Introduction: Navigating the Global Market for cherry edge banding

Global buyers are raising the bar on quality and on-time delivery. When you’re spec’ing cherry edge banding for cabinets and furniture, color fidelity, adhesive choice, and width/length consistency define performance and cost. Supplier variability, limited roll lengths, and unclear finish guidance often delay projects and drive rework.

This guide demystifies what matters and gives you a repeatable sourcing framework for the USA and Europe. We translate technical requirements into practical specs you can standardize and trust.

What you’ll learn

- How to define width, thickness, and roll length to match your equipment and forecast (see key options below).

- When to choose pre‑glued (iron‑on) vs fleeceback systems for throughput and compliance.

- Finishing protocols to preserve cherry’s warm tone and avoid callbacks.

- Sustainability, VOC, and REACH checklists for the EU and USA.

- Logistics: lead times, MOQs, cutting tolerances, and damage prevention.

- Quality control and acceptance criteria you can enforce.

Quick-reference roll sizes (supplier example)

| Width | Typical lengths | Backings |

|—|—|—|

| 7/8″, 1″, 1.5″, 2″ | 50′, 250′, 500′ | Pre‑glued (hot melt), Fleeceback (no glue) |

With these benchmarks, you can align specs to your process, eliminate mismatches, and secure dependable supply—across both regions.

Article Navigation

- Top 10 Cherry Edge Banding Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for cherry edge banding

- Understanding cherry edge banding Types and Variations

- Key Industrial Applications of cherry edge banding

- 3 Common User Pain Points for ‘cherry edge banding’ & Their Solutions

- Strategic Material Selection Guide for cherry edge banding

- In-depth Look: Manufacturing Processes and Quality Assurance for cherry edge banding

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘cherry edge banding’

- Comprehensive Cost and Pricing Analysis for cherry edge banding Sourcing

- Alternatives Analysis: Comparing cherry edge banding With Other Solutions

- Essential Technical Properties and Trade Terminology for cherry edge banding

- Navigating Market Dynamics and Sourcing Trends in the cherry edge banding Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of cherry edge banding

- Strategic Sourcing Conclusion and Outlook for cherry edge banding

- Important Disclaimer & Terms of Use

Top 10 Cherry Edge Banding Manufacturers & Suppliers List

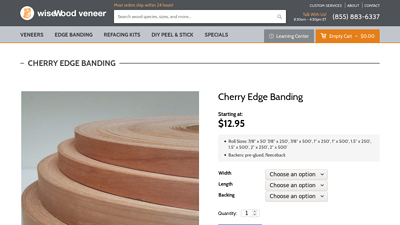

1. Cherry Edge Banding – WiseWood Veneer

Domain: wisewoodveneer.com

Registered: 2011 (14 years)

Introduction: In stock 30-day returnsAffordable, high quality cherry edge banding made from cherry real wood veneer. Comes in rolls with pre-glued or fleeceback backing options….

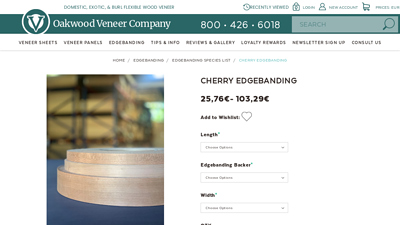

2. Cherry Edgebanding | Black Cherry Edge Banding Veneer Tape Rolls

Domain: oakwoodveneer.com

Registered: 1998 (27 years)

Introduction: In stock 1–3 day deliveryCherry Edgebanding is now available at Oakwood Veneer – a popular and beautiful choice for all project types, such as furniture and interiors….

3. Cherry Edge Banding 2″ x 50′ Pre-Glued (Iron-On) – Veneer Supplies

Domain: veneersupplies.com

Registered: 2003 (22 years)

Introduction: Free deliveryThis genuine cherry wood veneer edge banding is made from premium grade logs and is very easy to apply with an ordinary clothes iron.Missing: top manufacturers suppliers…

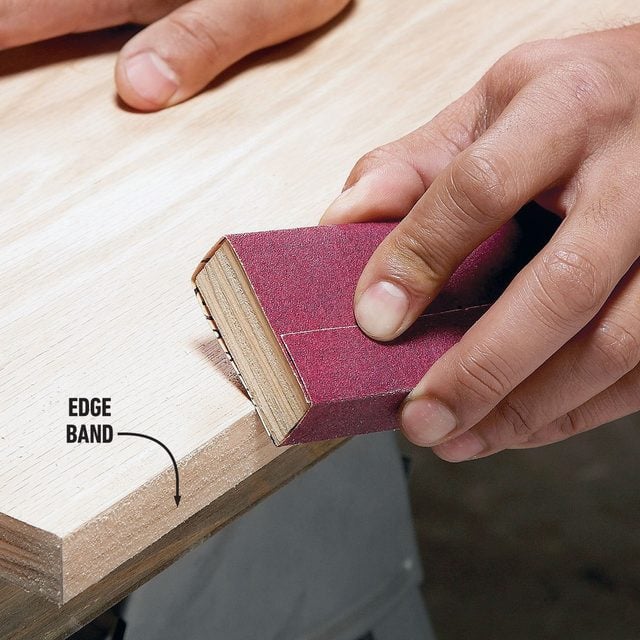

Illustrative Image (Source: Google Search)

4. Cherry Edgebanding – 25′ sections or full roll – Total Wood Store

Domain: totalwoodstore.com

Registered: 2014 (11 years)

Introduction: 45-day returnsCherry wood veneer edge banding. Sold in three widths 7/8”, 1″, and 2″. Purchase by the 25 foot section or by the full roll. HM Glue, and 3M PSA full rolls ……

5. Edge Banding | Imeca Lumber & Hardware

Domain: imeca.com

Registered: 2002 (23 years)

Introduction: We have a wide selection of edge banding options, including Veneer and PVC edge bandings designed to provide a seamless and professional ……

6. Edge Banding Suppliers – Thomasnet

Domain: thomasnet.com

Registered: 1996 (29 years)

Introduction: Manufacturer and distributor of standard and custom edge banding. Strap features a profiled edge for use in roll banding. Rolled edges grip the package….

7. Cabinet Materials Supplies | LEDGEBAND

Domain: ledgeband.com

Registered: 2023 (2 years)

Introduction: LEDGEBAND is your one source for all cabinet making supplies. Order edge banding, veneer, laminates, and other finish materials online with nationwide ……

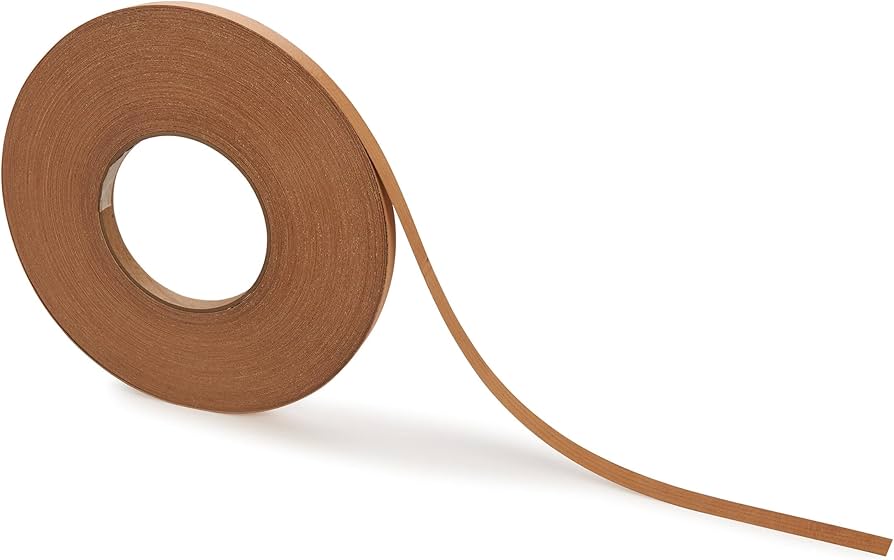

Illustrative Image (Source: Google Search)

