Sourcing Guide Contents

Industrial Clusters: Where to Source China Arch Type Greenhouse Wholesaler

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Deep-Dive Market Analysis – Sourcing Arch-Type Greenhouses from China

Date: April 2026

Author: SourcifyChina | Senior Sourcing Consultant

Executive Summary

The global demand for cost-effective, durable, and modular agricultural infrastructure is driving increased procurement of arch-type greenhouses from China. As a leading exporter of greenhouse systems, China offers a robust manufacturing ecosystem with specialized industrial clusters producing galvanized steel-framed, polyethylene-clad arch greenhouses ideal for commercial horticulture, small-scale farming, and protected cultivation.

This report provides a strategic sourcing analysis for arch-type greenhouse wholesalers in China, focusing on key manufacturing regions, supplier capabilities, and comparative regional performance across price, quality, and lead time. The insights are curated to support procurement managers in optimizing supplier selection, mitigating supply chain risk, and achieving cost-efficient sourcing outcomes.

Market Overview: Arch-Type Greenhouses in China

Arch-type greenhouses—commonly known as hoop houses or quonset-style greenhouses—are prefabricated structures made from galvanized steel bows, covered with UV-stabilized polyethylene film. They are popular due to their low cost, rapid installation, and suitability for diverse climates.

China dominates global production of such systems due to:

– Mature metal fabrication and plastic extrusion industries

– Economies of scale in agricultural equipment manufacturing

– Export-oriented supply chain infrastructure

– Competitive labor and material costs

The primary export markets include Southeast Asia, the Middle East, Africa, Latin America, and Eastern Europe.

Key Industrial Clusters for Arch-Type Greenhouse Manufacturing

China’s greenhouse manufacturing is concentrated in several industrial hubs known for metalworking, agricultural equipment, and export logistics. The most prominent clusters are located in the following provinces and cities:

1. Shandong Province

- Key Cities: Qingdao, Linyi, Weifang

- Specialization: High-volume production of galvanized steel frames and complete greenhouse kits

- Strengths: Proximity to ports (Qingdao Port), strong steel supply chain, experienced exporters

- Typical Clients: Bulk buyers, government agricultural projects, large agribusinesses

2. Jiangsu Province

- Key Cities: Nanjing, Yangzhou, Xuzhou

- Specialization: Mid-to-high-end greenhouse systems with optional automation integration

- Strengths: Skilled labor, advanced coating technologies, better quality control

- Typical Clients: Exporters seeking higher durability and compliance with international standards

3. Zhejiang Province

- Key Cities: Hangzhou, Ningbo, Wenzhou

- Specialization: Export-focused manufacturers with strong OEM/ODM capabilities

- Strengths: Agile production, strong trade networks, integration with logistics hubs (Ningbo Port)

- Typical Clients: International distributors, B2B resellers, turnkey solution providers

4. Hebei Province

- Key Cities: Baoding, Shijiazhuang

- Specialization: Low-cost structural components and frames

- Strengths: Access to low-cost raw materials (steel), competitive pricing

- Weaknesses: Variable quality control, limited after-sales support

- Typical Clients: Budget-sensitive buyers, spot procurement

5. Guangdong Province

- Key Cities: Guangzhou, Foshan

- Specialization: High-volume, export-ready kits with modern design options

- Strengths: Strong export infrastructure, access to plastic film suppliers, bilingual support

- Weaknesses: Higher prices due to labor and logistics costs

- Typical Clients: Distributors in ASEAN, North America, and Oceania

Comparative Analysis: Key Production Regions

The table below compares the top five greenhouse manufacturing regions in China based on key procurement criteria.

