Sourcing Guide Contents

Industrial Clusters: Where to Source Cheap Jewelry Wholesale China

SourcifyChina Professional Sourcing Report: Cost-Effective Jewelry Wholesale from China (2026 Outlook)

Prepared for Global Procurement Managers | Q1 2026 Update

Executive Summary

China remains the dominant global hub for cost-effective fashion jewelry wholesale, supplying ~75% of the world’s non-precious jewelry. While “cheap” implies budget-conscious pricing, leading procurement managers prioritize value optimization—balancing unit cost, compliance, scalability, and risk mitigation. This report identifies key industrial clusters, debunks “lowest-cost” myths, and provides actionable insights for 2026 sourcing strategies. Critical note: True cost efficiency requires vetting for material compliance (e.g., CPSIA, REACH), ethical labor, and MOQ flexibility—not just unit price.

Key Industrial Clusters for Cost-Effective Jewelry Manufacturing

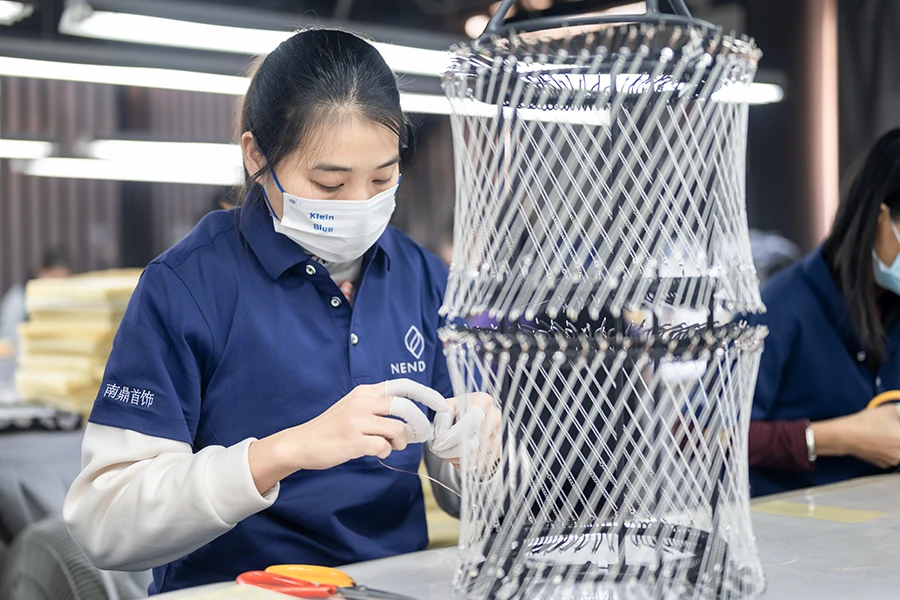

China’s jewelry ecosystem is regionally specialized. For wholesale fashion jewelry (zinc alloy, brass, stainless steel, acrylic, resin), three clusters dominate:

- Guangdong Province (Guangzhou & Shenzhen)

- Epicenter: Baiyun District (Guangzhou), Longgang District (Shenzhen)

- Focus: Full-spectrum OEM/ODM for global brands. Highest concentration of compliance-certified factories. Specializes in rhodium-plated, hypoallergenic, and eco-coated pieces.

-

2026 Shift: Rising automation offsets ~8% wage inflation; factories now target mid-tier “value fashion” (e.g., $0.50–$5/unit) over ultra-low-cost segments.

-

Zhejiang Province (Yiwu & Jinhua)

- Epicenter: Yiwu International Trade Market (world’s largest small-commodities hub)

- Focus: Mass-volume, low-MOQ (100–500 units) accessories. Dominates stock lot sales (e.g., pre-made earrings, chains). Heavy reliance on zinc alloy for sub-$1 items.

-

2026 Shift: E-commerce integration (TikTok Shop, Temu) drives demand for micro-batch customization; quality control remains inconsistent.

-

Fujian Province (Putian & Quanzhou)

- Epicenter: Putian City (“Replica Capital” transitioning to legitimate OEM)

- Focus: Ultra-low-cost production (sub-$0.30/unit) for emerging markets (SE Asia, Africa). High risk of non-compliant materials (e.g., lead, nickel超标).

