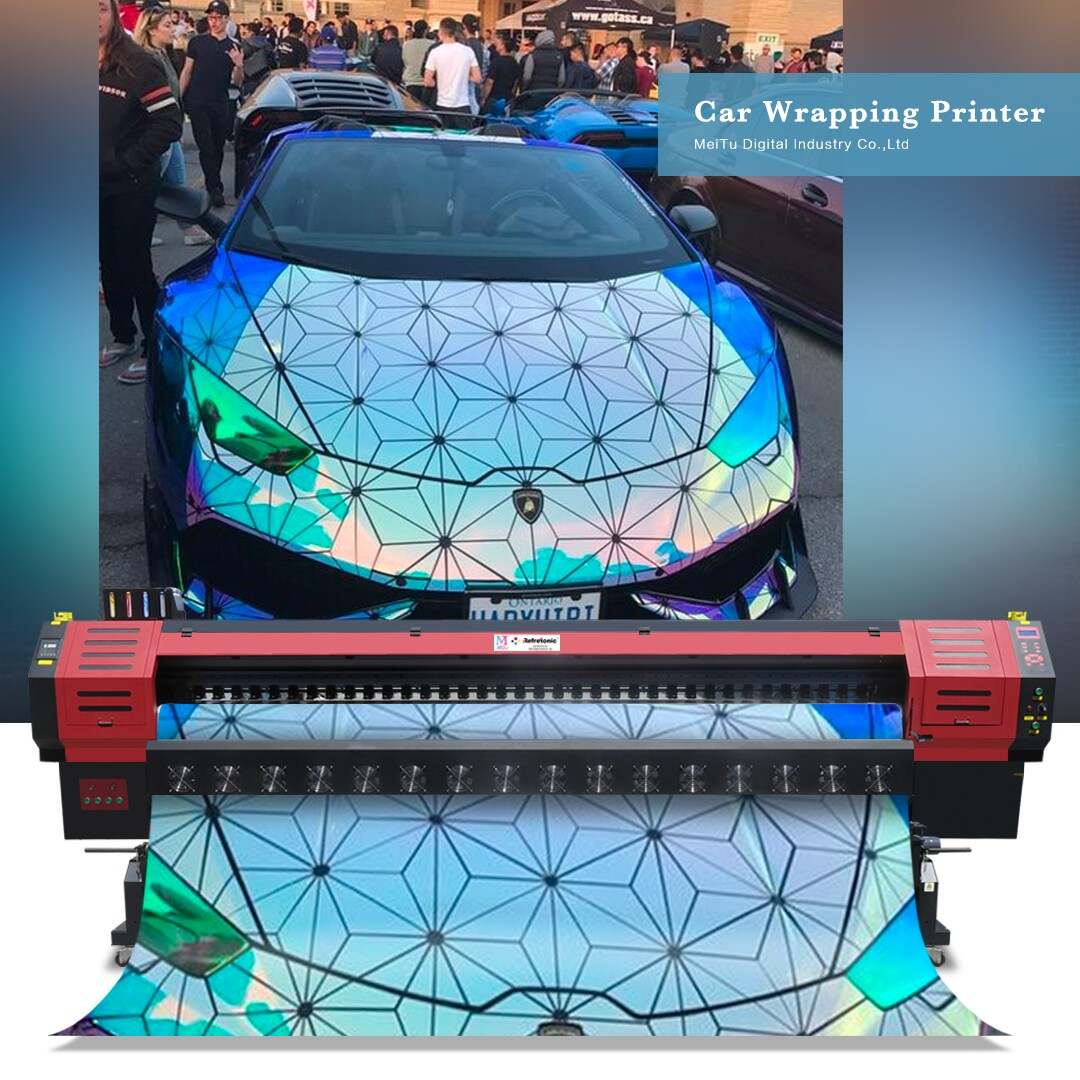

The global vehicle wrapping industry is undergoing rapid transformation, fueled by increasing demand for customizable, cost-effective branding and aesthetic solutions across commercial and consumer segments. According to Grand View Research, the global car wrap film market size was valued at USD 8.08 billion in 2024 and is projected to grow at a compound annual growth rate (CAGR) of 8.7% from 2024 to 2030. This expansion is driven by rising adoption in advertising, personalization trends, and advancements in digital printing technologies. As demand for high-resolution, durable wraps grows, so does the need for reliable, high-performance car wrap printers. Leading manufacturers are responding with innovative industrial inkjet solutions that deliver vibrant color reproduction, efficient throughput, and compatibility with diverse vinyl substrates. In this competitive landscape, selecting the right printer manufacturer is critical for print service providers aiming to scale operations and maintain a quality edge. Based on market presence, technological innovation, and customer feedback, here are the top 10 car wrap printer manufacturers shaping the future of digital vehicle customization.

