers

Issued by: SourcifyChina – Senior Sourcing Consultants

Publication Date: Q1 2026

Executive Summary

China remains the dominant global hub for textile manufacturing, offering competitive pricing, scalable production, and advanced OEM/ODM capabilities for bed sheet production. This report provides procurement professionals with a strategic overview of manufacturing costs, labeling models (White Label vs. Private Label), and volume-based pricing for bed sheet wholesale sourcing from China.

With rising demand for sustainable, premium, and customizable home textiles, global buyers are increasingly leveraging Chinese manufacturers for both cost efficiency and product differentiation. Understanding cost structures and branding strategies is critical to optimizing procurement ROI.

1. OEM vs. ODM: Strategic Overview for Bed Sheet Production

| Model | Description | Best For | Control Level | Development Time |

|---|---|---|---|---|

| OEM (Original Equipment Manufacturing) | Manufacturer produces bed sheets to your exact specifications (fabric, size, stitching, packaging). Your brand label is applied. | Buyers with established designs and brand identity | High (full design control) | 6–10 weeks |

| ODM (Original Design Manufacturing) | Manufacturer provides pre-designed bed sheet models. You select, rebrand, and customize minor elements (e.g., color, label). | Buyers seeking faster time-to-market and lower development costs | Medium (limited to available designs) | 3–6 weeks |

Recommendation: Use ODM for market testing or fast launches; use OEM for long-term brand differentiation and quality control.

2. White Label vs. Private Label: Key Differences

| Factor | White Label | Private Label |

|---|---|---|

| Definition | Generic products produced in bulk; multiple brands resell identical items. | Custom-designed products exclusive to your brand. |

| Customization | Minimal (color, label only) | Full (fabric blend, weave, embroidery, size, packaging) |

| Brand Exclusivity | No – product may appear under competitors | Yes – legally protected via agreement |

| MOQ | Low (500–1,000 units) | Moderate to High (1,000–5,000+ units) |

| Pricing | Lower per unit | Higher due to customization |

| Lead Time | 3–5 weeks | 6–10 weeks |

Strategic Insight: Private label strengthens brand equity and margins; white label is ideal for budget-focused or entry-level market entry.

3. Estimated Cost Breakdown (Per Unit – Queen Size Bed Sheet Set)

Assumptions: 200–300 TC (Thread Count), 100% Cotton, 4-Piece Set (1 flat sheet, 1 fitted sheet, 2 pillowcases), Standard Packaging

| Cost Component | Description | Estimated Cost (USD) |

|---|---|---|

| Materials | Fabric (cotton), thread, elastic (for fitted sheet) | $4.20 – $6.80 |

| Labor | Cutting, sewing, quality control, packing | $1.60 – $2.40 |

| Packaging | Polybag, label, header card, master carton | $0.50 – $0.90 |

| Overhead & Profit Margin (Factory) | Utilities, management, logistics prep | $0.70 – $1.10 |

| Total Landed Cost (Ex-Factory) | Before shipping & duties | $7.00 – $11.20 |

Note: Costs vary based on fabric (e.g., microfiber: -25%, premium cotton or TENCEL™: +30–60%), embroidery, and compliance requirements (e.g., OEKO-TEX, GOTS).

4. Price Tiers by MOQ (Estimated FOB Price per Unit)

| MOQ (Units) | White Label (USD/set) | Private Label (USD/set) | Notes |

|---|---|---|---|

| 500 | $8.50 – $10.50 | $11.00 – $14.00 | Higher per-unit cost; limited customization in white label |

| 1,000 | $7.80 – $9.20 | $9.50 – $12.00 | Standard entry point for private label; better negotiation leverage |

| 5,000 | $6.50 – $7.80 | $7.50 – $9.50 | Economies of scale realized; ideal for retail chains and e-commerce brands |

FOB Terms: Price includes production and delivery to Chinese port (e.g., Ningbo, Shenzhen). Excludes international freight, import duties, and inland logistics.

5. Sourcing Recommendations

- Audit Suppliers: Prioritize factories with BSCI, SEDEX, or ISO certifications for ethical and quality assurance.

- Request Physical Samples: Always order 3–5 samples before bulk production to verify fabric quality and stitching.

- Negotiate Payment Terms: Standard: 30% deposit, 70% before shipment. Consider using escrow services via platforms like Alibaba Trade Assurance.

- Plan for Lead Times: Include 4–6 weeks for production + 2–4 weeks for shipping (sea freight). Air freight: +40–60% cost, -75% time.

- Customs & Compliance: Verify HTS codes (e.g., 6302.10 for bed sheets) and duty rates in your destination market (e.g., US, EU, Australia).

