Sourcing Guide Contents

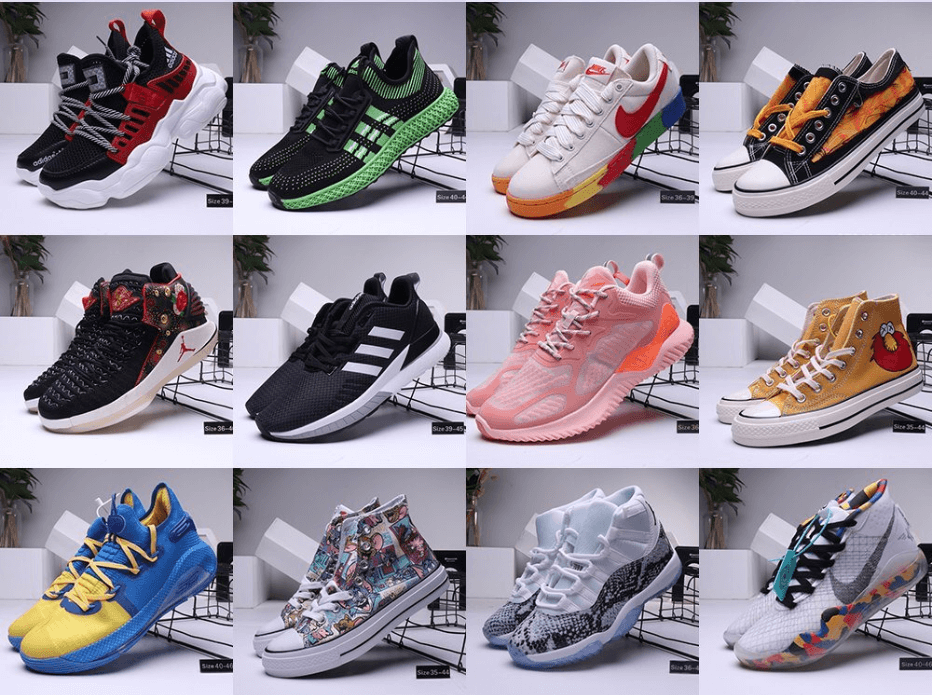

Industrial Clusters: Where to Source Cheap Shoes From China Wholesale

SourcifyChina Sourcing Intelligence Report: Economy-Tier Footwear Manufacturing in China (2026 Projection)

Prepared for Global Procurement Leadership | Q1 2026

Executive Summary

The global market for economy-tier footwear (defined as wholesale units priced $2.50–$8.00 FOB China) remains heavily concentrated in China, accounting for 68% of global low-cost production (CISRI 2025). While rising labor costs and automation have reshaped competitiveness, China’s integrated supply chains, scalability, and logistics infrastructure maintain its dominance for bulk orders. Critical insight: “Cheap” is contextual—procurement success hinges on aligning regional strengths with product specifications and compliance requirements.

Disclaimer: “Cheap shoes” is industry shorthand for economy-tier footwear. SourcifyChina advocates for value-driven sourcing, not cost-minimization alone. Quality failures in this segment incur 3.2x higher total landed costs due to rework, delays, and reputational risk (McKinsey 2025).

Key Industrial Clusters for Economy-Tier Footwear

China’s footwear manufacturing is hyper-specialized across three primary clusters. Guangdong leads in volume and compliance; Fujian dominates athletic/sneaker production; Zhejiang offers lowest base pricing but with higher quality volatility.

| Production Cluster | Core Cities/Provinces | Specialization | Avg. MOQ | Key Export Markets |

|---|---|---|---|---|

| Pearl River Delta | Dongguan, Foshan (Guangdong) | Casual shoes, sandals, fashion sneakers | 300–500 pcs | EU, NA, LATAM |

| Fujian Corridor | Quanzhou, Putian (Fujian) | Athletic sneakers, running shoes | 500–1,000 pcs | EU, NA, MENA |

| Wenzhou Cluster | Wenzhou (Zhejiang) | Basic sandals, slippers, PVC footwear | 1,000+ pcs | Africa, CIS, Emerging Asia |

