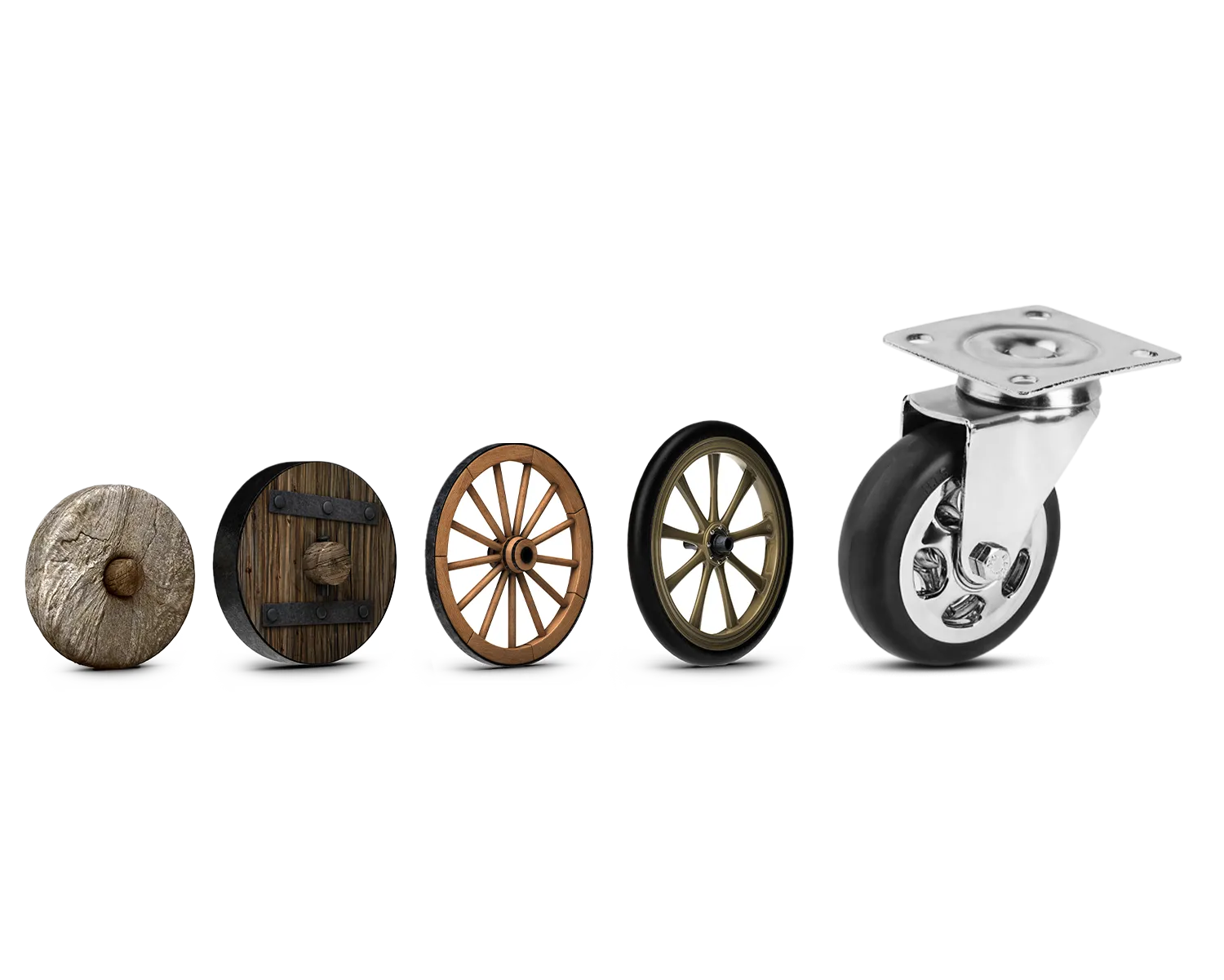

The global caster wheel market is experiencing steady growth, driven by rising demand from industries such as logistics, healthcare, manufacturing, and retail. According to a report by Mordor Intelligence, the global caster wheels market was valued at USD 3.8 billion in 2023 and is projected to grow at a CAGR of over 4.5% during the forecast period from 2024 to 2029. This expansion is fueled by increasing automation, the proliferation of material handling equipment, and a strong push toward ergonomic design in industrial and commercial applications. Additionally, growing e-commerce fulfillment and warehouse modernization are accelerating the need for high-performance, durable caster solutions. As competition intensifies, innovation in materials—such as thermoplastics, polyurethane, and stainless steel—and advancements in swivel mechanisms and load capacity are differentiating leading manufacturers. In this evolving landscape, the top 10 caster wheel manufacturers stand out through product reliability, customization capabilities, global supply networks, and R&D investment, shaping the future of mobility across sectors.

Top 10 Caster Wheel Types Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Hamilton Caster

Domain Est. 1996 | Founded: 1907

Website: hamiltoncaster.com

Key Highlights: A 4th generation family-owned and managed manufacturer, a passion for casters runs in the family. Since 1907, we’ve had a steadfast commitment to manufacturing ……

#2 Revvo Caster

Domain Est. 2001

Website: revvocaster.com

Key Highlights: Revvo Caster manufactures light, medium, heavy-duty, and specialized casters for OEM industrial, institutional, medical, low-profile, and other material ……

#3 Premium Casters and Wheels Supplier

Domain Est. 1999 | Founded: 1969

Website: phcasters.com

Key Highlights: Explore a wide variety of reliable casters and wheels, including heavy duty swivel and rigid casters. Being a trusted supplier since 1969, P&H Casters ……

#4 Albion Casters: The Caster Experts

Domain Est. 2000

Website: albioncasters.com

Key Highlights: Trust Albion Casters: the Caster Experts for your Industrial-Strength Caster needs. Swivel and rigid casters and wheels for industrial uses….

#5 Your caster and wheel manufacturer for all applications

Domain Est. 2002

Website: blickle.us

Key Highlights: Wheels & casters for every use ▷ years of experience ▷ swivel casters ▷ fixed casters ▷ heavy duty casters ▷ light duty casters, etc. ▷ find out more!…