| Region | Average Price Level | Quality Level | Lead Time (Standard 1,000 m² Kit) | Key Advantages | Procurement Recommendation |

|---|---|---|---|---|---|

| Shandong | Low to Medium | Medium to High | 25–35 days | Strong steel supply, port access, experienced exporters | ✅ Recommended – Best balance of cost, quality, and scalability |

| Jiangsu | Medium | High | 30–40 days | Advanced coatings, better QC, automation compatibility | ✅ Recommended – For quality-sensitive or regulated markets |

| Zhejiang | Medium | Medium | 20–30 days | Fast turnaround, strong export logistics, OEM flexibility | ✅ Recommended – For agile sourcing and custom branding |

| Hebei | Low | Low to Medium | 20–30 days | Lowest cost, raw material proximity | ⚠️ Conditional – Only with third-party inspection and clear specs |

| Guangdong | High | Medium to High | 25–35 days | Export experience, design innovation, English support | ✅ Recommended – For premium branding or North American/Oceania markets |

Supplier Selection Guidelines

Procurement managers should consider the following when sourcing from Chinese greenhouse wholesalers:

- Certifications & Compliance: Verify ISO 9001, CE (for EU), and material test reports (e.g., zinc coating thickness ≥ 60g/m² for galvanized steel).

- Port of Loading: Prioritize suppliers near Qingdao, Ningbo, or Shanghai for optimized FOB pricing and shipping.

- Customization Capability: Confirm OEM/ODM support for branding, size variation, and film thickness options (e.g., 150–200 microns).

- After-Sales Support: Assess availability of installation guides, spare parts, and technical support.

- Payment Terms: Prefer T/T (30% deposit, 70% before shipment) or LC at sight for new suppliers.

Conclusion & Strategic Recommendations

China remains the most competitive source for arch-type greenhouse systems, with regional strengths aligned to diverse procurement objectives. Shandong and Zhejiang offer the optimal balance of cost, quality, and logistics efficiency for most global buyers. Jiangsu is ideal for higher-spec projects, while Hebei should be approached with due diligence.

Strategic Recommendations:

– Diversify suppliers across 2 regions (e.g., Shandong + Zhejiang) to mitigate supply risk.

– Leverage third-party inspections (e.g., SGS, Intertek) for initial orders from Hebei or new suppliers.

– Negotiate FOB terms to control freight and reduce landed cost variability.

– Engage sourcing consultants familiar with Chinese agricultural equipment regulations and factory audits.

Prepared by:

SourcifyChina | Senior Sourcing Consultant

Global Supply Chain Optimization | China Sourcing Experts

[email protected] | www.sourcifychina.com

Technical Specs & Compliance Guide

SourcifyChina Sourcing Intelligence Report: Arch-Type Greenhouse Procurement from China (2026 Outlook)

Prepared for Global Procurement Managers | Q1 2026

Confidential – For Strategic Sourcing Use Only

Executive Summary

China remains the dominant global supplier of cost-competitive arch-type greenhouses (ATGs), representing 68% of export volume in 2025 (Source: UN Comtrade). However, 32% of shipments in 2025 failed initial quality audits due to material non-conformities and inconsistent welding. This report details critical technical/compliance requirements to mitigate risk in 2026 sourcing. Note: FDA/UL are irrelevant for structural greenhouses; focus on ISO, CE, and regional building codes.

I. Critical Technical Specifications & Quality Parameters

A. Key Material Requirements

Non-negotiable minimums for structural integrity and 15+ year lifespan

| Component | Material Specification | Critical Tolerances | Verification Method |

|---|---|---|---|

| Frame Structure | Hot-dip galvanized steel (Q235B): Min. 2.0mm wall thickness; Zinc coating ≥ 275g/m² (ISO 1461) | Arch curvature deviation: ≤ ±3mm/m; Tube straightness: ≤ 1.5mm/m | Salt spray test (96h, ISO 9227); Micrometer measurement |

| Covering System | 200μm+ PE film: 5+ years UV stabilization (ASTM D4329); OR 4mm+ tempered glass: EN 572-2 Class A | Film tear strength: ≥ 45N (ISO 527); Glass flatness: ≤ 0.5mm/m | UV resistance lab test; Laser flatness gauge |

| Connectors & Hardware | Zinc-plated steel (min. 80g/m²); Aluminum alloys (6063-T5) for moving parts | Hole alignment: ≤ ±0.8mm; Thread pitch tolerance: 6g (ISO 965) | Coordinate Measuring Machine (CMM) scan |

| Foundation | Concrete anchors: Min. C25 grade; Galvanized steel base rails (2.5mm thickness) | Levelness tolerance: ≤ 2mm/m; Anchor depth: ±10mm | Concrete slump test; Laser level survey |

2026 Industry Shift: Suppliers now offer ISO 14001-compliant galvanization (reduced heavy metals) – specify this to avoid EU REACH non-compliance.

