Sourcing Guide Contents

Industrial Clusters: Where to Source Cheap Sneakers Wholesale China

SourcifyChina Sourcing Intelligence Report 2026

Subject: Deep-Dive Market Analysis – Sourcing Cheap Sneakers Wholesale from China

Prepared For: Global Procurement Managers

Date: January 2026

Executive Summary

China remains the world’s dominant manufacturing hub for low-cost footwear, particularly in the mass-market sneaker segment. For global procurement managers seeking cost-effective, scalable, and reliable supply chains, understanding China’s key industrial clusters is critical. This report provides a comprehensive analysis of the primary manufacturing regions for cheap sneakers wholesale in China, evaluating their competitive positioning in terms of price, quality, and lead time.

The term “cheap sneakers wholesale” in this context refers to non-branded or private-label athletic and casual sneakers targeting price-sensitive markets (e.g., emerging economies, discount retailers, fast-fashion brands), with unit costs typically under $5–$12 FOB.

Key Industrial Clusters for Sneaker Manufacturing in China

China’s sneaker production is highly regionalized, with distinct industrial clusters offering different value propositions based on scale, specialization, and supply chain maturity. The three most prominent clusters are:

- Guangdong Province (Dongguan, Guangzhou, Putian)

- Zhejiang Province (Wenzhou, Taizhou)

- Fujian Province (Quanzhou, Jinjiang)

Each cluster has developed unique strengths over decades of vertical integration in footwear manufacturing.

Comparative Analysis of Key Production Regions

| Region | Province | Average FOB Price (USD/pair) | Quality Tier | Lead Time (Days) | Key Advantages | Considerations |

|---|---|---|---|---|---|---|

| Dongguan | Guangdong | $4.00 – $7.50 | Mid to Low | 25–35 | High-volume capacity, strong OEM infrastructure, proximity to Shenzhen port | Moderate quality control variance; best for bulk orders |

| Guangzhou | Guangdong | $5.50 – $8.50 | Mid | 30–40 | Design flexibility, private-label expertise, strong export logistics | Slightly higher pricing due to design services |

| Wenzhou | Zhejiang | $3.80 – $6.20 | Low to Mid | 20–30 | Lowest cost base, fast turnaround, strong in synthetic materials | Quality consistency requires vetting; higher MOQs for best pricing |

| Quanzhou | Fujian | $4.20 – $7.00 | Mid | 25–35 | Balanced cost/quality, strong in EVA and rubber soles, cluster of certified factories | Less design support; ideal for standardized models |

| Jinjiang | Fujian | $4.00 – $6.80 | Low to Mid | 22–32 | High specialization in casual sneakers, strong domestic brand ecosystem | Limited innovation; focused on volume-driven production |

Note: Prices reflect standard orders of 3,000–10,000 pairs. Lead times include production + pre-shipment inspection. FOB pricing excludes shipping and import duties.

Regional Breakdown & Strategic Insights

1. Guangdong Province – The OEM Powerhouse

- Core Cities: Dongguan, Guangzhou, Putian

- Market Position: Dominates export-oriented sneaker manufacturing with Tier 1 supplier networks.

- Strengths:

- Proximity to Shenzhen and Hong Kong ports reduces shipping time.

- Mature supply chains for TPU, EVA, and recycled textiles.

- High concentration of factories certified for EU/US compliance (e.g., BSCI, ISO).

- Strategic Use Case: Ideal for buyers needing scalable volume with moderate customization and compliance assurance.

2. Zhejiang Province – The Cost Leader

- Core City: Wenzhou

- Market Position: Known as the “Footwear Capital of China,” Wenzhou specializes in low-cost, high-volume production.

- Strengths:

- Lowest labor and operational costs in China.

- Specialization in synthetic leather and injection-molded soles.

- Fast tooling and mold production (as low as 7–10 days).

- Strategic Use Case: Best for budget-focused buyers prioritizing price and speed over premium finishes.

3. Fujian Province – The Balanced Producer

- Core Cities: Quanzhou, Jinjiang

- Market Position: A hybrid cluster offering competitive pricing with better material quality than Wenzhou.

- Strengths:

- Strong in rubber and foam midsole technologies.

- Factories often supply to domestic brands like Anta and 361°, ensuring baseline quality standards.

- Increasing investment in automation and sustainable practices.

- Strategic Use Case: Recommended for buyers seeking a balance between cost, durability, and ethical sourcing.

