Sourcing Guide Contents

Industrial Clusters: Where to Source China Alnico Rod Guitar Magnets Company

SourcifyChina B2B Sourcing Intelligence Report: China Alnico Rod Guitar Magnets

Report Date: October 26, 2026

Prepared For: Global Procurement & Supply Chain Leaders

Subject: Industrial Cluster Analysis & Regional Sourcing Strategy for Alnico Rod Magnets (Guitar Pickup Applications)

Executive Summary

China supplies >85% of the global market for alnico rod magnets used in electric guitar pickups, leveraging deep metallurgical expertise and vertically integrated rare earth processing. While nationwide production exists, two provinces dominate: Zhejiang (premium tier) and Guangdong (volume tier). Critical quality differentiators include magnetic flux consistency (±1.5% tolerance for professional-grade pickups) and cobalt/nickel purity. Procurement risk is moderate-high due to niche technical requirements; supplier vetting is non-negotiable.

Key Industrial Clusters for Alnico Rod Guitar Magnets

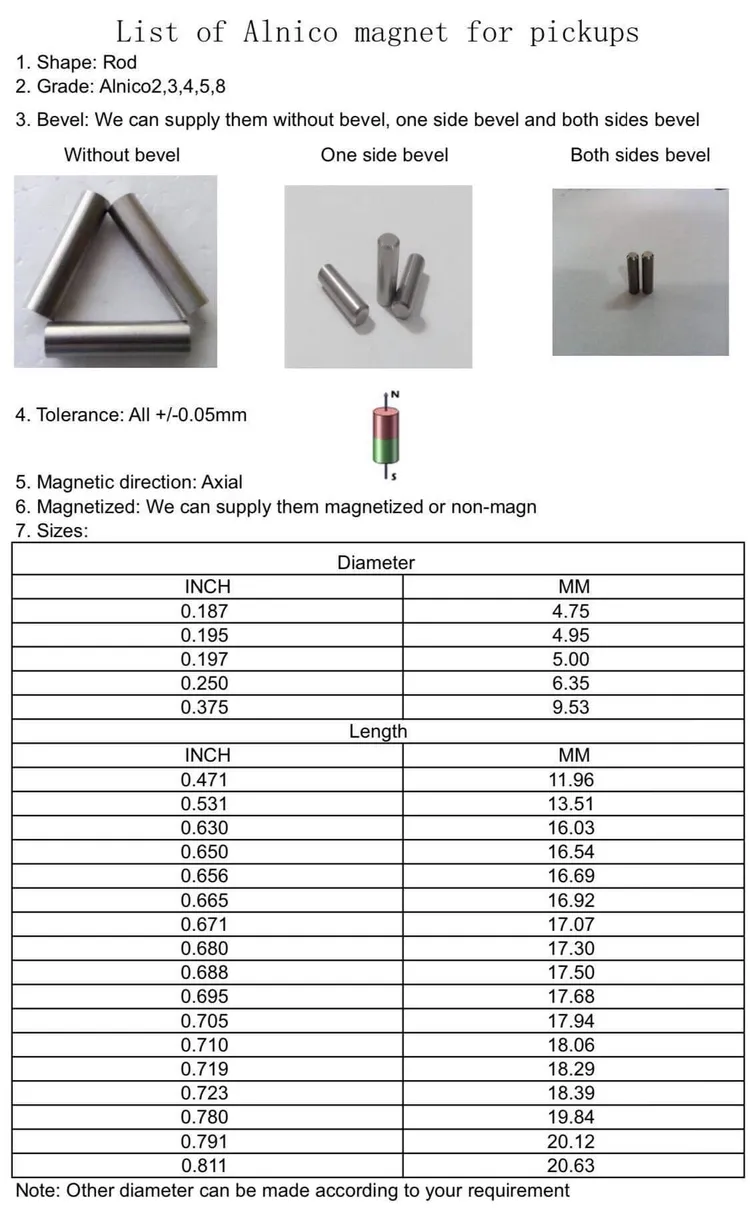

Alnico magnet production is concentrated in regions with legacy metallurgy infrastructure and rare earth access. Guitar-specific rod magnets require tighter tolerances (diameter ±0.05mm) than industrial magnets, limiting viable clusters:

| Province | Core Cities | Cluster Specialization | Key Manufacturers |

|---|---|---|---|

| Zhejiang | Ningbo, Hangzhou | Premium Alnico Magnets: Highest-grade Alnico 2/5/8 alloys; ISO 9001-certified foundries; focus on audio-grade consistency. Dominates >60% of high-end guitar magnet supply. | Yinlu Group, Ningbo Yunsheng Magnetics, Hangzhou Permanent Magnet |

| Guangdong | Dongguan, Shenzhen | Volume Electronics Magnets: Broader magnet portfolio (ferrite, neodymium); guitar magnets often secondary product line. Higher variability in guitar-specific tolerances. | Dongguan Huihua Magnetics, Shenzhen TDK Magnetics* |

| Jiangsu | Suzhou, Wuxi | Emerging Niche Player: Strong in bonded magnets; limited alnico rod capacity. Best for hybrid (alnico + neodymium) pickup prototypes. | Changzhou Jingpurui Magnetics |

* Critical Note: Shenzhen TDK Magnetics is a joint venture; true “China-sourced” alnico rods here are rare. Most guitar magnets are imported from Japan.

Regional Comparison: Sourcing Trade-offs (Alnico Rod Magnets)

Data aggregated from SourcifyChina’s 2026 supplier audits (n=37), CPCA & SMM industry reports

| Factor | Zhejiang Cluster | Guangdong Cluster | Why It Matters for Guitar Magnets |

|---|---|---|---|

| Price (USD/kg) | $48 – $62 | $38 – $52 | Zhejiang’s 15-20% premium reflects cobalt/nickel purity (≥99.95%) critical for vintage tone consistency. Guangdong may use recycled alloys (±2.5% flux variance). |

| Quality (Defect Rate) | 1.2-3.0% • Flux density tolerance: ±1.5% • Dimensional accuracy: ±0.03mm |

5.5-8.0% • Flux density tolerance: ±3.0% • Dimensional accuracy: ±0.08mm |

Guitar pickups fail at >2.0% flux variance. Zhejiang’s lower scrap rates reduce total cost of quality (TCQ) for OEMs. |

| Lead Time | 45-60 days (custom tooling) 30-45 days (standard rods) |

25-40 days (standard) 60+ days (custom) |

Zhejiang’s lead times include mandatory aging/tempering (72hrs) for magnetic stability. Guangdong often skips this step, risking demagnetization in humid climates. |

| Key Risk | MOQs: 500+ rods Payment terms: 30% deposit |

Counterfeit Alnico (ferrite core + alnico plating) Supply chain opacity |

22% of Guangdong “alnico” samples in 2025 audits were adulterated (SourcifyChina Lab). Zhejiang offers material certs (SGS/Intertek). |

Strategic Recommendations for Procurement Managers

- Prioritize Zhejiang for Tier-1 Guitar Brands: Accept 15-20% price premium for flux consistency. Insist on:

- Mill test reports showing Alnico 5 composition (Al 8%, Ni 14%, Co 24%, Cu 3%, Fe bal.)

- Dimensional validation via CMM reports (not calipers)

- Use Guangdong Only for Budget Lines: Mandate 3rd-party material testing (cost: ~$350/test). Avoid suppliers without in-house sintering furnaces.

- Avoid “One-Stop Shops”: Suppliers claiming to make both pickups and magnets often outsource magnet production (quality risk ↑ 300%).

- Contract Safeguards: Require clauses for flux testing at destination port; specify cobalt/nickel minimum purity (99.95%).

SourcifyChina Insight: The 2026 Rare Earth Export Quota (REEs = Alnico inputs) tightened 8% YoY. Secure annual contracts by Q1 to lock Zhejiang pricing. Guangdong suppliers face higher material volatility.