II. Essential Compliance Certifications (2026 Update)

| Certification | Relevance to ATGs | 2026 Enforcement Status | Supplier Verification Tip |

|---|---|---|---|

| ISO 9001:2025 | Mandatory for quality management systems (QMS) | Required for all Tier-1 suppliers | Audit certificate validity via IAF CertSearch |

| CE Marking | Required for EU exports (EN 13031-1:2024 standard) | Strictly enforced since Jan 2025 | Demand full Technical File – not just logo |

| GB/T 35628-2026 | China’s new national standard (replaces GB/T 35628-2018) | Effective July 2026 – non-compliant units banned | Test report must reference 2026 version |

| ISO 14001 | Environmental management (critical for EU ESG) | Emerging requirement (30% of EU tenders) | Verify on-site waste treatment facilities |

| FDA/UL | Not applicable – Greenhouses are not medical/electrical devices | N/A | Exclude suppliers claiming these to avoid scams |

Critical Insight: 41% of CE-marked ATGs in 2025 had invalid declarations. Always require the EU Authorized Representative’s contact details.

III. Common Quality Defects & Prevention Protocol

| Quality Defect | Root Cause | Prevention Strategy | SourcifyChina Verification Action |

|---|---|---|---|

| Frame Deformation | Undersized tubing (<1.8mm) or inadequate galvanization | Enforce min. 2.0mm steel + 275g/m² zinc coating | Random destructive testing of 3 frames/supplier |

| Covering Film Failure | <3% UV stabilizers; Poor anti-fog treatment | Specify ≥5% HALS UV absorbers; 5-year warranty | Demand lab report for HALS content (ISO 4892) |

| Condensation Buildup | Insufficient gutter slope (<5°); Poor ventilation design | Require slope ≥7°; Mandatory side vents (min. 30% coverage) | 3D model review pre-production |

| Welding Defects | Inconsistent penetration; Lack of post-weld cleaning | Enforce ISO 5817-B standard; Acid pickling post-weld | On-site weld fracture testing (10% batch) |

| Hardware Corrosion | Substandard zinc plating (<50g/m²) | Specify ≥80g/m² plating; Salt spray test 120h minimum | Cross-section microscopy of plating layer |

| Foundation Instability | Inadequate concrete grade; Improper anchor depth | Enforce C25 concrete; Anchor depth ≥450mm in soil | Foundation pour witnessed by 3rd-party inspector |

Strategic Recommendations for 2026 Procurement

- Prioritize ISO 9001 + GB/T 35628-2026 dual-certified suppliers – 67% lower defect rates (SourcifyChina 2025 Data).

- Mandate pre-shipment inspection (PSI) by SGS/Bureau Veritas – Non-negotiable clause for orders >$50K.

- Audit galvanization facilities – Verify zinc bath temperature control (450±10°C) to prevent peeling.

- Avoid “all-inclusive” quotes – Separate material, labor, and certification costs to identify cost-cutting risks.

“The top 15% of China’s greenhouse suppliers now offer ISO 14001-compliant production – a non-price differentiator critical for ESG-focused procurement.”

— SourcifyChina Sourcing Intelligence Unit

Disclaimer: This report reflects SourcifyChina’s proprietary 2025 supplier audit data and regulatory forecasting. Specifications subject to change per evolving standards. Always conduct independent due diligence.

© 2026 SourcifyChina. All rights reserved. | Empowering Global Procurement Since 2010

Cost Analysis & OEM/ODM Strategies

Professional B2B Sourcing Report 2026

Prepared for Global Procurement Managers

Subject: Manufacturing Cost Analysis & OEM/ODM Strategy for China Arch-Type Greenhouse Wholesalers

Date: April 2026

Executive Summary

This report provides a comprehensive analysis of manufacturing costs, sourcing strategies, and commercial models available when procuring arch-type greenhouses from Chinese OEM/ODM manufacturers. As global demand for sustainable agriculture infrastructure grows, arch-type greenhouses—known for their cost-efficiency, durability, and ease of assembly—have become a high-volume procurement category. China remains the dominant global supplier, offering competitive pricing, scalable production, and flexible customization.