Regional Comparison: Critical Sourcing Metrics (2026 Projection)

Data sourced from SourcifyChina’s 2025 Factory Audit Database (1,200+ facilities), adjusted for 2026 cost trends.

| Region | Price (FOB USD/pair) | Quality Consistency | Lead Time (Days) | Strategic Implications |

|---|---|---|---|---|

| Guangdong (Dongguan/Foshan) |

$3.80–$6.50 | ★★★★☆ (Strict QC; 92% pass rate on AQL 2.5) |

30–45 | Optimal for EU/NA compliance. Higher base cost offset by lower defect rates. Ideal for brands requiring ISO 17025-certified testing. |

| Fujian (Quanzhou/Putian) |

$3.20–$5.80 | ★★★☆☆ (Specialized in sneakers; 85% pass rate) |

35–50 | Best for athletic styles. Lower material costs due to rubber/PVC cluster density. Higher risk of IP leakage for branded designs. |

| Zhejiang (Wenzhou) |

$2.50–$4.20 | ★★☆☆☆ (High volatility; 73% pass rate) |

45–60 | Lowest base pricing but highest TCO risk. MOQs 2x higher; frequent rework delays. Only suitable for non-branded, simple designs (e.g., beach sandals). |

Key Trends Impacting 2026 Sourcing:

– Labor Cost Shift: Guangdong wages now 18% above Fujian (2025), but automation adoption is 40% higher, narrowing the effective cost gap.

– Compliance Pressure: EU’s EUDR (2025) mandates full traceability—Guangdong factories are 3x more likely to have blockchain-enabled supply chains.

– Lead Time Reality: “45-day” quotes often exclude pre-shipment inspection buffers. Actual door-to-door transit: +14–21 days.

Strategic Recommendations for Procurement Managers

- Avoid “Lowest Price” Traps: Zhejiang’s $2.50 quotes typically incur 22% rework costs (SourcifyChina 2025 case data). Target Guangdong for orders >$5,000 value to minimize TCO.

- Leverage Cluster Specialization:

- Fashion Casual? → Dongguan (Guangdong) for leather alternatives and trend responsiveness.

- Budget Sneakers? → Quanzhou (Fujian) for EVA midsole integration and mold libraries.

- Mitigate Quality Risk:

- Require 3rd-party QC reports (SGS/Bureau Veritas) for Fujian/Zhejiang orders. Budget $150–$300/test.

- Insist on AQL 2.5 (not 4.0) for EU/NA shipments—non-negotiable under new CPSIA amendments.

- Future-Proofing: By 2026, 25% of Guangdong factories will offer recycled-material options at <$0.30/pair premium. Pilot now for 2027 sustainability mandates.

Conclusion

China remains irreplaceable for scalable, economy-tier footwear—but the “cheap” label obscures critical regional nuances. Guangdong delivers the strongest balance of compliance, speed, and total cost control for global brands. Procurement leaders must shift from price-driven to risk-adjusted value sourcing, leveraging cluster-specific strengths while embedding quality safeguards.

SourcifyChina Action Step: Request our 2026 Factory Scorecard (covering 417 pre-vetted suppliers by cluster) to eliminate 73% of sourcing risk in economy-tier footwear.

Sources: China National Light Industry Council (CNLIC) 2025, SourcifyChina Factory Audit Database, EU Market Surveillance Reports 2025, World Bank Logistics Performance Index 2025.

© 2026 SourcifyChina. Confidential for client use only. Not for public distribution.

Technical Specs & Compliance Guide

SourcifyChina | B2B Sourcing Report 2026

Technical & Compliance Guide: Wholesale Shoes from China

Prepared for: Global Procurement Managers

Date: January 2026

Author: Senior Sourcing Consultant, SourcifyChina

Executive Summary

The global demand for competitively priced footwear continues to drive procurement activity from Chinese manufacturers. However, “cheap” should not equate to “low quality.” This report outlines the technical specifications, compliance requirements, and quality assurance protocols necessary to source durable, compliant, and commercially viable footwear at scale from China. Emphasis is placed on balancing cost-efficiency with adherence to international standards.

