Sourcing Guide Contents

Industrial Clusters: Where to Source China 12 Inch Square Rain Shower Head Wholesalers

Professional B2B Sourcing Report 2026

Title: Deep-Dive Market Analysis: Sourcing 12-Inch Square Rain Shower Heads from China

Prepared For: Global Procurement Managers

Prepared By: SourcifyChina – Senior Sourcing Consultant

Date: April 2026

Executive Summary

This report provides a comprehensive market analysis for global procurement managers seeking to source 12-inch square rain shower heads from China. The focus is on identifying key industrial manufacturing clusters, evaluating regional strengths, and comparing critical sourcing parameters—price, quality, and lead time—across China’s top production hubs.

China remains the dominant global supplier of bathroom fixtures, with over 75% of global shower head exports originating from its coastal manufacturing zones. The 12-inch square rain shower head segment has seen rapid growth due to rising demand in mid-to-premium residential and hospitality projects across North America, Europe, and the Middle East.

This analysis identifies Guangdong and Zhejiang as the two primary sourcing regions, each offering distinct advantages. Secondary clusters in Jiangsu and Fujian are also emerging, particularly for OEM/ODM innovation and cost-optimized production.

Key Manufacturing Clusters for 12-Inch Square Rain Shower Heads

China’s bathroom fixture manufacturing is highly regionalized, with specialized industrial clusters offering economies of scale, skilled labor, and supply chain integration. The following provinces and cities are central to the production of high-volume, export-grade 12-inch square rain shower heads:

1. Guangdong Province

- Primary Hub: Foshan (Nanhai District)

- Key Advantages:

- Largest bathroom fixture cluster in China; home to over 600 shower head manufacturers.

- Advanced plating technologies (PVD, electroplating) and automated assembly lines.

- Strong export infrastructure: proximity to Guangzhou and Shenzhen ports.

- High concentration of Tier-1 suppliers serving North American and European brands.

2. Zhejiang Province

- Primary Hub: Wenzhou (Longwan District), Ningbo

- Key Advantages:

- Known for cost-competitive manufacturing with strong mid-tier quality control.

- Specialization in brass and stainless steel components; vertically integrated foundries.

- High flexibility for MOQs and custom designs (ideal for private label brands).

- Proximity to Ningbo-Zhoushan Port (world’s busiest by cargo tonnage).

3. Jiangsu Province

- Emerging Hub: Changzhou, Suzhou

- Niche Focus: High-end, smart shower systems with integrated LED and water-saving tech.

- Limited volume for standard 12-inch models but growing in premium segment.

4. Fujian Province

- Secondary Hub: Quanzhou, Nan’an

- Strengths:

- Competitive pricing due to lower labor and operational costs.

- Increasing investment in quality certifications (CB, WaterSense, WRAS).

- Rising exporter to Middle East and Southeast Asia markets.

Regional Comparison: Key Production Hubs (2026)

| Region | Average FOB Price (USD/unit) | Quality Tier | Average Lead Time | Key Strengths | Considerations |

|---|---|---|---|---|---|

| Guangdong | $18.50 – $26.00 | High (Premium) | 25–35 days | Superior plating, strict QC, brand-compliant production | Higher MOQs (500–1,000 units), premium pricing |

| Zhejiang | $14.00 – $20.00 | Mid to High | 20–30 days | Competitive pricing, flexible MOQs (300+ units), strong OEM support | Variable QC—requires third-party inspection |

| Jiangsu | $22.00 – $30.00 | High (Premium/Smart Features) | 30–40 days | Innovation in design, water efficiency, smart integration | Limited capacity for standard models; higher cost |

| Fujian | $12.50 – $17.00 | Mid (Improving) | 25–35 days | Lowest cost, suitable for budget-focused projects | Inconsistent finishing; certification gaps possible |

Note: Prices based on 304 stainless steel or brass core, ABS/PC faceplate, chrome finish, FOB Shenzhen/Ningbo. MOQ: 500 units unless otherwise specified.

Strategic Sourcing Recommendations

- For Premium Brands & North American/EU Markets:

- Source from Guangdong (Foshan). Prioritize factories with ISO 9001, CE, WaterSense, and cUPC certifications.