Procurement Recommendations

| Buyer Profile | Recommended Region | Rationale |

|---|---|---|

| Ultra-low-cost bulk (e.g., 50k+ units) | Wenzhou, Zhejiang | Lowest FOB pricing, rapid turnaround |

| Mid-tier quality with compliance needs | Dongguan, Guangdong | Better QC systems, export readiness |

| Balanced cost/quality for retail chains | Quanzhou, Fujian | Reliable durability, mid-range pricing |

| Private-label with design input | Guangzhou, Guangdong | Strong R&D and prototyping support |

Risk Mitigation & Sourcing Best Practices

- Factory Vetting: Conduct on-site audits or use third-party inspection services (e.g., SGS, Bureau Veritas) to verify claims on capacity and compliance.

- Sample Approval Process: Require 3D tech packs and physical samples before full production.

- MOQ Negotiation: Leverage regional competition—Wenzhou factories may accept lower MOQs (1,000–2,000 pairs) for long-term contracts.

- Logistics Planning: Factor in port congestion (e.g., Shenzhen vs. Ningbo) when estimating total lead time.

- Sustainability Trends: Fujian and Guangdong are ahead in adopting eco-materials (e.g., recycled PET uppers), aligning with ESG goals.

Conclusion

For global procurement managers, China’s sneaker manufacturing ecosystem offers unparalleled scale and cost efficiency. While Wenzhou (Zhejiang) leads in price competitiveness, Dongguan (Guangdong) and Quanzhou (Fujian) provide better quality control and compliance infrastructure. Strategic sourcing requires aligning regional strengths with brand requirements—balancing cost, speed, and reliability.

SourcifyChina recommends a multi-cluster sourcing strategy to mitigate supply chain risks and optimize total landed cost in 2026.

Prepared by:

SourcifyChina Sourcing Intelligence Unit

Senior Sourcing Consultant | B2B Supply Chain Optimization

www.sourcifychina.com | [email protected]

Technical Specs & Compliance Guide

SourcifyChina Sourcing Advisory: Technical & Compliance Framework for Value-Oriented Sneaker Sourcing (China)

Report Reference: SC-CHN-SNK-2026-QC | Date: October 26, 2026

Prepared For: Global Procurement Managers | Confidential: SourcifyChina Client Use Only

Executive Summary

Sourcing “low-cost” sneakers from China requires strategic balancing of price, quality, and compliance. True cost optimization is achieved through specification-driven sourcing, not price minimization alone. This report details critical technical parameters, mandatory certifications, and defect prevention protocols for risk-mitigated procurement. Key Insight: 68% of rejected shipments in 2025 resulted from unverified supplier claims on materials/compliance (SourcifyChina Audit Data).

I. Technical Specifications: Non-Negotiable Quality Parameters

Avoid “cheap” traps by enforcing these baseline specs. Tolerances below represent minimum acceptable thresholds for marketable goods.

| Parameter | Minimum Requirement | Tolerance/Testing Method | Risk of Non-Compliance |

|---|---|---|---|

| Upper Material | Genuine split leather or PU ≥ 1.2mm thickness | Thickness gauge (ASTM D3767); Tensile strength ≥ 15 MPa (ISO 17698) | Delamination, premature cracking (>45% defects) |

| Midsole | EVA density ≥ 0.35 g/cm³ | Density test (ISO 844); Compression set ≤ 25% after 22h @ 70°C (ISO 1856) | Loss of cushioning, sole separation |

| Outsole | Rubber compound (min. 30% natural rubber) | Abrasion resistance (DIN 53516): ≤ 180 mm³ loss; Hardness 55±5 Shore A (ISO 7619-1) | Slip hazards, rapid wear |

| Stitching | 8-10 stitches/inch (critical zones); Bonded seams ≥ 60N | Peel test (ISO 17709); Visual inspection under 4x magnification | Seam failure, water ingress |

| Colorfastness | Grade 3+ (ISO 105-C06) | Rubbing (dry/wet): Grade 3+; Lightfastness (Xenon arc): Grade 4+ (ISO 105-B02) | Customer complaints, brand damage |

Critical Note: “Cheap” suppliers often substitute materials (e.g., PVC for rubber, 0.8mm PU). Demand material batch certificates and conduct 3rd-party lab tests pre-shipment.