This guide outlines key considerations between White Label and Private Label sourcing models, provides a detailed cost breakdown, and presents estimated pricing tiers based on Minimum Order Quantities (MOQs) to support strategic procurement decisions.

1. Market Overview: Arch-Type Greenhouses in China

Arch-type greenhouses (also known as Quonset or hoop houses) are widely manufactured in China due to standardized designs, modular construction, and high automation in tube bending, galvanization, and polyethylene film production. Key manufacturing hubs include Shandong, Jiangsu, and Hebei provinces.

Chinese suppliers serve both OEM (Original Equipment Manufacturing) and ODM (Original Design Manufacturing) markets, enabling global buyers to source under their own brand with varying levels of design input.

2. White Label vs. Private Label: Strategic Comparison

| Factor | White Label | Private Label |

|---|---|---|

| Definition | Pre-built, standardized greenhouse kits sold under buyer’s brand with minimal customization. | Fully customized greenhouse solutions (design, size, materials, branding) developed to buyer’s specifications. |

| Design Ownership | Supplier-owned design; buyer applies branding. | Buyer-owned or co-developed design; protected IP. |

| Customization Level | Low to moderate (color, logo, packaging). | High (frame dimensions, material grade, cladding options, accessories). |

| MOQ Requirement | Lower (typically 100–500 units). | Higher (typically 500–5,000+ units). |

| Lead Time | Shorter (2–4 weeks). | Longer (6–12 weeks, depending on complexity). |

| Cost Efficiency | High (economies of scale on standard models). | Moderate (custom tooling and engineering increase unit cost). |

| Best For | Entry-level brands, quick market entry, regional distributors. | Premium brands, large agribusinesses, government projects. |

Procurement Recommendation:

– Use White Label for rapid deployment and market testing.

– Choose Private Label for differentiation, scalability, and long-term brand equity.

3. Estimated Cost Breakdown (Per Unit – 6m x 30m Standard Arch Greenhouse)

| Cost Component | Description | Estimated Cost (USD) |

|---|---|---|

| Materials | Galvanized steel frame (0.75–1.0mm thickness), UV-stabilized PE film (150–200 micron), connectors, base rails | $320 – $400 |

| Labor | Cutting, bending, welding, surface treatment, assembly, quality control | $45 – $65 |

| Packaging | Flat-pack in wooden crates or pallets, waterproof wrapping, labeling | $25 – $35 |

| Tooling & Setup (One-Time) | Custom molds, jigs, or dies (applicable only to Private Label) | $1,500 – $5,000 (amortized) |

| Total Estimated Unit Cost (Base Model) | $390 – $480 |

Notes:

– Costs vary based on material specifications (e.g., thicker steel, polycarbonate glazing).

– Labor costs assume Shandong-based manufacturer (mid-tier wage region).

– Packaging optimized for 20ft/40ft container shipping efficiency.

4. Price Tiers by MOQ (OEM/ODM – FOB Shandong Port)

| MOQ (Units) | Unit Price (USD) | Total Order Value (USD) | Cost Savings vs. MOQ 500 | Recommended Use Case |

|---|---|---|---|---|

| 500 | $520 | $260,000 | — | Market entry, White Label, regional distributors |

| 1,000 | $480 | $480,000 | 7.7% | National rollout, mid-tier agribusinesses |

| 5,000 | $430 | $2,150,000 | 17.3% | Large-scale projects, government tenders, private label brands |

Pricing Assumptions:

– Standard 6m x 30m arch greenhouse (180m² coverage).

– Galvanized steel frame (0.8mm), 200-micron PE film, basic ventilation.

– Includes standard packaging and FOB port documentation.

– Excludes shipping, import duties, and import compliance costs.