Top 10 Car Wrap Printer Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1

Domain Est. 1995

Website: mutoh.com

Key Highlights: Top manufacturer of wide-format printers and cutting plotters for wraps, signage, textile and packaging industries. New year. New skills. Bigger opportunities….

#2 Vehicle Wraps and Decal Printer/Cutters

Domain Est. 1996

Website: global.rolanddg.com

Key Highlights: Equipped with fast, reliable and media versatile technology, Roland DG users can create everything from full wraps to airbrush stencils and anything in-between ……

#3 Metro Restyling

Domain Est. 2008

Website: metrorestyling.com

Key Highlights: Free delivery over $99 30-day returnsWe carry the latest and greatest vinyl car wrap and paint protection film technology in a variety of colors, patterns, and finishes….

#4 HEXIS Manufacturer of Sign Vinyl, Digital Printing and Laminates …

Domain Est. 2010

Website: hexis-graphics.com

Key Highlights: HEXIS have been a major manufacturer of self-adhesive films for the sign industry, vehicle wrapping, fleet branding and textile decoration….

#5 Vehicle Wraps – Large Format Print application

Domain Est. 1986

Website: hp.com

Key Highlights: Print vehicle wraps, vehicle graphics, and car decals that are easy to install and can be applied to any surface, we have just the car wrap printer for you….

#6 Discover Car Wraps and Graphics Solutions

Domain Est. 1993

Website: graphics.averydennison.com

Key Highlights: Learn how Avery Dennison can provide solutions for car and vehicle wraps using over 500 film colors in a cast and calendared series. Contact us today….