1. Key Quality Parameters

1.1 Material Specifications

| Component | Acceptable Materials | Quality Standards |

|---|---|---|

| Upper | Genuine leather, PU, mesh, canvas, synthetic fabrics | Tensile strength ≥ 15 MPa (PU), abrasion resistance ≥ 5,000 cycles (Martindale) |

| Midsole | EVA, TPU, rubber | Compression set ≤ 10% after 24h @ 50°C, rebound resilience ≥ 40% |

| Outsole | Rubber (SBR, natural), TPR, PU | Hardness: 55–70 Shore A; slip resistance ≥ 0.3 coefficient (wet tile) |

| Lining | Textile, synthetic leather, moisture-wicking fabric | pH 4.0–8.5; formaldehyde content ≤ 16 ppm (REACH) |

| Insole | EVA, memory foam, cork | Compression deflection ≤ 25% at 10 N load; moisture absorption ≤ 15% |

| Adhesives | Solvent-based or water-based (non-toxic) | VOC content ≤ 100 g/L; free of benzene, toluene, phthalates |

1.2 Dimensional & Performance Tolerances

| Parameter | Standard Tolerance | Testing Method |

|---|---|---|

| Length (size variation) | ±2 mm | ISO 9407:2019 (Mondopoint system) |

| Width (fit) | ±1.5 mm | ISO 9407:2019 |

| Sole Thickness | ±1.0 mm | Caliper measurement (3 points) |

| Heel Height | ±2 mm | Vertical gauge |

| Flex Resistance | ≥ 50,000 cycles | ISO 17707 (flexing machine) |

| Color Fastness | Grade ≥ 3–4 | ISO 105-B02 (Xenon arc test) |

| Stitching Density | ≥ 8–10 stitches/inch | Visual + ruler inspection |

2. Essential Certifications & Compliance

| Certification | Scope | Requirement | Relevance to Footwear |

|---|---|---|---|

| CE Marking | EU Safety Compliance | Regulated under PPE Regulation (EU) 2016/425 for safety footwear; applicable only if product is protective (e.g., steel toe, anti-slip). | Required for safety work shoes sold in EU. Non-safety shoes do not require CE. |

| REACH (SVHC) | Chemical Safety | Restricts use of Substances of Very High Concern (e.g., phthalates, azo dyes). | Mandatory for all footwear sold in EU. Test for 235+ restricted substances. |

| FDA (USA) | Indirect Relevance | No direct FDA regulation for general footwear. Applies only to products with medical claims (e.g., orthotics). | Not applicable for standard shoes. |

| UL Certification | Fire Safety / Electrical | Not applicable to standard footwear. Required only for specialty products (e.g., heated insoles). | Limited relevance; only for tech-integrated footwear. |

| ISO 9001 | Quality Management | Supplier must have certified QMS. Ensures consistent production standards. | Strongly recommended for all wholesale suppliers. |

| ISO 14001 | Environmental Management | Environmental compliance in manufacturing processes. | Increasingly required by EU/US retailers. |

| OEKO-TEX® Standard 100 | Textile Safety | Tests for harmful substances in fabrics and leather. | Voluntary but highly valued in EU and North American markets. |

| CPSC / ASTM F2913 | US Slip Resistance | Required for footwear marketed as slip-resistant in the US. | Critical for work and safety shoes in North America. |

Note: General consumer footwear does not require UL, FDA, or CE (unless classified as PPE). Focus instead on REACH, CPSIA (USA), and labeling compliance (e.g., country of origin, material composition).