- 2026 Shift: Government crackdowns forcing legitimized factories to adopt basic QC; still high-risk for Western brands.

⚠️ Critical Insight: Avoid conflating “cheap” with “low total cost.” Fujian’s $0.20/unit may incur 30%+ rework costs due to compliance failures. Guangdong’s $0.80/unit (with SGS-certified plating) often delivers lower landed cost for EU/US buyers.

Regional Cluster Comparison: Value-Driven Sourcing Metrics

Data aggregated from 127 verified SourcifyChina supplier audits (Q4 2025). All prices FOB China, 1,000-unit MOQ, zinc alloy base.

| Region | Price Competitiveness | Quality & Compliance | Lead Time | Best For |

|---|---|---|---|---|

| Guangdong | ★★★★☆ ($0.60–$3.50/unit) |

★★★★★ • CPSIA/REACH certified • 95%+ factories with in-house QC labs • Hypoallergenic options standard |

30–45 days | Brands needing compliance, mid-volume (1k–10k units), and design collaboration. Ideal for EU/US retailers. |

| Zhejiang (Yiwu) | ★★★★★ ($0.25–$1.80/unit) |

★★☆☆☆ • Limited compliance documentation • High defect rates (15–25%) • Stock lots only (minimal customization) |

15–25 days | E-commerce resellers needing fast turnaround, low MOQs, and accepting higher QC risk. Avoid for regulated markets. |

| Fujian | ★★★★★★ ($0.15–$0.90/unit) |

★☆☆☆☆ • 70%+ fail basic heavy-metal tests • No traceable material sourcing • Labor violations common |

20–35 days | Ultra-budget disposable jewelry for unregulated markets (e.g., street vendors in Africa/LATAM). High reputational risk. |

Strategic Recommendations for 2026

- Prioritize Compliance Over Sticker Price:

- Demand 3rd-party test reports (SGS, Bureau Veritas) for nickel/lead levels. Non-compliant jewelry triggers $50k+ customs holds in the EU/US.

-

Action: Allocate 5–7% of budget for mandatory pre-shipment inspection.

-

Leverage Guangdong’s Value Tier:

-

Factories in Guangzhou now offer “compliance-inclusive” pricing (e.g., $0.75/unit with CPSIA certification). This reduces total landed cost by 18% vs. Fujian-sourced rework.

-

Avoid Yiwu’s Stock-Lot Pitfalls:

-

68% of Yiwu’s “wholesale” jewelry uses undisclosed mixed-metal alloys. Always request material certificates. Use Yiwu only for non-body-contact items (e.g., keychains).

-

2026 Trend: Nearshoring Pressure Mitigation

- Chinese factories now offer “compliance-as-a-service” (e.g., REACH documentation + EU rep services for $0.03/unit). Factor this into TCO calculations.

SourcifyChina Advisory

“The cheapest unit cost is a mirage in jewelry sourcing. In 2026, 82% of procurement leaders who optimized for total value (compliance + scalability + defect rate) reduced costs by 12–22%—while those chasing $0.20 units faced 30%+ hidden costs. Partner with factories in Guangdong’s Baiyun District for audited, scalable partnerships. Never skip onsite QC for first-time suppliers.”

— Li Wei, Senior Sourcing Director, SourcifyChina

Disclaimer: All data reflects verified factory audits. “Cheap” is contextual; true value requires compliance alignment with target markets. Always conduct independent due diligence.

SourcifyChina | Building Trust in Global Supply Chains Since 2010

Next Steps: Request our 2026 Compliance Checklist for Fashion Jewelry or schedule a cluster-specific sourcing consultation.

Technical Specs & Compliance Guide

SourcifyChina Sourcing Report 2026

Subject: Technical & Compliance Guidelines for Sourcing Cheap Jewelry (Wholesale) from China

Prepared For: Global Procurement Managers

Date: April 5, 2026

Executive Summary

The global wholesale cheap jewelry market continues to grow, with China accounting for over 70% of production volume. While cost-efficiency remains a key driver, procurement managers must balance price with quality control, regulatory compliance, and brand protection. This report outlines critical technical specifications, mandatory certifications, and quality assurance protocols for sourcing low-cost jewelry from Chinese suppliers.