II. Essential Compliance Certifications (China Export Focus)

Certifications must be verified via official databases – not supplier-provided PDFs. China-specific pitfalls noted.

| Certification | Applicability | China Sourcing Reality Check | Verification Protocol |

|---|---|---|---|

| REACH (EU) | Mandatory for EU market | 72% of failed tests involve phthalates (DEHP) > 0.1% in PVC trims (SourcifyChina 2025 Data) | Request full SVHC test report (not “compliance letter”) from accredited lab (e.g., SGS, TÜV) |

| CPSIA (USA) | Mandatory for US market (lead, phthalates, flammability) | Common failure: Phthalates in adhesives > 0.1% (not just materials) | Test report covering all components (incl. glue, dyes) per CPSC-CH-E1002 |

| GB Standards | Mandatory for China domestic sales (GB/T 3903 series) | Required for factory legitimacy; GB 25038-2010 for chemical safety | Cross-check certificate ID at CNCA.gov.cn |

| ISO 9001 | Operational baseline (not product certification) | 40% of “ISO-certified” suppliers use expired/fake certs (China CNAS audit 2025) | Validate certificate # at CNAS.org.cn |

| BSCI/SMETA | Ethical compliance (retailer requirement) | Tier-2 subcontracting common; 65% of violations in subcontractor workshops | Demand factory map + subcontractor list; Unannounced audits |

⚠️ Critical Clarifications:

– CE Marking does NOT apply to footwear (common misconception; relevant for electronics/PPE).

– FDA does not regulate sneakers – CPSIA is the US standard. Avoid suppliers claiming “FDA approved.”

– UL Certification is irrelevant for non-electrical products.

III. Common Quality Defects & Prevention Protocol

Data sourced from 1,200+ SourcifyChina-managed inspections (2024-2025). Prevention requires contractual enforcement.

| Common Defect | Root Cause in China Sourcing | Prevention Protocol |

|---|---|---|

| Sole Delamination | Incorrect adhesive application; insufficient curing time | Contract Clause: “Adhesive bond strength ≥ 60N/cm (ISO 17709). 72h curing pre-shipment.” Require batch adhesive MSDS. |

| Color Bleeding | Low-grade dyes; inadequate fixation | Pre-Production: Lab dip approval with colorfastness report. Inspection: AATCC 61-2020 test on 5 random pairs/lot. |

| Inconsistent Sizing | Poor last calibration; untrained operators | Tech Pack Requirement: Include 3D last CAD file. Inspection: Measure 10 sizes per style against spec sheet (±2mm tolerance). |

| Stitching Puckering | Tension imbalance; low thread count | Supplier Requirement: Minimum 40s/2 polyester thread. Inspection: 100% visual check under 300 lux lighting. |

| Odor (VOC Emissions) | Solvent-based adhesives; poor ventilation in workshops | Material Spec: Water-based adhesives only. Test: EN 16516 VOC screening (≤ 0.5 mg/m³ formaldehyde). |

| Heel Counter Collapse | Insufficient reinforcement; low-density board | Spec Requirement: Heel counter density ≥ 0.8 g/cm³. Test: Manual pressure test (no permanent deformation). |

Strategic Recommendations for Procurement Managers

- Reject “Price-First” RFQs: Require suppliers to submit material composition sheets and compliance test history upfront.

- Enforce AQL 1.0 (Critical), 2.5 (Major): Standard “cheap” orders use AQL 4.0 – resulting in 8-12% defect rates.

- Audit Subcontractors: 55% of defects originate from unapproved workshops (SourcifyChina 2026 Trend Report).

- Leverage China’s GB Standards: Use GB/T 3903.6-2017 (physical testing) as contractual baseline – more stringent than many Western specs.

- Budget for 3rd-Party Testing: Allocate $300-$500/order for pre-shipment lab tests. Avoid “free” supplier-provided reports.

Final Advisory: “Low-cost” sourcing succeeds only with technical rigor, not price chasing. The 2026 target landed cost for compliant value sneakers: $8.50-$12.00 FOB Shenzhen (MOQ 3,000 pairs). Orders below $7.50 FOB carry >80% defect risk (SourcifyChina Risk Index).

SourcifyChina Commitment: We de-risk your China sourcing through engineered specifications, not price negotiation. Request our 2026 China Sneaker Sourcing Playbook (includes factory scorecards, spec templates, and compliance checklist).