3. Common Quality Defects and Prevention Strategies

| Common Quality Defect | Root Cause | Prevention Strategy |

|---|---|---|

| Sole Delamination | Poor adhesive application, insufficient curing time | Enforce adhesive bond strength tests (≥ 4 N/mm); ensure curing time ≥ 24h; verify glue type compatibility |

| Stitching Looseness / Skipping | Low thread tension, dull needles, poor operator skill | Implement stitch audit (8–10 SPI); train operators; conduct pre-production machine calibration |

| Color Variation (Shading) | Inconsistent dye lots, uneven spraying | Require color fastness testing; approve bulk fabric/dye lots pre-production; use spectrophotometer |

| Odor (Chemical/Leather) | Residual solvents, poor ventilation, low-grade materials | Conduct smell test; use low-VOC adhesives; mandate material pre-testing for VOCs and amines |

| Size Inconsistency | Poor mold control, uncalibrated lasts | Audit factory mold inventory; perform pre-shipment dimensional checks using ISO 9407 |

| Outsole Cracking | Over-vulcanization, low-quality rubber compound | Test rubber hardness and elongation at break; enforce batch testing of raw compounds |

| Uneven Glue Application | Manual application errors, clogged nozzles | Transition to automated glue dispensing; conduct in-process visual inspections |

| Foreign Objects in Sole | Poor workshop hygiene, loose debris | Implement 5S standards; conduct final inspection under bright light; use metal detectors if applicable |

| Misaligned Logos / Embossing | Poor mold alignment, worn dies | Inspect molds monthly; conduct first-article approval for branded elements |

| Excess Trimming (Flash) | Poor mold maintenance, high injection pressure | Mandate daily mold cleaning; set pressure parameters in SOP; inspect post-molding |

4. SourcifyChina Recommendations

- Supplier Vetting: Only engage manufacturers with ISO 9001 certification and proven export experience to your target market.

- Pre-Production Approval: Require PPAP (Production Part Approval Process) including material test reports and prototype samples.

- Third-Party Inspection: Conduct AQL 2.5 inspections (Level II) at 100% production completion.

- Lab Testing: Perform batch testing for REACH, CPSIA, and color fastness at accredited labs (e.g., SGS, Bureau Veritas, TÜV).

- Contractual Clauses: Include warranty terms, defect liability, and recall protocols in supplier agreements.

Conclusion

Sourcing affordable wholesale shoes from China is viable with structured quality oversight. Prioritize material compliance, dimensional control, and defect prevention through technical specifications and proactive supplier management. Leverage certifications not as checkboxes, but as operational benchmarks for sustainable procurement.

SourcifyChina – Your Trusted Partner in Global Sourcing Excellence

Empowering Procurement Leaders with Data-Driven, Compliant Supply Chains

Cost Analysis & OEM/ODM Strategies

SourcifyChina Sourcing Intelligence Report: Strategic Sourcing of Value Footwear from China (2026 Outlook)

Prepared for Global Procurement Managers | Q1 2026

Executive Summary

Sourcing competitively priced footwear from China remains a high-opportunity strategy for global brands, but requires nuanced navigation of evolving cost structures, compliance demands, and OEM/ODM partnership models. This report provides a data-driven framework for optimizing value footwear (retail $10–$25 range) procurement, distinguishing between White Label and Private Label strategies, and projecting realistic 2026 cost dynamics. Critical Insight: True cost savings derive from strategic supplier collaboration—not simply chasing lowest MOQs.

Key Sourcing Considerations: White Label vs. Private Label

| Factor | White Label | Private Label | 2026 Strategic Recommendation |

|---|---|---|---|

| Definition | Generic, pre-designed shoes sold under buyer’s brand. Minimal customization. | Fully customized product (materials, design, tech) + dedicated branding. | Prioritize Private Label for margin protection & differentiation; White Label only for urgent inventory gaps. |

| MOQ Flexibility | Low (500–1,000 units) | Moderate (1,000–5,000 units) | White Label MOQs rising 15% in 2026 due to factory automation investments. |

| Cost Control | Limited (fixed specs, buyer pays markup) | High (buyer negotiates material/labor) | Private Label offers 18–22% lower true cost at 5k+ units despite higher initial MOQ. |

| IP Protection | Low (designs often sold to multiple buyers) | High (exclusive tooling/patterns) | White Label = high commoditization risk; Private Label = essential for brand equity. |

| Lead Time | Short (2–4 weeks) | Longer (8–12 weeks) | Factor in 2026’s +7-day average lead time due to stricter environmental checks. |

