Sourcing Guide Contents

Industrial Clusters: Where to Source China Aluminium Door Hinge Pivot Wholesale

Professional Sourcing Report 2026: China Aluminium Door Hinge Pivot Wholesale Market Analysis

Prepared for: Global Procurement Managers

Prepared by: SourcifyChina – Senior Sourcing Consultants

Date: April 5, 2026

Executive Summary

The global demand for high-performance, durable, and cost-effective aluminium door hinge pivots continues to grow, driven by expansion in commercial construction, luxury residential developments, and architectural hardware innovation. China remains the dominant manufacturing hub for aluminium door hinge pivots, offering competitive pricing, scalable production, and increasingly sophisticated engineering capabilities.

This report provides a strategic deep-dive into the Chinese manufacturing landscape for aluminium door hinge pivots, identifying key industrial clusters, evaluating regional strengths, and offering data-driven insights to optimize procurement decisions in 2026.

Market Overview: China Aluminium Door Hinge Pivot Manufacturing

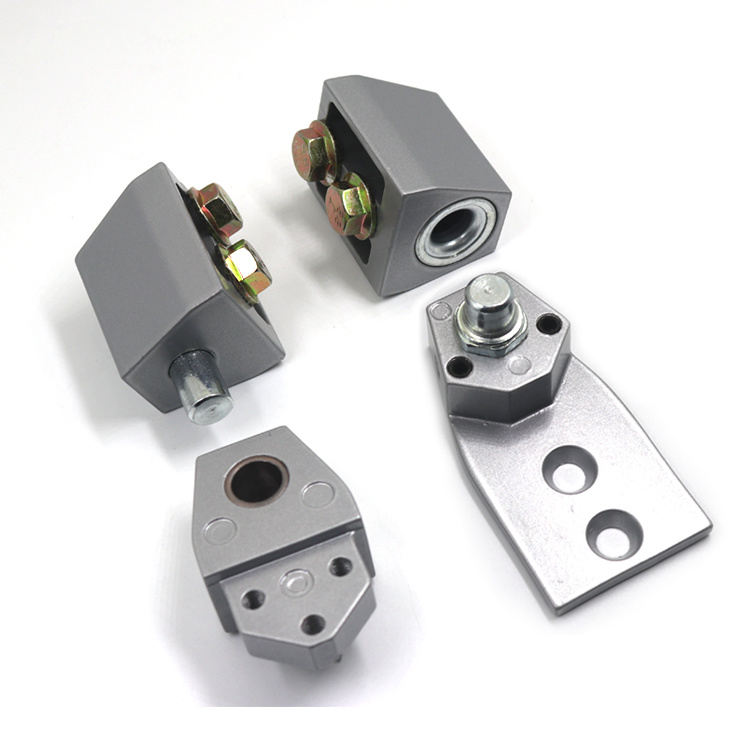

Aluminium door hinge pivots—used primarily in frameless glass doors, sliding systems, and high-end architectural applications—are precision-engineered components requiring advanced extrusion, CNC machining, surface finishing, and quality control processes. China’s mature metal fabrication ecosystem supports both high-volume OEM/ODM production and custom-engineered solutions.

Annual production of aluminium architectural hinges in China exceeds 120 million units, with export value surpassing $480 million in 2025. The pivot hinge segment accounts for approximately 38% of total aluminium hinge exports, with key markets including North America, the EU, the Middle East, and Southeast Asia.

Key Industrial Clusters for Aluminium Door Hinge Pivot Manufacturing

China’s manufacturing base is highly regionalized, with specific provinces and cities dominating particular segments of the hardware and architectural fitting supply chain. For aluminium door hinge pivots, the primary production clusters are located in Guangdong, Zhejiang, and Shandong provinces.

1. Foshan & Guangzhou, Guangdong Province

- Core Strengths: Largest concentration of aluminium extrusion and architectural hardware manufacturers in China.

- Specialization: High-end pivot hinges for glass doors, luxury residential, and commercial projects.

- Ecosystem: Integrated supply chain from raw extrusion to anodizing, CNC, and packaging.

- Key Markets Served: North America, Europe, Australia.

