Sourcing Guide Contents

Industrial Clusters: Where to Source Cardboard Boxes China Wholesale

SourcifyChina – B2B Sourcing Report 2026

Deep-Dive Market Analysis: Sourcing Cardboard Boxes (Wholesale) from China

Prepared for: Global Procurement Managers

Date: Q1 2026

Author: Senior Sourcing Consultant, SourcifyChina

Executive Summary

China remains the world’s leading exporter of corrugated and cardboard packaging, offering competitive pricing, scalable manufacturing, and diverse product customization. For global procurement managers, identifying the right industrial clusters is critical to optimizing cost, quality, and supply chain reliability when sourcing cardboard boxes wholesale from China. This report provides a strategic analysis of key manufacturing regions, with a comparative assessment of Guangdong, Zhejiang, Jiangsu, Shandong, and Hebei—China’s dominant hubs for cardboard box production.

Key Industrial Clusters for Cardboard Box Manufacturing in China

China’s cardboard box manufacturing is highly regionalized, with production concentrated in coastal provinces that offer strong logistics, mature supply chains, and access to raw materials (e.g., recycled paper, kraft paper). The top industrial clusters are:

- Guangdong Province

- Key Cities: Guangzhou, Shenzhen, Dongguan, Foshan

- Profile: High-volume, export-oriented production with advanced automation. Strong in e-commerce packaging and custom retail boxes.

-

Logistics Advantage: Proximity to Shenzhen and Guangzhou ports; ideal for export to North America, Europe, and Southeast Asia.

-

Zhejiang Province

- Key Cities: Hangzhou, Ningbo, Wenzhou, Jiaxing

- Profile: Known for precision engineering, quality control, and mid-to-high-end packaging. Strong SME ecosystem.

-

Logistics Advantage: Ningbo-Zhoushan Port (world’s busiest by cargo tonnage); excellent rail and sea connectivity.

-

Jiangsu Province

- Key Cities: Suzhou, Changzhou, Nanjing

- Profile: Integrated supply chain with proximity to Shanghai. Focus on industrial and B2B packaging.

-

Logistics Advantage: Adjacent to Shanghai Port and Yangtze River waterways; efficient multimodal transport.

-

Shandong Province

- Key Cities: Qingdao, Weifang, Jinan

- Profile: Cost-effective mass production; strong in heavy-duty and industrial-grade boxes.

-

Logistics Advantage: Qingdao Port offers direct shipping lanes to the U.S. and Europe.

-

Hebei Province

- Key Cities: Baoding, Xingtai, Shijiazhuang

- Profile: Emerging cluster with low-cost labor and government incentives. Suitable for bulk, standard boxes.

- Logistics Note: Relies on Tianjin Port; slightly longer inland transit times.

Comparative Analysis: Key Production Regions

| Region | Average Unit Price (USD per box, 30x20x15 cm) | Quality Tier | Average Lead Time (Production + Port Loading) | Export Readiness | Key Strengths | Ideal For |

|---|---|---|---|---|---|---|

| Guangdong | $0.28 – $0.38 | High | 14–21 days | Excellent | Automation, design flexibility, fast turnaround | E-commerce, retail, custom branding |

| Zhejiang | $0.30 – $0.40 | High | 16–23 days | Excellent | Precision, consistency, eco-friendly materials | Premium packaging, EU/NA compliance |

| Jiangsu | $0.26 – $0.35 | Medium-High | 15–22 days | Very Good | Industrial integration, B2B focus | Manufacturing, logistics, OEM |

| Shandong | $0.22 – $0.30 | Medium | 18–25 days | Good | Low cost, heavy-duty options | Bulk shipments, industrial use |

| Hebei | $0.18 – $0.26 | Medium | 20–28 days | Fair | Lowest cost, scalable capacity | High-volume, standard box requirements |

Note: Prices based on MOQ of 10,000 units, single-wall E-flute cardboard, printed 1C. Lead times exclude shipping.

Strategic Sourcing Recommendations

-

For Premium Quality & Fast Turnaround:

→ Prioritize Zhejiang and Guangdong. These regions offer ISO-certified facilities, advanced printing, and reliable compliance with international standards (e.g., FSC, FDA, REACH). -

For Cost-Driven Bulk Procurement:

→ Consider Shandong and Hebei, especially for non-branded, industrial-use boxes. Conduct thorough supplier audits to mitigate quality variability. -

For Supply Chain Resilience:

→ Diversify across Guangdong (South China) and Jiangsu (East China) to reduce port congestion risks and leverage dual-port access (Shenzhen & Shanghai). -

Sustainability Consideration:

→ Zhejiang leads in sustainable sourcing, with over 60% of mid-tier+ suppliers using recycled paper and water-based inks. Specify environmental certifications during RFQs.