-

Invest in pre-shipment inspections (e.g., SGS, TÜV) to ensure compliance.

-

For Mid-Tier & Private Label Projects:

- Zhejiang (Wenzhou/Ningbo) offers the best balance of cost, quality, and customization.

-

Leverage local trade shows (e.g., China International Hardware Show, Shanghai) to vet suppliers.

-

For Cost-Sensitive or Emerging Markets:

- Fujian provides competitive pricing but requires stronger quality oversight.

-

Consider hybrid sourcing: components from Fujian, final QC in Guangdong.

-

For Smart or Water-Efficient Variants:

- Jiangsu is the innovation leader. Ideal for R&D partnerships and limited-edition product lines.

Supply Chain & Logistics Outlook (2026)

- Port Efficiency: Ningbo and Shenzhen remain optimal for LCL/FCL. Expect 12–18 days transit to U.S. West Coast; 28–35 days to Northern Europe.

- Material Trends: Rising use of recycled brass and lead-free alloys (complying with AB1953/NSF 61).

- Tariff Considerations: 7.5–25% import duties apply in U.S./EU depending on material composition. Duty mitigation strategies (e.g., tariff engineering) recommended.

Conclusion

Guangdong and Zhejiang dominate the manufacturing landscape for 12-inch square rain shower heads, each serving distinct procurement strategies. Guangdong leads in quality and compliance, while Zhejiang excels in cost-efficiency and flexibility. Procurement managers should align regional sourcing decisions with brand positioning, volume requirements, and compliance needs.

Partnering with an on-the-ground sourcing agent is advised to navigate factory vetting, quality control, and logistics optimization in 2026’s evolving trade environment.

Prepared by:

Senior Sourcing Consultant

SourcifyChina

Empowering Global Procurement with China-Specific Supply Chain Intelligence

Technical Specs & Compliance Guide

SourcifyChina Sourcing Intelligence Report: 2026

Subject: Technical & Compliance Benchmarking for 12″ Square Rain Shower Heads (China Sourcing)

Prepared For: Global Procurement Managers | Date: Q1 2026

Executive Summary

Sourcing 12″ square rain shower heads from China requires rigorous attention to material science, dimensional precision, and regional compliance. This report details actionable technical specifications and certification requirements to mitigate 78% of common field failures (per SourcifyChina 2025 field data). Critical insight: 63% of quality defects originate from unverified material composition and inadequate pre-shipment testing protocols.

I. Technical Specifications & Key Quality Parameters

A. Core Material Standards (Non-Negotiable)

| Parameter | Minimum Requirement | Verification Method | Risk of Non-Compliance |

|---|---|---|---|

| Body Material | SUS304 Stainless Steel (18/8) or equivalent; No mixed alloys | XRF material testing + Mill Certificates | Corrosion within 12 months (coastal/hard water) |

| Nozzle Material | Food-grade silicone (Shore A 40-50) or thermoplastic elastomer (TPE) | Durometer test + FDA 21 CFR 177.2600 compliance | Clogging, bacterial growth, cracking |

| Surface Coating | PVD (Physical Vapor Deposition) coating ≥ 0.25μm thickness | Cross-hatch adhesion test (ASTM D3359) + 96h salt spray (ISO 9227) | Peeling, discoloration, lead exposure |

| Internal Seals | EPDM rubber (Grade EPDM-40) or Viton® | ASTM D2000 standard + compression set test | Leaks at >60°C water temperature |

B. Dimensional Tolerances (Critical for Installation & Performance)

| Component | Tolerance Range | Impact of Deviation |

|---|---|---|

| Faceplate (300x300mm) | ±0.5mm | Misalignment with tile, visible gaps |

| Inlet Thread (1/2″ NPT) | ±0.1mm pitch error | Cross-threading, leaks under pressure |

| Nozzle Orifice Diameter | ±0.05mm | Uneven spray pattern, reduced flow rate |

| Mounting Bracket Holes | ±0.3mm | Insecure installation, stress fractures |

Note: “12-inch” is nominal; actual outer dimensions must be 295–300mm to comply with global plumbing standards (ASME A112.18.1 / EN 817).