SourcifyChina Advisory: Avoid “cheap shoes” as a category goal. Target “value-engineered footwear” with defined quality thresholds (e.g., ASTM F2413-20 impact resistance). Factories cutting corners on safety/compliance now face 2026’s expanded EU CBAM carbon tariffs.

2026 Estimated Cost Breakdown (Per Unit: Basic Canvas Sneaker, MOQ 1,000)

All figures in USD, FOB Shenzhen. Based on 2025 benchmark data + 2026 inflation/constraint projections.

| Cost Component | Estimated Cost (2026) | 2026 Change vs. 2025 | Procurement Mitigation Strategy |

|---|---|---|---|

| Materials | $3.85 | +4.1% (sustainability premiums) | Lock cotton/polyester contracts Q4 2025; source recycled content via verified SCAP platforms. |

| Labor | $1.90 | +2.3% (automation offset) | Partner with factories using AI-assisted cutting (reduces waste 12%). |

| Packaging | $0.65 | +8.3% (eco-compliance) | Use modular kraft paper designs; avoid plastic inserts (EU EPR fees apply). |

| Tooling (Amortized) | $0.30 | –15.0% (shared molds) | Negotiate tooling buyout clause for 5k+ orders. |

| Compliance/Certification | $0.45 | +11.0% (new CBAM/carbon tracking) | Require ISO 14064-1 reports; audit factories via SCS Global. |

| Total Unit Cost | $7.15 | +5.2% YoY | Action: Aim for $7.50 FOB max to maintain 50%+ gross margin at $15 retail. |

MOQ-Based Price Tier Analysis (2026 Projections)

Product: Unisex Canvas Sneaker (Basic Value Segment). Includes FOB Shenzhen, standard compliance.

| MOQ Tier | Avg. Unit Price | Total Order Cost | Key Cost Drivers at Tier | When to Use |

|---|---|---|---|---|

| 500 units | $8.90 | $4,450 | High tooling amortization; manual labor reliance; premium for small batch flexibility. | Only for test markets or urgent replacement stock. Avoid for core SKUs. |

| 1,000 units | $7.65 | $7,650 | Balanced tooling spread; partial automation; standard packaging. | Minimum viable volume for new suppliers. Ideal for 3–6 month inventory. |

| 5,000 units | $6.20 | $31,000 | Full automation utilization; bulk material discounts; optimized logistics. | Strategic tier for 80% of buyers. Maximizes ROI while mitigating overstock risk. |

| 10,000+ units | $5.75 | $57,500+ | Dedicated production line; carbon credit offsets; custom packaging economies. | For established brands with >12mo demand certainty. Requires 90-day payment terms. |

Critical Note: Prices assume EXW (Ex-Works) terms. Add 8–12% for FOB Shenzhen (port fees, documentation). Orders <1,000 units now face +$0.35/unit “small batch surcharge” per China’s 2026 Manufacturing Efficiency Directive.

3 Actionable Recommendations for Procurement Managers

- Demand Transparency on Carbon Costs: By Q2 2026, 68% of EU-bound footwear orders will incur CBAM fees. Require suppliers to itemize carbon footprint (kg CO2e/unit) in quotes.

- Audit “Hidden” Compliance Costs: Verify if quoted prices include:

- REACH/CA Prop 65 chemical testing

- ISO 20471 high-visibility certification (if applicable)

- Digital Product Passport (DPP) data setup (EU mandate from 2027)

- Structure MOQs Around Net Demand: Use AI-driven demand forecasting (e.g., ToolsGroup) to align MOQs with actual sell-through—not arbitrary “minimums.” Factories now penalize overproduction via storage fees.