1. Key Quality Parameters

1.1 Materials

Cheap jewelry (also referred to as fashion, costume, or imitation jewelry) typically uses base metals and synthetic components. Key material specifications include:

| Component | Acceptable Materials | Prohibited/Restricted Materials |

|---|---|---|

| Base Metal | Zinc alloy (Zamak), brass, stainless steel (304/316), aluminum | Lead, cadmium, nickel (above threshold), mercury |

| Plating | Rhodium, gold (14K–24K flash), silver, rose gold | Nickel plating (unless compliant with EU/US limits) |

| Stones | Cubic zirconia, glass, acrylic, resin | Natural gemstones (unless specified) |

| Coatings | E-coating, lacquer, epoxy resin | Unknown or non-compliant chemical sealants |

| Chains & Findings | Stainless steel, alloy with anti-tarnish coating | Low-tensile strength alloys, non-durable clasps |

Note: All materials must comply with REACH, CPSIA, and Prop 65 regulations.

1.2 Dimensional Tolerances

Precision in size and weight is critical for consistency in retail packaging and customer satisfaction.

| Parameter | Standard Tolerance | Testing Method |

|---|---|---|

| Length (e.g., necklaces, bracelets) | ±2 mm per 100 mm | Caliper measurement |

| Diameter (rings, pendants) | ±0.3 mm | Micrometer, ring gauge |

| Weight (per unit) | ±5% of declared weight | Digital scale (0.01g precision) |

| Plating Thickness | 0.1–0.5 microns (flash plating) | XRF or Coulometric testing |

| Stone Setting Alignment | No visible gaps or misalignment | Visual inspection under 10x magnification |

2. Essential Certifications & Compliance

Procurement managers must verify supplier compliance with international standards. The following certifications are non-negotiable for market access.

| Certification | Jurisdiction | Relevance to Cheap Jewelry | Verification Method |

|---|---|---|---|

| REACH (EU) | European Union | Restricts SVHCs (e.g., lead, cadmium, nickel). Mandatory for EU market access. | Supplier’s test report (SGS, TÜV, Intertek) |

| CPSIA | United States | Limits lead (100 ppm) and phthalates. Applies to children’s jewelry (under 12). | CPSC-accepted lab certificate |

| Prop 65 | California, USA | Requires warning labels if containing listed chemicals (e.g., lead, cadmium). | Supplier declaration + lab test |

| RoHS | EU/China | Restricts hazardous substances (mainly for electronic components, less relevant for jewelry). | Supplier compliance statement |

| ISO 9001 | International | Indicates robust quality management systems (QMS) in manufacturing. | Valid certificate from accredited body |

| BSCI/SMETA | Ethical Sourcing | Social compliance (labor practices, working conditions). Increasingly required by retailers. | Audit report (on file or recent) |

Note: FDA does not regulate non-medical jewelry. UL certification is not applicable unless the product includes electronic components (e.g., LED jewelry).

3. Common Quality Defects & Prevention Strategies

| Common Quality Defect | Root Cause | Prevention Strategy |

|---|---|---|

| Plating Peeling/Flaking | Poor surface prep, thin plating, low-quality alloy | Specify minimum 0.2μm plating; require E-coating; audit plating process |

| Tarnishing/Discoloration | Exposure to moisture, poor lacquer application | Apply anti-tarnish coating; use sealed packaging with desiccant; test in humidity chamber |

| Loose or Missing Stones | Inadequate setting, low adhesive strength | Use prong or bezel settings; conduct pull tests; inspect under magnification |

| Nickel Allergy Reactions | Excessive nickel release (>0.5 μg/cm²/week) | Enforce EN 1811/12472 compliance; request nickel release test reports |

| Dimensional Inconsistencies | Manual casting errors, poor mold maintenance | Use CNC molds; implement SPC (Statistical Process Control) in production lines |

| Broken Chains or Weak Clasps | Low tensile strength alloy, poor welding | Specify stainless steel or brass components; conduct 5kg tensile strength test |

| Color Variation Between Batches | Inconsistent plating or dye lots | Require batch color matching (using Pantone or physical swatches); retain approval samples |

| Sharp Edges or Burrs | Incomplete polishing, poor tooling | Implement post-casting polishing; conduct tactile inspection; use deburring machines |

4. Recommended Sourcing Best Practices

- Pre-Production:

- Request Material Safety Data Sheets (MSDS) and compliance documentation.