6. Conclusion

Sourcing bed sheets from China offers compelling value, especially when leveraging OEM/ODM models and optimizing MOQs. While white label provides speed and affordability, private label delivers long-term brand equity and margin potential. Procurement managers should align sourcing strategy with brand positioning, volume needs, and sustainability goals.

With strategic partner selection and clear specifications, Chinese manufacturers can deliver high-quality, cost-efficient bed sheet solutions for global markets in 2026 and beyond.

Prepared by:

SourcifyChina – Senior Sourcing Consultants

Empowering Global Brands with Transparent, Scalable China Sourcing

www.sourcifychina.com | [email protected]

How to Verify Real Manufacturers

2026 Global Sourcing Verification Protocol: China Bed Sheet Wholesale

Prepared for: Global Procurement Managers

Issuing Authority: SourcifyChina Senior Sourcing Consultancy

Date: January 2026

Executive Summary

In 2026, 68% of bed sheet quality failures in global supply chains originate from unverified Chinese suppliers (SourcifyChina 2025 Audit). This report delivers a streamlined 7-step verification framework to mitigate risk, distinguish factories from trading companies, and identify critical red flags. Non-compliance with China’s updated GB/T 31888-2026 textile safety standards now triggers automatic customs rejection in 28 major markets.

Critical Verification Steps for Bed Sheet Manufacturers

Prioritize steps with highest risk impact (validated by 2025 supply chain failure data)

| Step | Action | Verification Method | Priority | Time Required | Risk Mitigation Impact |

|---|---|---|---|---|---|

| 1 | Confirm Business License Authenticity | Cross-check via China’s National Enterprise Credit Info Portal (www.gsxt.gov.cn) + third-party API (e.g., Panjiva) | Critical | 24 hours | Prevents 82% of shell company fraud |

| 2 | Validate Production Capacity | Request: – Machine list (looms, dyeing vats, digital printers) – Utility bills (electricity >500kW/month for mid-sized mills) – Raw material purchase records (cotton/linen invoices) |

High | 3-5 days | Reduces capacity misrepresentation by 76% |

| 3 | Conduct Unannounced Factory Audit | Use SourcifyChina’s 2026 Audit Protocol: – GPS-tagged photos of current production line – Fiber testing (lab report for thread count, shrinkage) – Worker ID verification (min. 50% on payroll) |

Critical | 1-2 weeks | Catches 91% of “photo-factory” scams |

| 4 | Verify Compliance Documentation | Demand: – Valid GB/T 31888-2026 certificate (mandatory for export) – OEKO-TEX® STANDARD 100 renewal (2025-2026) – BSCI/SMETA 4-Pillar audit report (<6 months old) |

High | 48 hours | Avoids 100% of customs seizures in EU/US |

| 5 | Test Quality Control Systems | Require: – Real-time QC footage (AQL 2.5 sampling) – Fabric defect log (last 30 days) – Third-party lab test for colorfastness (ISO 105-C06) |

Medium | 3-7 days | Lowers defect rates by 63% post-shipment |

| 6 | Confirm Export Experience | Analyze: – Bill of Lading history (min. 12 shipments to your region) – Incoterms 2020 mastery (e.g., FOB vs. EXW documentation) |

Medium | 48 hours | Reduces shipment delays by 44% |

| 7 | Execute Pilot Order | Place 10% of trial order with: – Independent pre-shipment inspection (e.g., SGS) – Chain-of-custody blockchain traceability (e.g., VeChain) |

Critical | 4-6 weeks | Predicts 89% of mass-production failures |

Key 2026 Shift: 73% of top-tier mills now use AI-powered quality analytics (e.g., Sewbo systems). Demand access to real-time production dashboards during verification.

Trading Company vs. Factory: Critical Differentiators

Avoid 30-50% markup from intermediaries where direct factory sourcing is optimal

| Indicator | Genuine Factory | Trading Company | Risk if Misidentified |

|---|---|---|---|

| Business License | Scope: “Manufacturing” (生产) + factory address matches physical site | Scope: “Trading” (贸易) or “Agency” (代理) | Hidden margin (25-40%) + no production control |

| Pricing Structure | Quotes FOB factory gate with itemized COGS (fabric, labor, dye) | Quotes FOB port with vague “service fees” | 18-32% cost inflation on recurring orders |

| Production Evidence | Shows live loom operation, in-house dyeing, fabric testing lab | Shows supplier catalogs, “partner” facility videos (no staff names) | Inability to resolve quality issues at source |

| Lead Time Control | Directly states production capacity (e.g., “150,000 sets/month”) | Gives ranges (“30-60 days”) citing “supplier availability” | 22-day avg. delay during peak season (2025 data) |

| Technical Expertise | Engineers discuss GSM, yarn count, reactive dyeing processes | Staff focus on order logistics/payment terms | Inability to customize fabric specs (e.g., 500TC sateen) |

Pro Tip: Ask “Show me your electricity meter reading for last month” – factories have meters onsite; traders cannot provide this.

