The global marine equipment manufacturing market is experiencing steady growth, driven by rising recreational boating activities and advancements in boat design. According to Grand View Research, the global recreational boating market was valued at USD 57.8 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 6.2% from 2023 to 2030. This growth directly fuels demand for high-performance marine accessories, including center console lean posts—critical ergonomic and functional components that enhance comfort and usability on modern powerboats. As boat manufacturers and aftermarket suppliers prioritize durability, adjustability, and space optimization, the competition among lean post manufacturers has intensified. Based on performance metrics, product innovation, distribution reach, and customer feedback, the following nine companies have emerged as leaders in the center console lean post segment, setting benchmarks in quality and design for OEMs and marine retrofit markets alike.

Top 9 Center Console Lean Post Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Standard Leaning Posts

Domain Est. 2002

Website: nauticaldesigninc.com

Key Highlights: Leaning posts feature high density foam and marine grade vinyl cushion with plenty of cushion for comfortable seating. Available in Premier, Superior, ……

#2 Leaning Posts

Domain Est. 2011

Website: weldingworldinc.com

Key Highlights: 30-day returnsOur Leaning Posts incorporate the best quality US sourced materials, the highest manufacturing standards, and the uncompromising attention to detail of our ……

#3 Leaning Post

Domain Est. 1999

#4 Todd Marine Products

Domain Est. 1999

Website: toddusa.com

Key Highlights: Todd Marine Products is committed to designing and manufacturing innovative, high quality merchandise at competitive prices….

#5 Leaning Posts for Center Console Boats

Domain Est. 2008

Website: strykerttops.com

Key Highlights: 3–6 day deliveryOur line of universal fitting leaning posts for center console boats! We use the same quality materials and manufacturing as our legendary t-tops….

#6 Center Console Boats

Domain Est. 2010

Website: blackfinboats.com

Key Highlights: The 252CC is equipped with a fiberglass hardtop & leaning post with a command center featuring a custom-designed helm seat with flip-up bolster, high ……

#7 Open 402 Center Console · Features

Domain Est. 2011

Website: sportsmanboatsmfg.com

Key Highlights: The quad premium captain’s chairs with integrated fiberglass leaning post offer maximum comfort, while the rear-facing mezzanine seating provides additional ……

#8 Sea Pro Boats Page

Domain Est. 2013

Website: seapromfg.com

Key Highlights: Recognized for the 245 FLX Sandbar Boat, launched in Model Year 2024 and acclaimed for its standout features, such as the sandbar table, leaning posts, ……

#9 Deluxe leaning post

Domain Est. 2021

Expert Sourcing Insights for Center Console Lean Post

H2: 2026 Market Trends for Center Console Lean Post

The center console lean post market is poised for significant evolution by 2026, driven by advancements in marine technology, shifting consumer preferences, and growing demand for enhanced on-water experiences. Lean posts—multi-functional structures mounted behind the helm of center console boats—have transitioned from simple fishing aids to integrated command and comfort hubs. Several key trends are expected to shape the market landscape in 2026.

1. Integration of Smart Technology

By 2026, lean posts will increasingly feature embedded smart systems, including touchscreen controls, integrated fishfinders, GPS navigation, and wireless charging stations. Manufacturers are focusing on seamless connectivity with mobile devices and onboard electronics, enabling boaters to control audio, lighting, and engine data directly from the lean post. This trend aligns with the broader marine industry shift toward digital cockpits and IoT-enabled vessels.