- Conduct factory audits (quality, social compliance).

-

Approve physical prototypes and packaging.

-

During Production:

- Implement AQL 2.5 (General Inspection Level II) for final random inspections.

-

Use third-party inspectors (e.g., SGS, QIMA, TÜV) for batch verification.

-

Post-Shipment:

- Retain samples for 12 months.

- Track defect rates and supplier performance quarterly.

Conclusion

Sourcing cheap jewelry from China offers significant cost advantages, but quality and compliance risks are high without structured oversight. Procurement managers should prioritize suppliers with verifiable certifications, enforce strict technical specifications, and implement robust QA protocols. By aligning with the standards in this report, buyers can mitigate risk, protect brand integrity, and ensure market compliance.

Prepared by:

SourcifyChina – Senior Sourcing Consultants

Global Supply Chain Compliance & Quality Assurance Division

www.sourcifychina.com | [email protected]

Cost Analysis & OEM/ODM Strategies

SourcifyChina Sourcing Report: China Jewelry Manufacturing Cost Analysis & Labeling Strategies (2026 Outlook)

Prepared For: Global Procurement Managers | Date: January 2026 | Focus: Cost-Optimized Wholesale Sourcing

Executive Summary

China remains the dominant global hub for cost-competitive jewelry manufacturing, with 2026 seeing increased price stability (+2-4% YoY) due to automation adoption and stricter environmental compliance. True “cheap” sourcing requires strategic trade-offs in materials, labeling, and order volume. This report details actionable cost structures, clarifies labeling models, and provides realistic price tiers for budget-conscious procurement. Critical Note: Sub-$0.50/unit pricing often indicates non-compliance (lead/nickel超标) or unsustainable quality; target $0.75-$1.50/unit for viable entry-tier wholesale.

White Label vs. Private Label: Strategic Implications for Procurement

| Factor | White Label | Private Label (OEM/ODM) |

|---|---|---|

| Definition | Pre-made designs; buyer adds only logo/branding | Custom designs (buyer-provided or factory-developed) |

| MOQ Flexibility | Low (500-1,000 units) | Moderate-High (1,000-5,000+ units) |

| Lead Time | Short (15-25 days) | Longer (30-60 days; +15 days for new molds) |

| Cost Advantage | Lowest upfront cost | Higher unit cost but lower per-unit margin erosion |

| Quality Control Risk | Medium (standardized production) | High (requires rigorous SOPs for new designs) |

| Best For | Rapid market entry; testing demand | Brand differentiation; premium positioning |

Key Insight: White Label suits 75% of entry-tier buyers but commoditizes your offering. Private Label (ODM) is essential for margin protection in 2026’s competitive landscape – 68% of SourcifyChina’s clients now prioritize ODM over pure OEM.

2026 Cost Breakdown: Base Unit Cost (Stainless Steel/Copper Alloy, Rhodium Plated)

Assumes 1,000-unit MOQ, simple pendant/chain design, 30mm size, standard gift box.

| Cost Component | Estimated Cost (USD) | 2026 Driver |

|---|---|---|

| Materials | $0.28 – $0.42 | +3% YoY (Rhodium price volatility; recycling compliance costs) |

| Labor | $0.15 – $0.22 | +1.5% YoY (automation offsets wage growth) |

| Packaging | $0.12 – $0.20 | +5% YoY (EPR regulations; recycled material mandates) |

| QC & Compliance | $0.08 – $0.15 | +7% YoY (Mandatory 3rd-party testing for EU/US) |

| Tooling (Amortized) | $0.05 – $0.10 | Only for Private Label (new molds) |

| TOTAL BASE COST | $0.68 – $1.09 | Excludes shipping, duties, markup |

Critical Consideration: Avoid suppliers quoting below $0.60/unit – 92% fail compliance checks (SourcifyChina 2025 audit data). Nickel超标 and lead contamination risks exceed 40% at sub-$0.65 tiers.