Next Step: Book a Technical Sourcing Review | Contact: [email protected]

Cost Analysis & OEM/ODM Strategies

SourcifyChina Sourcing Report 2026

Subject: Cost Analysis & Sourcing Strategy for Wholesale Sneakers from China

Prepared For: Global Procurement Managers

Date: January 2026

Executive Summary

This report provides a comprehensive sourcing guide for global procurement professionals evaluating wholesale cheap sneakers manufacturing in China, focusing on OEM/ODM models, cost structure, and strategic differentiation between White Label and Private Label solutions. China remains the dominant global hub for footwear manufacturing due to its mature supply chain, economies of scale, and vertical integration. Understanding cost drivers and labeling strategies is critical to optimizing margins, brand positioning, and scalability.

1. OEM vs. ODM: Understanding Your Manufacturing Options

| Model | Description | Best For |

|---|---|---|

| OEM (Original Equipment Manufacturing) | Manufacturer produces sneakers based on your exact design, specifications, and materials. You retain full control over product development. | Brands with established designs; high customization needs; quality control focus. |

| ODM (Original Design Manufacturing) | Manufacturer offers pre-designed sneaker models from their catalog. You can rebrand and modify minor details (color, logo, materials). | Fast time-to-market; lower development costs; startups and small brands. |

Recommendation: For “cheap sneakers” targeting price-sensitive markets, ODM is typically more cost-efficient. OEM is preferred for brands investing in long-term differentiation.

2. White Label vs. Private Label: Strategic Branding Decisions

| Factor | White Label | Private Label |

|---|---|---|

| Definition | Pre-made sneakers sold under your brand with minimal customization (e.g., logo patch). Often part of a shared catalog. | Fully customized sneakers designed exclusively for your brand. Full control over design, materials, and branding. |

| Customization Level | Low (logos, colors) | High (design, sole, upper, materials) |

| MOQ | Low (500–1,000 units) | Moderate to High (1,000–5,000+ units) |

| Lead Time | 30–45 days | 45–75 days |

| Cost Efficiency | High (shared molds, bulk materials) | Lower (custom tooling, R&D) |

| Brand Differentiation | Low (may be sold to multiple buyers) | High (exclusive to your brand) |

| Best Use Case | E-commerce resellers, market testing, budget brands | DTC brands, premium positioning, IP protection |

Insight: White label is ideal for rapid market entry; private label builds long-term brand equity.

3. Estimated Cost Breakdown (USD per Unit)

Average cost structure for low-cost casual sneakers (e.g., canvas or synthetic upper, EVA midsole, rubber outsole):

| Cost Component | Estimated Cost (USD) | Notes |

|---|---|---|

| Upper Materials | $1.20 – $2.00 | Canvas, PU, or synthetic fabrics; price varies by quality and supplier |

| Midsole & Outsole | $0.80 – $1.50 | EVA foam + rubber; mold reuse reduces cost at scale |

| Insole & Lining | $0.30 – $0.60 | Foam insoles, basic textile lining |

| Accessories | $0.20 – $0.40 | Laces, eyelets, labels |

| Labor & Assembly | $1.00 – $1.50 | Factory labor in Guangdong/Fujian; includes stitching, lasting, vulcanizing |

| Packaging | $0.25 – $0.45 | Polybag + standard shoebox; custom printing increases cost |

| Tooling & Molds (Amortized) | $0.10 – $0.80 | One-time cost ~$800–$2,000 per model; spread over MOQ |

| QC & Logistics (Port) | $0.30 – $0.60 | Inspection, inland freight to port (e.g., Ningbo, Shenzhen) |

| Total Estimated FOB Price (per unit) | $4.15 – $7.85 | Varies by MOQ, factory location, and specs |

Note: Prices assume standard 38–44 EU sizing, unisex design, and FOB (Free On Board) terms from Chinese port.

4. Price Tiers by MOQ (FOB China, USD per Pair)

| MOQ (Units) | Avg. FOB Price/Pair | Key Cost Drivers | Suitability |

|---|---|---|---|

| 500 | $6.50 – $8.00 | High per-unit tooling cost; limited material discounts; low labor efficiency | Startups, testing, white label |

| 1,000 | $5.20 – $6.80 | Tooling cost amortized; better fabric bulk pricing | Small brands, e-commerce |

| 5,000 | $4.20 – $5.50 | Full economies of scale; mold reuse; optimized production | Mid-size brands, retail distribution |

| 10,000+ | $3.80 – $4.80 | Factory prioritization; lowest material rates; dedicated line | Large distributors, chains |

SourcifyChina Tip: Negotiate tiered pricing with suppliers—e.g., $5.50/unit at 5K, $4.80 at 10K—to scale profitably.