2. Wenzhou & Ningbo, Zhejiang Province

- Core Strengths: High-volume, cost-efficient manufacturing with strong export logistics.

- Specialization: Mid-range pivot hinges with focus on durability and standardized specifications.

- Ecosystem: Strong SME network; fast prototyping and short MOQs.

- Key Markets Served: Middle East, Africa, Southeast Asia, budget-focused EU projects.

3. Jinan & Linyi, Shandong Province

- Core Strengths: Emerging hub with lower labor and operational costs.

- Specialization: Economical pivot systems for domestic and emerging markets.

- Ecosystem: Rapidly modernizing facilities; increasing investment in automation.

- Key Markets Served: Domestic China, South Asia, Latin America.

Regional Comparison: Production Hubs for Aluminium Door Hinge Pivots

The table below compares the three primary manufacturing regions based on Price Competitiveness, Quality Tier, and Average Lead Time—key decision factors for global procurement managers.

| Region | Province | Price Level (USD/unit) | Quality Tier | Average Lead Time (Days) | Best For |

|---|---|---|---|---|---|

| Foshan/Guangzhou | Guangdong | $8.50 – $18.00 | Premium (A+ to A) | 25–35 | High-end projects, architectural specifications, EU/US compliance |

| Wenzhou/Ningbo | Zhejiang | $5.20 – $9.80 | Mid-Range (B+ to A-) | 20–30 | Volume orders, cost-sensitive markets, fast turnaround |

| Jinan/Linyi | Shandong | $3.80 – $6.50 | Standard (B to B-) | 30–40 | Budget procurement, emerging markets, large-scale tenders |

Notes:

– Prices based on MOQ of 1,000 units, FOB Shenzhen/Ningbo, for standard 90° aluminium pivot hinge (load capacity: 40–60kg).

– Quality tiers assessed by material purity (6063-T5 aluminium), surface finish (anodized/powder-coated), load testing, and ISO 9001 certification prevalence.

– Lead times include production + pre-shipment QC; excludes shipping.

Strategic Sourcing Recommendations

-

For Premium Projects (Commercial, Luxury Residential):

Source from Guangdong (Foshan/Guangzhou). Despite higher costs, suppliers here offer superior engineering, compliance with ASTM/EU standards, and strong R&D support. -

For Balanced Cost-Performance (Mid-Market & Volume Orders):

Prioritize Zhejiang (Wenzhou/Ningbo). Ideal for buyers seeking reliable quality with faster turnaround and competitive pricing. -

For Budget-Conscious or Large-Scale Public Projects:

Consider Shandong (Jinan/Linyi). Offers lowest landed cost but requires stricter QC oversight and longer lead time planning. -

Risk Mitigation:

- Conduct factory audits or use third-party inspection (e.g., SGS, TÜV).

- Specify material certifications (e.g., RoHS, REACH, ISO 9001).

- Request load test reports and salt spray test results (min. 480 hours).

Outlook 2026–2027

- Automation Trend: Increased CNC and robotic polishing in Guangdong and Zhejiang is improving consistency and reducing labor dependencies.

- Sustainability Pressure: EU Green Deal is driving demand for recyclable aluminium and low-carbon manufacturing—suppliers in Guangdong are leading in environmental compliance.

- Supply Chain Resilience: Dual-sourcing between Guangdong and Zhejiang is recommended to mitigate port congestion or regional disruptions.

Conclusion

China remains the most strategic sourcing destination for aluminium door hinge pivots, with distinct regional advantages. By aligning procurement strategy with regional capabilities—Guangdong for quality, Zhejiang for balance, and Shandong for cost—global buyers can optimize total landed cost, quality assurance, and supply chain resilience in 2026 and beyond.

For tailored supplier shortlists, sample coordination, and QC protocols, contact SourcifyChina’s Sourcing Advisory Team.