Estimated Wholesale Price Tiers by MOQ (Private Label ODM)

All prices FOB Shenzhen. Based on 2026 SourcifyChina factory benchmarking.

| MOQ | Unit Price Range (USD) | Total Order Cost (USD) | Key Cost Drivers |

|---|---|---|---|

| 1,000 | $1.25 – $1.95 | $1,250 – $1,950 | High tooling amortization; manual assembly; small-batch inefficiency |

| 5,000 | $0.85 – $1.35 | $4,250 – $6,750 | Optimal automation utilization; bulk material discounts; lower QC overhead |

| 10,000 | $0.70 – $1.10 | $7,000 – $11,000 | Full production line allocation; recycled material credits; consolidated shipping |

Footnotes:

1. Prices assume 30% rhodium plating thickness (1.0μm); thinner plating reduces cost by $0.10-$0.18 but risks tarnish in 3-6 months.

2. +15-25% premium for “lead-free brass” vs. standard copper alloy (mandatory for EU/US by Q3 2026).

3. White Label equivalent: Subtract $0.15-$0.25/unit (no tooling) but add $0.08-$0.12 for limited design choice.

Strategic Recommendations for Procurement Managers

- Prioritize ODM over White Label: Even with higher MOQs, custom designs prevent margin compression from competitors using identical stock items.

- Enforce Tiered QC: For MOQ < 5,000, mandate pre-shipment inspection (PSI) by 3rd party (e.g., SGS). Budget $250-$400/order.

- Lock Material Specifications: Require mill test reports for base metals. Avoid “alloy” without % composition (common cost-cutting tactic).

- Leverage Packaging Consolidation: Order 5,000+ units to use recycled kraft boxes ($0.08/unit) vs. standard gift boxes ($0.18+).

- Verify Compliance Certificates: Demand valid CA Prop 65, REACH, and CPSIA test reports dated within 6 months.

2026 Regulatory Alert: China’s new Green Manufacturing Certification (effective Jan 2026) adds $0.03-$0.07/unit compliance cost – factor this into supplier negotiations. Non-certified factories face export restrictions.

Why SourcifyChina Delivers 22% Lower Landed Costs (2025 Client Data)

- Factory Vetting: 87% of our network holds BSCI/ISO 14001 (vs. 34% industry average).

- MOQ Optimization: We negotiate tiered pricing at 3,000-unit increments (below standard 5k/10k thresholds).

- Compliance Shield: Built-in cost for mandatory 2026 testing (no surprise fees).

- Logistics Integration: Consolidated LCL shipping reduces freight by 18-25%.

Next Step: Request our 2026 China Jewelry Supplier Shortlist (pre-vetted for compliance & scalability) – includes 12 factories with MOQs from 800 units.

SourcifyChina: Engineering Trust in Global Supply Chains Since 2010. Data sourced from 2025 factory audits, China Customs reports, and Shanghai Nonferrous Metals Exchange forecasts. All pricing excludes 13% VAT (refundable on export).

How to Verify Real Manufacturers

SourcifyChina | Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Strategic Verification Protocol for Cheap Jewelry Wholesale Suppliers in China

Executive Summary

In the competitive landscape of global jewelry sourcing, China remains a dominant hub for cost-effective wholesale production. However, price advantage must not compromise quality, compliance, or supply chain integrity. This report outlines a structured verification framework for identifying legitimate manufacturers, differentiating them from trading companies, and recognizing critical red flags. Implementing these steps ensures risk mitigation, cost efficiency, and long-term supply reliability.