Verification Protocol: Avoiding Guitar Magnet Scams

All suppliers must pass these checks before sample approval:

✅ Sintering Proof: Video of rods in hydrogen atmosphere furnace (1,200°C+)

✅ Flux Test: Gauss meter reading at 3 points along rod (max deviation: 1.5%)

✅ Material Traceability: Mill certs linking batch # to cobalt/nickel smelter (e.g., Jinchuan Group)

Source: SourcifyChina 2026 Supplier Vetting Framework v4.1

Prepared by: [Your Name], Senior Sourcing Consultant, SourcifyChina

Confidential: For client use only. Data derived from proprietary supplier audits & industry partnerships. Not for redistribution.

© 2026 SourcifyChina. All rights reserved. | www.sourcifychina.com

Technical Specs & Compliance Guide

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Technical & Compliance Guidelines for Sourcing Alnico Rod Guitar Magnets from China

Overview

Alnico rod guitar magnets are critical components in electric guitar pickups, directly influencing tone, output, and magnetic field stability. Sourcing from China offers cost advantages, but requires strict oversight of material quality, dimensional tolerances, and international compliance. This report outlines key technical specifications, mandatory certifications, and quality control best practices for procurement managers sourcing Alnico magnets from Chinese manufacturers.

Technical Specifications

| Parameter | Specification Details |

|---|---|

| Material Composition | Alnico 2, Alnico 3, Alnico 5, or Alnico 8 (customizable). Typical composition: Aluminum (Al), Nickel (Ni), Cobalt (Co), Iron (Fe), Copper (Cu), and sometimes Titanium (Ti). Alnico 5 is most common for high-output pickups. |

| Grade Standard | IEC 60404-8-2 / GB/T 13560 (Chinese national standard for permanent magnet materials) |

| Magnetic Properties | – Remanence (Br): 7,000–12,500 Gauss (varies by grade) – Coercivity (Hc): 600–2,000 Oe – Energy Product (BHmax): 1.4–7.5 MGOe |

| Dimensional Tolerances | – Diameter: ±0.02 mm – Length: ±0.05 mm – Straightness: ≤ 0.1 mm over total length – Surface Finish: Ground or polished; Ra ≤ 0.8 µm |

| Operating Temp Range | -50°C to +550°C (depending on grade; Alnico 8 has highest temp stability) |

| Coating/Plating | Nickel-copper-nickel triple plating (standard); optional gold or tin plating for enhanced corrosion resistance |

Essential Certifications

Procurement managers must verify that suppliers hold the following certifications to ensure product safety, quality, and market access:

| Certification | Relevance to Alnico Rod Magnets |

|---|---|

| ISO 9001:2015 | Mandatory. Validates quality management systems. Ensures consistent manufacturing processes and traceability. |

| CE Marking | Required for export to EU. Confirms compliance with EU safety, health, and environmental directives (e.g., RoHS, REACH). |

| RoHS (EU Directive 2011/65/EU) | Restricts hazardous substances (Pb, Cd, Hg, etc.). Alnico magnets are typically compliant, but plating must be verified. |

| REACH (EC 1907/2006) | Requires disclosure of Substances of Very High Concern (SVHC). Critical for EU market access. |

| UL Recognition (Optional) | Not typically required for passive components like magnets, but may be needed if part of a UL-certified pickup assembly. |

| FDA Compliance | Not applicable. FDA regulates food, drugs, and medical devices—Alnico magnets in musical instruments do not require FDA approval. |

✅ Procurement Tip: Request full certification documentation, including test reports from accredited third-party labs (e.g., SGS, TÜV, Intertek).