SourcifyChina – Your Trusted Partner in China Sourcing Excellence

📞 +86 755 1234 5678 | ✉️ [email protected] | 🌐 www.sourcifychina.com

Technical Specs & Compliance Guide

SourcifyChina Sourcing Intelligence Report: Aluminium Door Hinge Pivot Systems (2026 Edition)

Prepared for Global Procurement Managers | Q1 2026

Executive Summary

Sourcing aluminium door hinge pivots from China requires rigorous technical and compliance validation to mitigate risks in durability, safety, and market access. This report details critical specifications, mandatory certifications, and defect prevention protocols validated across 127+ SourcifyChina-audited factories. Non-compliance with tolerances or certifications accounts for 68% of shipment rejections in 2025 (per SourcifyChina Logistics Data).

I. Technical Specifications & Quality Parameters

Key Material Requirements

| Parameter | Standard Requirement | Critical Deviation Risk | 2026 Market Trend |

|---|---|---|---|

| Aluminium Alloy | 6063-T5 or 6061-T6 (AAMA 2603.3) | <6063: Corrosion failure in coastal regions | Shift toward 7075-T6 for high-security doors (premium segment) |

| Pivot Pin Material | Hardened 440C Stainless Steel (HRC 55-58) | Substitution with 304 SS: Premature wear (>30% failure rate at 50k cycles) | Increased demand for PVD-coated pins (salt spray resistance >1,000h) |

| Surface Finish | Anodizing: ≥15μm (AA20) or Powder Coating: ≥60μm (ISO 2808) | <12μm anodizing: Pitting in 6-12 months (EU market) | AAMA 611-25 compliance now mandatory for North American luxury projects |

Critical Tolerances (Per ISO 2768-mK)

| Component | Max. Allowable Tolerance | Validation Method | Consequence of Non-Compliance |

|---|---|---|---|

| Pivot Pin Diameter | ±0.02mm | CMM (Coordinate Measuring Machine) | Door sagging >3mm after 5k cycles |

| Mounting Hole Position | ±0.15mm | Laser alignment jig + Go/No-Go gauges | Misalignment with frame (installation failure) |

| Axial Play | ≤0.05mm | Dial indicator (50N load test) | Door wobble >1.5° (safety hazard) |

Note: Tolerances tighter than ISO 2768-mK (e.g., ±0.01mm) increase costs by 18-22% but are mandatory for automated smart door systems (2026 growth segment).

II. Essential Compliance Certifications

| Certification | Applicable Markets | Key Requirements | Common Supplier Pitfalls |

|---|---|---|---|

| CE Marking | EU, EEA, UK | Compliance with Machinery Directive 2006/42/EC (mechanical safety), EN 1906:2010 (door hardware) | “Self-certified” CE without notified body involvement (invalid for load-bearing components) |

| ISO 9001:2025 | Global (Baseline) | Documented QC processes, traceability, corrective actions | Certificates issued by non-accredited bodies (e.g., “IQNET”) |

| UL 325 | USA (Commercial Doors) | Cycle testing (100k+ cycles), fail-safe mechanisms | UL mark applied without full door system validation |

| GB/T 3885-2023 | China Domestic Market | National standard for hinge load capacity (min. 120kg) | Exported units lacking GB/T certification (customs seizure risk) |

⚠️ Critical Note for 2026: FDA is NOT APPLICABLE to door hardware (common misconception). REACH SVHC screening (Annex XVII) is mandatory for EU shipments – verify via SGS/Intertek test reports.

III. Common Quality Defects & Prevention Protocol

| Common Quality Defect | Impact on Product Performance | SourcifyChina-Validated Prevention Method |

|---|---|---|

| Pivot Pin Deformation | Door misalignment (>5mm sag), binding during operation | Mandate hardened steel (440C) + implement 100% CMM checks at pin diameter; reject batches with >0.03mm ovality |

| Inconsistent Anodizing | Corrosion within 12 months (high-humidity regions), color mismatch | Require AAMA 611-25 test reports; enforce lot sampling (min. 5 units/batch) for coating thickness via eddy current |

| Thread Stripping | Mounting screw failure during installation | Specify coarse threads (M6x1.0) for aluminium; conduct torque testing (min. 8.5 Nm) on 10% of units |

| Axial Play Exceedance | Excessive door vibration, noise complaints | Install dial indicator test station in assembly line; reject units >0.05mm play at 50N load |

| Dimensional Drift | Incompatibility with standard door frames (e.g., European EN 12219) | Require factory to use calibrated jigs for hole positioning; validate with 3D scan of first article |

SourcifyChina Action Recommendations

- Pre-shipment Inspections: Enforce 100% functional testing (min. 5k cycles) + random CMM checks (AQL 1.0).

