The global demand for sustainable and energy-efficient building materials has propelled the carbon slate panels market into a phase of robust growth. According to Grand View Research, the global green building materials market was valued at USD 297.4 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 10.9% from 2023 to 2030—driven by tightening environmental regulations, rising urbanization, and increased investment in energy-efficient infrastructure. As a high-performance cladding solution combining aesthetic appeal with low carbon footprint, carbon slate panels are gaining traction among commercial and residential developers seeking compliant, durable, and eco-conscious materials. With North America and Europe leading adoption due to stringent building codes and decarbonization targets, a select group of manufacturers are emerging at the forefront of innovation, scalability, and product sustainability. Based on market presence, production capacity, and technological advancement, the following three companies represent the leading carbon slate panel manufacturers capitalizing on this expanding niche.

Top 3 Carbon Slate Panels Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Milliken Flooring

Domain Est. 1994

Website: milliken.com

Key Highlights: Explore a wide range of carpet tiles, resilient flooring, entrance systems, broadloom, rugs, and installation products—along with quick shipping options and ……

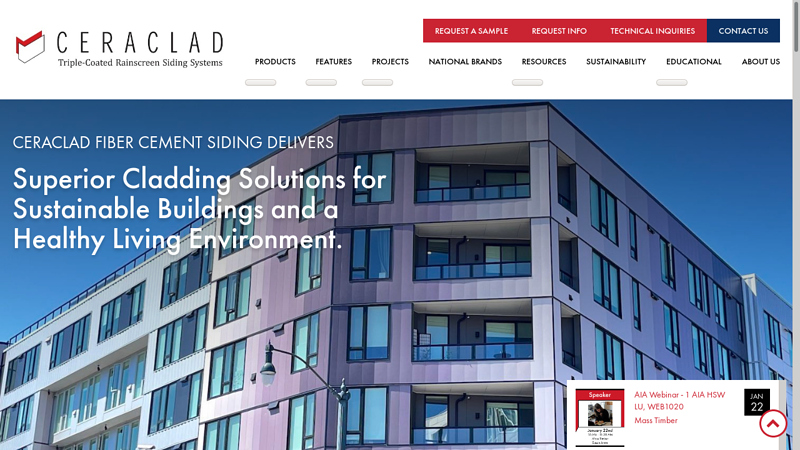

#2 CERACLAD

Domain Est. 2010

Website: ceraclad.com

Key Highlights: CERACLAD is a ceramic-coated siding assembly engineered for residential and commercial buildings. Get in touch with our team to start your project today….

#3 Explore Our Premium Wall Panels Today

Domain Est. 2023

Website: carbon-slate.com

Key Highlights: Explore our high-quality decorative panels featuring marble effects, stone textures, and luxurious designs….

Expert Sourcing Insights for Carbon Slate Panels

2026 Market Trends for Carbon Slate Panels

By 2026, the market for Carbon Slate Panels is poised for significant transformation, driven by converging forces in sustainability, technological innovation, and evolving construction demands. These engineered panels—typically composed of recycled carbon fiber composites and mineral-based substrates designed to mimic natural slate—will occupy a growing niche in high-performance building materials.

Accelerated Demand for Sustainable and Low-Carbon Building Materials

Environmental regulations and corporate ESG (Environmental, Social, and Governance) commitments will intensify, pushing architects and developers toward low-carbon alternatives. Carbon Slate Panels, with their potential for using recycled carbon fiber and reduced embodied energy compared to quarried slate or heavy concrete roofing, will benefit from this shift. Lifecycle assessments (LCAs) will increasingly favor Carbon Slate due to lower transportation emissions (lighter weight) and longer service life, enhancing their appeal in green building certifications like LEED v5 and BREEAM.

Integration with Smart and Resilient Building Systems

By 2026, Carbon Slate Panels will begin incorporating smart functionalities. Manufacturers will embed sensors directly into the composite matrix during production to monitor structural integrity, moisture levels, and temperature. This integration supports predictive maintenance and contributes to the broader smart building ecosystem. Additionally, the inherent strength and impact resistance of carbon fiber will make these panels attractive in regions prone to extreme weather, aligning with growing demand for climate-resilient construction.