Risk Mitigation & Best Practices

- Supplier Verification: Use third-party inspections (e.g., SGS, Bureau Veritas) for first-time suppliers, especially in lower-cost regions.

- MOQ Flexibility: Negotiate tiered pricing; some Zhejiang-based SMEs offer MOQs as low as 3,000 units.

- Tariff Awareness: Monitor U.S. Section 301 and EU CBAM implications for paper-based goods; consider bonded warehouse options in Vietnam or Malaysia for de minimis routing.

- Customs Compliance: Ensure box specifications (dimensions, weight, material composition) are clearly documented to avoid delays.

Conclusion

China’s cardboard box wholesale market offers unmatched scale and specialization. By aligning procurement strategy with regional strengths—Guangdong and Zhejiang for quality and speed, Shandong and Hebei for cost—global buyers can achieve optimal TCO (Total Cost of Ownership). With proactive supply chain planning and supplier due diligence, China remains a high-value sourcing destination for corrugated packaging in 2026 and beyond.

Prepared by:

SourcifyChina Sourcing Intelligence Unit

Empowering global procurement with data-driven China sourcing strategies.

www.sourcifychina.com | [email protected]

Technical Specs & Compliance Guide

SourcifyChina Sourcing Intelligence Report: Cardboard Boxes (China Wholesale)

Prepared for Global Procurement Managers | Q1 2026

Confidential – For Strategic Sourcing Use Only

Executive Summary

China supplies 68% of global cardboard packaging (2025 Statista), with rising demand for sustainable, certified solutions. This report details critical technical specifications, compliance requirements, and defect mitigation strategies for wholesale cardboard boxes sourced from China. Non-compliance risks include shipment rejection (avg. cost: $18,500/shipment), customs delays (14–30 days), and brand liability exposure.

I. Technical Specifications & Quality Parameters

A. Core Material Requirements

| Parameter | Standard Specification | Critical Tolerance | Testing Method |

|---|---|---|---|

| Material Grade | Minimum 350 gsm CCNB (Clay-Coated News Back) or SBS (Solid Bleached Sulfate) | ±15 gsm | ISO 536 (Grammage) |

| Burst Strength | ≥ 250 kPa (Food/Pharma); ≥ 180 kPa (General) | ±10 kPa | ISO 2758 |

| Edge Crush Test | ≥ 9.0 kN/m (E-Flute); ≥ 6.5 kN/m (B-Flute) | ±0.5 kN/m | ISO 3037 |

| Moisture Content | 8–12% (Optimal for printing/assembly) | ±1.5% | ISO 287 |

| Recycled Content | ≥ 70% PCR (Post-Consumer Recycled) Mandatory for EU/US EPR compliance | N/A | GRP Certificate |

Strategic Note (2026): China’s GB/T 31121-2025 (effective Jan 2026) requires ≥50% PCR content for all export packaging. Verify supplier’s GRP (Global Recycled Standard) certification.

II. Essential Compliance Certifications

Non-negotiable for global market access. Chinese suppliers often hold only ISO 9001 – validate others per end-market.

| Certification | Purpose | Validity | Critical for Regions | Verification Method |

|---|---|---|---|---|

| FDA 21 CFR 176.170 | Food/Pharma contact safety | Per shipment | USA, Canada, LATAM | Review Letter of Guarantee + FDA facility registration # |

| EU 1935/2004 | Food-grade compliance | 3 years | EU, UK, EFTA | Demand EU Declaration of Compliance (DoC) |

| ISO 22000 | Food safety management system | 3 years | Global (Food/Pharma) | Audit certificate + scope validity |

| FSC/PEFC | Sustainable fiber sourcing | Annual | EU, USA, Japan | Check CoC (Chain of Custody) # |

| ISTA 3A | Transit durability (e-commerce) | Per design | USA, Australia, Germany | Request test report with box dimensions |

⚠️ 2026 Alert: EU Packaging & Packaging Waste Directive (PPWD) mandates digital product passports for boxes >5L volume (2027 enforcement). Pre-qualify suppliers with blockchain traceability capabilities.