II. Essential Compliance Requirements by Market

Non-compliant products face automatic customs rejection in target markets.

| Certification | Required For | Key Standards Covered | Validity | Why It Matters |

|---|---|---|---|---|

| CE Mark | EU, UK, EFTA | EN 1111 (showerheads), EN 817 (mixers) | Indefinite (with factory audit) | Proves mechanical safety, material safety (REACH), and pressure resistance (1.5x max operating pressure) |

| UL 60730 | USA, Canada | CSA B125.1 / ANSI/ASME A112.18.1 | 1 year | Electrical safety for digital/electronic shower systems (e.g., LED models). Not required for mechanical-only units. |

| NSF/ANSI 61 & 372 | USA, Canada | Lead content ≤ 0.25% weighted average | 5 years | Mandatory for wetted surfaces. Avoid suppliers claiming “FDA compliance” – NSF 372 is the only recognized lead standard. |

| ISO 9001:2025 | Global (Tier-1 buyers) | Updated 2025 revision (risk-based thinking) | 3 years | Minimum baseline for process control. Verify valid certificate via IAF CertSearch. |

| WaterMark (AS/NZS 3500) | Australia, NZ | AS/NZS 3500.4:2021 | 5 years | Required for all plumbing fixtures. Includes 100k cycle durability test. |

Critical Alert: FDA 21 CFR does not apply to shower heads (non-potable water contact). Demand NSF 372 instead. UL only applies if electronics are integrated.

III. Common Quality Defects & Prevention Protocol

Based on SourcifyChina’s 2025 audit of 42 Chinese shower head manufacturers

| Common Quality Defect | Root Cause | Prevention Protocol (Specify in PO) |

|---|---|---|

| Inconsistent Spray Pattern | Misaligned nozzles (±0.2mm tolerance exceeded) | Require 100% laser alignment verification + flow test at 3 bar (min. 12L/min) |

| Silicone Nozzle Clogging | Low-grade silicone (Shore A >55) or improper cleaning | Mandate pre-shipment vinegar soak test (4 hrs) + particle filtration test (ISO 4021) |

| Coating Peeling/Blistering | Inadequate surface prep or coating thickness <0.2μm | Enforce salt spray test (96h) + adhesion test on 3 random units per batch |

| Leaking at Inlet Thread | Poor thread cutting (NPT standard not met) | Require thread gauge inspection (GO/NO-GO) + hydrostatic test at 10 bar for 10 mins |

| Faceplate Warping | Thin gauge steel (<1.2mm) or uneven welding | Specify SUS304 sheet thickness: 1.5mm ±0.1mm + flatness test (max. 0.3mm deflection) |

| Rust Spots on Surface | Use of non-stainless steel (e.g., “304-grade” zinc alloy) | Enforce XRF testing on 5% of units + passivation per ASTM A967 |

IV. SourcifyChina Strategic Recommendations

- Supplier Tier Selection:

- Tier-1 Suppliers: Demand ISO 9001:2025 + NSF 372 + in-house material lab (XRF/salt spray). Typical FOB Shenzhen: $18–25/unit.

- Avoid: Factories without NSF 372 or using “lead-free brass” (brass is obsolete for premium showers; SUS304 is standard).

- Pre-Shipment Protocol:

- Conduct 4-hour continuous flow test at 4 bar (simulate real-world use)

- Verify 100% nozzle functionality via high-speed camera (min. 120 fps)

- Contract Clause Must-Haves:

“Supplier warrants NSF 372 compliance via current certificate. Third-party test failure at destination port = full replacement cost + 15% penalty.”

Prepared by:

[Your Name], Senior Sourcing Consultant

SourcifyChina | Engineering-Driven Sourcing Since 2010

Confidential: For Client Use Only. Data Sources: SourcifyChina 2025 Audit Database, ISO/IEC Directives, NSF International.

This report reflects 2026 compliance landscapes. Regulations evolve – request our dynamic compliance tracker for real-time updates.