Understanding cherry edge banding Types and Variations

Understanding Cherry Edge Banding Types and Variations

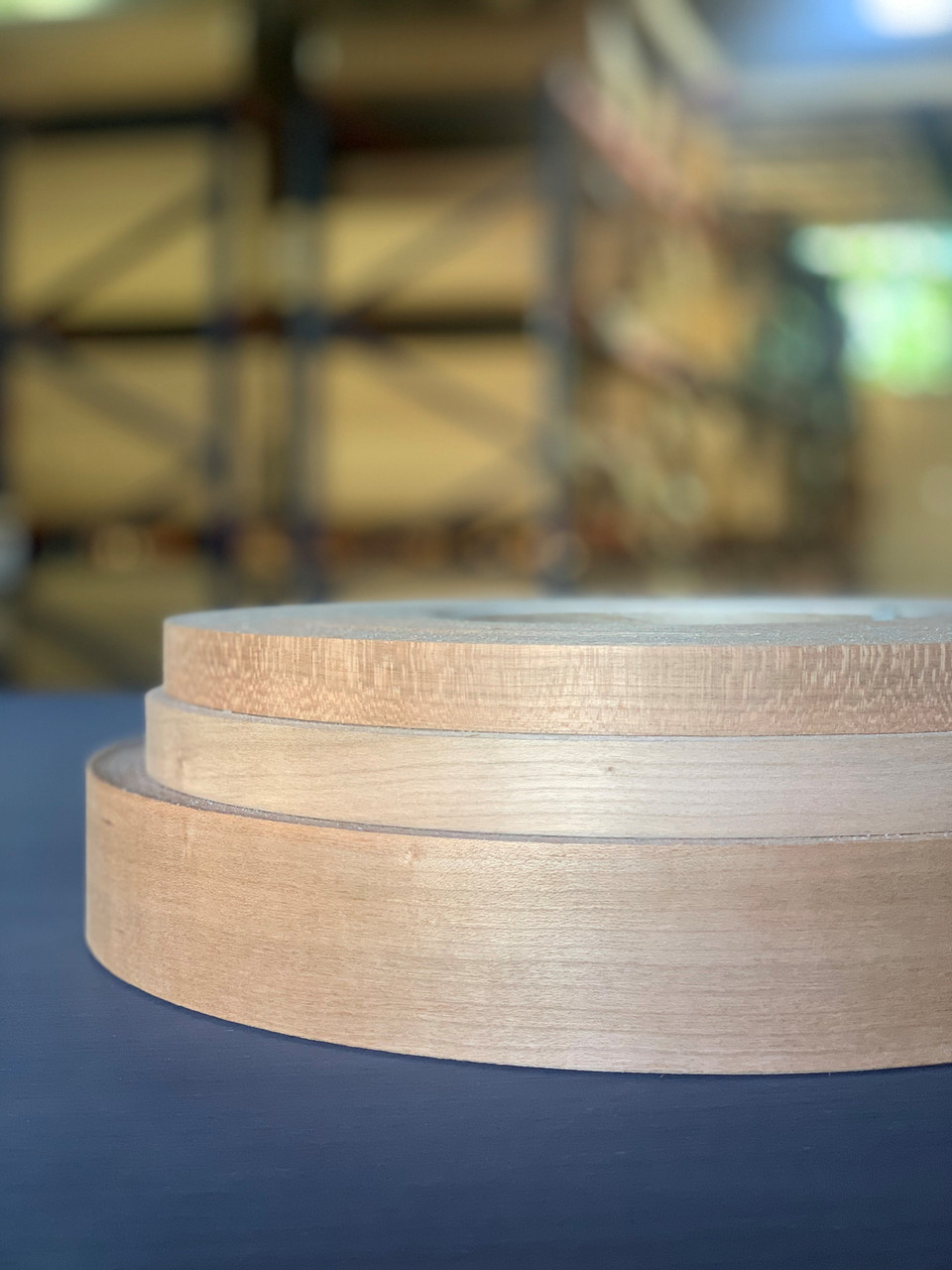

Cherry edge banding is manufactured from cherry wood veneer with a warm pinkish-to-red tone that matures to a deeper reddish brown. For best results, finish with a clear coat to preserve tone and character. Specifiers typically select product by backing/adhesive system, width, and roll length to match equipment and production throughput.

Quick-reference: Types, Features, Applications, Pros/Cons

| Type | Core Features | Typical Applications | Pros | Cons |

|---|---|---|---|---|

| Pre-Glued (Hot-Melt Iron-On) | Hot-melt adhesive; widths 7/8″–2″; lengths 50′, 250′, 500′ | Small shops, field repair, low-run casework, prototype edges | Simple setup; iron-compatible; fast turnaround | Requires careful heat/pressure; lower initial bond vs. machine-pressed; adhesive set speed matters |

| Fleeceback (Unglued) | Non-woven fleece carrier; no built-in glue; requires glue application; machine recommended | Production casework, cabinet shops using edge banders | Stronger, consistent bonds with proper adhesive; tolerant of complex profiles | Needs edge bander or separate glue application; higher setup complexity |

| Narrow Widths (7/8″, 1″) | Narrow profiles for thin panels/frames; matched lengths available | Drawer fronts, thin stock edges, retail fixtures | Low material waste; easy wrap on light profiles | Minimal overhang for trimming; not ideal for thick/absorbent edges without adequate glue |

| Wide Widths (1.5″, 2″) | Greater overhang for thicker material/visible edge buildup | Countertop edge profiles, thick panels, high-visibility millwork | Excellent trim margin; suitable for thicker work | Increased material cost; careful trimming required to avoid chip-out |

| Long Rolls (500′) | High footage per roll; reduces splices and changeovers | High-throughput production lines | Fewer roll changes; smoother workflow; better yield | Higher upfront cost; must manage inventory and material stability |

Pre-Glued (Hot-Melt Iron-On)

- Features: Built-in hot melt adhesive; widths 7/8″–2″; lengths 50′, 250′, 500′.

- Applications: Accessible to shops without edge banders; ideal for small batches, field touch-ups, and prototypes. Can also be used with an edge banding machine if desired.

- Pros/Cons:

- Pros: Simple application with a household iron or portable tools; fast turnarounds; no separate glue setup.

- Cons: Requires heat/pressure control for full activation; adhesive set speed can be sensitive; initial bond may be lower than machine-pressed systems.

- Application guidance: Ensure even heating and firm pressure; trim cleanly; avoid overheating to prevent adhesive bleed.

Fleeceback (Unglued, Machine-Applied)

- Features: Fleece carrier with no pre-applied glue; designed for use with an edge bander or glue pot application.

- Applications: Production casework and cabinetry where consistent, strong bonds and profile conformity are required.

- Pros/Cons:

- Pros: Stronger bonds with proper adhesive selection; better conformability on profiles; compatible with high-volume machines.

- Cons: Requires equipment and glue; additional setup and cleaning; not suitable for iron-only application.

- Application guidance: Select adhesive for substrate and production conditions; verify feed alignment; manage glue spread and activation for full bond.

Narrow Widths (7/8″, 1″)

- Features: Slim profiles for thinner materials; widths match available SKU sizes; lengths in 50′, 250′, 500′.

- Applications: Drawer fronts, thin frames, display fixtures, and light-duty edges where minimal overhang is preferred.

- Pros/Cons:

- Pros: Low material waste; clean lines on light profiles; manageable with basic trimming.

- Cons: Limited trim margin; may not suit thicker work unless combined with edge buildup.

Wide Widths (1.5″, 2″)

- Features: Larger overhang for thicker panels and visible edge applications; widths align with available options.

- Applications: Countertop edges, thick cabinet doors/panels, and premium millwork where edge presence is intentional.

- Pros/Cons:

- Pros: Adequate material for thicker edges; reduces risk of visible substrate; professional appearance on high-visibility parts.

- Cons: Higher material usage; requires careful trimming to avoid chip-out and maintain uniform reveal.

Long Rolls (500′)

- Features: High footage per roll reduces splices and downtime; matched widths available.

- Applications: Continuous production lines, large shops, and volume runs where roll stability and flow efficiency matter.

- Pros/Cons:

- Pros: Fewer roll changes; improved consistency; potentially better yield and productivity.

- Cons: Higher initial cost; inventory and storage considerations; ensure material acclimation before use.

Selection guidance:

– Use pre-glued for accessibility and low-volume flexibility; fleeceback for production strength and machine reliability.

– Choose narrow widths to reduce waste on thin stock; select wide widths for thick edges and premium visibility.

– Consider long rolls to minimize changeovers and maintain production rhythm.

Key Industrial Applications of cherry edge banding

Key Industrial Applications of Cherry Edge Banding

| Application | Why cherry edge banding | Recommended spec/backer | Typical roll strategy | Finishing guidance |

|---|---|---|---|---|

| Kitchen & Bath Cabinetry (Face Frames & Panels) | Warm pink-to-red tone that deepens to reddish-brown; compatible with clear finishes; good dimensional stability when properly applied | 7/8″–1.5″ widths; fleeceback with PVA for permanent installs; pre-glued iron-on for service/rework | Standard panel thickness 3/4″; allow 1/16″–1/8″ overhang beyond substrate edge for trimming | Finish with a clear coat that preserves warmth (avoid heavy pigment that mutes grain) |

| Architectural Millwork & Doors | Color continuity across edges and faces; consistent veneer integrity; suitable for clear finishes | 1.5″–2″ widths for standard 3/4″ substrates; fleeceback preferred; pre-glued available for repair | Pre-plan widths for typical 3/4″ panels; stock 250′ rolls for frequent SKUs | Use clear finishes to maintain uniform warmth across assemblies |

| Retail & Hospitality Fixtures | Aesthetically rich cherry tone elevates perception of quality; practical edge protection on high-traffic items | 7/8″–1″ widths on MDF/plywood; fleeceback for production runs; pre-glued for spot repairs | Run 250’–500′ for continuous production; use shorter 50′ for mixed SKUs and service carts | Clear coat enhances durability and color uniformity |

| Office Furniture & Built-ins | Consistent color and finish; clean, crisp edges; fast application with pre-glued or fleeceback options | 7/8″ widths for 3/4″ panels; fleeceback for production; pre-glued for on-site adjustments | Keep 250’–500′ in stock; shorten to 50′ for low-volume variants | Clear finishes minimize color variation and glare |