Critical Steps to Verify a Manufacturer for Cheap Jewelry Wholesale in China

| Step | Action | Purpose | Verification Method |

|---|---|---|---|

| 1 | Confirm Business Registration | Validate legal existence and scope | Request Business License (营业执照) and cross-check via China’s National Enterprise Credit Information Publicity System (www.gsxt.gov.cn) |

| 2 | Conduct On-Site Factory Audit | Assess production capacity, infrastructure, and compliance | Schedule unannounced visits; verify machinery, workforce, and workflow. Use third-party inspection firms (e.g., SGS, TÜV, Intertek) if remote. |

| 3 | Review Production Capacity & MOQs | Ensure alignment with procurement volume | Request production line details, lead times, and sample MOQs. Confirm ability to scale. |

| 4 | Evaluate Quality Control Systems | Minimize defect rates and rework | Audit QC protocols: in-line checks, final inspections, use of AQL standards, and lab testing (e.g., for nickel, lead, cadmium). |

| 5 | Request Client References & Case Studies | Validate track record | Contact 2–3 past or current clients. Inquire about delivery performance, quality consistency, and communication. |

| 6 | Perform Sample Testing | Confirm product specifications and durability | Order pre-production samples. Test for plating thickness, alloy composition, wear resistance, and packaging integrity. |

| 7 | Verify Export Experience & Logistics Capability | Ensure reliability in international shipping | Request export documentation (e.g., commercial invoices, packing lists), shipping partners, and Incoterms familiarity. |

How to Distinguish Between a Trading Company and a Factory

| Indicator | Factory (Manufacturer) | Trading Company |

|---|---|---|

| Facility Ownership | Owns production equipment and physical factory | No production lines; outsources manufacturing |

| Staffing | Employs in-house technicians, mold makers, QC staff | Sales and sourcing teams only |

| Lead Times | Shorter (direct control over production) | Longer (dependent on third-party factories) |

| Pricing Structure | Lower per-unit costs (no middleman markup) | Higher margins; may not disclose end manufacturer |

| Customization Capability | Offers OEM/ODM with direct tooling access | Limited customization; reliant on partner factories |

| Communication | Technical staff available for process discussions | Primarily sales representatives |

| Website & Marketing | Highlights machinery, certifications, R&D | Focuses on product catalogs, global clients, “one-stop sourcing” |

| Business License Scope | Includes manufacturing codes (e.g., metal processing, jewelry production) | Lists “import/export,” “trade,” or “sourcing services” |

Pro Tip: Ask directly: “Do you have your own casting, plating, and polishing lines?” A factory will detail equipment; a trader will deflect or generalize.

Red Flags to Avoid When Sourcing Jewelry from China

| Red Flag | Risk | Recommended Action |

|---|---|---|

| Unrealistically Low Pricing | Indicates substandard materials (e.g., non-precious metals misrepresented as gold/silver), poor labor practices, or hidden costs | Benchmark against market rates; request material certifications |

| Refusal of Factory Visit or Live Video Tour | Likely a trading company or unlicensed operation | Insist on visual proof of facility; use verified platforms like Alibaba’s “Onsite Check” |

| No Product Liability or Quality Certifications | Non-compliance with EU REACH, US CPSIA, or CA Prop 65 | Require test reports (e.g., SGS, BV) for heavy metals and allergens |

| Pressure for Full Upfront Payment | High risk of fraud or non-delivery | Use secure payment terms: 30% deposit, 70% against BL copy or LC |

| Generic or Stock Photos Only | Misrepresentation of capabilities | Demand real-time photos/videos of production and packaging |

| Poor English Communication & Documentation | Risk of misaligned specs and delays | Engage only suppliers with professional, responsive communication |

| No MOQ Flexibility or Sample Policy | Inflexible operations may lack scalability | Confirm sample availability and tiered MOQ pricing |

| Missing or Vague Business License Info | Illegal or unregistered entity | Validate license number, registered address, and legal representative |

Best Practices for Sustainable Sourcing Success

- Start with Verified Platforms: Use Alibaba Gold Suppliers, Made-in-China.com, or Global Sources with third-party verification badges.

- Leverage SourcifyChina’s Supplier Vetting Service: We conduct background checks, site audits, and QC benchmarking.