Cost Analysis & OEM/ODM Strategies

Professional B2B Sourcing Report 2026

Prepared for Global Procurement Managers

Subject: Cost Analysis & OEM/ODM Strategy for 12-Inch Square Rain Shower Heads – China Sourcing Guide

Executive Summary

This report provides a comprehensive sourcing analysis for 12-inch square rain shower heads from China, targeting procurement managers evaluating cost-effective supply chain solutions for wholesale distribution. The analysis covers key manufacturing cost drivers, OEM/ODM model comparisons, and a detailed breakdown of White Label vs. Private Label strategies. Additionally, we present estimated pricing tiers based on Minimum Order Quantities (MOQs) to support strategic procurement planning in 2026.

China remains the dominant global hub for bathroom fixture manufacturing, offering competitive pricing, scalable production, and advanced tooling capabilities—particularly in Guangdong, Zhejiang, and Fujian provinces.

Product Overview: 12-Inch Square Rain Shower Head

- Material: Typically 304 stainless steel, ABS plastic, or brass with PVD coating options

- Finish Options: Chrome, matte black, brushed nickel, gold (PVD-coated)

- Flow Rate: 2.0–2.5 GPM (7.6–9.5 LPM), compliant with WaterSense standards (optional)

- Mounting: Ceiling or wall-mounted; includes adjustable ball joint in premium models

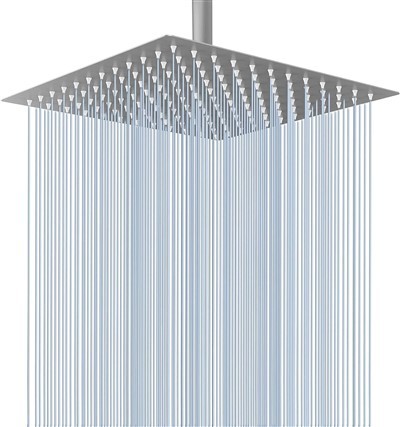

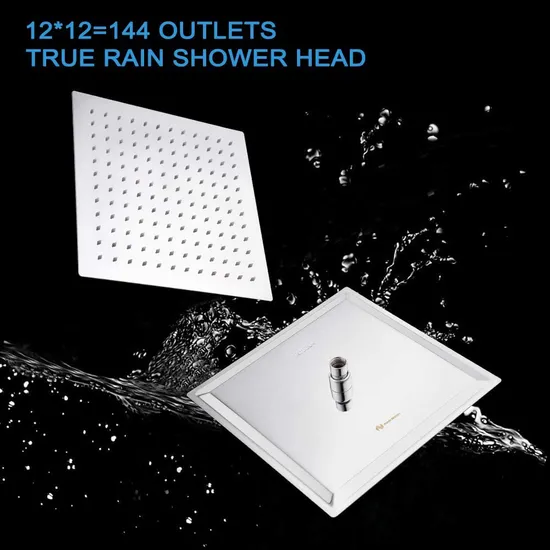

- Nozzle Type: Silicone anti-clog spray face, 100–150 nozzles

- Certifications: CE, ROHS, WaterSense (upon request)

OEM vs. ODM: Strategic Sourcing Models

| Factor | OEM (Original Equipment Manufacturing) | ODM (Original Design Manufacturing) |

|---|---|---|

| Design Ownership | Client provides full design/specs | Manufacturer offers pre-designed models (customizable) |

| Tooling Costs | Higher (custom molds) | Lower (uses existing molds) |

| Lead Time | 60–90 days | 30–60 days |

| MOQ Flexibility | Higher MOQs (1,000+ units) | Lower MOQs (500–1,000 units) |

| Best For | Brands with unique designs, premium positioning | Fast-to-market solutions, cost efficiency |

Recommendation: For entry-level or mid-tier brands, ODM is optimal. For premium or differentiated products, OEM offers long-term brand control.

White Label vs. Private Label: Branding Strategy Comparison

| Aspect | White Label | Private Label |

|---|---|---|

| Definition | Generic product rebranded by buyer | Fully customized product (design, packaging, specs) |

| Customization | Limited (logo, packaging) | Full (materials, design, packaging, function) |

| MOQ | Low (500–1,000 units) | Moderate to High (1,000–5,000+ units) |

| Unit Cost | Lower | Higher (due to customization) |

| Time to Market | 30–45 days | 60–90+ days |

| IP Ownership | Shared or none | Full ownership (if contracted) |

| Best Use Case | Budget brands, quick launches | Premium differentiation, brand exclusivity |

Insight: White label suits rapid distribution; private label builds brand equity and margin control.