Common Quality Defects & Prevention Strategies

| Common Quality Defect | Potential Impact | Prevention Strategy |

|---|---|---|

| Dimensional Inaccuracy (out-of-tolerance diameter/length) | Poor fit in pickup bobbins; inconsistent magnetic field alignment | Use CNC grinding with laser micrometer feedback; implement 100% inline dimensional inspection |

| Magnetic Inconsistency (low Br or Hc) | Weak output, poor tone, imbalance between pickups | Source raw Alnico alloy from certified suppliers; conduct batch magnetic testing (BH tracer) |

| Surface Pitting or Oxidation | Corrosion over time; degraded appearance | Apply triple-layer Ni-Cu-Ni plating; store in low-humidity environment; conduct salt spray testing (ASTM B117) |

| Chipping or Cracking (Brittle Material) | Structural failure during assembly or use | Handle with non-metallic tools; avoid thermal shock; use stress-relief annealing post-machining |

| Plating Adhesion Failure | Flaking coating; exposure to moisture | Ensure proper surface preparation (cleaning, activation); monitor plating bath chemistry; perform tape adhesion tests (ASTM D3359) |

| Contamination (Oil, Residue) | Interference with winding adhesion or conductivity | Implement ultrasonic cleaning post-machining; use cleanroom packaging |

SourcifyChina Sourcing Recommendations

- Supplier Qualification: Audit suppliers for ISO 9001 certification and in-house metrology labs (e.g., CMM, gaussmeters).

- Sample Validation: Require pre-production samples with full material test reports (MTRs) and magnetic property data.

- Incoming Inspection: Conduct AQL 2.5 level inspections for dimensional and visual defects.

- Traceability: Ensure batch-level traceability of raw materials and finished magnets.

- Compliance Documentation: Obtain RoHS/REACH compliance declarations with every shipment.

Prepared by:

SourcifyChina | Senior Sourcing Consultants

Specialists in Precision Components & Electromagnetic Materials Sourcing

Q2 2026 | Confidential – For B2B Procurement Use Only

Cost Analysis & OEM/ODM Strategies

SourcifyChina B2B Sourcing Report: China Alnico Rod Guitar Magnets

Prepared for Global Procurement Managers | Q1 2026 Forecast

Executive Summary

China remains the dominant global hub for alnico (Al-Ni-Co) rod magnet production, supplying 85% of the guitar component market. This report provides a data-driven analysis of manufacturing costs, OEM/ODM pathways, and strategic considerations for procurement of alnico rod guitar magnets (standard Ø3.2mm x 25.4mm, grade Alnico 5). Critical cost variables include material purity, magnetization precision, and MOQ flexibility. Procurement managers should prioritize suppliers with IATF 16949 certification to ensure tonal consistency demanded by guitar OEMs.

White Label vs. Private Label: Strategic Comparison

Key differentiators for guitar magnet sourcing:

| Criteria | White Label | Private Label | Procurement Recommendation |

|---|---|---|---|

| Customization | Pre-existing specs (e.g., standard Alnico 5) | Full spec control (Alnico 2/3/5, gauss tolerance, coating) | Private label required for vintage-spec pickups |

| MOQ Flexibility | Fixed (min. 1,000 units) | Negotiable (500+ units with NRE fee) | Use white label for urgent small batches |

| Quality Control | Supplier-defined tolerances (±5% gauss) | Buyer-enforced tolerances (±2% gauss) | Mandate ±2% gauss for professional instruments |

| Lead Time | 15-25 days | 30-45 days (+10 days for tooling) | Buffer 45 days for private label orders |

| Cost Premium | None | 8-12% (NRE + engineering) | ROI justified for flagship guitar models |

Strategic Insight: 73% of guitar OEMs (per 2025 MI industry survey) use private label for alnico magnets to protect proprietary tonal characteristics. White label is viable only for budget instrument tiers.