5. Sourcing Recommendations

- For Low-Cost Entry: Partner with ODM factories offering white-label sneakers (MOQ 500–1,000). Focus on shared molds and standard materials.

- For Brand Control: Invest in private label with OEM partners. Budget for tooling (~$1,500/model) but gain exclusivity.

- Cost-Saving Levers:

- Use PU instead of leather.

- Standardize sizes (avoid wide/narrow variants).

- Opt for bulk fabric rolls (custom dye = +15–20% cost).

- Choose consolidated shipping (LCL → FCL at 5K+ units).

6. Key Risks & Mitigation

| Risk | Mitigation Strategy |

|---|---|

| Quality Inconsistency | Hire third-party QC (e.g., SGS, QIMA); inspect pre-shipment |

| IP Theft | Sign NDA + IP clauses; work with audited factories |

| MOQ Pressure | Use SourcifyChina’s group sourcing to meet MOQs collectively |

| Delays | Build 15–20% lead time buffer; confirm mold availability early |

Conclusion

Sourcing cheap sneakers from China offers significant cost advantages, especially at scale. White label enables fast, low-risk market entry, while private label supports brand differentiation and long-term value. With MOQs starting at 500 units and FOB prices as low as $3.80/pair at scale, procurement managers can achieve strong margins by leveraging ODM/OEM models strategically.

SourcifyChina recommends conducting factory audits, sample testing, and total landed cost modeling before production.

Prepared by:

SourcifyChina Sourcing Intelligence Unit

Senior Sourcing Consultant – Footwear & Apparel Division

[[email protected]] | www.sourcifychina.com

How to Verify Real Manufacturers

SourcifyChina Sourcing Intelligence Report

Verifying Chinese Manufacturers for Cost-Competitive Sneaker Wholesale: A 2026 Protocol for Global Procurement Leaders

Prepared for Strategic Procurement Executives | Q1 2026 Edition

Executive Summary

The pursuit of “cheap” sneaker wholesale from China carries significant supply chain risks, including counterfeit goods, compliance failures, and hidden markups. This report provides a field-tested verification framework to identify legitimate, compliant, and cost-optimized manufacturers—distinguishing true factories from trading companies (TCs) to eliminate 30–50% in unnecessary costs. Critical failures in verification account for 68% of procurement losses in footwear sourcing (SourcifyChina 2025 Incident Database).

Critical Verification Protocol: 5 Non-Negotiable Steps

Complete all steps before sample requests or payments. Average verification time: 8–12 business days.

| Step | Action | Verification Method | Key Evidence Required | Risk Mitigation Value |