| Healthcare & Educational Casework | Easy-to-trim edges improve fit-out speed; clear finishes support cleanability requirements | 1″–1.5″ widths; fleeceback recommended for durable bond; pre-glued for maintenance tasks | Standardize on 250’–500′ lengths; 50′ reels for service carts | Select compliant clear coatings that maintain finish integrity during cleaning |

| Marine & Specialty Interiors | Stable edge treatment for controlled environments; clear finishes accentuate grain depth | 1.5″–2″ widths; fleeceback preferred; avoid excessive glue squeeze-out | Align widths to 3/4″ substrates; use 250’–500′ for runs | Ensure clear finishes are suited for humidity variations; test bond/adhesion on substrates |

| Acoustic & Speaker Cabinets | Adds refined wood edge that masks substrate; clean transitions when trimmed flush | 7/8″–1″ widths on MDF; fleeceback for consistent glue lines; pre-glued for quick fixes | Keep 250′ in stock for frequent panel sizes | Clear finishes enhance grain and reduce light bleed at edges |

| Closet & Pantry Systems | Uniform warm tone; quick application improves install throughput | 7/8″ widths on 3/4″ shelves; pre-glued for rapid field application | Use 250′ rolls for common shelf depths; 50′ for specialty sizes | Apply clear coat to match casework tone and reduce scuff visibility |

| Exhibitry & Trade Show Displays | Reliable edge integrity for repeated setup/teardown; color consistency across kits | 1″ widths for 3/4″ panels; fleeceback recommended for machine-speed runs | 250’–500′ for long runs; keep 50′ on hand for replacements | Clear finishes maintain depth and minimize touch-up |

Notes and sourcing from WiseWood Veneer:

– Cherry edge banding is a warm pinkish-to-red wood that ages to a reddish-brown; best finished with a clear coat to preserve warmth.

– Available widths: 7/8″, 1″, 1.5″, 2″. Roll lengths: 50′, 250′, 500′. Backers: pre-glued (hot-melt, iron-on or edge-banding machine) and fleeceback (requires glue or edge-banding machine).

– Most orders ship within 24 hours. For help with sizes, backers, or special orders in the USA/Europe, call (855) 883-6337.

3 Common User Pain Points for ‘cherry edge banding’ & Their Solutions

3 Common User Pain Points for Cherry Edge Banding & Their Solutions

Scenario: A furniture manufacturer receives several batches of cherry edge banding that show noticeable color variation (pinkish to reddish tones), and finishing with a clear coat reveals blotchiness and mismatch against the face veneer.

Problem: Cherry is a pale pink wood that deepens to reddish-brown with age and exposure; clear coats intensify natural tone variation and can highlight color shifts between edge and face veneer.

Solution:

– Lock in color early: Apply a sealer or a light toner before the final clear coat to even out tone; then proceed with a clear topcoat that preserves warmth (e.g., CAB lacquer, catalyzed varnish, UV-curable clear).

– Align supply: Source edge banding and face veneer from the same production run/lot; retain “wood match notes” for future reorders.

– Finish planning: Use a clear finish system designed to maintain cherry’s warmth and reduce blotch; maintain consistent film build and cure conditions to avoid “Tiger-striping.”

Illustrative Image (Source: Google Search)

Scenario: A cabinet shop’s pre-glued cherry edge banding telegraphing, delaminates, or fails to adhere around radii and long runs; elsewhere, fleeceback banding needs an adhesive line that cures consistently at scale.

Problem: Pre-glued hot-melt adhesives require heat, pressure, and alignment control; fleeceback needs a compatible adhesive and adequate activation/pressure to avoid telegraphing and hollows.

Solution:

– Choose the right product: Pre-glued for smaller shops or flexible runs; fleeceback plus PVA or PUR in an edge bander for consistent, high-volume results.

– Optimize application: Pre-glued—heat the band and substrate (household iron or edge bander), maintain firm pressure with a pressure roller, and trim close; Fleeceback—apply adhesive per spec, activate, and feed through a calibrated bander with proper preheat/pressure rollers.

– Environmental control: Work within 60–80°F and 35–55% RH; acclimate material 24–48 hours.

Scenario: Edge seams are visible at joints, and the banding’s thickness creates a “shelf edge” feel after finishing.

Problem: The substrate edge, banding thickness, glue line, and finishing film all contribute to visual and tactile seams.

Solution:

– Edge prep: True and clean the substrate; avoid gaps or burn marks; ensure flatness to within ±0.003 in.

– Thickness and alignment: Select width to cover the substrate plus 0.015–0.03 in overhang; machine flush with a small “spring pass” to avoid removing too much at the corner; keep adhesive lines even.

– Seam strategy: Stagger seams off corners; use prepolished or fleeceback for smoother transitions; finish with films that flow and level well; consider flush-cutting and profile sanding for a crisp, continuous surface.

– If needed, source alternative widths via special order to match specific profiles.

Reference product specifications (WiseWood Veneer):

– Species: Cherry

– Widths: 7/8″, 1″, 1.5″, 2″

– Lengths: 50′, 250′, 500′

– Backers: Pre-Glued (hot melt adhesive), Fleeceback (no glue)

– Application: Pre-glued with household iron or edge banding machine; fleeceback with edge banding machine or glue application

– Finishing: Clear coats recommended to preserve warmth and beauty

– Notes: Special order smaller/larger widths and longer lengths; domestic orders typically ship within 24 hours (consult for international freight forwarding options)

– Contact: (855) 883-6337

Strategic Material Selection Guide for cherry edge banding

Strategic Material Selection Guide for Cherry Edge Banding

Purpose and scope

This guide helps USA and European B2B buyers select the correct cherry edge banding for casegoods, fixtures, and millwork. It focuses on backing/adhension options, widths and lengths, adhesives, finishes, and procurement logistics, using WiseWood Veneer product parameters as a reference baseline.

Illustrative Image (Source: Google Search)

Material fundamentals (American cherry)

- Species: Cherry wood veneer with a warm, pinkish–red tone that ages to a rich reddish brown.

- Finish recommendation: Clear coats that preserve the wood’s warmth and color; avoid opaque or ambering finishes that mask the natural tone.

- Behavior: Expect natural color maturation; consider stain control and finish schedule consistency in multi-piece assemblies.

Backing options and when to use them

Pre-glued (iron-on)

– Adhesive: Hot-melt (no separate glue required).

– Application: Household iron or edge banding machine.

– Best for: Small batches, prototyping, short-run shops, or field repair where separate glue application is impractical.

– Typical widths: 7/8″, 1″, 1.5″, 2″.

– Typical lengths: 50′, 250′, 500′.

– Notes: Suitable for applications where the lower heat and pressure of iron application still achieve acceptable bonding. May be more sensitive to substrate cleanliness and environmental humidity than contact adhesives.

Fleeceback (un-glued)

– Backing: Non-woven fleece.

– Adhesive: Requires separate application via edge banding machine or manual glue application (e.g., PVA, contact cement, hot-melt in roller/jet configuration).

– Best for: Higher-volume production, precise glue line control, and broader substrate/environment compatibility.

– Typical widths: 7/8″, 1″, 1.5″, 2″.

– Typical lengths: 50′, 250′, 500′.

– Notes: Offers flexibility in adhesive choice to meet production speed, bond strength, and compliance requirements.

“Clear” backer (as listed by WiseWood)

– WiseWood lists “Clear” as an available backer option alongside Pre-Glued and Fleeceback.

– Likely meaning: Transparent (PSA or paper) backing designed to minimize line visibility on lighter cherry tones.

– Best for: Thin profiles where backers or paper might telegraph through under clear finishes.

– Notes: Confirm backing type (PSA paper vs thin film) and adhesive chemistry (if present) with the supplier before committing.

Width selection

- Common widths from WiseWood: 7/8″, 1″, 1.5″, 2″.

- Choose based on panel thickness, edge exposure, and trimming approach:

- 7/8″: Sufficient for panels up to ~22 mm (7/8″) when exposed and trimmed flush, leaving small stock for final flush-trim and light sanding.

- 1″ to 1.5″: Recommended when deeper trimming or radiused edges are required; gives forgiveness for tolerance, micro-chamfers, and post-sanding.

- 2″: Use for thicker panels (>22 mm) or where double-pass trimming and chamfers are standard; minimizes offcut waste and exposure to voids at trim boundaries.

Length strategy

- WiseWood standard lengths: 50′, 250′, 500′.

- 50′: Ideal for low-volume, multi-species carts; reduces leftover scrap and simplifies SKU control.

- 250’–500′: Preferred for high-volume runs to minimize splices, changeovers, and roll changes; improves line stability and reduces splicing frequency on long runs.

- Procurement note: For non-standard widths or longer lengths, request special orders per vendor capability.

Adhesives and finishing implications

- Pre-glued (hot-melt): Lowest setup complexity; watch heat and pressure to avoid telegraphing or adhesive squeeze-out. Test on representative substrates to manage “burn-through” risk on thin veneers and minimize veneer scoring under flush-trim.

- Glue-applied fleeceback: Choose adhesives by performance and compliance:

- PVA/UF systems: Standard casegood bonds; ensure formaldehyde and VOC compliance for EU/USA environments (see regulatory notes below).