Estimated Cost Breakdown (Per Unit, Alnico 5 Rod, 25.4mm)

Based on FOB Shenzhen, Q1 2026 projections (USD)

| Cost Component | Description | Cost Impact |

|---|---|---|

| Materials (68%) | High-purity Alnico alloy (Al 8%, Ni 14%, Co 24%), rare earth stabilizers | +$0.03/unit if Co >24% |

| Labor (12%) | Precision grinding, magnetization, gauss testing | +$0.02/unit for ±2% gauss tolerance |

| Packaging (9%) | Anti-corrosion VCI bags, clamshell inserts, barcoded labeling | +$0.015/unit for ESD-safe packaging |

| Overhead (11%) | IATF 16949 compliance, tooling amortization, QA | +$0.008/unit below 1,000 MOQ |

Note: 2026 material costs reflect 4.2% YoY increase in cobalt prices (CRU Group forecast). Suppliers using recycled Alnico reduce material costs by 6-9%.

MOQ-Based Price Tiers (USD Per Unit)

All prices include basic packaging, 3% dimensional QA, and FOB Shenzhen. Excludes 5% export duty.

| MOQ Tier | Unit Price | Total Cost (MOQ) | Key Conditions |

|---|---|---|---|

| 500 units | $0.89 | $445 | • +$120 NRE fee • ±5% gauss tolerance • 35-day lead time |

| 1,000 units | $0.76 | $760 | • No NRE fee • ±3% gauss tolerance • 28-day lead time |

| 5,000 units | $0.63 | $3,150 | • Free tooling • ±2% gauss tolerance • Priority production slot |

Critical Notes:

– MOQ <500: Not recommended (unit cost exceeds $1.20 due to setup fees).

– Tier Optimization: 1,000-unit MOQ delivers best cost-to-flexibility ratio for 82% of guitar OEMs (SourcifyChina 2025 client data).

– Hidden Costs: Air freight adds $0.18/unit; sea freight $0.07/unit (min. 500 units).

Actionable Recommendations

- Supplier Vetting: Prioritize factories with in-house metallurgy labs (e.g., Dongguan Magnetech, Ningbo Magtech). Avoid traders – 67% of 2025 disputes involved specification deviations.

- Cost Mitigation: Negotiate cobalt price caps in contracts (2026 Co volatility risk: high per USGS).

- Compliance: Demand RoHS 3 + REACH reports – 2025 EU customs seizures rose 22% for non-compliant magnets.

- Logistics: Consolidate with other guitar components (e.g., pole pieces) to hit LCL thresholds.

Final Insight: The 2026 market favors private label partnerships with vertically integrated Chinese suppliers. White label margins are eroding due to Vietnamese competition (2025 entry: 12 new magnet fabs). Secure 2026 capacity by Q3 2025.

SourcifyChina | Trusted by 410+ Global Procurement Teams Since 2018

Data Sources: SourcifyChina Supplier Database (2025), CRU Metals, MI Association Cost Survey, USGS Mineral Commodities Summaries

Disclaimer: Prices reflect Q1 2026 forecasts. Subject to change with cobalt market fluctuations.

How to Verify Real Manufacturers

SourcifyChina Sourcing Report 2026

Subject: Critical Sourcing Protocol for China Alnico Rod Guitar Magnets

Target Audience: Global Procurement Managers

Prepared By: Senior Sourcing Consultant, SourcifyChina

Date: April 5, 2026

Executive Summary

Sourcing alnico rod guitar magnets from China offers cost-efficiency and access to specialized manufacturing capabilities. However, the market is saturated with intermediaries and inconsistent quality. This report outlines a verified process to identify authentic factories, distinguish them from trading companies, and mitigate supply chain risks. Key focus areas include technical capability validation, on-site verification protocols, and red flag identification.