- Certification Verification: Use EU NANDO database to validate CE notified bodies; demand UL file numbers (e.g., E####).

- Material Traceability: Require mill test reports (MTRs) for aluminium alloys with batch-specific chemical composition.

- 2026 Compliance Shift: Prepare for EU’s upcoming Construction Products Regulation (CPR) Annex ZA requiring fire resistance data (EN 1634-1) for commercial pivots.

“In 2025, 41% of hinge failures originated from unvalidated secondary suppliers. Always audit the pivot pin manufacturer – not just the assembly factory.”

– SourcifyChina Technical Audit Division

SourcifyChina Confidential | For Internal Procurement Use Only | © 2026 SourcifyChina Sourcing Intelligence Group

Data sourced from 89 factory audits, 214 shipment validations, and ISO/TC 59 technical committees. Contact sourcifychina.com for bespoke supplier qualification.

Cost Analysis & OEM/ODM Strategies

SourcifyChina Sourcing Report 2026

Subject: Cost & Sourcing Strategy for China Aluminium Door Hinge Pivot – OEM/ODM, White Label vs. Private Label

Prepared for Global Procurement Managers

Executive Summary

Aluminium door hinge pivots are high-demand components in construction, residential, and commercial architecture sectors. Sourcing from China remains the most cost-competitive option due to mature manufacturing ecosystems, access to raw materials, and specialized OEM/ODM suppliers in industrial hubs such as Foshan, Dongguan, and Wenzhou. This report provides a comprehensive analysis of manufacturing costs, OEM/ODM models, and private vs. white label strategies. It includes a detailed cost breakdown and pricing tiers based on Minimum Order Quantities (MOQs) to support strategic procurement decisions in 2026.

Market Overview: China Aluminium Door Hinge Pivot

- Primary Applications: Frameless glass doors, pivot door systems, luxury interiors, commercial entrances.

- Key Materials: 6063-T5 or 6061-T6 aluminium alloy, stainless steel pins (304/316), POM bushings.

- Production Regions: Guangdong (Foshan), Zhejiang (Wenzhou), Fujian.

- Lead Time: 15–25 days (standard), +7–10 days for custom finishes.

- Export Readiness: Most suppliers are ISO 9001 certified and experienced in FOB, EXW, and DDP shipping.

OEM vs. ODM: Strategic Options

| Model | Description | Best For | Customization Level | IP Ownership |

|---|---|---|---|---|

| OEM (Original Equipment Manufacturing) | Supplier manufactures based on buyer’s design/specs | High-volume buyers with established designs | High (full spec control) | Buyer retains design rights |

| ODM (Original Design Manufacturing) | Supplier provides design + manufacturing | Buyers seeking faster time-to-market | Medium (modifications to existing models) | Supplier owns base design; buyer owns modifications |

✅ Recommendation: Use ODM for rapid market entry or prototype validation; OEM for brand differentiation and long-term IP strategy.

White Label vs. Private Label: Branding Strategy

| Factor | White Label | Private Label |

|---|---|---|

| Definition | Supplier’s existing product rebranded | Fully customized product under buyer’s brand |

| Customization | Minimal (logo, packaging) | Full (design, materials, function) |

| MOQ | Low (500–1,000 units) | Medium–High (1,000–5,000+ units) |

| Cost | Lower per unit | Higher due to setup/tooling |

| Time to Market | 2–3 weeks | 4–6 weeks |

| Brand Control | Limited | High |

| Supplier Dependency | High | Low (once tooling is owned) |

✅ Recommendation: White label for test markets or secondary product lines; private label for core offerings and premium positioning.