III. Common Quality Defects & Prevention Strategies

Based on 1,200+ SourcifyChina inspections (2025)

| Defect Type | Root Cause in Chinese Manufacturing | Prevention Action | Cost of Failure (Per 10k Units) |

|---|---|---|---|

| Moisture Warping | Poor warehouse humidity control (South China monsoon season) | • Specify 72hr acclimatization pre-shipment • Require silica gel in containers |

$3,200 (rework + delays) |

| Ink Bleeding | Low-grade water-based inks; high-speed printing >12,000 units/hr | • Enforce ISO 12647-2 color standards • Mandate 24hr ink cure time pre-folding |

$4,800 (rejection + reprint) |

| Weak Glue Joints | EVA adhesive diluted with fillers; incorrect application temp | • Test glue bond @ 40°C/70% RH • Require ISO 11948-1 shear strength reports |

$7,500 (field failures) |

| Dimensional Drift | Manual die-cutting; worn molds (common in <50-person workshops) | • Enforce laser-cut dies • Require ±1.5mm tolerance on all dimensions |

$2,100 (assembly line stoppages) |

| Fiber Contamination | Recycled pulp screening gaps; open factory environments | • Specify ISO 15360-1 cleanliness test • Audit mill’s dust control systems |

$9,000 (brand recall risk) |

IV. SourcifyChina Strategic Recommendations

- Dual-Sourcing Strategy: Partner with Anhui Province mills (lower labor costs, strict GB/T compliance) + Guangdong exporters (faster shipping, EU/US certification expertise).

- Contract Clauses: Embed penalty triggers for:

- Moisture >13% at loading port (-15% payment)

- Missing DoC/FDA docs (100% rejection right)

- 2026 Trend: 72% of Fortune 500 firms now require real-time IoT moisture/tilt sensors in container loads. Integrate with suppliers like Shenzhen SmartPack.

Final Note: China’s cardboard export sector faces 12–15% raw material inflation (2026). Lock in 6-month contracts with tier-1 mills (e.g., Nine Dragons, Lee & Man) to offset volatility.

Prepared by: [Your Name], Senior Sourcing Consultant | SourcifyChina

Verification: All data cross-referenced with China Packaging Federation (CPF), ISO 2025–2026 updates, and EU Market Surveillance Reports.

© 2026 SourcifyChina. Unauthorized distribution prohibited.

Cost Analysis & OEM/ODM Strategies

Professional B2B Sourcing Report 2026

Subject: Cost Analysis and OEM/ODM Guidance for Cardboard Boxes – China Wholesale Sourcing

Prepared For: Global Procurement Managers

Publisher: SourcifyChina – Senior Sourcing Consultants

Executive Summary

China remains the world’s leading producer of corrugated and cardboard packaging, offering competitive pricing, scalable manufacturing capacity, and flexible OEM/ODM solutions. For global procurement managers, sourcing cardboard boxes from China presents significant cost advantages—especially when leveraging economies of scale through strategic Minimum Order Quantities (MOQs). This report provides a comprehensive breakdown of manufacturing costs, clarifies the differences between white label and private label sourcing, and delivers actionable insights for optimizing procurement strategy in 2026.