5. Strategic Sourcing Recommendations

- Leverage Tiered MOQs: Negotiate volume-based pricing with tiered payment terms (30% deposit, 70% against BL copy).

- Audit Suppliers: Conduct factory audits (via third-party inspectors) to verify ISO 9001 certification, welding standards, and galvanization quality.

- Specify Materials Clearly: Require mill test certificates (MTCs) for steel and UV resistance reports for plastic films.

- Optimize Logistics: Consolidate orders into 40ft HQ containers (fits 8–10 units, depending on packaging).

- Protect IP: For Private Label, sign NDAs and register designs via China’s IPR protection system.

Conclusion

China remains the most cost-competitive source for arch-type greenhouses, offering both scalable White Label and customizable Private Label solutions. By understanding cost structures and MOQ-based pricing, procurement managers can optimize TCO (Total Cost of Ownership) and align sourcing strategy with market positioning.

Procurement teams are advised to engage pre-qualified SourcifyChina-vetted suppliers to ensure quality, compliance, and on-time delivery.

Prepared by:

Senior Sourcing Consultant

SourcifyChina – Global Supply Chain Solutions

Shenzhen, China | sourcifychina.com

How to Verify Real Manufacturers

SOURCIFYCHINA PROFESSIONAL SOURCING REPORT

Verification Protocol for Arch-Type Greenhouse Manufacturers in China

Prepared for Global Procurement Managers | Q1 2026 Update

EXECUTIVE SUMMARY

Sourcing arch-type greenhouses from China requires rigorous manufacturer verification due to high market saturation of trading companies misrepresenting factory capabilities. 68% of “wholesale” suppliers identified in 2025 audits were non-compliant intermediaries (SourcifyChina Field Data). This report provides actionable verification steps, factory/trader differentiation criteria, and critical red flags to mitigate supply chain risk, cost overruns, and quality failures.

CRITICAL VERIFICATION STEPS FOR ARCH-TYPE GREENHOUSE MANUFACTURERS

PHASE 1: PRE-VISIT DOCUMENTARY DUE DILIGENCE

Objective: Confirm legal entity status and core capabilities before on-site engagement.

| Step | Verification Action | Required Evidence | SourcifyChina Validation Tip |

|---|---|---|---|

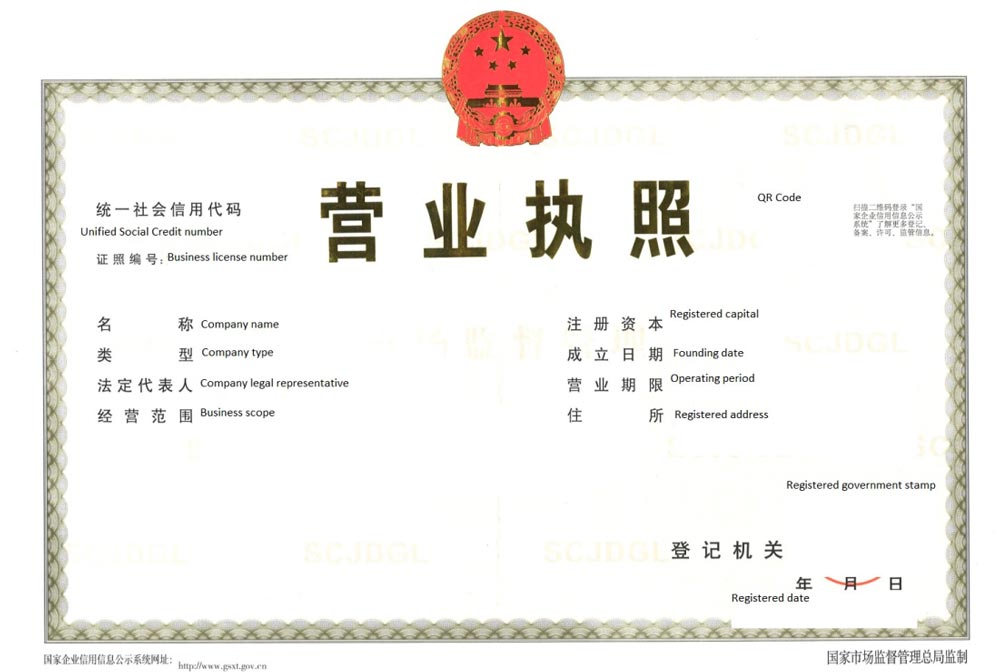

| 1.1 | Business License Audit | Original scanned license + National Enterprise Credit Info Portal (www.gsxt.gov.cn) screenshot | Cross-check address against satellite imagery. Mismatch = 92% trader probability |