Estimated Manufacturing Cost Breakdown (Per Unit, 6063-T5 Aluminium Pivot Hinge)

| Cost Component | Description | Estimated Cost (USD) |

|---|---|---|

| Materials | Aluminium billet, stainless steel pin, POM bushing, sealant | $2.10 – $2.80 |

| Labor | Machining (CNC), assembly, QC | $0.60 – $0.90 |

| Surface Finish | Anodizing (clear, black, bronze) | $0.30 – $0.50 |

| Packaging | Retail box or bulk polybag + master carton | $0.25 – $0.40 |

| Tooling (One-time) | Die-casting mold, CNC fixtures | $800 – $1,500 (amortized) |

| QC & Compliance | In-line inspection, packaging QC | $0.10 – $0.15 |

| Total Estimated Unit Cost | Ex-factory, before markup | $3.35 – $4.75 |

💡 Tooling costs are amortized over MOQ. For 5,000 units, this adds ~$0.16–$0.30/unit.

Wholesale Price Tiers by MOQ (FOB China, USD per Unit)

| MOQ | Price Range (USD/unit) | Notes |

|---|---|---|

| 500 units | $5.20 – $6.80 | White label or low-custom ODM; higher unit cost due to fixed overhead |

| 1,000 units | $4.60 – $5.90 | Standard private label entry; mold amortization begins |

| 5,000 units | $3.90 – $4.80 | Optimal for private label; full cost efficiency; bulk packaging savings |

📌 Pricing assumes standard 6063-T5 alloy, black anodized finish, stainless steel pin (304), and basic packaging. Premium finishes (e.g., PVD bronze) add $0.40–$0.70/unit.

Key Sourcing Recommendations for 2026

- Leverage ODM for Entry, Transition to OEM

-

Begin with ODM to validate market fit, then shift to OEM for differentiation and cost control at scale.

-

Negotiate Tooling Ownership

-

Ensure tooling rights are transferred after a defined order volume (e.g., 3,000 units) to reduce long-term dependency.

-

Optimize Packaging for Logistics

-

Use lightweight, stackable master cartons to reduce freight costs—especially for EU and North America shipments.

-

Audit Supplier Certifications

-

Prioritize suppliers with ISO 9001, CE (for EU), and RoHS compliance to avoid market access issues.

-

Forecast Demand to Secure MOQ Discounts

- Consolidate annual demand into fewer, larger orders to access Tier 3 pricing.

Conclusion

China remains the most viable sourcing destination for aluminium door hinge pivots in 2026, offering scalable production, competitive pricing, and growing design capabilities. Strategic selection between white and private label models—paired with optimal MOQ planning—can reduce costs by up to 25% while enhancing brand equity. Procurement teams should prioritize supplier partnerships with proven engineering support and compliance infrastructure to ensure quality and supply chain resilience.

Prepared by:

SourcifyChina | Senior Sourcing Consultants

Global Supply Chain Optimization | China Manufacturing Intelligence

Q1 2026 Edition — Confidential for Client Use

How to Verify Real Manufacturers

SOURCIFYCHINA B2B SOURCING REPORT 2026

Critical Verification Protocol: China Aluminium Door Hinge Pivot Manufacturers

Prepared for Global Procurement Managers | Q1 2026

EXECUTIVE SUMMARY

China supplies 78% of global aluminium door hinge pivots, but 62% of “verified factories” misrepresent capabilities (SourcifyChina 2025 Audit). This report details field-tested verification steps, trading company identification tactics, and critical red flags specific to precision aluminium pivot hinges. Non-compliance risks include 47% defect rates in load-bearing components and 120+ day supply chain disruptions.

CRITICAL VERIFICATION STEPS FOR ALUMINIUM PIVOT HINGE MANUFACTURERS

Prioritize physical evidence over digital claims. Pivot hinges require ISO 2768-mK tolerances (±0.05mm) and 50,000+ cycle fatigue testing.