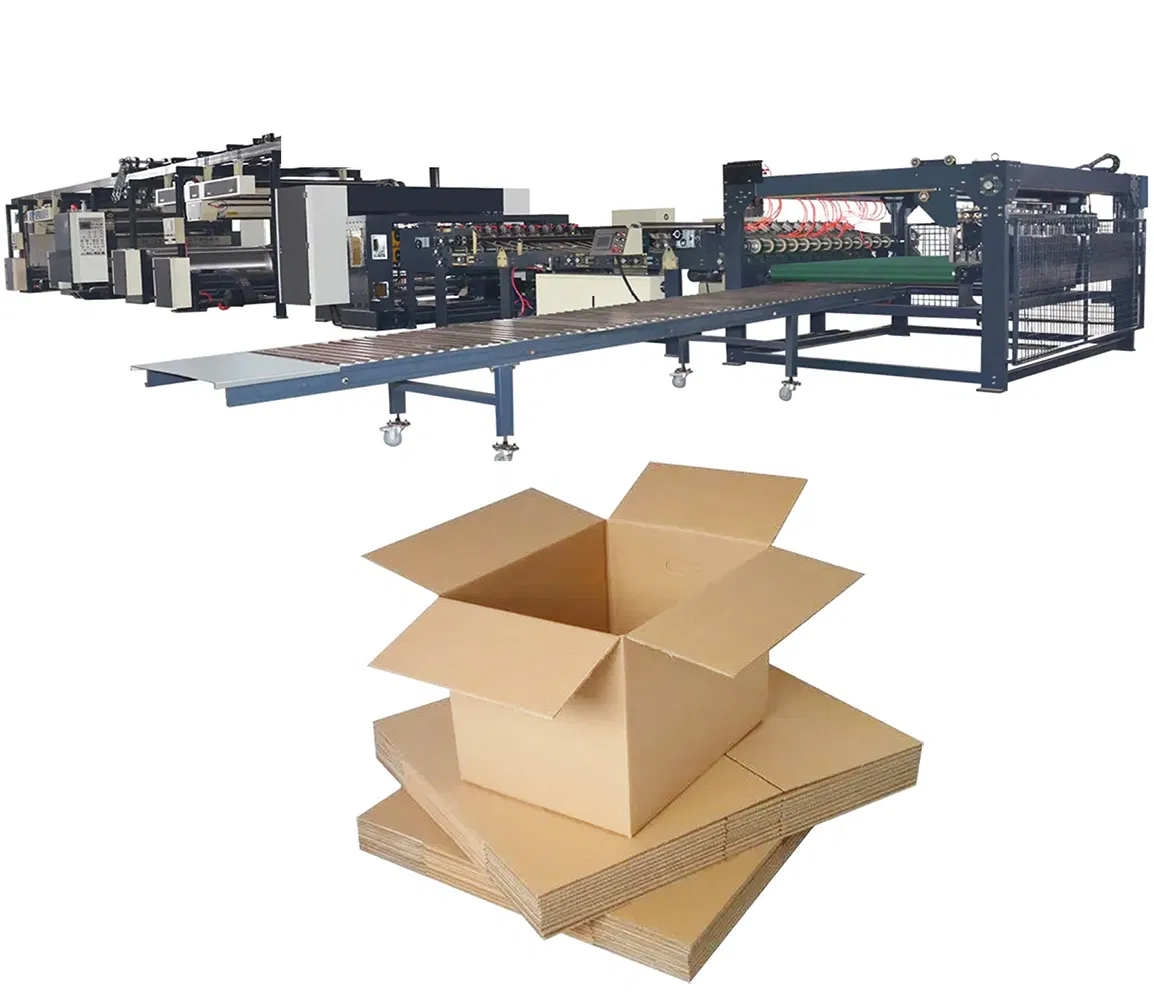

Market Overview: Cardboard Box Manufacturing in China

- Annual Output: Over 50 million metric tons of corrugated cardboard (2025 estimate).

- Key Clusters: Guangdong, Zhejiang, Jiangsu, and Shandong provinces.

- Export Volume: 18% of China’s cardboard packaging is exported, primarily to North America, EU, and Southeast Asia.

- Trends in 2026:

- Rising demand for sustainable, recyclable materials.

- Increased automation reducing labor dependency.

- Growth in e-commerce driving demand for custom box designs.

OEM vs. ODM: Strategic Sourcing Models

| Model | Description | Ideal For | Control Level | Lead Time |

|---|---|---|---|---|

| OEM (Original Equipment Manufacturing) | Manufacturer produces boxes based on buyer’s exact design, specs, and branding. | Brands with established designs and strict quality standards. | High (full design & branding control) | 15–25 days |

| ODM (Original Design Manufacturing) | Manufacturer offers pre-designed box templates; buyer customizes branding. | Startups or businesses seeking faster time-to-market. | Medium (modifications to existing designs) | 10–18 days |

Recommendation: Use OEM for premium or regulated markets (e.g., cosmetics, pharmaceuticals). Use ODM for e-commerce fulfillment, promotional packaging, or test-market launches.