#6 Homepage Custom Casters

Domain Est. 2012

Website: colsongroupusa.com

Key Highlights: Over 20000 casters to choose from. We can design custom casters for your specific need. Choose from Medical Casters, Heavy-Duty Casters, ……

#7 Casters and Wheels

Domain Est. 1996

Website: elesa.com

Key Highlights: Enhance your machinery and carts with Elesa’s high-performance casters and wheels. Choose from polyurethane, technopolymer, rubber, or duroplast options….

#8 Industry Wheels & Casters

Domain Est. 1997

Website: rwmcasters.com

Key Highlights: At RWM, we manufacture and provide a wide array of wheels and casters suitable for a variety of industries. Call us today to learn more!…

#9 Caster Wheels

Domain Est. 1998

Website: casterconcepts.com

Key Highlights: Caster Concepts produces a large variety of heavy duty caster wheels in all sizes to meet your specific application. This includes cast iron wheels and ……

#10 Types of Caster Wheels

Domain Est. 1999

Website: casterconnection.com

Key Highlights: Types of Caster Wheels · CAST IRON/SEMI-STEEL CASTER WHEELS · FLANGED CASTER WHEELS · FORGED STEEL OR DUCTILE STEEL CASTER WHEELS · GLASS FILLED NYLON CASTER WHEELS….

Expert Sourcing Insights for Caster Wheel Types

2026 Market Trends for Caster Wheel Types

As industries continue to evolve with advancements in automation, material handling, and sustainable practices, the caster wheel market is poised for significant transformation by 2026. Caster wheels—essential components in mobility solutions across sectors such as logistics, healthcare, manufacturing, and retail—are being reimagined to meet growing demands for efficiency, durability, and environmental responsibility. This analysis explores key market trends shaping the future of various caster wheel types through 2026.

Rising Demand for High-Performance and Specialty Caster Wheels

By 2026, there is a pronounced shift toward high-performance caster wheels engineered for specific industrial applications. Industries requiring resistance to extreme temperatures, chemicals, or heavy loads—such as pharmaceuticals, food processing, and aerospace—are driving demand for specialty casters made from materials like polyurethane, nylon, and high-grade thermoplastics. These materials offer superior load capacity, noise reduction, and floor protection compared to traditional rubber or steel options. The market for polyurethane casters, in particular, is expected to grow at a CAGR of over 6% due to their balance of soft-floor compatibility and durability.