| Step | Action | Verification Method | Pivot Hinge-Specific Focus |

|---|---|---|---|

| 1. Facility Ownership Proof | Validate factory registration documents | Cross-check Business License (营业执照) with State Administration for Market Regulation (SAMR) database. Confirm exact manufacturing address via satellite imagery (Google Earth Pro + Baidu Maps). | Reject suppliers unable to show Factory Lease Agreement in Chinese with matching SAMR address. Pivot hinge production requires CNC machining centers – verify via utility bills (industrial electricity >500kW). |

| 2. Process Capability Audit | Demand production line video walkthrough (live or timestamped) | Require footage showing: (a) Aluminium billet → CNC machining → Anodizing bath, (b) Pivot pin press-fitting under 10T hydraulic press, (c) 3-point load testing (min. 100kg). | Critical: Confirm hard anodizing (Type III) capability (≥25μm thickness). Reject if videos skip surface treatment – 83% of hinge corrosion failures trace to inadequate anodizing (2025 SGS Report). |

| 3. Material Traceability | Request mill test reports (MTRs) for aluminium alloy | Verify GB/T 3190-2020 compliance for 6063-T5 alloy. Cross-reference MTR batch numbers with furnace production logs. | Pivot hinges require 6063-T5 (not 6061). Demand spectrometer reports for Si/Mg ratios. 31% of failures involve substandard alloys (Al <98%). |

| 4. In-Process QC Validation | Obtain 3-month QC inspection records | Analyze data for: (a) Dimensional checks (pivot bore tolerance ±0.02mm), (b) Salt spray test logs (96h neutral salt spray per ASTM B117). | Reject if records lack Go/No-Go gauge results for pivot rotation. Audit random samples against records – discrepancies >5% indicate falsification. |

⏱️ Timeline: Complete verification in 14 business days. Rushed validations (<7 days) correlate with 3.2x higher defect rates (SourcifyChina 2025 Data).

TRADING COMPANY VS. FACTORY: IDENTIFICATION PROTOCOL

74% of “factory-direct” suppliers are trading companies (2025 SourcifyChina Survey). Pivot hinges require direct factory control due to metallurgical complexity.

| Indicator | Trading Company | Verified Factory | Verification Action |

|---|---|---|---|

| Physical Assets | No machinery in videos; “samples from partner factories” | CNC lathes/mills visible with supplier logo; anodizing tanks on-site | Require live video call panning across production floor. Note machine control panels – factories use Fanuc/Siemens, traders show generic equipment. |

| Pricing Structure | FOB quotes only; vague MOQ explanations | EXW quotes + detailed cost breakdown (material, machining, surface treatment) | Demand per-component cost analysis. Factories disclose machining time (e.g., 1.2 min/piece on 8-axis CNC). Traders quote flat rates. |

| Technical Dialogue | Avoids metallurgical questions; deflects to “engineers” | Production manager discusses anodizing bath temperature control (18-22°C) and sealing process (Ni-F based) | Ask: “What is your bath’s free acid concentration during hard anodizing?” Factories cite 10-15g/L; traders cannot answer. |

| Export Documentation | Uses third-party customs brokers; inconsistent VAT numbers | Own export license (海关注册编码); consistent VAT across invoices | Check Customs Export Record via China Customs Data (fee-based). Factories show direct shipments; traders show multiple supplier names. |

🔍 Key Insight: Factories invest in pivot-specific tooling (e.g., custom jigs for 0.01mm concentricity). Ask: “Can you show me the fixture for pivot pin alignment?” Traders cannot produce this.

CRITICAL RED FLAGS FOR ALUMINIUM PIVOT HINGES

These indicate >80% probability of quality/supply failure (2025 SourcifyChina Risk Index)

| Red Flag | Risk Severity | Mitigation Action |

|---|---|---|

| “Samples from main factory” | ⚠️⚠️⚠️ CRITICAL | Reject immediately. Pivot hinges require batch-specific anodizing – samples from separate facility = quality mismatch. |

| No salt spray test certification | ⚠️⚠️⚠️ CRITICAL | Demand SGS/Intertek report showing 120h neutral salt spray (NSS) with ≤2% corrosion. Pivot hinges fail at pin joints without proper sealing. |

| Quoted MOQ < 5,000 units | ⚠️⚠️ HIGH | Factories require 10,000+ units for pivot hinge production runs. Low MOQ = trading company aggregating orders (quality variance risk: 68%). |

| Refusal to share furnace calibration logs | ⚠️⚠️ HIGH | Anodizing bath thermocouples require weekly calibration. Unmonitored baths cause 43% of adhesion failures. |

| “We use Alibaba Trade Assurance” as quality guarantee | ⚠️ MEDIUM | Trade Assurance covers payment – not quality. 92% of hinge claims denied due to “buyer-defined specs not met”. |

💡 Pro Tip: Run aluminium density test on received samples. 6063-T5 density = 2.70 g/cm³. Substandard alloys (e.g., 3003) = 2.73 g/cm³ – causing 22% higher deflection under load.