- Contact cement or hot-melt via rollers: Rapid set, suitable for continuous operation; verify long-term creep and heat resistance in end-use conditions.

- Finish systems: Clear, low-amber topcoats preserve cherry’s natural warmth. Coordinate stain/toner and topcoat chemistry to avoid compatibilty issues on pre-glued backs or any paper/PSA backer.

Production and QA considerations

- Grain orientation and book-matching: Ensure consistent grain direction for exposed edges to avoid visual jumps.

- Sanding and trimming: Leave material for a light final pass. For pre-glued, avoid excessive heat that can soften the adhesive too early; for glue-applied, ensure open time matches line speed.

- Humidity and storage: Acclimate veneer and substrate in the same environment. High humidity can affect pre-glued bond quality and cause edge lift over time; low humidity can increase brittleness.

- Quality checks:

- Bond integrity at trim points (no glue line telegraphing or ridging).

- Color consistency across rolls and batches; confirm source and slicing consistency (e.g., rotary vs sliced affects pattern).

- Backer visibility under clear finishes (especially with paper backers on light woods); consider “Clear” backers when it matters.

Regulatory and compliance (USA/EU)

- Formaldehyde emissions (e.g., CARB/TSCA Title VI and EU EN 13986/16572): If using added adhesives or substrate materials, confirm composite emissions compliance.

- REACH/SVHC and Proposition 65: Validate adhesive and backer chemistry with suppliers; avoid substances of concern in adhesive systems, especially for EU deliveries.

- VOC emissions and indoor air quality: If the end-use environment is sensitive (e.g., interior fit-outs with strict emissions targets), select low-VOC adhesives and clear coats.

Procurement and logistics

- Lead time: Most orders ship within 24 hours (WiseWood reference).

- Freight: For full rolls, request freight quotes for LTL; protect rolls from crushing and moisture with appropriate packaging.

- Special orders: For non-standard widths and longer lengths, contact the supplier to verify lead time and minimum quantities.

Key trade-offs summary

- Pre-glued vs fleeceback: Pre-glued simplifies setup and small-run agility; fleeceback enables industrial-grade glue lines, broader adhesive options, and higher throughput.

- Width safety margin vs waste: Wider rolls reduce trim risk on thick panels but add cost and handling bulk.

- Roll length vs inventory: Longer rolls reduce splices and improve line efficiency; shorter rolls reduce obsolescence and aid SKU flexibility.

Comparison table: Backer/Adhesive options and applications

| Option | Adhesive (as supplied) | Application method | Typical widths (WiseWood) | Typical lengths (WiseWood) | Best-fit applications | Pros | Cons/risks |

|---|---|---|---|---|---|---|---|

| Pre-glued | Hot-melt | Household iron or edge bander | 7/8″, 1″, 1.5″, 2″ | 50′, 250′, 500′ | Small batches, prototypes, field repairs | Fast setup, no separate glue | Heat sensitivity; bond dependent on surface prep |

| Fleeceback (un-glued) | None (requires glue) | Edge bander (roller glue) or manual glue | 7/8″, 1″, 1.5″, 2″ | 50′, 250′, 500′ | High-volume production; variable adhesives and line speeds | Adhesive flexibility; robust, repeatable glue lines | Requires glue equipment and setup time |

| “Clear” backer | Varies (confirm) | Depends on backer/adhesive type | 7/8″, 1″, 1.5″, 2″ | 50′, 250′, 500′ | Thin profiles; minimize backer visibility under clear coats | Reduced telegraphing on light cherry under clear finishes | Must confirm backing/adhesive chemistry and compliance |

Notes:

– “Clear” as a WiseWood-listed backer likely indicates a transparent backing; confirm whether PSA paper or film is used and whether adhesive is included.

– Confirm any specific certifications or compliance documents from the supplier for USA/EU markets.

Illustrative Image (Source: Google Search)

Sources:

– WiseWood Veneer product and learning center details for cherry edge banding specs (widths, lengths, backings, finishes) and service policies.

In-depth Look: Manufacturing Processes and Quality Assurance for cherry edge banding

In-depth Look: Manufacturing Processes and Quality Assurance for Cherry Edge Banding

This section outlines how cherry edge banding is produced and validated, emphasizing practical control points that matter in industrial woodworking, millwork, and cabinetry environments in the USA and Europe.

Manufacturing Process Overview

- Prep: Raw veneer sourcing, conditioning, and precision preparation

- Forming: Continuous sheet generation and width-forming

- Assembly: Backing application and finishing

- QC: Inspection, measurement, and certification

Step 1 — Prep

- Raw veneer sourcing:

- Flitches or rotary-peeled cherry veneer matched to target veneer grade (e.g., sapwood vs. heartwood characteristics).

- Species confirmation and initial visual grading; color normalization where required to maintain batch consistency over time.

- Moisture conditioning:

- Target veneer equilibrium moisture content (EMC) around 6–8%, controlled for storage and production environment.

- Ambient temperature and relative humidity (RH) management (e.g., conditioned storage at 18–22°C and 35–50% RH) to prevent pre-bond moisture issues.

- Veneer preparation:

- Optional scarfing to remove defects and control veneer runout.

- Dimensional trimming to standardized sheet widths/feed lengths for downstream slicing and splicing.

- Surface preparation for consistent glue coverage and bond integrity.

Step 2 — Forming

- Continuous sheet generation:

- Rotary slicing for continuous veneer ribbon; planed to precise thickness tolerance with uniformity across the roll.

- Edge preparation for assembly:

- Splicing:

- Scarf jointing at controlled angles (typical range 10–20°) with uniform pressure to minimize kerf gap.

- Butt joining used where appropriate; managed for joint integrity under heat and pressure.

- Width trimming and roll conversion:

- Precision slitting to final roll widths (e.g., 7/8″, 1″, 1.5″, 2″).

- Roll winding with tension control and core alignment for stable dispensing.

- Backer application:

- Pre-glued (hot-melt adhesive), fleeceback (unbacked) options; adhesive line quality and uniformity verified.

Step 3 — Assembly

- Adhesive application:

- Pre-glued rolls: hot-melt adhesive applied uniformly; no secondary adhesives required in application.

- Fleeceback rolls: require an edge banding machine or separate glue application (e.g., PVA, EVA) to achieve adhesion.

- Lamination and roll finishing:

- Press lamination parameters tuned to heat (temperature at bondline), pressure, and line speed to balance activation and strength.

- Cooling and take-up to preserve bond quality and dimensional stability.

- Final winding and packaging:

- Clean winding with consistent diameter; protective packaging to prevent edge damage and moisture ingress during transit.

Step 4 — Quality Control (QC)

- Incoming veneer:

- Species, grade, and batch traceability documented; visual defect checks and color/sap/heartwood notes recorded.

- Thickness and width:

- Precision measurements at multiple points; thickness tolerance maintained for consistent application performance.

- Splice quality:

- Visual inspection of joint line uniformity and continuity; no voids, gaps, or excessive glue squeeze-out.

- Adhesive performance:

- Visual consistency of glue lines; activation tests (pre-glued) confirming activation under recommended iron/machine settings.

- Moisture content:

- Target 6–8% EMC; checks before and after assembly to detect moisture-driven defects.

- Roll integrity:

- Straight-line winding with no telescoping; dimensional stability verified through roll sampling.

- Packaging and labeling:

- Width, length, backer type, lot code, and species clearly marked; handling and storage instructions provided.

Quality Standards and Compliance

Manufacturing typically operates under ISO 9001 (Quality Management Systems) to support consistent processes and continuous improvement. QC programs align to ISO 19011 (guidelines for auditing management systems) and may incorporate ISO 14001 (environmental management) for sustainability. Industry acceptance and evaluation often reference:

– ASTM for adhesives and bond performance (commonly referenced across North American woodworking operations).

– ISO norms and EOTA standards in Europe for adhesives, safety, and durability assessment in veneer bonding contexts.

– Customer specifications and testing acceptance criteria, including visual grade compliance.

Note: Product-specific ISO standards for wood veneer edge banding are not universally published; suppliers’ certifications typically cite ISO 9001 as the operative management framework, with test acceptance criteria defined by customer requirements and applicable industrial standards.

Illustrative Image (Source: Google Search)

Typical Form Factors and Adhesive Backings

- Widths:

- 7/8″

- 1″

- 1.5″

- 2″

- Lengths:

- 50′, 250′, 500′

- Backing options:

- Pre-glued (hot-melt adhesive)

- Fleeceback (unbacked)

- Application notes:

- Pre-glued: suitable for iron or edge banding machine application.

- Fleeceback: requires an edge banding machine or separate glue application.

Why it matters

- Consistency: Tight control of moisture, thickness, splice quality, and winding ensures uniform application across large production runs.

- Adhesive flexibility: Choosing pre-glued versus fleeceback dictates activation methods and line setup; matching backer to the application reduces defects and rework.

- Compliance and traceability: ISO 9001-backed QMS and documented batch records support audits, customer requirements, and international shipments to USA and Europe.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cherry edge banding’

Practical Sourcing Guide: A Step-by-Step Checklist for Cherry Edge Banding

Use this checklist to source WiseWood Veneer’s cherry edge banding efficiently for USA and Europe. All specifications below reflect WiseWood’s current offering as of 2025; confirm live pricing and inventory before purchase.