Cost Reductions and Scalability Through Advanced Manufacturing

Economies of scale and improvements in automated production techniques—such as robotic layup and rapid-cure resin systems—will begin to lower the cost premium of Carbon Slate Panels. As recycling infrastructure for end-of-life carbon fiber matures, the supply of reclaimed feedstock will stabilize, further reducing material costs. This improved affordability will expand market access beyond luxury or specialty projects into mid-tier commercial and residential developments.

Geographic Expansion and Regulatory Tailwinds

Europe and North America will lead adoption due to stringent building codes and carbon pricing mechanisms. However, by 2026, emerging markets in Asia-Pacific and the Middle East will show increased interest, particularly in high-rise and sustainable urban developments. Government incentives for energy-efficient construction and net-zero building mandates will act as key catalysts, creating favorable policy environments for advanced materials like Carbon Slate.

Competitive Differentiation Through Aesthetic Customization

Manufacturers will leverage the moldability of composite materials to offer extensive customization in color, texture, and profile, enabling Carbon Slate Panels to replicate not only traditional slate but also bespoke architectural finishes. This design flexibility, combined with consistent quality and lightweight performance, will position Carbon Slate as a premium alternative to both natural stone and synthetic substitutes.

Common Pitfalls When Sourcing Carbon Slate Panels: Quality and Intellectual Property

Sourcing Carbon Slate Panels—advanced composite materials often used in aerospace, defense, or high-performance industrial applications—can present significant challenges, particularly concerning quality assurance and intellectual property (IP) protection. Overlooking these areas can lead to supply chain disruptions, legal exposure, and compromised product performance.

Quality-Related Pitfalls

Inconsistent Material Composition and Performance

Carbon slate panels require precise manufacturing processes to ensure uniform fiber alignment, resin distribution, and curing. Sourcing from suppliers without stringent quality controls can result in batch-to-batch variability, leading to structural weaknesses or failure in critical applications.

Lack of Certification and Traceability

Reputable applications demand panels that meet specific industry standards (e.g., ASTM, MIL-SPEC, or aerospace certifications). Failing to verify proper documentation, material traceability, and third-party testing reports increases the risk of receiving substandard or non-compliant panels.

Inadequate Testing and Validation

Some suppliers may provide panels that pass basic inspections but fail under real-world stress conditions. Without rigorous mechanical, thermal, and environmental testing data, buyers may unknowingly integrate components that degrade prematurely or underperform.

Intellectual Property-Related Pitfalls

Unauthorized Replication or Reverse Engineering

Carbon slate technology often involves proprietary manufacturing techniques and resin formulations. Sourcing from unvetted suppliers—especially in regions with weak IP enforcement—risks exposure to reverse-engineered products that infringe on patents or trade secrets.

Ambiguous Ownership of Design Specifications

When custom panels are developed, unclear contracts may leave ownership of tooling, molds, or design data in dispute. Suppliers could claim rights to innovations or resell similar designs to competitors, undermining competitive advantage.

Lack of IP Protections in Contracts

Failure to include robust IP clauses in supply agreements—such as confidentiality, non-disclosure, and assignment of improvements—can leave buyers vulnerable to leaks, disputes, or loss of control over proprietary technology.

Avoiding these pitfalls requires thorough due diligence, supplier audits, clear contractual terms, and collaboration with legally and technically vetted partners.

Logistics & Compliance Guide for Carbon Slate Panels

This guide outlines the essential logistics considerations and compliance requirements for the safe, efficient, and legal handling, transportation, and installation of Carbon Slate Panels.

Product Overview & Handling

Carbon Slate Panels are ultra-thin, lightweight composite panels featuring a natural slate veneer bonded to a carbon fiber-reinforced backing. Their low weight and high strength make them ideal for roofing and cladding applications, but they require careful handling to prevent chipping, cracking, or delamination.

- Storage: Store panels flat on a level, dry surface protected from moisture, direct sunlight, and extreme temperatures. Use supportive racks or skids spaced no more than 16 inches apart. Keep packaging intact until ready for installation.

- Handling: Always handle panels with clean gloves to prevent surface contamination. Lift panels using two people or mechanical aids—never by an edge. Avoid dragging or dropping.

- On-Site Protection: Cover stored panels with breathable protective sheeting. Do not stack materials directly on panels.

Packaging & Transportation

Proper packaging and transport protocols are critical to ensure panels arrive undamaged.