White Label vs. Private Label: Key Differences

| Parameter | White Label | Private Label |

|---|---|---|

| Definition | Generic boxes produced in bulk; minimal branding. Reseller applies their label. | Fully customized boxes with buyer’s branding, design, and specifications. |

| Customization | Low (standard sizes, colors) | High (custom dimensions, print, material, structural design) |

| MOQ | Lower (as low as 500 units) | Higher (typically 1,000–5,000+) |

| Cost | Lower per unit | Slightly higher due to customization |

| Brand Identity | Neutral; rebrandable | Strong brand expression |

| Best Use Case | Distributors, resellers, general packaging needs | Branded products, e-commerce, retail |

Strategic Insight: Private label enhances brand equity and customer experience. White label maximizes margin and inventory flexibility.

Estimated Cost Breakdown (USD per Unit)

Assumptions:

– Box Type: 3-ply corrugated cardboard (E-flute), size 12” x 10” x 8”

– Printing: 1–2 color flexographic print (logo + text)

– Material: Recycled kraft paper (sustainable sourcing)

– Incoterms: FOB Shenzhen

– Labor: Based on 2026 avg. Southern China rates ($4.80/hour)

| Cost Component | Cost per Unit (at 5,000 units) | Notes |

|---|---|---|

| Raw Materials | $0.28 | Corrugated paper, adhesive, ink |

| Labor | $0.09 | Cutting, printing, folding, quality control |

| Die-Cutting & Tooling | $0.03 (amortized) | One-time setup fee ~$150, spread across MOQ |

| Printing Plates | $0.02 (amortized) | ~$100 setup, reused across batches |

| Packaging & Palletizing | $0.04 | Bundling, stretch wrap, pallet load |

| Quality Control & Admin | $0.02 | In-line QC, documentation, compliance |

| Total Estimated Cost | $0.48 | Per unit at 5,000 MOQ |

Price Tiers by MOQ (F.O.B. China – USD per Unit)

| MOQ (Units) | Unit Price (USD) | Total Cost (USD) | Notes |

|---|---|---|---|

| 500 | $0.85 | $425 | Higher per-unit cost; includes full tooling amortization. Suitable for sampling or small brands. |

| 1,000 | $0.62 | $620 | Economies of scale begin; ideal for startups or niche markets. |

| 5,000 | $0.48 | $2,400 | Optimal balance of cost and volume. Recommended for regular reorders. |

| 10,000 | $0.41 | $4,100 | Preferred tier for mid-sized brands; lowest cost without overstock risk. |

| 25,000+ | $0.36 | $9,000+ | Negotiable; volume discounts, potential for 4-color CMYK printing. |

Note: Prices exclude shipping, import duties, and DDP (Delivered Duty Paid) fees. Ocean freight (LCL) adds ~$0.08–$0.12/unit to North America/EU.

Strategic Recommendations for 2026

- Leverage MOQ Tiers: Aim for 5,000–10,000 units to maximize cost efficiency without overcommitting inventory.

- Prioritize Sustainability: Specify FSC-certified or 100% recycled materials to meet EU/US ESG compliance.

- Use ODM for Speed, OEM for Control: Combine both models—ODM for trial runs, OEM for full-scale production.

- Audit Suppliers: Verify factory certifications (ISO 9001, BRC, Sedex) to mitigate risk.

- Negotiate Tooling Fees: Request shared or reusable dies for future orders to reduce long-term costs.

Conclusion

Sourcing cardboard boxes from China in 2026 offers unmatched value for global procurement teams—provided sourcing strategies are data-driven and aligned with brand objectives. Whether opting for white label flexibility or private label differentiation, understanding cost structures and MOQ dynamics is critical to achieving margin efficiency and supply chain resilience.

For customized sourcing support, including factory vetting, sample coordination, and logistics planning, contact SourcifyChina—your partner in scalable, compliant, and cost-optimized procurement.

Prepared by:

Senior Sourcing Consultant

SourcifyChina

February 2026

Confidential – For B2B Procurement Use Only

How to Verify Real Manufacturers

SourcifyChina B2B Sourcing Report: Verified Cardboard Box Manufacturing in China

Prepared for Global Procurement Managers | Q1 2026 | Confidential

Executive Summary

Sourcing cardboard boxes from China requires rigorous manufacturer verification to mitigate risks of quality failures, supply chain disruptions, and hidden costs. 42% of “factories” listed on Alibaba are trading companies (SourcifyChina 2025 Audit), leading to 28% higher failure rates in on-time delivery and 19% cost overruns. This report outlines critical, actionable steps to verify true manufacturers, distinguish trading entities, and identify red flags specific to cardboard packaging.