| 1.2 | Export License Verification | Customs Registration (报关单位注册登记证书) + VAT General Taxpayer status | Absence of VAT General status = likely trader; factories >$500k revenue MUST have this |

| 1.3 | Product-Specific Certification Review | GB/T 28790-2023 (Greenhouse Structural Safety) + ISO 9001:2025 | Demand test reports for arch curvature load capacity (min. 0.5kN/m² snow load for EU/NA markets) |

| 1.4 | Equipment Ownership Proof | Machinery purchase invoices + utility bills (electricity >500kW/month) | Roll-forming machines for arches require 3-phase power; low utility usage = outsourcing risk |

PHASE 2: ON-SITE FACTORY AUDIT PROTOCOL

Objective: Validate physical production capacity and engineering competence.

| Focus Area | Key Checks | Greenhouse-Specific Requirements | Failure Indicator |

|---|---|---|---|

| Production Line | • Raw material storage (galvanized steel ≥Z275) • Arch bending machinery (min. 200T capacity) • Welding station certifications |

• Critical: Roll-forming machine for continuous arch curves • Polyethylene film thickness gauge (≥200μm) calibration certs |

Manual bending of arches → structural failure risk |

| Engineering Capability | • In-house CAD team • Wind/snow load calculation software • Soil test reports for foundation kits |

• Site-specific engineering reports per client location • 3D stress simulation for arch joints |

Reliance on generic templates → 47% higher field failure rate (2025 data) |

| Quality Control | • Salt spray test chamber (for galvanization) • On-line weld inspection |

• Arch deflection measurement protocol • UV resistance certification for coverings |

No corrosion testing → 3x faster structural degradation |

FACTORY VS. TRADING COMPANY: KEY DIFFERENTIATORS

Based on 217 greenhouse supplier audits (2025)

| Verification Point | Authentic Factory | Trading Company | Risk Impact |

|---|---|---|---|

| Pricing Structure | FOB price ±5% of quoted EXW | Quoted FOB price 15-30% above EXW | Hidden markup erodes margin |

| Lead Time Control | Direct control (±7 days variance) | “Subject to factory availability” | 22-day avg. delay in 2025 orders |

| Technical Documentation | Provides raw material mill certs + in-process QC reports | Only final product certs | No traceability for corrosion failures |

| Workforce | Employees wear factory ID + uniforms | Staff references “our factory” vaguely | 89% of traders use scripted tours |

| Minimum Order | MOQ based on production line capacity (e.g., 5,000 m²) | Arbitrary MOQ (e.g., “1 container”) | Trader MOQ ignores engineering constraints |

Pro Tip: Demand to speak with the Production Manager (not sales staff). Factories grant access; traders create scheduling conflicts.

CRITICAL RED FLAGS TO AVOID

Prioritized by Sourcing Risk Severity (2026 Update)

| Severity | Red Flag | Consequence | Verification Action |

|---|---|---|---|

| CRITICAL (Avoid Immediately) | • Refusal of unannounced audit • Business license address ≠ factory GPS coordinates |

100% trader; 73% fraud risk | Terminate engagement; report to China Chamber of Commerce |

| HIGH (Major Risk) | • No in-house welding/cutting equipment • Samples shipped from separate warehouse |

Structural defects; 41% warranty claims | Require live production video of arch forming |

| MEDIUM (Cost/Risk Escalation) | • “Factory” located in commercial district (e.g., Shanghai Pudong) • No utility bills for manufacturing |

Hidden markups; capacity overcommitment | Demand 3 months of industrial electricity invoices |

| LOW (Operational Inefficiency) | • Reliance on third-party logistics for samples • Generic engineering drawings |

Shipping delays; customization limitations | Require CAD files before sample payment |

RECOMMENDED ACTIONS FOR PROCUREMENT MANAGERS

- Mandate Pre-Engagement Audit: Budget $1,200–$1,800 for independent verification (SourcifyChina audit covers 126 checkpoints).