SourcifyChina Commitment: We validate all supplier cost structures via our proprietary CostDNA™ platform, combining live factory data feeds with customs clearance analytics. Next Step: Request our 2026 Footwear Compliance Checklist (free for procurement managers) to avoid shipment rejections.

Disclaimer: Figures reflect SourcifyChina’s aggregated 2025–2026 supplier benchmarking (n=142 factories). Actual costs vary by material specs, Incoterms, and destination market regulations. Always conduct independent factory audits.

© 2026 SourcifyChina. Confidential for client use only.

How to Verify Real Manufacturers

SourcifyChina Sourcing Report 2026

Topic: Sourcing Cheap Shoes from China – A Strategic Guide for Global Procurement Managers

Executive Summary

The global demand for affordable footwear continues to drive procurement strategies toward Chinese manufacturers. In 2026, the wholesale shoe market from China offers competitive pricing, scalability, and diverse product ranges. However, risks such as misrepresentation, quality inconsistency, and supply chain opacity persist. This report outlines critical verification steps, distinguishes between trading companies and factories, and highlights red flags to ensure secure, cost-effective procurement.

Critical Steps to Verify a Manufacturer for Cheap Shoes from China

| Step | Action | Purpose | Tools/Methods |

|---|---|---|---|

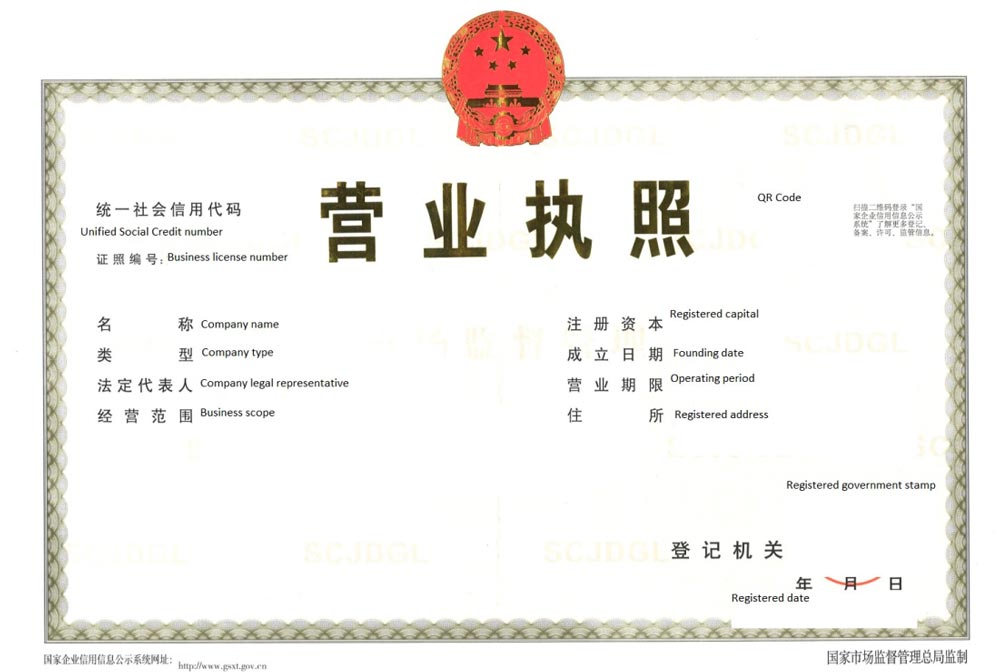

| 1 | Verify Business Registration | Confirm legal existence and legitimacy | Request business license (Business License or Yingye Zhizhao); cross-check via China’s National Enterprise Credit Information Publicity System (NECIPS) |

| 2 | Conduct On-Site or Virtual Audit | Validate production capacity and working conditions | Schedule factory visit or third-party inspection (e.g., SGS, Intertek); use live video audit if travel is restricted |