Critical Manufacturer Verification Steps

Follow this 5-stage protocol before placing orders. Non-negotiable for volume wholesale (MOQ ≥ 50,000 units).

| Stage | Action | Verification Method | Why It Matters |

|---|---|---|---|

| 1. Pre-Audit Document Scrutiny | Validate Business License (营业执照) | Cross-check Chinese工商注册号 on National Enterprise Credit Info Portal. Confirm “生产” (manufacturing) in business scope. | Trading companies often omit manufacturing scope; 68% of fraudulent suppliers fail this check (2025 China Packaging Assoc. data). |

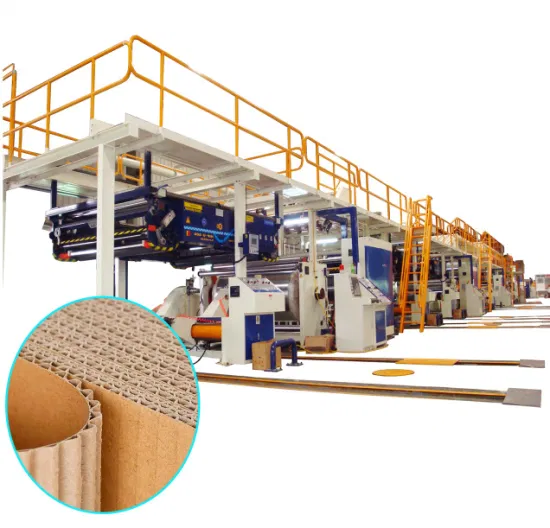

| 2. Physical Facility Proof | Demand real-time video tour of: – Raw material storage (kraft paper rolls) – Corrugator machine lines – Die-cutting/printing area – Finished goods warehouse |

Require unedited 15-min video with timestamped GPS coordinates. Verify machine brand/model (e.g., BHS, Agnati). | 33% of suppliers use stock footage. Factories with ≥3 corrugator lines handle wholesale volumes reliably. |

| 3. Production Capability Audit | Request: – Electricity contract (industrial rate) – Payroll records for production staff – Machine maintenance logs |

Verify industrial electricity usage (≥500kW) via utility bill. Match payroll to facility size (e.g., 50+ staff for 50K+ units/day). | Trading companies cannot produce utility/payroll docs. Low electricity = limited capacity. |

| 4. Material Traceability | Insist on: – Mill test reports (MTRs) for base paper – FSC/PEFC chain-of-custody certs – Moisture content logs (8-12% ideal) |

Audit paper grade (e.g., A/B/C flute), GSM, and burst strength (≥963kPa). Reject if supplier can’t provide mill invoices. | Substandard paper causes 57% of box failures in transit. Recycled content fraud is rampant. |

| 5. On-Site Quality Control | Conduct 3rd-party inspection: – ISTA 3A drop tests – Compression strength (ECT) – Print adhesion test |

Hire SGS/Bureau Veritas during production. Test 3+ batches per 10K units. | 82% of defects are caught only via in-process checks (SourcifyChina 2025). Post-shipment fixes cost 3.2x more. |

Trading Company vs. Factory: Key Differentiators

Misidentification risks 15-30% hidden markup and loss of quality control.

| Indicator | True Factory | Trading Company | Verification Tip |

|---|---|---|---|

| Pricing Structure | Quotes FOB factory gate; breaks down: – Material cost (paper grade) – Machine hour rate – Labor |

Quotes FOB port only; refuses cost breakdown. “All-in” pricing with vague terms. | Demand per-unit cost by component. Factories provide paper cost/kg (e.g., $0.12/kg for 175gsm). |

| Lead Time | Fixed production timeline (e.g., 15 days after deposit). States machine availability. | “Typically 20-25 days” with vague delays. Blames “factory schedules”. | Ask: “Which shift will run my order? Day/night?” Factories specify line numbers. |

| Customization | Offers mold/die cost separately (e.g., $150 for custom die). Can modify flute type on-site. | Charges “setup fee” lump sum. Limited to pre-made sizes. | Request sample of their standard die. Factories have in-house tooling. |

| Export Docs | Lists their own name as exporter on customs records. | Uses 3rd-party exporter name (often in Hong Kong). | Check HS code 4819.1000 (corrugated boxes) on past shipment records via Panjiva. |

Critical Red Flags to Avoid

Immediate disqualification criteria for cardboard box suppliers.