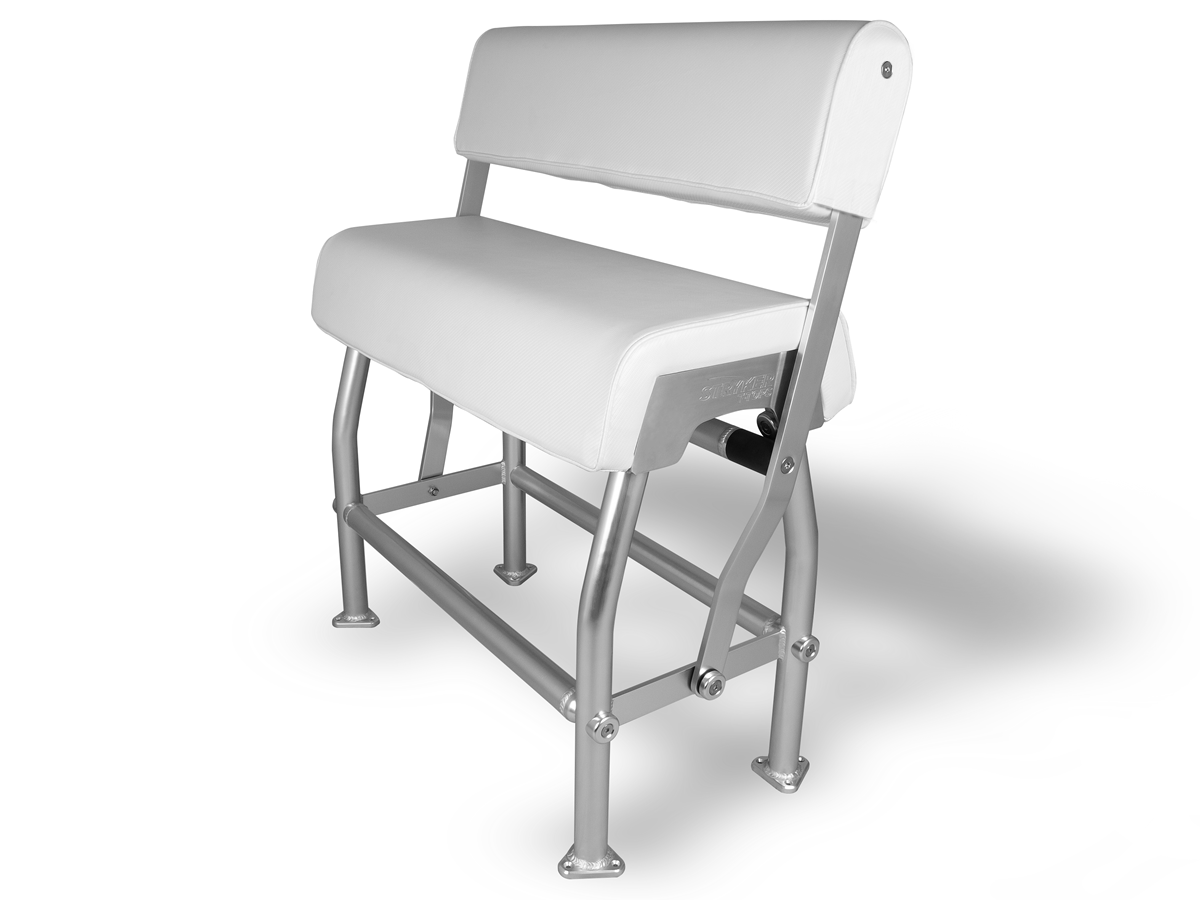

2. Focus on Ergonomics and Comfort

As center console boats expand into luxury and multi-day cruising segments, lean posts are being redesigned with greater emphasis on comfort. Expect to see more adjustable seating, padded backrests, and convertible lounging options. Premium materials such as marine-grade vinyl, carbon fiber, and powder-coated aluminum will dominate to balance durability with aesthetic appeal.

3. Modular and Customizable Designs

Modularity will be a major selling point in 2026. Consumers demand flexibility—lean posts that can be reconfigured for fishing, entertaining, or sunbathing. Add-on accessories like rod holders, coolers, dive tank racks, and shade systems will be designed for easy installation and removal. Customization options, including color-matching to boat interiors and brand-specific styling, will appeal to a more discerning buyer.

4. Sustainability and Lightweight Materials

Environmental concerns are influencing material choices. Manufacturers are adopting recyclable composites and lightweight alloys to improve fuel efficiency and reduce environmental impact. Lean posts engineered for durability without excess weight will be favored, especially as electric and hybrid propulsion systems gain traction in the marine sector.

5. Expansion in Recreational and Luxury Segments

While lean posts originated in offshore fishing, their appeal is broadening. By 2026, they will be standard in mid-to-large-sized center consoles used for family recreation, coastal cruising, and entertainment. High-end models will include features like integrated beverage centers, ambient lighting, and sound systems, blurring the line between fishing platforms and luxury yachts.

6. Regional Market Growth

North America remains the dominant market, but growth in Europe and Asia-Pacific is accelerating. Countries with expanding coastal economies and rising boating participation—such as Australia, Japan, and the UAE—are adopting center console designs with lean posts, fueling global demand.

In conclusion, the 2026 center console lean post market will be defined by innovation, personalization, and convergence of utility with lifestyle enhancement. As boatbuilders respond to sophisticated consumer demands, the lean post will solidify its role as a central feature in the next generation of center console vessels.

Common Pitfalls Sourcing Center Console Lean Post (Quality, IP)

Sourcing a Center Console Lean Post—often used in marine or off-road vehicle applications—can present several challenges, particularly concerning quality consistency and intellectual property (IP) risks. Being aware of these pitfalls helps mitigate supply chain disruptions, legal exposure, and performance failures.

Quality Inconsistencies

One of the most prevalent issues when sourcing Center Console Lean Posts is inconsistent product quality, especially when working with overseas or low-cost manufacturers. These inconsistencies may include:

- Material Substitution: Suppliers may use lower-grade plastics, composites, or metals not specified in the design, leading to reduced durability and structural integrity.

- Poor Manufacturing Tolerances: Inaccurate machining or molding can result in misalignment with console components, compromising ergonomics and safety.

- Inadequate Finishing: Surface defects, rough edges, or inconsistent paint/coating can affect both aesthetics and long-term resistance to UV, moisture, or corrosion.

- Lack of Testing Compliance: Some suppliers may skip or falsify performance tests (e.g., load-bearing, vibration, impact), increasing the risk of in-field failure.