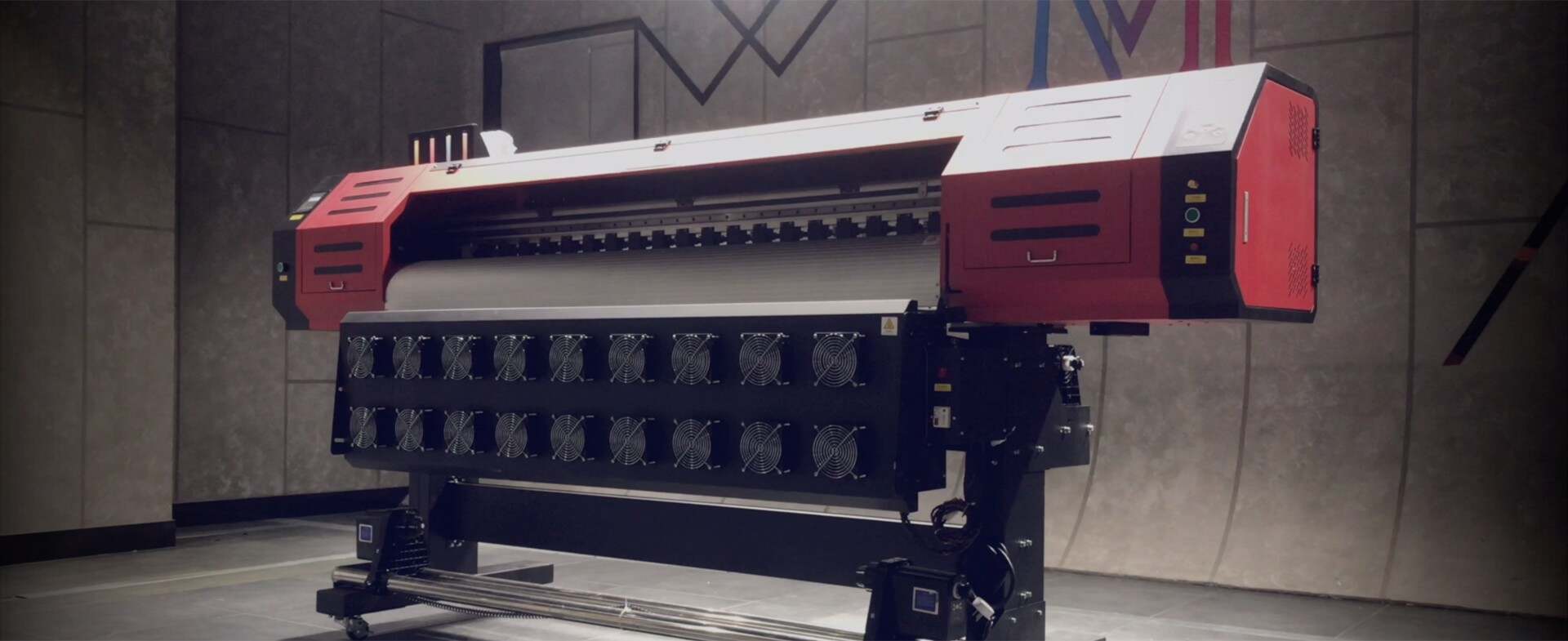

#7 Custom Vinyl Wrap Printing Machines

Domain Est. 1996

Website: rolanddga.com

Key Highlights: And there’s no better machine to build your custom vehicle wrap and car decal printing business around than a Roland DG custom vinyl wrap printing machine….