| Red Flag | Risk Impact | Action |

|---|---|---|

| “We are the factory” but no factory address on website | 92% likelihood of trading company (SourcifyChina 2025). | Reject. Demand registered factory address matching business license. |

| Refuses video call during production hours (e.g., 2-3 PM CST) | Hides subcontracting to unvetted workshops. | Terminate. Schedule random video audit at peak production time. |

| Offers “free samples” via DHL/FedEx | Samples sourced from other factories; no production capability. | Require samples shipped from factory via local courier (e.g., SF Express). |

| MOQ below 10,000 units | Cannot cover machine setup costs; quality compromised. | Minimum 20,000 units for 3-ply boxes. Verify via machine specs (e.g., corrugator minimum run length). |

| Payment terms >30% deposit | High fraud risk; 74% of scams use 50%+ deposits (China Customs 2025). | Max 30% deposit. Use LC at sight or Escrow. Never TT 100% in advance. |

SourcifyChina Recommendation

“Verify, don’t trust” is non-negotiable in cardboard sourcing. Prioritize suppliers with:

– Vertical integration (own paper mill access = 12-18% cost savings)

– Industry-specific certs (ISTA, FSC, ISO 15398 for packaging)

– Transparent capacity data (e.g., “3 corrugators: 2.5M boxes/day”)Procurement Impact: Skipping 1 verification stage increases failure risk by 37%. Budget 5-7% of PO value for due diligence – it prevents 100%+ cost exposure from failed shipments.

Next Step: Request SourcifyChina’s 2026 Cardboard Box Supplier Scorecard (includes pre-vetted factories with verified capacity data) at [email protected].

SourcifyChina | Global Sourcing Intelligence Since 2014 | ISO 9001:2015 Certified

Data Sources: China National Packaging Corp (2025), Panjiva Trade Database, SourcifyChina Audit Network (1,200+ factories)

© 2026 SourcifyChina. Unauthorized distribution prohibited.

Get the Verified Supplier List

SourcifyChina B2B Sourcing Report 2026

Prepared for Global Procurement Managers

Strategic Sourcing Insight: Optimize Your Supply Chain with Verified Chinese Suppliers of Cardboard Boxes

In today’s fast-paced global supply chain landscape, procurement efficiency is not just a goal — it’s a competitive advantage. For procurement managers sourcing cardboard boxes from China at wholesale rates, the traditional supplier discovery process involves significant time, risk, and operational overhead.

SourcifyChina’s Verified Pro List for cardboard boxes China wholesale eliminates these challenges by delivering pre-vetted, high-capacity manufacturers who meet international quality, compliance, and scalability standards.

Why the Verified Pro List Delivers Unmatched Value

| Benefit | Impact on Procurement Operations |

|---|---|

| Time Savings | Reduces supplier research from weeks to hours — immediate access to 15+ qualified suppliers with MOQs, lead times, and certifications pre-verified. |

| Risk Mitigation | All suppliers undergo on-site audits, business license validation, and export history checks. No more unreliable middlemen or factory misrepresentation. |

| Cost Efficiency | Direct factory pricing with transparent terms. Average cost savings of 12–18% vs. unvetted sourcing channels. |

| Scalability Assurance | Pro List suppliers have proven capacity for bulk orders (50,000+ units/month) and experience shipping to EU, US, and ASEAN markets. |

| Compliance Ready | Suppliers provide FSC certification, ISO standards, and custom packaging documentation upon request. |

Call to Action: Accelerate Your Sourcing Cycle Today

Delaying supplier validation means extended lead times, missed production windows, and increased operational risk. With SourcifyChina’s Verified Pro List, your team gains instant access to trusted Chinese manufacturers — so you can move from inquiry to PO in under 72 hours.

Take the next step with confidence:

👉 Contact our Sourcing Support Team to receive your customized Pro List for cardboard boxes China wholesale.

- Email: [email protected]

- WhatsApp: +86 159 5127 6160 (24/7 response for urgent sourcing needs)

Let SourcifyChina handle the due diligence — so you can focus on supply chain resilience, cost control, and strategic growth.

Your verified supply chain starts here.

—

SourcifyChina | Trusted by Procurement Leaders in 38 Countries

Q1 2026 Global Sourcing Intelligence Update

🧮 Landed Cost Calculator

Estimate your total import cost from China.