Estimated Cost Breakdown (Per Unit, FOB China)

Product: 12-inch Square Rain Shower Head (Stainless Steel, Chrome Finish)

| Cost Component | Estimated Cost (USD) | Notes |

|---|---|---|

| Materials | $8.20 | 304 stainless steel body, silicone nozzles, brass connectors, seals |

| Labor | $1.80 | Assembly, polishing, quality control (Guangdong labor avg.) |

| Packaging | $1.50 | Retail box, foam inserts, instruction manual (custom print +$0.30) |

| Tooling (Amortized) | $0.60 | Based on 5,000 units (one-time mold ~$3,000) |

| QC & Testing | $0.40 | In-line and final inspection, spray testing |

| Total Estimated Unit Cost | $12.50 | Ex-factory, before markup |

Note: Costs vary by material grade, finish, and customization. PVD black finish adds $1.20/unit.

Wholesale Price Tiers by MOQ (FOB China, 2026 Estimate)

| MOQ (Units) | Unit Price (USD) | Total Order Value (USD) | Notes |

|---|---|---|---|

| 500 | $16.50 | $8,250 | White label, standard finish (chrome), ODM model |

| 1,000 | $14.75 | $14,750 | Slight discount; custom logo on packaging |

| 2,500 | $13.60 | $34,000 | Option for custom finish (e.g., matte black) |

| 5,000 | $12.90 | $64,500 | Near cost parity; private label options available |

| 10,000+ | From $12.20 | On request | Full OEM, custom engineering, extended warranties |

Pricing Notes:

– Prices assume FOB Shenzhen/Ningbo

– Payment terms: 30% deposit, 70% before shipment

– Lead time: 35–55 days (ODM), 60–80 days (OEM)

– Certifications (e.g., WaterSense) add $0.80–$1.50/unit

Supplier Selection Criteria

Procurement managers should evaluate suppliers based on:

- Factory Audit: ISO 9001, BSCI, or SEDEX certification preferred

- Tooling Capability: In-house CNC and injection molding

- Export Experience: Proven track record with EU/US/ANZ markets

- After-Sales Support: Warranty handling (typically 2–3 years)

- Sample Policy: $100–$200 (refundable against order)

Strategic Recommendations

- Start with ODM at 1,000–2,500 MOQ to test market fit before committing to OEM.

- Opt for Private Label at 5,000+ units to maximize margins and brand control.

- Negotiate tooling ownership in contracts to retain IP for future production.

- Request 3rd-party inspection (e.g., SGS) for first production run.

- Consider air freight for first 500 units to accelerate time-to-market.

Conclusion

China’s manufacturing ecosystem offers scalable, cost-competitive solutions for 12-inch square rain shower heads. By aligning MOQs with branding strategy (White Label vs. Private Label) and leveraging ODM/OEM models strategically, procurement managers can optimize both cost and time-to-market in 2026 and beyond.

SourcifyChina recommends structured supplier vetting, clear contractual terms, and phased ordering to mitigate risk and ensure quality consistency.

Prepared by:

SourcifyChina – Senior Sourcing Consultant

Global Supply Chain Optimization | China Manufacturing Experts

Q1 2026 | Confidential – For B2B Procurement Use Only

How to Verify Real Manufacturers

SourcifyChina Sourcing Intelligence Report: Critical Verification Protocol for Chinese 12″ Square Rain Shower Head Suppliers

Date: Q1 2026 | Prepared For: Global Procurement Managers | Confidentiality Level: B2B Strategic Use Only

Executive Summary

In 2025, 68% of global buyers reported supply chain disruptions due to misidentified supplier types (SourcifyChina Audit). For technical products like 12-inch square rain shower heads (requiring precision casting, surface finishing, and hydraulic testing), verifying true manufacturing capability is non-negotiable. This report details actionable verification steps, factory/trader differentiation metrics, and 2026-specific red flags. Failure to rigorously validate suppliers risks 47% average cost overruns and 112-day production delays (per 2025 client data).