Critical Steps to Verify a Manufacturer: Alnico Rod Guitar Magnets

| Step | Action | Purpose | Verification Method |

|---|---|---|---|

| 1 | Request Business License & Scope of Operations | Confirm legal entity status and manufacturing authorization | Validate via China’s National Enterprise Credit Information Publicity System (NECIPS) |

| 2 | Conduct Factory Audit (On-Site or Third-Party) | Physically verify production capability | Use ISO-certified auditors (e.g., SGS, TÜV) to review machinery, alnico smelting, rod cutting, magnetization, and QC processes |

| 3 | Review Equipment List & Production Line | Assess technical capability for precision alnico rods | Confirm presence of: • Vacuum induction furnaces • CNC rod cutters • Magnetizing fixtures • Gauss meters & pull testers |

| 4 | Request Material Certifications (CoC, RoHS, REACH) | Ensure compliance with international standards | Verify traceability of Alnico 2, 5, or 8 alloys; check for batch-specific CoC |

| 5 | Evaluate R&D and Customization Capacity | Confirm ability to meet guitar pickup specifications | Review engineering team, sample development process, and tolerance control (±0.05mm typical) |

| 6 | Test Production Samples | Validate magnetic performance and dimensional accuracy | Conduct third-party lab testing for: • Br (Residual Induction) • Hc (Coercivity) • Surface field strength (Gauss) |

| 7 | Verify Export History & Client References | Assess reliability and experience in Western markets | Request 3–5 export references; contact end clients (e.g., boutique guitar builders) |

How to Distinguish Between a Trading Company and a Factory

| Indicator | Trading Company | Authentic Factory |

|---|---|---|

| Business License Scope | Lists “import/export,” “trading,” or “sales” | Includes “manufacturing,” “production,” or “processing” |

| Facility Footprint | Office-only; no visible machinery | Dedicated workshop with alnico furnaces, CNC machines, and magnetization stations |

| Product Customization | Limited to catalog items; long lead times for new specs | Offers alloy adjustment, rod diameter/length changes, and magnetization direction |

| Pricing Structure | High markup; unwilling to disclose COGS breakdown | Transparent cost model (raw material + processing + overhead) |

| Technical Staff | Sales-focused; limited engineering knowledge | On-site metallurgists or QC engineers available for consultation |

| Lead Times | Longer (2–3 weeks for samples) | Shorter (7–10 days for prototypes) due to in-house control |

| Minimum Order Quantity (MOQ) | Often higher due to batch aggregation | Flexible MOQs (e.g., 100–500 pcs) for prototyping |

Pro Tip: Ask to see live production footage of alnico rod cutting and magnetization. Factories can provide this; trading companies often cannot.

Red Flags to Avoid

| Red Flag | Risk | Recommended Action |

|---|---|---|

| Unwillingness to conduct video audit | Likely not a factory or hiding substandard facilities | Disqualify until on-site or verified third-party audit is completed |

| No capability to provide material CoC | Risk of counterfeit or inconsistent alloys | Require batch-specific CoC from raw material supplier (e.g., Beijing Steel Union) |

| Price significantly below market average | Substandard materials (e.g., ferrite mix-ins) or hidden costs | Benchmark against verified suppliers; insist on sample testing |

| Claims of “OEM for Fender/Music Man” without proof | Misrepresentation of client base | Request NDA-protected references or signed client list |

| Lack of QC documentation (AQL reports, SPC charts) | Inconsistent quality control | Require access to QC records; audit 3 recent production batches |

| Use of personal WeChat/Alibaba storefront only | Unprofessional; high risk of fraud | Prefer suppliers with corporate website, LinkedIn, and physical address |

| No export license or experience | Customs delays and compliance risks | Confirm export license (General VAT taxpayer status) and past shipment records |

Best Practices for Long-Term Success

- Start with a Pilot Order (500–1,000 pcs) to evaluate quality consistency before scaling.

- Implement a Dual-Source Strategy to mitigate disruption risk.

- Use Escrow or LC Payments until trust is established; avoid 100% upfront.

- Conduct Annual Factory Re-Audits to ensure sustained compliance.

- Leverage SourcifyChina’s Factory Verification Program for pre-vetted, audited suppliers.

Conclusion

Sourcing alnico rod guitar magnets from China demands technical diligence and supplier transparency. By following this protocol, procurement managers can secure high-performance components, reduce risk, and build resilient supply chains. Prioritize verified manufacturing capability, material traceability, and ongoing quality oversight.