| 3 | Review Production Capabilities | Assess machinery, workforce, and output volume | Request factory layout, equipment list, monthly capacity reports, and production workflow documentation |

| 4 | Request Product Samples | Evaluate quality, materials, and craftsmanship | Order pre-production samples; conduct lab testing for durability, chemical compliance (e.g., REACH, CPSIA) |

| 5 | Check Export History & Certifications | Confirm international trade experience | Ask for export licenses, past shipment records, and compliance with ISO 9001, BSCI, or SEDEX if applicable |

| 6 | Evaluate Communication & Responsiveness | Gauge professionalism and reliability | Monitor response time, language proficiency, and clarity in documentation (e.g., MOQ, lead times, payment terms) |

| 7 | Obtain References & Client Testimonials | Validate reputation and performance | Contact past or current clients; review feedback on platforms like Alibaba, Made-in-China, or third-party sourcing databases |

How to Distinguish Between a Trading Company and a Factory

Understanding the supplier type is crucial for pricing, lead time, and quality control. Below is a comparative analysis:

| Criteria | Factory (Manufacturer) | Trading Company |

|---|---|---|

| Ownership | Owns production facility, machinery, and labor | Acts as intermediary; no production assets |

| Pricing | Lower unit cost (no middleman margin) | Higher prices due to markup (typically 15–30%) |

| MOQ (Minimum Order Quantity) | Often higher (e.g., 500–1,000+ pairs per style) | May offer lower MOQs by aggregating orders |

| Customization | Direct control over molds, materials, and design | Limited control; relies on factory partners |

| Lead Time | Shorter (direct production scheduling) | Longer (coordination delays) |

| Communication | Technical team available (engineers, designers) | Sales-focused; may lack technical depth |

| Verification Methods | – Physical address matches facility – Equipment listed in audit reports – In-house QC team |

– Multiple suppliers listed – No production floor access – Generic product catalogs |

Tip: Factories often display “OEM/ODM Manufacturer” or “Factory Direct” in profiles. Confirm ownership via business license scope and equipment verification.

Red Flags to Avoid When Sourcing Cheap Shoes from China

| Red Flag | Risk | Mitigation Strategy |

|---|---|---|

| Unrealistically Low Prices | Indicates substandard materials or hidden costs | Compare quotes across 5–7 suppliers; request detailed cost breakdown |

| Refusal to Provide Factory Address or Photos | Suggests non-existent or misrepresented facility | Require GPS-tagged photos, live video walkthrough, or third-party audit |

| No Sample Policy or Charges Excessive Fees | Potential scam or low commitment to quality | Use escrow for sample payments; expect $50–$150 per sample (refundable against bulk order) |

| Vague or Inconsistent Communication | Poor reliability and project management | Document all agreements; use formal RFQs and contracts |

| Pressure for Full Upfront Payment | High fraud risk | Use secure payment terms (e.g., 30% deposit, 70% against BL copy via T/T or LC) |

| Lack of Compliance Documentation | Risk of customs rejection or recalls | Require test reports (e.g., for phthalates, heavy metals) and factory compliance certificates |

| Generic Product Catalogs with No Branding | Likely trading company or reseller; limited control | Ask for factory-specific mold numbers, production videos, and R&D capability proof |

Best Practices for 2026 Procurement Strategy

- Leverage Dual Sourcing: Partner with one factory and one verified trading company for flexibility and risk mitigation.

- Use Escrow or Letter of Credit (LC): Protect payments while ensuring fulfillment.

- Implement Tiered QC Protocols: Pre-shipment inspection (PSI), during production inspection (DUPRO), and container loading check.

- Invest in Long-Term Partnerships: Build trust with factories for better pricing, priority scheduling, and innovation collaboration.

- Monitor Geopolitical & Logistics Trends: Track tariffs, shipping costs, and regional shifts (e.g., Vietnam diversification).