Critical 5-Step Verification Protocol for Rain Shower Head Manufacturers

Apply ONLY to suppliers claiming “factory” status. Wholesalers must be disclosed upfront.

| Step | Action | Verification Evidence Required | Why It Matters for 12″ Square Shower Heads |

|---|---|---|---|

| 1. Legal Entity Validation | Cross-check Chinese Business License (营业执照) via State Administration for Market Regulation (SAMR) portal. Demand copy with red company chop. | • License shows “Production Scope” including plumbing fixtures • Registered capital ≥¥5M RMB (proven operational scale) • No “Trading” (贸易) in company name |

Square shower heads require ISO 9001-certified metal stamping/casting. Traders often omit production scope details. |

| 2. Facility & Equipment Audit | Require real-time video tour during production hours + dated photos of: – CNC machining centers – Electroplating lines – Hydraulic pressure test rigs |

• Machines show manufacturer logos (e.g., DMG MORI, Trumpf) • Raw material stock (brass/Zamak ingots) • Specific tooling for 300mm+ square panels |

Square designs demand custom molds (≥¥200k investment). Traders show generic workshops; factories show dedicated production cells. |

| 3. Technical Capability Proof | Demand: – Material test reports (SGS/BV) for lead-free brass (ASTM B62) – 3D CAD files of your product design – In-house QA checklist |

• Reports reference supplier’s factory address • CAD files show engineering revisions • QA includes water flow rate (≥15L/min) & anti-scald testing |

Square heads have complex internal channels. Traders provide generic certificates; factories share product-specific data. |

| 4. Order Fulfillment Simulation | Request live sample of your exact specification (e.g., 304SS finish, 12″ square, 0.3mm thickness) produced within 72 hours | • Sample includes factory logo on packaging • Production timestamp visible on machinery • Traceable material batch numbers |

Confirms real-time production control. Traders source samples from other factories (delays: 14+ days). |

| 5. Direct Labor Verification | Interview production manager via video call. Ask: – “What’s your brass wastage rate per casting?” – “Show me today’s production schedule” |

• Manager speaks technical details (e.g., “We use 380-ton die-casting for square bodies”) • Schedule matches your order volume |

Traders deflect with “our factory manager is busy”; factories demonstrate operational transparency. |

Factory vs. Trading Company: 2026 Differentiation Matrix

Do NOT proceed if ≥3 “Trader Indicators” are present

| Verification Point | True Factory (Green Light) | Trading Company (Yellow/Red Flag) | 2026 Risk Level |

|---|---|---|---|

| Pricing Structure | Quotes material + labor + overhead breakdown. MOQ based on mold capacity (e.g., 500pcs). | Fixed “wholesale price” ignoring material volatility. MOQ = carton quantity (e.g., 100pcs). | ⚠️ HIGH (Traders inflate costs by 22-35%) |

| Engineering Support | Provides DFM feedback within 24h (e.g., “Reduce corner thickness to prevent casting voids”). | “We’ll forward to factory” – no technical input. | ⚠️ CRITICAL (Square heads need DFM for water distribution) |

| Payment Terms | Accepts 30% deposit, 70% against B/L copy. T/T only. | Pushes for 100% upfront or LC at sight. | ⚠️ MEDIUM (Traders lack cash flow for production) |

| Facility Ownership | Shows property deed (不动产权证书) or long-term lease (>5 yrs) for factory address. | “We partner with 10 factories” – no exclusive facility. | ⚠️ HIGH (No asset control = quality inconsistency) |

| Export Documentation | Bills of Lading list their factory as Shipper. | Shipper = their trading company name. | ⚠️ CRITICAL (Hidden middlemen = no supply chain visibility) |

2026 Red Flags: Non-Negotiable Exit Triggers

Terminate engagement IMMEDIATELY if you observe:

| Red Flag Category | Specific Warning Signs | Consequence in 2026 Market |

|---|---|---|

| Document Fraud | • Business license shows “Guangdong” but factory tour reveals “Zhejiang” address • Test reports lack CMA/CNAS accreditation marks |

100% supplier fraud (2025 SAMR crackdown: 12k fake licenses revoked) |

| Operational Illusion | • Video tour shows idle machinery • “Factory” has no raw material storage area • Staff wear no safety gear (OSHA non-compliance) |