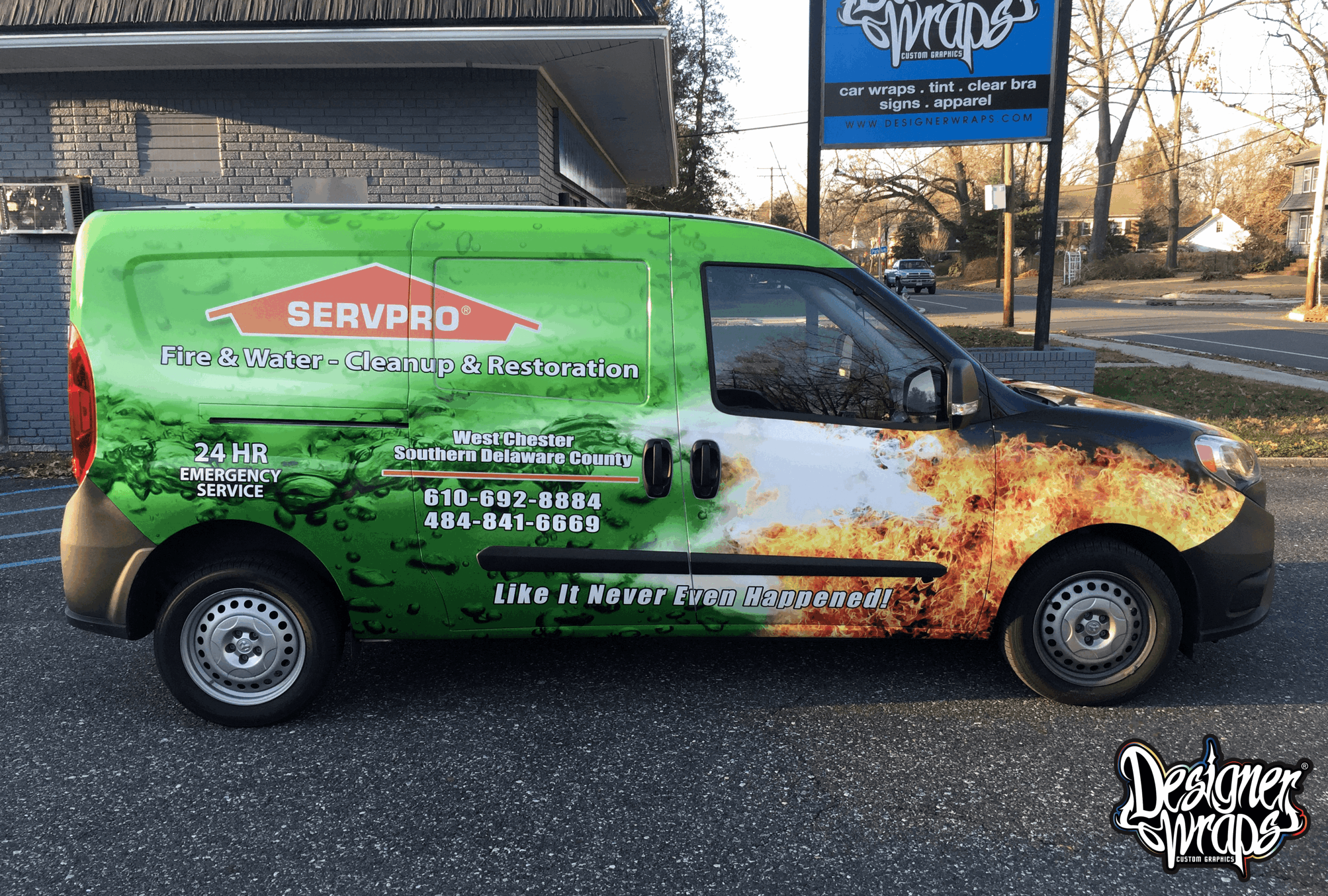

#8 Nationwide Vinyl wrap printing & shipping

Domain Est. 2003

Website: designerwraps.com

Key Highlights: Commercial Vehicle Wrap Printing & Nationwide Shipping. Super-fast production! We offer quality, commercial digital printing solutions for ANY SIZE project, ……

#9 Wrapstock

Domain Est. 2012

Website: wrapstock.com

Key Highlights: Our designs, fit to any type of car, makes a smooth wrapping process. It’s quick and easy! Simply choose your design, download it, print it and wrap today! You ……

#10 MAXDECAL

Domain Est. 2019

Website: maxdecalsticker.com

Key Highlights: MAXDECAL has been proven to be a reliable supplier for the automotive industry, digital printing materials, signage and decoration vinyls, car wrap film, and ……

Expert Sourcing Insights for Car Wrap Printer

2026 Market Trends for Car Wrap Printers

The car wrap printer market is poised for significant evolution by 2026, driven by technological advancements, shifting consumer demands, and expanding applications. Key trends shaping the industry include:

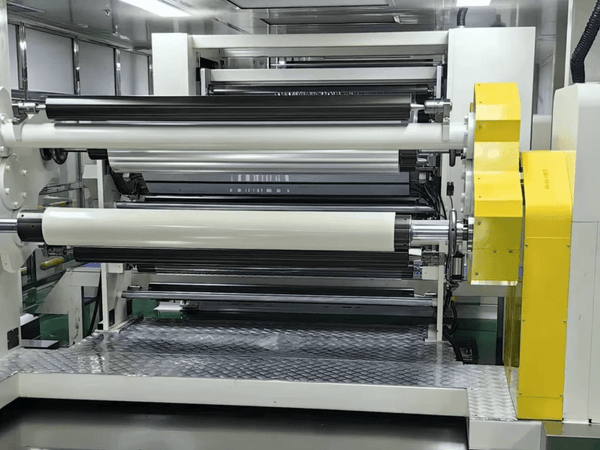

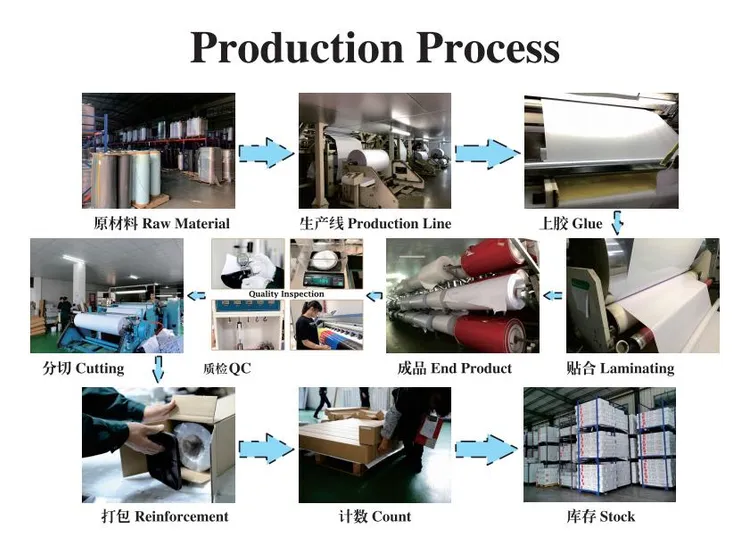

Advancements in Printer Technology and Efficiency

By 2026, car wrap printers will increasingly feature higher resolution, faster printing speeds, and improved inkjet reliability. Manufacturers are investing in precision printhead technology and intelligent calibration systems to ensure consistent color accuracy and edge definition, critical for large-format vehicle wraps. Automation features such as self-cleaning mechanisms, predictive maintenance alerts, and integrated RIP (Raster Image Processing) software will become standard, reducing downtime and labor costs for print service providers.