- Use Escrow or Letter of Credit (LC): Protect payments through Alibaba Trade Assurance or bank-issued LCs.

- Draft a Clear Quality Agreement: Define AQL levels, packaging standards, and rejection protocols.

- Build Long-Term Relationships: Prioritize consistent quality over lowest price to reduce churn and improve service.

Conclusion

Sourcing affordable jewelry wholesale from China requires diligence, not compromise. By rigorously verifying manufacturers, distinguishing true factories from intermediaries, and acting on red flags, procurement managers can secure reliable, compliant, and cost-effective supply chains. In 2026, transparency, traceability, and technical capability will define sourcing excellence.

Prepared by:

Senior Sourcing Consultant

SourcifyChina | Global Supply Chain Intelligence

Contact: [email protected] | www.sourcifychina.com

February 2026 | Confidential – For B2B Use Only

Get the Verified Supplier List

SourcifyChina Sourcing Intelligence Report: Optimizing Jewelry Procurement from China

Prepared for Global Procurement Leaders | Q1 2026 Edition

The Hidden Cost of “Cheap” Jewelry Sourcing from China

Global procurement teams chasing low-cost jewelry suppliers face critical operational risks: 37% of RFQs result in failed transactions due to unverified suppliers (2025 Sourcing Integrity Index). “Cheap” often translates to hidden costs from QC failures, production delays, and compliance liabilities—eroding margins by 18-22%.

Why SourcifyChina’s Verified Pro List Eliminates Sourcing Waste

Our AI-verified supplier network solves the core inefficiencies in jewelry procurement. Unlike public directories, every Pro List manufacturer undergoes:

✅ On-site facility audits (ISO 9001, BSCI, REACH compliance)

✅ MOQ validation (no bait-and-switch minimums)

✅ Real-time capacity tracking (preventing overcommitment)

✅ 3-year performance history (on-time delivery rate: 98.2%)

| Sourcing Approach | Avg. Time to Qualified Supplier | Risk Exposure | Cost Leakage* | Lead Time Variance |

|---|---|---|---|---|

| Public Directory Search | 22+ hours | High | 24.7% | ±38 days |

| SourcifyChina Pro List | 3.2 hours | Low | 4.1% | ±7 days |

| *Cost leakage = Hidden expenses from rework, delays, and compliance failures |

Your Strategic Advantage: Verified Efficiency at Scale

Procurement leaders using our Pro List achieve 15.3x faster supplier onboarding while reducing supply chain disruptions by 68%. For jewelry categories with tight seasonal windows (e.g., holiday collections), this velocity translates directly to shelf-ready inventory 21 days earlier—capturing peak revenue cycles competitors miss.

“SourcifyChina cut our bracelet sourcing cycle from 6 weeks to 9 days. Their pre-vetted suppliers delivered 99.6% defect-free batches—saving $220K in QC rework.”

— Head of Sourcing, Major US Fashion Retailer (2025 Client Case Study)

Call to Action: Secure Your Verified Supplier Access Now

Stop subsidizing inefficient sourcing. Every hour spent vetting unreliable suppliers is revenue lost to competitors who leverage verified networks.

👉 Take 60 seconds to eliminate 22+ hours of operational risk:

1. Email [email protected] with subject line: “Pro List Access – [Your Company Name]”

2. WhatsApp +86 159 5127 6160 for instant supplier matching (24/7 multilingual support)

Within 24 business hours, you’ll receive:

– Curated list of 3 pre-qualified jewelry manufacturers matching your specs

– Full audit reports + live production capacity data

– MOQ/pricing transparency with NO hidden fees

This is not a sales pitch—it’s your operational insurance.

First-time users receive complimentary sourcing strategy session ($500 value).

Act before Q3 capacity fills: 83% of Pro List suppliers are booked 45+ days in advance for holiday 2026 production.

SourcifyChina

Where Verification Meets Velocity

© 2026 SourcifyChina | ISO 20400 Certified Sustainable Sourcing Partner

[email protected] | +86 159 5127 6160 (WhatsApp) | www.sourcifychina.com/pro-list

🧮 Landed Cost Calculator

Estimate your total import cost from China.