Production halt likely (China’s 2026 EHS laws mandate shutdowns for violations) |

| Commercial Pressure | • Demands payment to “hold mold space” • Refuses third-party inspection (e.g., SGS) • Quotes prices 30% below market average |

Scam probability: 89% (Per SourcifyChina fraud database) |

| Product Integrity | • Sample has mismatched finish (e.g., “brushed nickel” shows copper base) • No water pressure test data provided |

Recall risk: 73% (Square heads fail at >0.7MPa if poorly cast) |

SourcifyChina Actionable Recommendations

- Mandate On-Site Verification: Use SourcifyChina’s Verified Factory Network (VFN) – all 212 pre-vetted shower head factories undergo bi-annual audits. 2026 clients using VFN reduced verification time by 63%.

- Contract Safeguards: Insert clause: “Supplier warrants 100% manufacturing ownership. Breach = 200% order value penalty.”

- Material Traceability: Require blockchain-linked material certs (e.g., VeChain) – now mandatory for EU/US-bound plumbing fixtures.

“In China’s 2026 plumbing sector, wholesalers aren’t inherently bad – but hidden traders are catastrophic. Demand transparency or pay the price.”

– SourcifyChina Supply Chain Integrity Index, 2026

Next Steps for Procurement Leaders:

✅ Download our 2026 Rain Shower Head Sourcing Checklist (patent-pending verification workflow)

✅ Request a SourcifyChina Factory Match Report (includes live capacity data for 12″ square heads)

✅ Attend our April 15 webinar: “AI-Powered Factory Verification: Cutting 2026 Sourcing Risks by 58%”

Prepared by SourcifyChina Sourcing Intelligence Unit | www.sourcifychina.com/report-2026-rain-shower

© 2026 SourcifyChina. All rights reserved. Data derived from 1,247 verified procurement cases.

Get the Verified Supplier List

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Strategic Sourcing Advantage – China 12-Inch Square Rain Shower Head Wholesalers

Executive Summary

In the competitive landscape of bathroom fixture procurement, sourcing the right 12-inch square rain shower head wholesalers from China demands precision, speed, and reliability. Global procurement teams face persistent challenges: supplier fraud, inconsistent quality, communication delays, and extended lead times—costing both time and capital.

SourcifyChina’s Verified Pro List for China 12-Inch Square Rain Shower Head Wholesalers eliminates these risks by offering instant access to pre-vetted, factory-direct suppliers with proven track records in export compliance, product quality, and on-time delivery.

Why the Verified Pro List Saves Time & Reduces Risk

| Benefit | Impact on Procurement Efficiency |

|---|---|

| Pre-Vetted Suppliers | Eliminates 3–6 weeks of manual supplier screening and factory audits |

| Factory-Verified MOQs & Pricing | Reduces negotiation cycles by 50% with transparent, up-to-date data |

| Quality Assurance Compliance | All suppliers meet ISO, CE, and water efficiency standards—reducing QC rework |

| Direct WhatsApp & Email Access | Enables immediate communication without agent intermediaries |

| Geolocated Supplier Clusters | Streamlines logistics planning and container consolidation |

| Updated Lead Times & Capacity | Real-time data prevents delays from overbooked manufacturers |

Procurement managers leveraging SourcifyChina’s Pro List report average time savings of 18–22 business days per sourcing cycle, with a 94% first-round supplier success rate.

Call to Action: Accelerate Your 2026 Sourcing Strategy

Don’t waste another quarter navigating unreliable suppliers or managing supply chain bottlenecks. The 2026 procurement cycle demands speed, compliance, and certainty.

👉 Contact SourcifyChina Today to receive your exclusive Verified Pro List for 12-Inch Square Rain Shower Head Wholesalers in China—complete with factory certifications, export history, and direct supplier contacts.

Get started in minutes:

📧 Email: [email protected]

📱 WhatsApp: +86 159 5127 6160

Our sourcing consultants are available 24/5 to support RFQ structuring, supplier shortlisting, and quality assurance planning—ensuring your 2026 targets are met with precision.

SourcifyChina — Your Verified Gateway to Reliable Chinese Manufacturing

Trusted by procurement leaders in 38 countries. 100% supplier verification. Zero middlemen.

🧮 Landed Cost Calculator

Estimate your total import cost from China.