Growth in Eco-Friendly and Sustainable Solutions

Environmental concerns will drive demand for sustainable printing solutions. Solvent-free and low-VOC (volatile organic compound) ink technologies—such as UV-curable, latex, and water-based inks—will gain wider adoption. Printers designed for energy efficiency and compatibility with recyclable or biodegradable media will appeal to environmentally conscious businesses and clients. Regulatory pressures and corporate sustainability goals will accelerate this shift, making eco-friendly car wrap printers a competitive necessity.

Expansion of Digital Customization and On-Demand Services

The rise of personalized branding and individual expression will fuel demand for on-demand, short-run car wraps. Digital printing allows for cost-effective customization, enabling fleet operators, small businesses, and individual car owners to create unique designs without high setup costs. By 2026, seamless integration between design software, cloud-based workflows, and print hardware will streamline the customization process, supporting rapid turnaround times and mass personalization.

Increased Demand from Emerging Markets and Diverse Applications

While North America and Europe remain strong markets, growth in Asia-Pacific, Latin America, and the Middle East will accelerate due to rising vehicle ownership and urbanization. Beyond traditional automotive uses, car wrap printers will see expanded applications in public transit, delivery fleets, advertising vehicles, and even electric and autonomous vehicles requiring distinctive branding. This diversification will drive demand for versatile printers capable of handling different substrates and vehicle types.

Integration of AI and Smart Manufacturing

Artificial intelligence (AI) and IoT (Internet of Things) will play a growing role in optimizing print operations. AI-powered color matching, substrate detection, and defect detection systems will enhance print quality and reduce waste. Smart printers connected to centralized production systems will enable real-time monitoring, remote troubleshooting, and data-driven decision-making, improving overall operational efficiency in print shops.

Consolidation and Competitive Differentiation

The market may experience consolidation as larger players acquire niche innovators to expand their technology portfolios. Competition will intensify around total cost of ownership (TCO), service support, and ecosystem integration. Vendors offering comprehensive solutions—including printers, inks, media, software, and training—will have a strategic advantage in capturing market share by 2026.

In conclusion, the 2026 car wrap printer market will be defined by innovation, sustainability, and digital integration, offering new opportunities for print providers who embrace these evolving trends.

Common Pitfalls When Sourcing a Car Wrap Printer (Quality, IP)

Sourcing a car wrap printer involves significant investment and long-term operational impact. Avoiding common pitfalls is crucial to ensure print quality, reliability, and protection of your intellectual property. Here are key areas to watch out for:

Overlooking Print Quality and Consistency

One of the most frequent mistakes is focusing solely on price while neglecting long-term print quality. Low-cost printers may produce inconsistent colors, poor resolution, or banding, which is unacceptable for high-visibility vehicle wraps. Always request sample prints on actual wrap media and evaluate color accuracy, detail sharpness, and ink laydown consistency across large panels.

Ignoring Ink and Media Compatibility

Some printers are optimized for specific ink and media combinations. If the printer uses proprietary consumables, you may face high recurring costs or limited flexibility. Ensure the printer supports a wide range of third-party and industry-standard wrap films and eco-solvent or UV inks to maintain cost efficiency and output versatility.

Underestimating Maintenance and Reliability

Car wrap printers operate under heavy use and require regular maintenance. Models with poor service support or complex upkeep can lead to costly downtime. Evaluate the manufacturer’s service network, availability of parts, and ease of maintenance. Printers with automated cleaning systems and robust printhead protection tend to offer better uptime.

Falling for Unrealistic Speed Claims

Manufacturers often advertise maximum print speeds under ideal conditions. In real-world use, print quality settings, media handling, and RIP processing reduce actual throughput. Always verify real-world speed performance with test runs and consider how it aligns with your production volume needs.

Neglecting Intellectual Property (IP) Risks

Using a printer with firmware or RIP software that logs job data or transmits usage information can expose your designs and client projects. Some low-cost or foreign-made printers may include hidden telemetry that compromises confidentiality. Research the brand’s data policies and ensure the system operates offline or allows full control over data handling to protect sensitive client IP.