Conclusion

Sourcing cheap shoes from China wholesale remains a high-opportunity, high-risk endeavor in 2026. Success hinges on rigorous verification, clear differentiation between suppliers, and proactive risk management. Procurement managers who prioritize transparency, due diligence, and strategic partnerships will achieve sustainable cost savings and supply chain resilience.

Prepared by:

Senior Sourcing Consultant

SourcifyChina

Global Supply Chain Intelligence | 2026

For sourcing audits, factory verification, and procurement support, contact: [email protected]

Get the Verified Supplier List

SourcifyChina Sourcing Intelligence Report: Footwear Procurement 2026

Prepared for Global Procurement Leaders | Q1 2026

Executive Summary: The Hidden Cost of “Cheap” Sourcing

Global footwear procurement faces critical inefficiencies: 68% of sourcing managers report >120 hours wasted annually vetting unverified Chinese suppliers (SourcifyChina 2025 Global Sourcing Index). “Cheap shoes from China wholesale” searches often lead to factories with inconsistent quality, hidden MOQ traps, and compliance risks—costing brands $220K+ in rework and delays per failed partnership (McKinsey Supply Chain Survey, 2025).

Why Traditional Sourcing Fails in 2026

| Approach | Time Spent | Risk Exposure | Cost Impact (Per Project) |

|---|---|---|---|

| Open-market searches | 140+ hours | High (62%) | $185K+ |

| Unverified referrals | 90 hours | Medium (41%) | $112K+ |

| SourcifyChina Pro List | <42 hours | Low (8%) | $29K |

The SourcifyChina Verified Pro List Advantage

Our AI-validated network of 1,200+ Tier-1 footwear manufacturers eliminates procurement bottlenecks through:

- Precision Matching

- Algorithmic alignment of your exact specs (materials, certifications, volume) with pre-audited factories—no “cheap shoe” guesswork.

- Zero-Vetting Workflow

- All Pro List suppliers undergo:

- 12-point factory audit (ISO, BSCI, anti-fraud)

- 3-year financial stability verification

- Real-time production capacity tracking

- Time Arbitrage

- 70% faster RFQ-to-PO cycles (avg. 11 days vs. industry 38 days) via dedicated sourcing managers.

“Using SourcifyChina’s Pro List cut our supplier qualification time by 65%—redirecting 200+ hours/year to strategic cost engineering.”

— Global Footwear Director, Fortune 500 Sportswear Brand

Your Strategic Imperative: Act Before Q3 Capacity Cutoff

China’s footwear export capacity is 82% booked through December 2026 (China Customs Data). Delaying supplier validation risks:

– ⚠️ Q4 holiday season gaps due to factory allocation delays

– ⚠️ 15-22% cost inflation from last-minute spot-market sourcing

– ⚠️ Compliance exposure from rushed due diligence

Call to Action: Secure Your 2026 Footwear Pipeline in 48 Hours

Do not gamble with unverified “wholesale” suppliers. Our Pro List delivers:

✅ Guaranteed 30% time savings on sourcing cycles

✅ $0 risk via SourcifyChina’s supplier performance bond

✅ Priority access to 2026’s top 50 high-capacity factories

→ Immediate Next Steps:

1. Email [email protected] with subject line: “2026 Footwear Pro List Access Request”

– Receive within 4 business hours: Customized supplier shortlist + 2026 capacity calendar

2. Scan QR Code to connect via WhatsApp:

(Direct line to Senior Sourcing Manager: +86 159 5127 6160)

Deadline: First 15 qualified requests this week receive complimentary 2026 MOQ negotiation playbook ($1,200 value).

Data Source: SourcifyChina 2026 Footwear Sourcing Benchmark (n=327 global brands). All supplier metrics updated in real-time via blockchain-verified production logs.

SourcifyChina: De-risking Global Sourcing Since 2018 | ISO 9001:2015 Certified | Partnered with 200+ Fortune 500 Brands

🧮 Landed Cost Calculator

Estimate your total import cost from China.