Growth in Ergonomic and Silent Casters

Workplace safety and ergonomics are becoming central to operational efficiency, pushing manufacturers to develop quieter, smoother-rolling casters. Silent casters, often made with advanced elastomers or hybrid materials, reduce noise pollution in environments like hospitals, libraries, and offices. The healthcare sector is a major adopter, where noise reduction contributes to patient comfort. By 2026, ergonomic casters with swivel lock mechanisms, precision bearings, and low push-force designs are expected to dominate in sectors focused on worker well-being and productivity.

Expansion of Smart and IoT-Enabled Casters

A notable innovation trend is the integration of IoT (Internet of Things) technology into caster systems. Smart casters equipped with sensors can monitor load weight, movement patterns, wheel wear, and even location tracking in real time. This data enhances predictive maintenance, optimizes warehouse logistics, and improves asset management. While still in the early adoption phase, the smart caster segment is projected to grow rapidly, especially in automated guided vehicles (AGVs) and smart factories. By 2026, an increasing number of industrial casters will feature connectivity options as part of broader Industry 4.0 initiatives.

Sustainability and Eco-Friendly Materials

Environmental regulations and corporate sustainability goals are influencing caster wheel production. Manufacturers are exploring bio-based polymers, recycled materials, and longer-life designs to reduce environmental impact. Recyclable thermoplastic polyurethane (TPU) and casters made with reduced carbon footprints are gaining traction. By 2026, eco-conscious procurement policies in Europe and North America are expected to elevate the market share of green caster solutions, particularly in public sector and institutional applications.

Regional Market Dynamics

Asia-Pacific is anticipated to be the fastest-growing region for caster wheels by 2026, fueled by booming e-commerce, logistics infrastructure, and manufacturing in countries like China, India, and Vietnam. Meanwhile, North America and Europe continue to lead in high-value, technologically advanced caster adoption, especially in automation and healthcare. Localized production and supply chain resilience are becoming strategic priorities, prompting global manufacturers to establish regional production hubs.

Conclusion

The 2026 caster wheel market is defined by innovation, specialization, and sustainability. From high-performance materials to smart functionality and eco-design, caster wheel types are adapting to meet the complex demands of modern industry. Companies that invest in R&D, embrace digital integration, and align with sustainability goals will be best positioned to capture growth in this evolving landscape.

Common Pitfalls When Sourcing Caster Wheel Types (Quality, IP)

Sourcing the right caster wheels is critical for equipment performance, safety, and longevity. However, overlooking key factors related to quality and intellectual property (IP) can lead to costly mistakes. Below are common pitfalls to avoid:

Overlooking Material Quality and Load Ratings

Choosing caster wheels based solely on price often results in substandard materials that fail under load or wear prematurely. Low-quality polymers, weak metal cores, or inadequate wheel hardness can compromise performance. Always verify actual load capacity, material composition, and certifications — not just manufacturer claims.

Ignoring Environmental and Application Requirements

Casters used in wet, corrosive, or temperature-sensitive environments (e.g., food processing, cleanrooms, or freezers) require specific materials and IP-rated sealing. Using standard wheels without proper ingress protection (IP) ratings may lead to rust, contamination, or mechanical failure. Ensure wheels are rated for exposure to water, chemicals, dust, and temperature extremes.

Misunderstanding IP (Ingress Protection) Ratings

Many buyers assume all “industrial” casters are sealed against dust and moisture, but this isn’t always true. Misinterpreting IP ratings (e.g., using IP54 instead of IP67 in washdown environments) can lead to premature bearing failure or safety hazards. Confirm the required IP rating based on the operating environment and verify test certification.

Falling for Counterfeit or Copycat Products

Popular caster designs are often copied without licensing, leading to IP infringement risks. Sourcing from unauthorized suppliers may result in poor performance and potential legal liability. Always work with reputable manufacturers or authorized distributors and verify trademarks, patents, and design rights.