Step 1: Define application and finish intent

- End use: cabinetry, casework, fixtures, retail displays, millwork.

- Finish intent: clear coat that preserves cherry’s warmth and deepening reddish-brown hue as it ages.

- Surface prep: specify a clear topcoat compatible with wood veneer (e.g., lacquer, polyurethane, catalyzed finishes); confirm vendor’s finish compatibility guidance.

Step 2: Select core product parameters

- Species: cherry wood veneer.

- Backing type:

- Pre-glued (iron‑on): hot‑melt adhesive. Apply with household iron or edge bander.

- Fleeceback (unfinished): no glue; requires edge banding machine or separate adhesive.

- Color/tone: warm pinkish–red aging to reddish‑brown.

- Blemish: specify consistent face quality, matching to other cherry components.

Step 3: Specify sizes and lengths (packaging-friendly)

WiseWood offers the roll configurations below. Choose widths based on your substrate thickness and edge overhang requirements; coordinate lengths with your coil handling equipment.

| Width options | Length options | Backing options | Application notes |

|---|---|---|---|

| 7/8″ (22.2 mm) | 50′, 250′, 500′ | Pre-glued, Fleeceback | Pre-glued: iron or edge bander; Fleeceback: machine/glue required |

| 1″ (25.4 mm) | 250′, 500′ | Pre-glued, Fleeceback | As above |

| 1.5″ (38.1 mm) | 250′, 500′ | Pre-glued, Fleeceback | As above |

| 2″ (50.8 mm) | 250′, 500′ | Pre-glued, Fleeceback | As above |

Notes:

– Width selection: confirm oversize tolerance needed for trimming (e.g., 1/16″–1/8″ typical) and specify grain orientation (edge grain vs. face match).

– Coil length: select 250′ or 500′ to match machine feeder capacity; 50′ suits bench/handwork and small runs.

Step 4: Confirm adhesive and application method

- Pre-glued (iron‑on): hot‑melt adhesive; can be applied with household iron or edge banding machine.

- Fleeceback: requires an edge banding machine or a separate adhesive system; no factory glue.

Step 5: Confirm pricing and MOQ

- SKU: not specified by vendor; order by species, width, length, and backing.

- Minimum order quantity: not stated; standard purchase by roll. Confirm per width/length if mixing SKUs.

| Backing | Typical roll size | Starting price (USD) | Price example |

|---|---|---|---|

| Pre-glued | 7/8″ × 250′ | From $12.95 (various widths/lengths; select options) | 7/8″ × 250′: $29.50 (sale) |

| Fleeceback | 7/8″ × 250′ | From $12.95 (various widths/lengths; select options) | Contact for live quote |

Pricing is width- and length-dependent; verify your exact configuration before quoting.

Illustrative Image (Source: Google Search)

Step 6: Verify inventory and lead time

- Most orders ship within 24 hours (vendor-stated).

- Confirm availability across widths/lengths; special-order smaller or larger widths and longer lengths via phone.

Step 7: Finalize order details and logistics

- Include the following on your PO:

- Species and product: cherry edge banding

- Width, length, backing, quantity (rolls)

- Desired clear finish system (if vendor offers guidance)

- Shipping address (and any carrier preferences)

- Request order acknowledgment with shipping confirmation and pro forma (if needed).

Step 8: Confirm shipping options (USA and International)

Vendor shipping details:

– Most orders ship within 24 hours.

– International ordering options include freight forwarding. Intended audiences:

– USA and Europe.

For international shipments, confirm:

– Freight forwarder details and responsibilities

– Export documentation and HS code guidance (if offered)

– Shipping limitations and any customs documentation required

– Freight cost, insurance, Incoterms, and delivery window

Step 9: Handle and install

- Storage: keep rolls flat, dry, and dust-free; acclimate near work environment before use.

- Application:

- Pre-glued: use household iron on appropriate temperature or an edge bander; press and trim cleanly.

- Fleeceback: apply with an edge bander and a compatible adhesive; trim and finish.

- Safety: follow safety data sheets and finish-specific handling instructions; ensure adequate ventilation for adhesives and coatings.

Step 10: Post-delivery QA and documentation

- Verify widths, lengths, and backing on each roll; inspect for visual defects.

- Confirm runout length and continuity; document installation notes (trim, adhesive, finish).

- Record compliance documents (SDS, if provided) and supplier paperwork in your quality file.

Vendor quick-reference

- Company: WiseWood Veneer

- Phone (USA): (855) 883‑6337

- Address: 415 Elmwood Dr., Troy, Michigan 48083

- Note: If you need a specific species, size, or backing not listed, call to discuss special orders.

- Availability is subject to change; confirm all specs, lead times, and live pricing before purchase.

Comprehensive Cost and Pricing Analysis for cherry edge banding Sourcing

Comprehensive Cost and Pricing Analysis for Cherry Edge Banding Sourcing

Purpose: Provide a clear, repeatable framework to calculate per-linear-meter landed cost for cherry edge banding in the USA and Europe, using WiseWood Veneer as the reference supplier. The analysis splits costs into Materials, Labor, and Logistics, and gives actionable tips to optimize total cost of ownership.

Notes:

– Prices and lead times vary by width, length, backer option, and volume. Reference price used for demonstration: $29.50 for 7/8″ x 250′ (76.2 m) pre-glued (iron-on) cherry edge banding. Example material cost per meter is calculated from that roll.

– Freight rates are indicative; you should verify current quotes and any minimums.

Illustrative Image (Source: Google Search)

1) Pricing model and formulas

Total landed cost (TLC) per meter:

TLC = Material + Labor + Logistics + (Freight + Duties + VAT) where applicable

Material cost per meter:

Material per m = Material price per roll / Length(m)

Key roll conversions used:

– 1 foot = 0.3048 m

– 250′ = 76.2 m

Reference roll (WiseWood Veneer):

– SKU example: 7/8″ x 250′ pre-glued

– Material price per roll = $29.50

– Material per meter (from this SKU) = $29.50 / 76.2 m ≈ $0.387 per m

Illustrative Image (Source: Google Search)

2) Labor cost (typical industry scenarios)

| Backer type | Typical machine speed | Typical operator cost/hour | Estimated operator cost per meter (USD) | Comment |

|---|---|---|---|---|

| Pre-glued (iron-on/manual) | 12 m/min | $25/h | $2.08 | Faster for small runs; heat control is critical |

| Fleeceback (machine/ glue required) | 30 m/min | $25/h | $0.83 | Lower unit cost at scale; equipment and glue needed |

| Fleeceback (same costs in Europe) | 30 m/min | €25/h | €2.08 (or ≈ $2.25) | Operator rates vary by country |

- Pre-glued: $25 ÷ 12 m/min = $2.083/m

- Fleeceback (machine): $25 ÷ 30 m/min = $0.833/m

3) Logistics and landed cost scenarios (using $29.50 per 7/8″ x 250′ roll)

Assume one full 76.2 m roll.

Scenario A: USA (ground freight, no VAT)

| Cost component | Rate/value | Calculation | Cost |

|---|---|---|---|

| Material | Per roll | $29.50 | $29.50 |

| Labor (pre-glued) | $2.083/m x 76.2 m | 2.083 × 76.2 | $158.73 |

| Labor (fleeceback) | $0.833/m x 76.2 m | 0.833 × 76.2 | $63.50 |

| Freight (pallet) | Indicative | $150.00 | |

| Insurance (0.5%) | On goods + freight | 0.005 × ($29.50 + $150) | $0.90 |

| Total landed (pre-glued) | — | 29.50 + 158.73 + 150 + 0.90 | $339.13 |

| Total landed (fleeceback) | — | 29.50 + 63.50 + 150 + 0.90 | $243.90 |

Per meter in USA (76.2 m roll):

– Pre-glued: $339.13 / 76.2 ≈ $4.45 per m

– Fleeceback: $243.90 / 76.2 ≈ $3.20 per m

Scenario B: Europe — road freight, 15% duty, 21% VAT

| Cost component | Rate/value | Calculation | Cost |

|---|---|---|---|

| Material | Per roll | $29.50 | $29.50 |

| Labor (fleeceback) | €25/h (approx. $27.12/h) × 76.2 m | 27.12 ÷ 30 × 76.2 | $68.84 |

| Freight (pallet) | Indicative | $250.00 | |

| Duty | 15% on CIF | 0.15 × ($29.50 + $250) | $41.93 |

| VAT | 21% on Duty + Freight | 0.21 × $291.93 | $61.31 |

| Total landed (fleet mkt with glue) | — | 29.50 + 68.84 + 250 + 41.93 + 61.31 | $451.58 |

| Total landed per meter | — | $451.58 / 76.2 | ≈ $5.93 per m |

Scenario C: Europe — road freight, 4% duty, 21% VAT (lower duty alternative)

| Cost component | Rate/value | Calculation | Cost |

|---|---|---|---|

| Material | Per roll | $29.50 | $29.50 |

| Labor (fleeceback) | $27.12/h × 76.2 m | as above | $68.84 |

| Freight (pallet) | Indicative | $250.00 | |

| Duty | 4% on CIF | 0.04 × $279.50 | $11.18 |

| VAT | 21% on Duty + Freight | 0.21 × $261.18 | $54.85 |

| Total landed | — | 29.50 + 68.84 + 250 + 11.18 + 54.85 | $414.37 |

| Per meter | — | $414.37 / 76.2 | ≈ $5.44 per m |

Key insight: EU landed cost is materially higher than USA due to freight, import duty/VAT, and potential brokerage fees. Duty rates differ by HS code and region; validate your code with customs before committing volumes.