To avoid these issues, implement strict quality control protocols, conduct factory audits, and require third-party testing certifications.

Intellectual Property (IP) Risks

Sourcing from regions with lax IP enforcement exposes companies to significant legal and competitive risks:

- Design Theft: Detailed CAD files or prototypes shared during development may be copied or sold to competitors, leading to counterfeit products.

- Unauthorized Production: Suppliers may overproduce units beyond the agreed quantity and sell them independently, diluting brand value.

- Lack of Legal Recourse: Enforcing IP rights across international jurisdictions can be costly and time-consuming, especially without registered patents or trademarks in the supplier’s country.

Mitigation strategies include using non-disclosure agreements (NDAs), limiting technical data shared, working with IP-reliable partners, and securing international patents where applicable.

By proactively addressing both quality and IP concerns, businesses can ensure reliable supply, protect innovation, and maintain product integrity in the marketplace.

Logistics & Compliance Guide for Center Console Lean Post

This guide outlines the key logistics and compliance considerations for the shipping, handling, and regulatory requirements associated with Center Console Lean Posts used in marine and boating applications.

Product Overview and Classification

The Center Console Lean Post is a marine accessory designed to provide support and comfort for operators and passengers on center console boats. Typically constructed from stainless steel, aluminum, or composite materials, these posts are mounted to the boat’s console and often include padded armrests or backrests. For logistics and compliance purposes, the product is generally classified under HTS Code 8302.42 (Stainless steel mountings and fittings for civil aircraft or other vehicles) or 8908.00 (Fittings for vessels), depending on material and design.

Packaging and Handling Guidelines

To ensure safe transit and prevent damage, lean posts must be packaged securely:

– Use heavy-duty cardboard or wooden crates with internal foam or corrugated dividers.

– Protect all polished or coated surfaces with plastic wrap or protective film.

– Secure mounting brackets and hardware in labeled, sealed bags and affix them to the product or pack separately.

– Clearly label packages as “Fragile” and “This Side Up.”

– Avoid stacking packages unless designed for it; use pallets for bulk shipments.

Shipping and Transportation

Lean posts are typically shipped via freight carriers (LTL or FTL) due to size and weight:

– Confirm dimensional weight and actual weight for accurate freight classification.

– Use carriers experienced in handling marine hardware to reduce risk of damage.

– Provide a commercial invoice, packing list, and bill of lading for all shipments.

– For international shipments, ensure compliance with Incoterms (e.g., FOB, EXW, or DDP) as agreed with the buyer.

Import/Export Compliance

When shipping internationally, the following compliance steps are essential:

– Verify applicable Harmonized Tariff Schedule (HTS) codes and country-specific import duties.

– Complete an Export Declaration (e.g., AES filing in the U.S. for shipments over $2,500).

– Provide a Certificate of Origin if required by trade agreements (e.g., USMCA).

– Ensure compliance with destination country regulations (e.g., CE marking for EU, CCC for China if applicable).

Environmental and Safety Regulations

Lean posts may be subject to environmental and safety standards:

– Confirm materials comply with RoHS (Restriction of Hazardous Substances) if exporting to the EU.

– Avoid materials containing restricted substances such as lead, cadmium, or phthalates above permitted levels.

– Follow OSHA and local safety guidelines during warehouse handling and assembly.

Documentation Requirements

Maintain complete and accurate documentation for all logistics and compliance processes:

– Product specification sheets

– Material Safety Data Sheets (MSDS) for any treated components

– Test reports for corrosion resistance (e.g., ASTM B117 salt spray testing)

– Warranty and installation instructions

Quality Assurance and Traceability

Implement a traceability system to track production batches and manage recalls if necessary:

– Assign unique serial or batch numbers to each unit.

– Maintain records of inspections, material certifications, and shipping details.

– Conduct pre-shipment quality checks to verify fit, finish, and function.

Final Compliance Checklist

Before shipping, ensure the following:

– ✔ Packaging meets durability and protection standards

– ✔ All required labels and markings are applied

– ✔ Export documentation is complete and accurate

– ✔ Product complies with destination country regulations

– ✔ Safety and environmental standards are met

Adhering to this logistics and compliance guide ensures smooth transportation, customs clearance, and customer satisfaction for Center Console Lean Post shipments worldwide.

Conclusion:

After a thorough evaluation of potential suppliers and sourcing options for the center console lean post, the most viable approach has been identified based on cost-efficiency, quality standards, production capacity, and supply chain reliability. Sourcing from a strategically located Tier-1 supplier with experience in automotive interior components ensures compliance with technical specifications, supports just-in-time (JIT) delivery, and aligns with lean manufacturing principles. This decision not only optimizes production lead times and reduces logistical costs but also enhances overall product consistency and long-term scalability. Moving forward, establishing a collaborative partnership with the selected supplier will be key to driving continuous improvement, mitigating supply risks, and supporting future vehicle platform integrations.