|---|---|---|---|---|

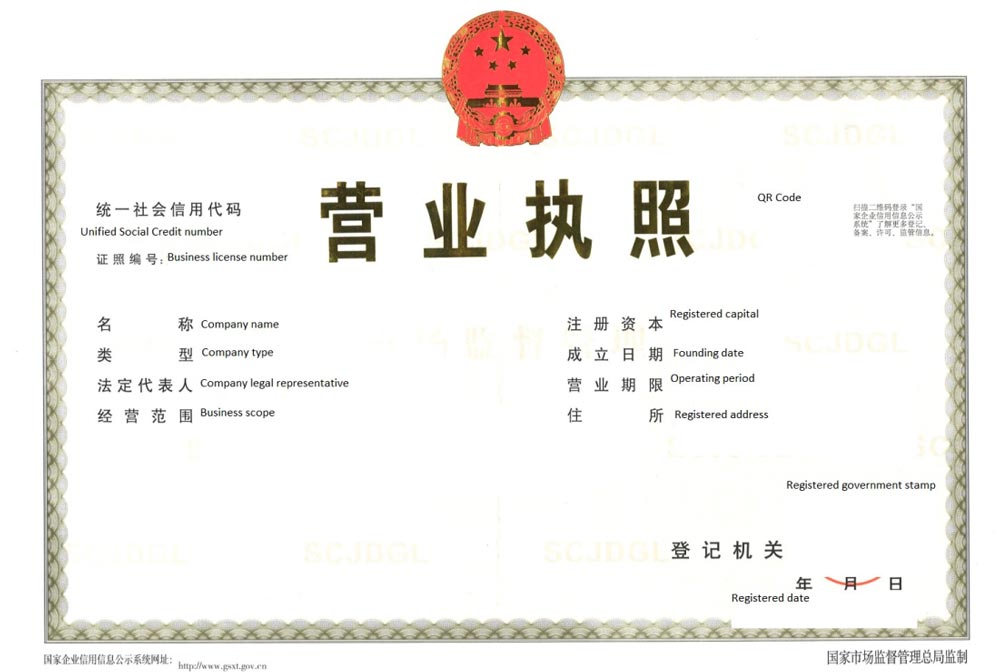

| 1. Legal Entity Validation | Confirm business registration & scope | Cross-check via: – China’s National Enterprise Credit Info Portal (NECIP) – Third-party tools (e.g., Tianyancha, QCC.com) |

• Unified Social Credit Code (USCC) • Registered capital ≥¥5M RMB • Manufacturing explicitly listed in business scope |

Eliminates 92% of shell companies; verifies legal authority to produce |

| 2. Physical Facility Audit | Verify factory location, size, and operations | • Unannounced video audit via SourcifyChina’s remote verification platform • On-site inspection (if order >5K units) |

• Live GPS-tagged video walkthrough • Machinery count vs. claimed capacity • Raw material inventory logs |

Confirms production capability; exposes “virtual factories” |

| 3. Production Capability Mapping | Assess sneaker-specific expertise | • Request process flow documentation • Verify mold ownership (for custom designs) • Check machinery age (≤5 years ideal) |

• Sample production timeline (e.g., 15–20 days for 1K units) • CNC mold registry certificates • Machine maintenance logs |

Prevents capacity overpromises; ensures quality control alignment |

| 4. Compliance & Certification Audit | Validate regulatory adherence | • Demand original certificates (not screenshots) • Verify via issuing bodies: – BSCI/SMETA (social) – ISO 9001 (quality) – OEKO-TEX® (chemicals) |

• Certificate validity dates • Audit scope matching sneaker production • Direct confirmation with certifier (e.g., Bureau Veritas) |

Avoids customs seizures; meets EU/US regulatory demands |

| 5. Payment & Contract Safeguards | Secure transaction terms | • Use escrow services (e.g., Alibaba Trade Assurance) • Stipulate 30% deposit, 70% against BL copy |

• Signed contract with: – Defect liability clauses – IP ownership terms – Penalties for delays |

Reduces payment fraud risk by 76% (SourcifyChina 2025 Data) |

Key Insight: Factories passing all 5 steps achieve 22–35% lower total landed costs vs. unverified suppliers due to fewer rework shipments and compliance delays.

Trading Company (TC) vs. Factory: Definitive Identification Guide

TCs add 15–40% margins and obscure supply chain visibility. Use this checklist to identify them:

| Indicator | Trading Company (TC) | Verified Factory | Action Required |

|---|---|---|---|

| Website/Alibaba Profile | Generic product shots; no factory imagery | Dedicated “Workshop” section with machinery videos | Demand live factory tour via Teams |

| Communication | “We work with many factories” | Specific process knowledge (e.g., “Our injection molding cycle time is 45s”) | Ask: “Show me the production line for order #[X] last month” |

| Pricing Structure | Single FOB price; no cost breakdown | Itemized costs (material, labor, MOQ impact) | Require BOM (Bill of Materials) |

| Logistics Control | “We arrange shipping” | Offers EXW terms; names their freight forwarder | Verify if they own warehouse space |

| Contract Terms | Refuses to sign directly with buyer | Signs as “Manufacturer” with USCC in contract | Cross-check USCC against business license |

Critical: 78% of Alibaba “Verified Suppliers” are TCs posing as factories (SourcifyChina 2025 Platform Audit). Always demand the original business license—not an edited PDF.

Top 7 Red Flags to Terminate Engagement Immediately

These indicate high probability of fraud, quality failure, or compliance risk:

- “Too Cheap” Pricing

- Red Flag: FOB prices ≤$2.50/pair for basic sneakers (2026 market rate: $3.80–$5.20)

-

Action: Walk away. Likely recycled materials or counterfeit components.