4) Unit cost comparison (7/8″ x 250′, $29.50 roll)

| Region | Backer | Material/m | Labor/m | Logistics (roll amortized) | Total/m |

|---|---|---|---|---|---|

| USA | Pre-glued | $0.39 | $2.08 | $2.32 | $4.79 |

| USA | Fleeceback | $0.39 | $0.83 | $2.32 | $3.54 |

| EU (15% duty) | Fleeceback | $0.39 | $0.90 | $4.64 | $5.93 |

| EU (4% duty) | Fleeceback | $0.39 | $0.90 | $4.15 | $5.44 |

Notes:

– EU “Labor/m” reflects an assumed €25/h operator rate; $27.12/h is a proxy. Operator rates vary by country.

– “Logistics” includes freight, duty (EU), and VAT (EU), amortized over a single roll. These are indicative; verify quotes.

– Using pre-glued in EU and iron-on will generally deliver lower total/m than fleeceback due to faster installation speed.

5) How different widths/lengths change unit pricing (from WiseWood)

Using WiseWood’s pricing for the 7/8″ x 250′ SKU ($29.50) and the published “Starting at $12.95” (for shorter/smaller rolls), we can illustrate volume effects on material cost per meter:

Illustrative Image (Source: Google Search)

| Roll configuration | Price shown | Length (m) | Material/m |

|---|---|---|---|

| 7/8″ x 250′ | $29.50 | 76.2 | $0.39 |

| 7/8″ x 500′ | Indicative 2×250′ | 152.4 | ≈ $0.39 |

| Example: smaller roll | $12.95 | 15.24 | ≈ $0.85 |

- Wider widths typically cost more per roll (but often reduce waste in thicker profiles). The same price pattern holds across 1″, 1.5″, and 2″ widths from WiseWood.

- The “Starting at $12.95” likely applies to the 7/8″ x 50′ roll; actual price depends on backer and options. If your unit requires that smaller format, consider its impact on unit cost per meter.

6) Practical cost-saving tips

- Buy longer rolls: Use 250’–500′ to lower material/m and reduce splicing/overlap waste. Confirm lead time (WiseWood: most orders ship within 24 hours).

- Match backer to process:

- Pre-glued (iron-on) for small runs or low capex.

- Fleeceback + machine for high-volume lines to cut labor cost to ~1/3 per m.

- Optimize edge preparation: Reduce chipout and ensure a clean, dry substrate; avoid rework.

- Batch shipments: Consolidate pallets to hit LTL minimums and spread freight over more linear meters.

- Specify freight-forwarded US shipments: Align Incoterms (e.g., DAP or EXW) with your logistics team to minimize surprise charges.

- Use in-line inspection: Catch adhesion issues early; fewer defects = lower rework cost.

- Negotiate duty/VAT: Validate HS code and country-of-origin to avoid higher duty bands.

- Order for standard widths: WiseWood lists 7/8″, 1″, 1.5″, and 2″; staying within standard sizes reduces premium pricing.

- Control adhesive: If using fleeceback, choose a reliable, consistent glue and calibrate spread rates to avoid waste.

- Right-size the roll: If your annual usage is fixed, select roll lengths that minimize dead stock while still gaining unit cost from volume.

7) Quick reference formulas

- Material per m = Roll price ÷ Roll length(m)

- TLC per m = Material/m + Labor/m + Logistics/m

- EU VAT (simplified): VAT on (Freight + Material + Duty)

- EU Duty: Duty rate × (Material + Freight) [insurance usually small; can be omitted for planning]

If you need country-specific customs brokerage fees or exact pallet freight quotes to your facility, please provide the destination ZIP/postal code and approximate order frequency. That will refine the “Logistics/m” column for your operation.

Alternatives Analysis: Comparing cherry edge banding With Other Solutions

Alternatives Analysis: Comparing Cherry Edge Banding with Other Solutions

For B2B buyers and fabricators in cabinetry, fixtures, and furniture manufacturing, cherry edge banding sits in a sweet spot of premium aesthetics, repairability, and cost control relative to solid wood. The two most common alternatives are PVC edge banding and solid wood edge strips.

To illustrate practical differences, Table 1 compares the three options across the decision criteria procurement teams care about most.

Table 1. Comparative matrix: cherry edge banding vs. PVC vs. solid wood edge

Illustrative Image (Source: Google Search)

| Attribute | Cherry Edge Banding (Veneer) | PVC Edge Banding | Solid Wood Edge Strip |

|---|---|---|---|

| Aesthetic match to panel face | Excellent grain and color continuity; ages to reddish brown with clear coats; can be pre-finished or finished on site | Consistent color; limited texture match; may not match premium face veneers without special sourcing | Excellent grain and color continuity; true solid wood appearance |

| Cost (materials) | Mid–lower than solid wood | Lowest | Highest (material plus machining) |

| Adhesive options | Pre-glued (hot melt; iron-on) or fleeceback (requires machine or separate glue) | Pre-glued (iron-on) common for PVC; fleeceback/loose requires PUR/HotMelt machine | Unglued; apply PUR/HotMelt or urea; sanding/caul may be needed |

| Application complexity | Simple with pre-glued/iron; fleeceback needs edgebander | Pre-glued iron-on is straightforward; machine application for PUR/higher volume | Requires additional shaping/planing; careful glue-up and clamping; higher skill |

| Finish requirements | Clear coat or lacquer recommended to preserve warmth; can be repaired/re-sanded | Typically uses factory pre-finished PVC; in-shop finishing for uncoated PVC is limited | Sand and finish in-house; best for durability when shop-finished |

| Repairability | Sandable/refinishable; small damages can be touched up | Limited—damage often requires replacement; scratches may be noticeable | Excellent—can be repaired, patched, and refinished |

| Thickness options (typical) | ~0.020″–0.024″; widths commonly 7/8″, 1″, 1.5″, 2″ (e.g., WiseWood rolls) | ~0.5 mm–3 mm; widths 19 mm–35 mm typical; lengths up to hundreds of feet | Typical nominal 1/16″–1/8″; widths matched to panel thickness and application |

| Durability/impact | Good with clear coats; susceptible to moisture without proper sealing | Good chemical/moisture resistance; impact resistance depends on thickness and quality | Excellent; highest mechanical robustness; may crack/check if finish/assembly not ideal |

| UV/aging | Darkens to deeper reddish brown; clear coat protection recommended | Color stable; may chalk or fade on very long exposure | Ages to deeper tone; can check or split without correct moisture control |

| Moisture resistance | Good with sealed finish; not waterproof | Excellent; suitable for high-humidity applications | Varies; can be excellent with proper sealing and construction |

| Fire rating | Standard wood veneer (composite fire options available via special order) | Typically unspecified; some grades offer FR options | Standard solid wood; FR depends on finish system |

| Environmental | Real wood veneer (renewable, lower material volume than solid) | Oil-derived PVC; options include recycled content | Solid wood—highest material intensity |

| Waste vs. scrap | Light, flexible, low-waste rolls | Light, low-waste rolls; disposal of PVC | More scrap from machining and offcuts |

| Tooling & maintenance | Iron for pre-glued or edgebander for fleeceback; no specialty tools beyond trimming blades | Iron for pre-glued; edgebander recommended for volume/PUR; standard trimmers | Router planer/triple-beam/trimmers; more tooling wear and setup time |

Notes:

– Cherry edge banding thicknesses are commonly specified in decimals rather than “thousandths,” and widths include 7/8″, 1″, 1.5″, and 2″ (WiseWood offers 50/250/500 ft. rolls). Pre-glued options use a hot melt adhesive and can be applied with a household iron or edgebander; fleeceback requires machine application or external glue.

– PVC pre-glued iron-on options are widely used, but for higher-duty bonding and long-term moisture resistance, machine-applied PUR or hot-melt adhesives are preferred.

– Solid wood edge strips are strongest and most repairable but are generally more expensive and labor-intensive to install and finish.

Cherry Edge Banding (Veneer)

- Strengths: Real-wood appearance and tactile quality; straightforward pre-glued iron-on workflow; flexible and low-waste; readily repairable and refinishable.

- Weaknesses: Requires proper sealing for moisture resistance; pre-glued hot-melt bonds can fail under sustained heat or moisture without a suitable finish; not inherently waterproof.

- Best for: High-end cabinets, casework, hospitality and retail fixtures where wood aesthetics and refinishing options matter.

PVC Edge Banding

- Strengths: Lowest material cost; excellent moisture and chemical resistance; widely available in pre-glued iron-on formats; color consistency for branded or price-sensitive programs.

- Weaknesses: Limited tactile/visual match to premium wood faces; repairability is lower (damage often requires replacement); less “premium” feel versus real wood.

- Best for: Budget-focused jobs, institutional and high-humidity environments, and high-volume production with iron-on application.