Skipping Real-World Testing and Sampling

Relying only on datasheets without testing samples in actual operating conditions can result in mismatched performance. Factors like floor type, rolling resistance, noise, and swivel ease vary significantly. Request and evaluate prototypes under real load and environmental conditions before bulk ordering.

Neglecting Compliance and Certification Requirements

Industries such as healthcare, food & beverage, or explosive environments (ATEX) require casters to meet strict regulatory standards. Overlooking certifications (e.g., FDA, NSF, UL, ATEX) can result in non-compliance, recalls, or safety incidents. Confirm all regulatory and industry-specific certifications are valid and documented.

Assuming All Suppliers Provide Equivalent Quality

Even with identical specifications, manufacturing processes and quality control vary widely between suppliers. A lack of audits or quality management systems (e.g., ISO 9001) increases the risk of inconsistencies. Conduct supplier assessments and request quality assurance documentation before finalizing sourcing decisions.

Logistics & Compliance Guide for Caster Wheel Types

Understanding caster wheel types is essential for ensuring efficient material handling, workplace safety, and regulatory compliance across various industries. The right caster selection impacts mobility, load capacity, floor protection, and adherence to health and safety standards. Below is a guide to common caster wheel types with key logistics and compliance considerations.

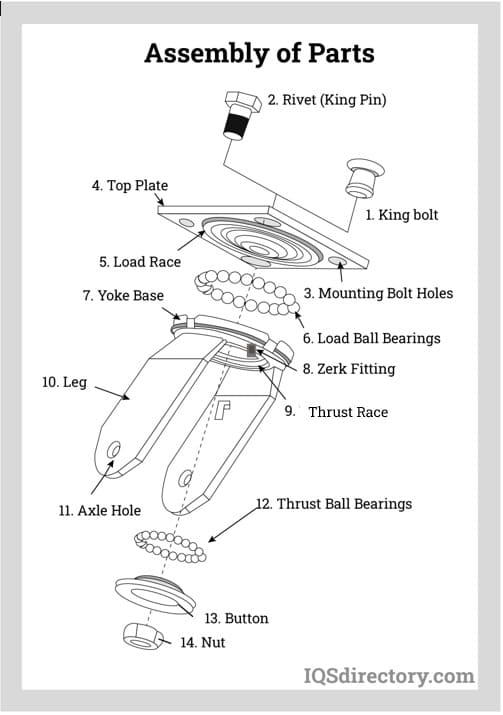

Rigid vs. Swivel Casters

Rigid casters are fixed in direction and provide straight-line movement, ideal for guiding heavy loads along set paths. Swivel casters feature a rotating fork that allows 360-degree movement, enabling greater maneuverability around obstacles.

Logistics Considerations:

Use rigid casters on two legs of a cart or equipment to maintain stability and directional control. Pair with swivel casters on the other two legs for balanced mobility and turning radius.

Compliance Notes:

OSHA (Occupational Safety and Health Administration) recommends stable configurations to prevent tipping. Equipment with improper caster setup may violate 29 CFR 1910.176 (Material Handling), increasing the risk of workplace injuries.

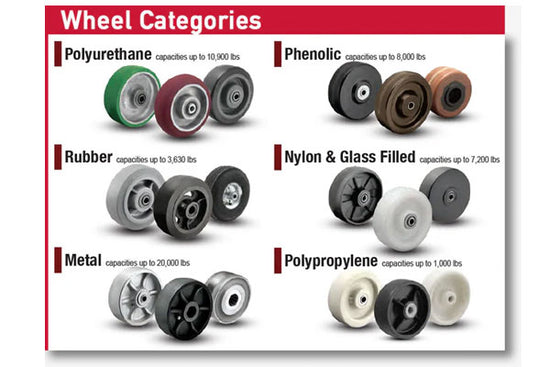

Wheel Materials and Floor Compatibility

Different wheel materials are designed for specific floor types and environmental conditions. Common materials include polyurethane, rubber, nylon, and phenolic.

- Polyurethane Wheels: Offer excellent floor protection, moderate load capacity, and resistance to oils and abrasion. Ideal for indoor use on sealed concrete or tile.