Choosing Based on Brand Alone Without Verification

Well-known brands don’t always guarantee suitability for car wrapping. Confirm that the printer model is specifically designed or commonly used for large-format vehicle graphics. Seek user reviews, case studies, or peer recommendations from other wrap specialists before finalizing a purchase.

Skipping On-Site Testing and Support

Avoid buying solely based on online specs. Whenever possible, conduct on-site demonstrations using your preferred media and designs. Verify not only print quality but also software integration, color management tools, and technical support responsiveness—critical factors for protecting both output quality and your business IP.

Logistics & Compliance Guide for Car Wrap Printer

Shipping and Handling of Printed Car Wraps

Ensure printed car wraps are rolled tightly on rigid cardboard cores (typically 3” or 6” diameter) to prevent creasing and warping. Use protective inner liners such as kraft paper or silicon-coated release liner to avoid adhesive contamination. Seal each roll in heavy-duty polyethylene or waterproof mailing tubes for transit. Label shipments clearly with handling instructions (e.g., “Fragile,” “This End Up,” “Do Not Bend”). Utilize reputable courier services with tracking and insurance options, especially for international shipments. Maintain inventory in a climate-controlled environment (15–25°C, 40–60% humidity) to preserve material integrity.

Domestic and International Shipping Regulations

Comply with carrier-specific size and weight restrictions (e.g., UPS, FedEx, DHL). For international shipments, prepare accurate commercial invoices specifying product description (“vinyl adhesive film for vehicle wraps”), value, country of origin, and harmonized system (HS) code (typically 3919.10 or 3919.90). Include export declarations when required. Verify destination country regulations regarding adhesive materials or chemical content. Avoid restricted or hazardous labeling to prevent customs delays. Use Incoterms (e.g., EXW, FOB, DDP) clearly in contracts to define responsibility for shipping, duties, and taxes.

Material Safety and Environmental Compliance

Adhere to REACH (EU), RoHS, and Prop 65 (California) regulations for chemical content in inks and substrates. Maintain Safety Data Sheets (SDS) for all consumables (inks, adhesives, cleaning solutions). Ensure printer inks are low-VOC or solvent-free where possible to meet EPA and local air quality standards. Implement proper waste disposal procedures for used inks, rags, and substrates in accordance with local environmental laws. Use certified eco-friendly materials when possible to support sustainability claims and meet client expectations.

Import Duties and Customs Documentation

Research applicable import tariffs based on the destination country and material composition. Accurately classify products using the correct HS code to avoid overpayment or penalties. Provide complete documentation: commercial invoice, packing list, bill of lading/air waybill, and certificate of origin if required. For shipments to the EU, ensure compliance with the EU Market Surveillance Regulation and CE marking if applicable. Consider working with a customs broker for high-volume or complex international deliveries.

Installation and End-Use Compliance

Inform customers that proper installation by certified professionals is essential for warranty and performance. Provide care and maintenance instructions, including cleaning recommendations and expected lifespan. Note any limitations (e.g., not suitable for high-heat areas or off-road use). Comply with local regulations on vehicle advertising (e.g., size, placement, reflectivity) where wraps are used for commercial branding. Retain records of job specifications and materials used for traceability and compliance audits.

Conclusion for Sourcing a Car Wrap Printer

After evaluating various options, features, and market offerings, sourcing a high-quality car wrap printer is a critical investment for any business focused on vehicle customization, advertising, or fleet branding. A reliable large-format printer capable of handling vinyl and specialty media with precision, color accuracy, and durability is essential to produce professional-grade wraps that withstand environmental exposure and meet client expectations.

Key factors such as print resolution, ink type (solvent, eco-solvent, or latex), print speed, media compatibility, and maintenance requirements must align with your production volume and application needs. Additionally, considering total cost of ownership—including inks, substrates, printer longevity, and technical support—ensures long-term profitability and operational efficiency.

Ultimately, sourcing a car wrap printer from a reputable manufacturer with strong technical support and a proven track record in the vehicle graphics industry will empower your business to deliver vibrant, durable, and high-impact wraps. By making an informed decision based on performance, reliability, and serviceability, you position your operation for sustained growth and competitive advantage in the expanding market for vehicle wraps.