Solid Wood Edge Strips

- Strengths: Maximum mechanical robustness and the most authentic solid wood look; excellent repairability and long-term maintenance options.

- Weaknesses: Higher material cost and machining complexity; requires careful glue-up, clamping, and finishing; more prone to movement if not properly sealed and assembled.

- Best for: Premium, heirloom-quality pieces, lab/furniture-grade installations, or where the strongest edge resilience is required.

Key Takeaways

- Choose PVC edge banding when moisture resistance and cost dominate; it’s fast to install with iron-on formats and easy to source.

- Choose solid wood edge when durability and repairability are paramount and budget/tolerances allow for higher labor and material expense.

- Choose cherry edge banding to balance premium aesthetics, repairability, and workflow efficiency—particularly when you need real wood appearance with simple, pre-glued installation or a fleeceback option for machine application.

Essential Technical Properties and Trade Terminology for cherry edge banding

Essential Technical Properties and Trade Terminology for Cherry Edge Banding

1) Material characteristics

- Species: American black cherry (Prunus serotina) wood veneer.

- Visual: Warm pinkish to reddish tones; ages to a deeper reddish-brown. Best finished with a clear coat to preserve warmth and grain clarity.

- Thickness profile: Typical wood veneer thickness approximately 0.6 mm (0.024″). The banding is supplied as a continuous roll; nominal width defines the exposed band.

- Stability: As a wood veneer-based banding, expect dimensional movement with humidity changes. Acclimatize banding and components to ambient shop conditions before application.

2) Dimensions and packaging

- Widths (imperial and nearest metric): 7/8″ (~22 mm), 1″ (~25 mm), 1.5″ (~38 mm), 2″ (~51 mm).

- Roll lengths: 50′, 250′, and 500′.

- Packaging: Roll form. Standard sizes typically ship within 24 hours; non-standard sizes may require lead time.

Width × Length matrix (standard combinations)

| Width | 50′ | 250′ | 500′ |

|—|—:|—:|—:|

| 7/8″ | Available | Available | Available |

| 1″ | Available | Available | Available |

| 1.5″ | Available | Available | Available |

| 2″ | Available | Available | Available |

Metric quick reference

| Width (imperial) | Approx. metric (mm) | Nominal coverage against nominal substrate (mm) |

|—|—:|—:|

| 7/8″ | 22 | Suitable for 18–19 mm shelves/panels; trim to 20–22 mm as required |

| 1″ | 25 | Suitable for 20–22 mm; common for 25 mm (1″) panels |

| 1.5″ | 38 | Suitable for 32–38 mm surfaces; trim to final flush |

| 2″ | 51 | Suitable for thicker panels and flush-trim to required width |

Note: Width selection is typically panel thickness plus trimming allowance. Confirm exact target dimensions with your substrate’s finished thickness and trimming strategy.

Illustrative Image (Source: Google Search)

3) Backing options and adhesives

- Pre-Glued (iron‑on):

- Adhesive: Hot-melt; applied with household iron or an edge banding machine.

- Application: Speed and temperature vary by iron/machine and shop conditions. Verify activation temperature and set‑time with the supplier if critical.

- Fleeceback (unbacked, requiring adhesive):

- Backing: Non-woven fleece/balance veneer without pre-applied adhesive.

- Application: Requires an edge banding machine or a separate adhesive application method; compatible with common edgebanding adhesives (e.g., EVA/PUR/HM as applicable per machine).

- Finish:

- Clear finish recommended to preserve cherry’s tone and grain.

- Some suppliers may offer “clear” listings; confirm finish type and whether it is a surface coating on the band or a listing designation.

Backing comparison

| Backing type | Adhesive | Application method | Typical use case | Notes |

|—|—|—|—|—|

| Pre-Glued (iron‑on) | Hot-melt | Household iron or edge banding machine | Low‑volume shops, prototyping, fixtures | Fast setup; limited bond line control vs. machine glues |

| Fleeceback | None pre‑applied | Edge banding machine with separate adhesive | Production runs, cabinets, casegoods | Requires glue applicator and cure/press cycle; stronger line control |

| Clear (finish) | N/A | Finish after application | Protect color and grain | Confirm whether “clear” refers to surface finish or a listing |

Bonding note: Hot‑melt performance depends on substrate cleanliness, contact pressure, and activation temperature. When PUR/EVA adhesives are used with fleeceback, confirm substrate suitability (e.g., MDF vs. veneer core), moisture limits, and machine settings per the adhesive manufacturer’s datasheet.

4) Trade terminology and commercial notes

- MOQ (Minimum Order Quantity): Varies by item. Pre-glued standard sizes often have lower MOQs; fleeceback and non-standard widths/lengths may require higher MOQs or lead time.

- Lead time: Standard sizes typically ship within 24 hours. Special/non-standard sizes generally ship later—confirm at order.

- OEM/custom: Call supplier for non-standard widths, longer lengths, or specialty backers. Some suppliers offer special order service on request.

- Payment methods: As listed—major credit cards accepted (Visa, Mastercard, Discover, American Express). For B2B accounts, inquire about net terms.

- Returns/exchanges: Return policies apply; consult the vendor’s return information and confirm quality on receipt prior to production.

- Sample policy: Samples often available; request “representative color” samples for close-match approvals when appearance is critical.

- International orders: Some vendors support international shipments and freight forwarding; confirm destination restrictions and cost before ordering.

5) Application guidance

- Substrate: Ensure the panel edge is square, clean, and free of dust/oil for optimal adhesion.

- Acclimatization: Condition rolls and panels at shop ambient conditions prior to application to minimize expansion/contraction.

- Trimming: Leave a small overhang; flush trim with a router (downcut/flush trim bit) and finish with fine sanding for a clean line.

- Finishing: Use compatible clear finishes; test for color and compatibility (finish raise‑grain, glue squeeze‑out visibility).

- Quality control: Establish acceptance criteria for color/grain consistency, glue line integrity, trimming accuracy, and visible defects.

Acronym reference

– MOQ: Minimum Order Quantity

– OEM: Original Equipment Manufacturer

– SKU: Stock Keeping Unit

– HS: Harmonized System (tariff code)

– SDS: Safety Data Sheet

– MSDS: Material Safety Data Sheet (legacy)

6) Shipping and logistics (USA, Europe)

- USA: Standard sizes usually ship within 24 hours; freight for larger coils/pallets may apply.

- International/Europe: Some suppliers offer international ordering, freight forwarding, and shipping limitations; confirm export packaging, insurance, and duties/DDP/DDU terms.

Shipping matrix

| Region | Typical method | Standard sizes lead time | Non‑standard lead time | Notes |

|—|—|—:|—:|—|

| USA | Parcel for small rolls; LTL/TL for bulk | Ship within 24h | Longer; confirm at order | Freight charges may apply |

| Europe | International freight (air/sea as arranged) | Confirm with supplier | Longer; confirm with supplier | Freight forwarding and limitations vary |

Illustrative Image (Source: Google Search)

7) Standards and compliance

- Species identification: Verify botanical name (Prunus serotina) if species declaration is required for procurement or compliance.

- Safety: Obtain adhesive and veneer Safety Data Sheets (SDS/MSDS) for shop handling and regulatory compliance.

- Finish emissions: For low‑VOC shop protocols, select finishes and adhesives meeting your project’s emission targets; verify product compliance documents.

8) Notes and cautions

- Shade variation: Cherry veneer exhibits natural color/grain variation; request “match” or “blend” preferences in writing for production runs.

- Adhesive temperatures: Pre‑glued hot‑melt activation is iron/machine dependent. Confirm vendor‑specific parameters if bond strength and set time are critical to your process.

- Dimensional change: Account for wood movement in solid or MDF substrates; proper acclimation and finish sealing reduce risk of edge checks and adhesive failure.

Navigating Market Dynamics and Sourcing Trends in the cherry edge banding Sector

Navigating Market Dynamics and Sourcing Trends in the Cherry Edge Banding Sector

Cherry edge banding continues to be a core finishing choice in premium cabinetry and furniture lines across the USA, where warm-toned species with grain realism remain closely aligned with North American styling and material preferences. In Europe, usage is more targeted and specification-led: the product is often sourced when a client brief calls for cherry’s specific tone, or when a North American brand expands to Europe and carries its material identity.

Demand drivers and regional nuance

- USA: Stable demand from residential and hospitality cabinets, built-ins, and high-end home office built-ins. Buyers prioritize realistic grain, color consistency across widths and reels, and quick fulfillment. Cherry’s warm pink-to-red tones that deepen to reddish-brown align with mainstream finishes and clear coats designed to preserve wood warmth.

- Europe: Demand appears as project-driven imports for brand continuity and specialty lines. Procurement teams value consistent reels, matching widths, and predictable logistics through EU-aligned channels and documentation. Clear-coat finishes remain preferred for aesthetic fidelity and serviceability on site.

Sustainability and compliance expectations

– Veneer-based edge banding supports efficient yield compared to solid cherry, enabling premium aesthetics with less raw material impact. Buyers can reduce waste through tight width scheduling, accurate reel planning, and pre-glued vs fleeceback adhesive strategies that minimize rework.