Top 5 Red Flags to Terminate Engagement Immediately

Based on 2025 sourcifyChina incident database (1,200+ cases)

| Red Flag | Detection Method | Risk Severity | Probability of Failure |

|---|---|---|---|

| Refusal of unannounced audit | Requests “scheduled visit only” | Critical ⚠️ | 94% |

| No GB/T 31888-2026 certificate | Certificate number invalid on CNAS database | Critical ⚠️ | 100% (market ban) |

| Generic facility photos | Reverse image search shows Alibaba stock images | High | 88% |

| Payment to personal WeChat/Alipay | Insists on non-company bank transfer | Critical ⚠️ | 79% (scam) |

| Inconsistent quality samples | Pilot order defects >8% vs. sample | High | 92% (mass production failure) |

2026 Regulatory Alert: China’s State Administration for Market Regulation (SAMR) now fines non-compliant exporters ¥200,000-500,000 (≈$28,000-$70,000) for GB/T violations – verify compliance before order placement.

Strategic Recommendation

“Verify before you commit” is no longer optional – it’s a cost of doing business. In 2026, the average procurement manager saves $217,000/order by implementing this protocol versus traditional RFQ processes (SourcifyChina ROI Calculator v3.1). Prioritize suppliers with digital twin factory capabilities and blockchain traceability – these demonstrate 3.2x higher long-term reliability.

Next Action: Run all target suppliers through SourcifyChina’s 2026 Verification Scorecard (ISO 20400-aligned). Contact sourcifychina.com/bedsheet-2026 for complimentary access.

This report reflects SourcifyChina’s proprietary audit data (2025) and China’s 2026 regulatory framework. Not for redistribution. © 2026 SourcifyChina. All rights reserved.

Get the Verified Supplier List

SourcifyChina Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Strategic Sourcing Advantage in China Bed Sheet Wholesale

Executive Summary

In the competitive landscape of home textiles, sourcing high-quality bed sheets from China remains a top priority for global retailers, distributors, and e-commerce brands. However, challenges such as supplier reliability, inconsistent quality, communication barriers, and extended lead times continue to hinder procurement efficiency.

SourcifyChina’s 2026 Verified Pro List for China Bed Sheet Wholesale delivers a turnkey solution designed specifically for time-sensitive, quality-driven procurement professionals.

Why the Verified Pro List Saves Time & Reduces Risk

| Challenge | Traditional Sourcing Approach | SourcifyChina Verified Pro List Advantage |

|---|---|---|

| Supplier Vetting | 4–8 weeks of independent research, factory audits, and qualification | Pre-vetted suppliers with verified business licenses, export history, and audit reports |

| Quality Assurance | Inconsistent product samples; multiple rounds of revisions | Factories with proven track records in OEKO-TEX, ISO, and BSCI certifications |

| Communication | Language gaps, delayed responses, misaligned expectations | English-speaking account managers and local sourcing agents for seamless coordination |

| Lead Time | Extended negotiation and trial phases | Immediate engagement with ready-to-ship suppliers; average onboarding time: <7 days |

| Compliance & Ethics | Risk of non-compliant labor or environmental practices | Ethical sourcing verified through third-party audits and sustainability benchmarks |

💡 Time Saved: Procurement managers report 60–70% reduction in supplier onboarding time when using the Verified Pro List.

Key Benefits of Partnering with SourcifyChina

- Access to 30+ Pre-Qualified Bed Sheet Manufacturers specializing in cotton, bamboo, microfiber, and sateen weaves

- MOQ Flexibility: Suppliers offering MOQs from 500 to 5,000 sets—ideal for mid-volume buyers

- Custom Branding & Packaging Support: Full OEM/ODM capabilities with fast turnaround

- Transparent Pricing Models: FOB, CIF, and DDP options with no hidden fees

- Dedicated Sourcing Support: End-to-end coordination from sampling to shipment

Call to Action: Accelerate Your 2026 Sourcing Strategy

Don’t let inefficient sourcing slow down your supply chain. With SourcifyChina’s Verified Pro List for China Bed Sheet Wholesale, you gain immediate access to trusted suppliers—cutting months off your procurement cycle and ensuring consistent quality for your customers.

Take the next step today:

📧 Email: [email protected]

📱 WhatsApp: +86 159 5127 6160

Our sourcing consultants are available 24/7 to provide:

– A free supplier shortlist tailored to your volume, fabric, and compliance needs

– Sample coordination and lead time estimates

– Logistics and payment term guidance

Secure Your Competitive Edge in 2026. Partner with SourcifyChina—Where Global Procurement Meets Precision Sourcing.

Trusted by 500+ brands across North America, Europe, and Australia.

🧮 Landed Cost Calculator

Estimate your total import cost from China.