- Rubber Wheels: Provide superior shock absorption and quiet operation, suitable for finished floors and healthcare environments.

- Nylon Wheels: High load capacity and durability, but can damage softer flooring. Best for industrial settings with heavy loads.

- Phenolic Wheels: Withstand high temperatures and heavy loads but are rigid and noisy. Often used in warehouse and manufacturing applications.

Logistics Considerations:

Match wheel material to floor type to prevent damage and ensure smooth movement. Using incorrect materials can lead to increased rolling resistance, higher energy use, and premature wear.

Compliance Notes:

Facilities governed by ADA (Americans with Disabilities Act) standards must ensure that movable equipment can be operated with minimal force. Softer wheels (e.g., polyurethane or rubber) reduce push/pull force, aiding compliance with ADA accessibility requirements.

Load Capacity and Wheel Size

Casters must support the total weight of equipment and its load, with a safety margin. Wheel diameter and width directly affect load capacity and rolling ease.

Logistics Considerations:

Larger diameter wheels roll more easily over thresholds and debris. For loads exceeding 1,000 lbs per caster, consider dual-wheel or heavy-duty configurations. Always calculate total load and distribute evenly across casters.

Compliance Notes:

Under OSHA 29 CFR 1910.132 (Personal Protective Equipment), employers must ensure equipment is safe for use. Overloaded casters can fail catastrophically, posing hazards. Regular inspection and load verification are required.

Brake and Locking Mechanisms

Casters may include wheel brakes, swivel locks, or total lock (brake + swivel lock) mechanisms to secure equipment in place.

Logistics Considerations:

Use total-lock casters on mobile workstations, medical carts, or elevated platforms to prevent unintended movement during use.

Compliance Notes:

OSHA 29 CFR 1910.212 requires machine guarding and secure positioning. In healthcare, The Joint Commission mandates secure medical equipment to prevent falls and injuries. Locking casters are often required in accredited facilities.

Environmental and Regulatory Compliance

Certain environments (e.g., food processing, pharmaceuticals, cleanrooms) require non-marking, chemical-resistant, or non-particle-shedding casters.

Logistics Considerations:

Specify stainless steel or non-marking polyurethane casters in food and beverage plants. Use conductive or static-dissipative casters in ESD-sensitive areas (e.g., electronics manufacturing).

Compliance Notes:

FDA 21 CFR Part 110 (Current Good Manufacturing Practice for Food) requires equipment to be cleanable and non-contaminating. NSF-certified casters may be required. In ESD environments, compliance with ANSI/ESD S20.20 is critical.

Maintenance and Inspection Protocols

Regular maintenance ensures caster performance and safety over time.

Logistics Considerations:

Implement a preventive maintenance schedule to check for wheel wear, loose bolts, brake functionality, and swivel smoothness.

Compliance Notes:

OSHA’s general duty clause (Section 5(a)(1)) requires employers to provide a workplace free from recognized hazards. Worn or damaged casters contribute to unsafe conditions and may result in citations during inspections.

By selecting the appropriate caster wheel types and adhering to logistics best practices and regulatory standards, organizations can ensure safe, efficient, and compliant material handling operations across diverse environments.

Conclusion on Sourcing Caster Wheel Types

Selecting the appropriate caster wheel type is a critical decision that directly impacts mobility, durability, safety, and operational efficiency across various applications. Through careful evaluation of load requirements, flooring surfaces, environmental conditions, mobility needs (e.g., swivel vs. rigid), and material composition (such as polyurethane, rubber, nylon, or steel), businesses can identify the optimal caster solution.

When sourcing caster wheels, it is essential to balance performance with cost-effectiveness while prioritizing quality and supplier reliability. Partnering with reputable manufacturers or suppliers who offer a diverse product range, technical support, and compliance with industry standards ensures long-term reliability and reduces downtime. Additionally, considering custom solutions for unique applications can provide significant operational advantages.

In summary, a strategic and informed approach to sourcing caster wheels—based on thorough application analysis and supplier evaluation—leads to improved equipment functionality, enhanced safety, and reduced lifecycle costs. Making the right choice in caster wheel types is not just a procurement decision, but an investment in operational efficiency and longevity.