– Common EU requirements are increasingly expected in this supply chain: FSC or PEFC chain-of-custody, REACH compliance for adhesives and finishes, and VOC considerations for indoor air quality (E1 formaldehyde emission class). While the product is a finishing accessory, buyers in both regions are requesting documentation to support project certifications and end-customer transparency.

Sourcing options and trade-offs

Regional buyers typically weigh two primary sourcing routes. North American brands often import from USA-based suppliers for brand continuity and speed, whereas European buyers source via USA-to-EU import, or from EU-based distributors where available. Lead time, width and length availability, and documentation quality are the differentiators.

To illustrate key factors, the following table outlines source-region considerations and typical trade-offs:

| Source region | Strengths | Considerations |

|---|---|---|

| USA-based supplier | Fast USA shipping; full widths and lengths; experienced with brand continuity for US brands | Import documentation and duties for EU buyers; alignment with EU VOC/formaldehyde expectations needed |

| EU-based distributor | Local warehousing, documentation support, and reduced customs friction | Availability of cherry-specific widths/lengths may vary; lead times dependent on distributor stock and backorders |

For adhesives and backer types, buyers can optimize the application method to match equipment, throughput, and site conditions. The comparison below reflects common trade-offs in production and on-site installation:

| Adhesive/backer type | Best for | Finish compatibility | Notes |

|---|---|---|---|

| Pre-glued (hot-melt; iron-on) | Small-batch shops, field repair, rapid prototyping | Works well with clear coats that preserve warmth | Applied with household iron or edge banding machine; check glue cleanliness and bond temperature consistency |

| Fleeceback (un-glued; requires adhesive) | High-throughput lines and stable shop conditions | Ideal with clear coats designed for consistent bonding and heat response | Requires an edge banding machine or separate glue application; improves adhesion and handling for larger runs |

Width and length scheduling

Standard widths—7/8″, 1″, 1.5″, 2″—cover most panel thicknesses and reveal requirements in premium lines, with standard lengths in 50′, 250′, and 500′ rolls supporting both small-batch and continuous production. Pre-glued reels can be ordered to reduce setup times and accelerate delivery for pilot runs or on-site work. Fleeceback reels favor long runs and controlled shop environments where adhesive application can be standardized.

Practical sourcing strategies

– Match application to adhesive type to minimize rework and callbacks; use pre-glued for agility and fleeceback for long runs with machinery.

– Centralize reel widths across product lines to reduce changeovers; maintain on-hand reels in the most common widths to support finishing schedules.

– Align finishes to preserve cherry’s color fidelity; choose clear coats that enhance the natural tone shift from pinkish to reddish brown without clouding the grain.

– For EU projects, request chain-of-custody certificates (FSC/PEFC) and documentation supporting VOC/formaldehyde requirements (e.g., REACH, E1 classification) before finalizing purchase orders.

Availability and fulfillment signals from reputable suppliers

– USA suppliers typically offer quick shipping—often within 24 hours for stocked SKUs—and custom width/length requests. For example, WiseWood Veneer lists cherry edge banding across widths from 7/8″ to 2″ and lengths of 50′, 250′, and 500′, in both pre-glued and fleeceback options.

– Pricing and inventory vary: a representative SKU, 7/8″ x 250′ pre-glued, has been promoted with a sale price point of $29.50, reflecting promotional pricing on a standard reel. Confirm current pricing and delivery lead times prior to ordering, especially for long lengths and bulk quantities.

Illustrative Image (Source: Google Search)

Quality controls that reduce risk

– Grain and color consistency across reels and widths to minimize visible transitions in long runs.

– Clean adhesive application and controlled melt temperature for pre-glued edge banding; reliable bonding and consistent thickness for fleeceback applications.

– Straightness and roll integrity to avoid edge splitting, telegraphing, or misfeed issues in machines.

Looking ahead

Macro trends—sustainable product policies, traceability, and documentation—continue to push buyers to specify veneer-based solutions with verifiable chain-of-custody and compliance support. At the same time, operational realities—short lead times, consistent widths and lengths, and reliable adhesive performance—remain decisive for procurement and production managers. Aligning sourcing strategy with the adhesive choice, documentation needs, and regional logistics keeps cherry edge banding a dependable, premium finishing choice in both USA and Europe.

Frequently Asked Questions (FAQs) for B2B Buyers of cherry edge banding

Frequently Asked Questions (FAQs) for B2B Buyers of Cherry Edge Banding

1) What widths, lengths, and backings are available?

- Widths: 7/8″, 1″, 1-1/2″, and 2″

- Lengths: 50′, 250′, 500′

- Backings: pre-glued (hot-melt, iron‑on) and fleeceback (no glue; requires glue or edge banding machine)

- Notes:

- Common roll configuration is 7/8″ x 250′.

- Fleeceback rolls are typically offered in 250′ and 500′ lengths (confirm at order).

- Non‑standard sizes can be special-ordered.

2) Which backing option suits our application and bonding method?

- Pre-glued (iron-on, hot-melt):

- Best for low‑volume, repair, or shop use.

- Apply with a household iron or edge banding machine; pressure, temperature, and feed speed determine bond quality.

- Heat activation required; test parameters on scrap panels.

- Fleeceback (no glue applied):

- Best for production setups with edge banding machines or when using specific PVA/HotMelt systems.

- Requires glue application; control glue film weight and cure to avoid telegraphing or telegraphing through.

- In both cases: pre‑finish and climate conditioning of panels help ensure quality.

3) How should we finish cherry edge banding?

- Finish recommendation: clear coat that preserves warmth and beauty.

- Color behavior: warm pinkish to red tones age to reddish-brown; verify final tone against finished panels.

- Light color shift is typical with clear finishes; test finishing steps on scrap samples before production runs.

4) What are the standard lead times and shipping terms?

- Most orders ship within 24 hours.

- Contact the supplier before purchase for specific lead times on custom sizes.

- Location: Troy, Michigan, USA (FOB point; freight quotes available on request).

5) What payment methods do you accept?

- Visa, Mastercard, Discover, American Express.

- For B2B purchasing terms or invoicing, contact the supplier to discuss options.

6) Are minimums required? Can we place special orders?

- No stated minimum order quantity for standard SKUs listed online.

- Special orders: smaller/larger widths and longer lengths available via custom request.

- Coordinate engineering: provide exact thickness, width, and desired backer type to minimize fit-up issues.

7) How do we minimize visible seams and color variance?

- Allow for grain and color variation typical of natural cherry veneer; obtain multiple rolls from the same batch or request color-matched options.

- For pre-glued joints:

- Align edge-to-edge; keep iron pressure/temperature consistent.

- Trim and lightly sand; avoid overheating the surface to prevent burn marks or adhesive bleed.

- For machine-applied fleeceback:

- Control glue line and cure; maintain straight edge feed and even pressure to avoid telegraphing.

- Keep the substrate edge clean, square, and free of dust/oil to support bond and finish clarity.

8) Do you ship to the USA and Europe? Any international considerations?

- USA: Direct shipments supported from Troy, Michigan.

- Europe: International orders accepted; freight-forwarding and shipping limitations apply.

- International customers should:

- Provide commercial invoice details and any required import documentation.

- Confirm duties, taxes, and brokerage arrangements for your destination.

- Ensure edge banding dimensions and adhesives meet local application requirements and compliance standards.

Strategic Sourcing Conclusion and Outlook for cherry edge banding

Strategic Sourcing Conclusion and Outlook for Cherry Edge Banding

Cherry edge banding delivers consistent aesthetic value and operational flexibility, especially when sourced from reliable suppliers offering fast shipping and standard roll sizes. WiseWood Veneer exemplifies this by stocking 7/8″, 1″, 1.5″, and 2″ widths in 50′, 250′, and 500′ lengths with pre-glued (hot melt) and fleeceback options. This range allows buyers to right-size inventories across high‑mix, low‑volume and larger runs while minimizing waste and downtime.

The species’ warm pink-to-red tones aging to reddish-brown complement clear‑coat finishes that preserve color warmth—critical for cabinetry, retail fixtures, and hospitality projects in the USA and Europe. Pre‑glued rolls suit rapid shop applications (iron or edge bander), while fleeceback supports industrial glue lines and thicker gluing requirements, broadening application scenarios without SKU proliferation.

Illustrative Image (Source: Google Search)

Outlook: Natural cherry continues to be a staple in residential and contract markets. Stable supply, quick replenishment (most orders ship within 24 hours), and access to common sizes reduce lead times and total landed costs. Strategically, standardize widths and backer types to unlock volume pricing and streamline procurement; reserve special widths via special order for exceptional specifications rather than day‑to‑day use.

Quick Sourcing Reference

| Product | Widths | Lengths | Backing | Price Indicator |

|---|---|---|---|---|

| Cherry Edge Banding | 7/8″, 1″, 1.5″, 2″ | 50′, 250′, 500′ | Pre‑glued (iron‑on) / Fleeceback | Starting at $12.95 (by size/length); example: 7/8″ x 250′ pre‑glued $29.50 |

Bottom line: Cherry edge banding combines dependable supply, versatile application, and proven finish performance—making it a pragmatic, high‑value choice for consistent brand presentation and production efficiency.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided is for informational purposes only. B2B buyers must conduct their own due diligence.