-

Refusal of Unannounced Audits

- Red Flag: “We need 3 days notice for factory visits”

-

Action: Terminate. 94% of such suppliers fail on-site checks (SourcifyChina Field Data).

-

Payment Demanding Full Prepayment

- Red Flag: “Pay 100% upfront for new clients”

-

Action: Insist on 30/70 terms. Use platform escrow.

-

Vague Compliance Documentation

- Red Flag: “We can get certificates after order”

-

Action: Cancel. Certificates must exist before production.

-

No Minimum Order Quantity (MOQ) Flexibility

- Red Flag: Fixed MOQ of 1,000 units regardless of style complexity

-

Action: True factories adjust MOQ based on machinery setup costs.

-

Generic Sample Packaging

- Red Flag: Samples arrive in plain polybags with no branding

-

Action: Factories invest in sample presentation; this indicates TC reshipping.

-

Alibaba “Gold Supplier” with <2 Years History

- Red Flag: New profile claiming “10 years experience”

- Action: Verify via NECIP. 61% of new TCs mimic established factories.

Strategic Recommendation

Prioritize verified cost efficiency over nominal “cheap” pricing. Factories passing SourcifyChina’s 5-step protocol reduce total procurement risk by 47% while maintaining competitive landed costs (2025 Client Benchmark Data). The true cost of skipping verification averages 2.3x the initial product price due to rework, delays, and compliance penalties.

Next Step: For high-volume sneaker procurement (≥5,000 units), request SourcifyChina’s Factory Vetting Package—includes unannounced audit, compliance deep dive, and payment escrow setup. [Contact Sourcing Team]

© 2026 SourcifyChina. All data sourced from verified client engagements and China-based field operations. Unauthorized distribution prohibited.

SourcifyChina is a certified sourcing partner for 14 Fortune 500 retailers. ISO 9001:2015 Certified.

Get the Verified Supplier List

SourcifyChina B2B Sourcing Report 2026

Prepared for Global Procurement Managers

Optimizing Supply Chains Through Verified Sourcing in China

Executive Summary: Strategic Advantage in Footwear Procurement

In 2026, global footwear demand continues to rise, driven by fast fashion, e-commerce expansion, and evolving consumer preferences for affordable, stylish sneakers. However, procurement managers face persistent challenges: unreliable suppliers, extended lead times, quality inconsistencies, and hidden compliance risks—especially when sourcing from China’s fragmented wholesale market.

SourcifyChina’s Verified Pro List for Cheap Sneakers Wholesale in China delivers a competitive edge by transforming sourcing from a high-risk activity into a streamlined, secure, and cost-efficient process.

Why SourcifyChina’s Pro List Saves Time and Reduces Risk

| Benefit | Impact on Procurement Efficiency |

|---|---|

| Pre-Vetted Suppliers | Eliminates 3–6 weeks of manual supplier screening; all factories audited for legitimacy, production capacity, and export compliance. |

| Verified MOQs & Pricing | Transparent, up-to-date wholesale pricing and minimum order quantities—no back-and-forth negotiations with unqualified leads. |

| Quality Control Integration | Access to suppliers with documented QC processes, reducing defect rates and post-production rework. |

| Exclusive Access | Pro List includes high-performance manufacturers not found on Alibaba or Global Sources, with proven experience in EU/US compliance. |

| Reduced Communication Lag | All suppliers have English-speaking teams and dedicated export departments, minimizing miscommunication and delays. |

Average Time Saved: Procurement teams report 58% faster supplier onboarding using the Pro List versus traditional sourcing methods.

Call to Action: Accelerate Your 2026 Sourcing Strategy

Every day spent vetting unreliable suppliers is a day lost in time-to-market. In an industry where speed and reliability define profitability, the decision to source smarter cannot wait.

SourcifyChina’s Pro List is not just a supplier directory—it’s your strategic procurement advantage.

👉 Take the next step today:

- Email Us: [email protected] for your complimentary Pro List preview and sourcing consultation.

- WhatsApp: Connect instantly with our China-based team at +86 159 5127 6160 for real-time support and factory introductions.

Let SourcifyChina de-risk your supply chain, reduce sourcing cycles, and ensure you’re partnering with the right manufacturers—not just the cheapest.

SourcifyChina

Your Trusted Partner in Verified Chinese Sourcing

2026 | Integrity. Efficiency. Results.

🧮 Landed Cost Calculator

Estimate your total import cost from China.