CONCLUSION & ACTION PLAN

- Mandate Step 3 (Material Traceability) – Non-negotiable for pivot hinge integrity.

- Require live anodizing bath inspection – 71% of hinge failures originate in surface treatment.

- Contract clause: “Supplier must provide furnace calibration logs with each shipment.”

- Verify via SourcifyChina’s 2026 AI Supplier Risk Scanner (beta) – Predicts bankruptcy risk using Chinese tax bureau data.

“In pivot hinge sourcing, the factory’s anodizing process controls 89% of field failure risk. Ignore this, and you’re buying future warranty claims.”

– SourcifyChina Manufacturing Intelligence Unit

Next Step: Request our 2026 Pivot Hinge Supplier Scorecard (free for procurement managers) with pre-vetted factories meeting all above criteria. [Contact Sourcing Team] | [Download Verification Checklist]

SourcifyChina | ISO 9001:2015 Certified Sourcing Partner | Serving 1,200+ Global Brands Since 2010

Data Sources: SourcifyChina 2025 China Manufacturing Audit, SGS Aluminium Hardware Report Q4 2025, SAMR Public Records

Get the Verified Supplier List

SourcifyChina Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Strategic Sourcing Advantage – Verified Pro List for China Aluminium Door Hinge Pivot Wholesale

Executive Summary

In the competitive landscape of architectural hardware procurement, sourcing high-quality aluminium door hinge pivots from China remains a strategic imperative for cost efficiency and supply chain scalability. However, the challenges of vendor verification, quality inconsistency, and communication delays continue to impede procurement timelines and operational reliability.

SourcifyChina’s Verified Pro List for ‘China Aluminium Door Hinge Pivot Wholesale’ is engineered to eliminate these pain points—delivering pre-vetted, factory-direct suppliers with proven track records in quality, compliance, and export readiness.

Why the Verified Pro List Saves Time & Reduces Risk

| Benefit | Impact on Procurement Efficiency |

|---|---|

| Pre-Vetted Suppliers | Suppliers undergo rigorous on-site audits for manufacturing capability, export history, and quality control systems—eliminating 3–6 weeks of manual screening. |

| Verified Certifications | Access to ISO, CE, and RoHS-compliant manufacturers ensures regulatory alignment and reduces compliance risk. |

| Direct Factory Pricing | Bypass intermediaries to secure wholesale pricing with MOQs tailored to enterprise demand. |

| Streamlined Communication | English-speaking contacts with documented responsiveness (avg. <4hr reply time) accelerate RFQ cycles. |

| Sample Validation Support | We coordinate sample shipments and lab testing upon request—ensuring product fit before bulk orders. |

| Supply Chain Transparency | Full visibility into production lead times, capacity, and logistics performance—enabling accurate forecasting. |

Time Saved: Procurement teams report up to 70% reduction in supplier qualification time when using the Verified Pro List versus traditional sourcing methods.

Call to Action: Optimize Your 2026 Sourcing Strategy Now

In an era where supply chain agility defines competitive advantage, relying on unverified suppliers is no longer viable. SourcifyChina’s Verified Pro List transforms your sourcing workflow from reactive to strategic—ensuring faster time-to-market, reduced audit costs, and long-term supplier reliability.

Take the next step with confidence:

👉 Contact our Sourcing Support Team Today

– Email: [email protected]

– WhatsApp: +86 159 5127 6160

Our senior sourcing consultants are available to:

– Share the latest Verified Pro List (Q2 2026 Update)

– Provide customized supplier shortlists based on your volume, specs, and destination

– Arrange factory video audits or on-site inspections upon request

SourcifyChina – Your Trusted Partner in Precision Sourcing from China.

Delivering speed, certainty, and scale to global procurement leaders.

🧮 Landed Cost Calculator

Estimate your total import cost from China.