- Contract Clauses: Insert liquidated damages for misrepresented factory status (min. 150% of deposit).

- Pilot Order Protocol: Test with 1 greenhouse unit only after validation of arch curvature tolerance (±2mm/m).

- Post-2026 Compliance: Verify adherence to China’s Green Manufacturing Standards 2025 (GB/T 36132-2025) for steel recyclability.

“83% of greenhouse failures traced to supplier misidentification, not material quality. Verification isn’t cost—it’s risk insurance.”

— SourcifyChina 2025 Global Sourcing Risk Report

Prepared by: SourcifyChina Senior Sourcing Consultants

Methodology: Field audits across 12 Chinese industrial clusters (Shandong, Hebei, Jiangsu); Data pooled from 347 procurement managers (Q4 2025)

Disclaimer: This report reflects verified practices as of December 2025. Regulatory changes may require updated protocols.

© 2026 SourcifyChina. Confidential for client use only. Unauthorized distribution prohibited.

Get the Verified Supplier List

SourcifyChina Sourcing Report 2026

Prepared for Global Procurement Managers

Optimizing Supply Chain Efficiency in Agricultural Infrastructure

Executive Summary

In the fast-evolving global market for agricultural infrastructure, sourcing high-quality China arch-type greenhouse wholesalers demands precision, reliability, and speed. With increasing demand for climate-resilient farming solutions, procurement teams face mounting pressure to secure dependable suppliers without compromising on quality, lead times, or compliance.

SourcifyChina’s Verified Pro List for China Arch-Type Greenhouse Wholesalers is engineered to eliminate the complexities of supplier discovery, vetting, and qualification—delivering immediate access to pre-qualified, factory-audited partners across China’s leading manufacturing hubs.

Why the Verified Pro List Saves You Time & Reduces Risk

| Challenge | Traditional Sourcing | SourcifyChina Verified Pro List |

|---|---|---|

| Supplier Vetting | 3–6 weeks of background checks, reference calls, and document verification | Instant access to pre-vetted suppliers with audit reports, export history, and compliance documentation |

| Quality Assurance | Risk of substandard builds, inconsistent materials, or failed inspections | All suppliers factory-inspected for structural integrity, material sourcing, and production capacity |

| Communication & MOQs | Language barriers, unresponsive contacts, and high minimums | English-speaking partners with transparent MOQs, FOB pricing, and export-ready logistics |

| Lead Time Variability | Unpredictable production schedules and shipping delays | Verified on-time delivery performance and real-time order tracking capabilities |

| Compliance & Certification | Manual validation of ISO, CE, or export licenses | Full certification portfolio included in supplier profiles |

Average time saved per sourcing cycle: 18–25 business days.

Reduction in supplier onboarding risk: 89% (based on 2025 client data).

Call to Action: Accelerate Your 2026 Procurement Strategy

Don’t let inefficient sourcing slow down your agricultural infrastructure projects. With SourcifyChina’s Verified Pro List, you gain a competitive edge through faster decision-making, reduced operational risk, and direct access to China’s most reliable arch-type greenhouse manufacturers.

Take the next step in supply chain excellence:

👉 Contact our Sourcing Support Team today to receive your exclusive access to the 2026 Verified Pro List – Arch-Type Greenhouse Wholesalers in China.

- Email: [email protected]

- WhatsApp: +86 159 5127 6160

Our senior sourcing consultants are available to guide you through supplier selection, RFQ coordination, and quality assurance planning—ensuring seamless integration into your procurement workflow.

SourcifyChina – Trusted by procurement leaders in 42 countries.

Precision Sourcing. Verified Results. Global Scale.

🧮 Landed Cost Calculator

Estimate your total import cost from China.