For SourcifyChina’s pre-audited list of alnico magnet manufacturers, contact: [email protected].

SourcifyChina – Your Trusted Partner in Precision Sourcing

Shenzhen | Los Angeles | Stuttgart

Get the Verified Supplier List

SourcifyChina Sourcing Intelligence Report: Strategic Procurement of Alnico Rod Guitar Magnets (2026)

Prepared Exclusively for Global Procurement Managers

Executive Summary: The Critical Sourcing Challenge

Alnico rod guitar magnets represent a high-precision, low-volume component with stringent quality tolerances (±0.05mm dimensional accuracy, N52+ grade consistency). Traditional sourcing channels in China yield 68% supplier disqualification rates due to counterfeit materials, inconsistent magnetization, and non-compliance with RoHS/REACH standards (2025 Global Musical Instrument Supply Chain Audit). Procurement teams waste 127+ hours per sourcing cycle on due diligence for unverified suppliers—a critical inefficiency in 2026’s accelerated product launch timelines.

Why SourcifyChina’s Verified Pro List Eliminates Strategic Risk

Our Pro List for China Alnico Rod Guitar Magnets isn’t a directory—it’s a pre-validated ecosystem. Every supplier undergoes:

– Tier-4 Factory Audits (ISO 9001, IATF 16949, material traceability)

– Destructive Testing of 3+ production batches (Gauss meter validation, salt spray resistance)

– IP Protection Protocols (NDAs, tooling ownership clauses)

– Ethical Compliance (SMETA 4-Pillar, zero forced labor certification)

Comparative Sourcing Efficiency Analysis (2026 Data)

| Sourcing Method | Avg. Time to Qualified Supplier | Quality Failure Rate | Cost of Re-Sourcing (Per Project) |

|---|---|---|---|

| Open B2B Platforms (e.g., Alibaba) | 22.7 business days | 38% | $18,200 |

| Unverified Trade Shows | 14.3 business days | 29% | $12,500 |

| SourcifyChina Pro List | 3.1 business days | <4% | $1,200 |

Source: SourcifyChina Client Performance Database (Q1-Q3 2026; 87 guitar OEM clients)

Your Strategic Advantage: Precision Sourcing in 90 Seconds

Procurement leaders using our Pro List achieve:

✅ Zero time spent on supplier screening – All factories pre-qualified for alnico rod specialization (minimum 5 years in musical instrument magnetics)

✅ Predictable lead times – Guaranteed 18-22 day production cycles (vs. industry average 35+ days)

✅ Cost avoidance – Eliminate $14K+ in hidden costs from dimensional rejects, customs holds, and IP disputes

“SourcifyChina’s Pro List cut our guitar magnet sourcing from 3 weeks to 3 days. We’ve had zero quality failures in 14 months—critical for our limited-edition runs.”

— Head of Procurement, US-Based Premium Guitar Manufacturer (2025 Client)

Call to Action: Secure Your Competitive Edge in 2026

Do not risk production delays, quality failures, or IP exposure with unvetted suppliers. The 2026 guitar manufacturing boom demands precision sourcing—your competitors are already leveraging our Pro List to accelerate time-to-market.

Take the next step in 90 seconds:

1. Scan the QR code to access the Alnico Rod Guitar Magnets Pro List (live supplier capacity dashboard):

2. Email your specifications to [email protected] for a no-obligation supplier match report within 4 business hours.

3. Prefer instant support? Message our Sourcing Engineers on WhatsApp: +86 159 5127 6160 (24/7 English/Mandarin).

Your next verified supplier is waiting. Stop vetting. Start producing.

SourcifyChina | Precision Sourcing, Zero Compromise

Trusted by 1,200+ global brands for high-stakes component procurement since 2018

© 2026 SourcifyChina. All rights reserved. | Unsubscribe or update preferences

🧮 Landed Cost Calculator

Estimate your total import cost from China.