- Packaging: Panels are typically crated or bundled with edge protectors and interlayer padding. Labels must indicate “Fragile,” “This Side Up,” and “Protect from Moisture.”

- Loading: Secure crates or bundles to prevent shifting during transit. Use padded straps and avoid overloading. Forklift use must be with appropriate attachments to prevent puncture or bending.

- Environmental Protection: Ensure transport vehicles are weatherproof and temperature-controlled where possible. Avoid prolonged exposure to humidity or freezing conditions.

- Delivery Coordination: Schedule deliveries to minimize on-site storage. Confirm site accessibility for delivery vehicles and unloading equipment.

International Shipping & Customs Compliance

When shipping across borders, compliance with international regulations is mandatory.

- HS Code: Confirm the appropriate Harmonized System (HS) code (e.g., 6802.91 or 6802.92 for worked slate) for accurate tariff classification.

- Documentation: Provide commercial invoices, packing lists, certificates of origin, and material safety data sheets (MSDS) where required.

- Import/Export Regulations: Verify country-specific restrictions, especially for composite materials or carbon fiber components. Some regions may require environmental or safety certifications.

- Duty & Tax Considerations: Account for applicable import duties, VAT, or GST. Utilize Free Trade Agreement benefits if eligible.

Regulatory & Environmental Compliance

Ensure all products and practices meet relevant regulatory standards.

- Material Composition: Confirm that resins, adhesives, and backing materials comply with REACH (EU), TSCA (USA), and other chemical regulations.

- Environmental Certifications: Provide documentation for sustainability claims (e.g., low embodied carbon, recyclability). Panels may qualify for LEED or BREEAM credits.

- RoHS & VOC Compliance: Verify that manufacturing processes and materials meet Restriction of Hazardous Substances (RoHS) and low volatile organic compound (VOC) requirements.

- Fire Safety: Panels must meet local fire performance standards (e.g., ASTM E84, EN 13501-1). Provide fire classification reports upon request.

Installation & Safety Compliance

Installation must adhere to building codes and safety standards.

- Training: Only trained and certified installers should handle and install Carbon Slate Panels.

- Fall Protection: Follow OSHA (USA) or equivalent fall protection regulations when working at height.

- Tool Safety: Use appropriate cutting tools with dust extraction to minimize silica exposure. Provide PPE including gloves, eye protection, and respirators.

- Building Codes: Installation must comply with local roofing and cladding codes, including wind uplift, load-bearing, and thermal expansion requirements.

End-of-Life & Recycling

Support sustainable disposal and circular economy initiatives.

- Recycling Guidance: Provide instructions for panel separation (slate vs. carbon backing) and local recycling facilities capable of handling composite materials.

- Waste Management: Advise compliance with local construction and demolition (C&D) waste regulations. Avoid landfill disposal where alternatives exist.

- Take-Back Programs: Offer or partner with recycling programs for end-of-life panels where feasible.

Documentation & Recordkeeping

Maintain accurate records to ensure traceability and compliance.

- Certificates: Supply product conformity certificates, test reports, and installation manuals with each shipment.

- Batch Tracking: Implement a system to trace panel batches from production to installation.

- Compliance Files: Keep updated records of regulatory approvals, safety data, and audit reports.

Adherence to this guide ensures the safe, legal, and sustainable use of Carbon Slate Panels throughout their lifecycle.

Conclusion for Sourcing Carbon Slate Panels

In conclusion, sourcing carbon slate panels presents a strategic opportunity to combine aesthetic appeal with durability and sustainability in architectural and design applications. These panels offer a lightweight, low-maintenance, and weather-resistant alternative to natural stone, making them ideal for both interior and exterior use. When sourcing, it is critical to evaluate suppliers based on product quality, consistency, environmental certifications, and adherence to sustainability standards.

Key considerations include verifying the manufacturing process—particularly the use of recycled materials and low-emission production methods—as well as assessing logistical factors such as lead times, shipping costs, and technical support. Engaging with reputable suppliers who provide comprehensive warranties and performance data ensures long-term reliability and client satisfaction.

Ultimately, successful sourcing of carbon slate panels hinges on a balanced approach that aligns performance, aesthetics, cost-efficiency, and environmental responsibility. With careful due diligence, these advanced composite materials can significantly enhance modern building projects while supporting sustainable construction goals.