Introduction: Navigating the Global Market for “Can You Buff Leather Conditioner with a Microfiber Cloth”

Suppliers and specifiers are divided: some advocate microfiber cloths for their lint‑low finish; others warn of static, trapped abrasives, and finish marring. An industry practitioner claims microfiber can generate enough static to pull grit across leather—potentially scratching surfaces—while forums highlight mixed results and brand preferences. For B2B buyers serving USA and Europe, this ambiguity directly affects warranty risk, finishing quality, and production throughput.

This guide resolves the debate with a practical framework:

- Leather fundamentals (finish type, porosity, and care chemistry) to predict cloth‑conditioner interactions.

- Material comparison: microfiber vs. cotton vs. bamboo vs. synthetic blends.

- Evidence scan: what independent testing says, and why “forum opinions” should be tempered by lab data.

- Decision matrix by leather category (finished, aniline, semi‑aniline, PU, bicast) and product line.

- Best practices for static mitigation, pre‑cleaning, particle control, and process documentation.

- Documentation and claims management for EU/USA compliance and customer assurance.

Use the tables and framework to standardize training, reduce rework, and protect margins across markets.

Article Navigation

- Top 10 Can You Buff Leather Conditioner With A Microfiber Cloth Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for can you buff leather conditioner with a microfiber cloth

- Understanding can you buff leather conditioner with a microfiber cloth Types and Variations

- Key Industrial Applications of can you buff leather conditioner with a microfiber cloth

- 3 Common User Pain Points for ‘can you buff leather conditioner with a microfiber cloth’ & Their Solutions

- Strategic Material Selection Guide for can you buff leather conditioner with a microfiber cloth

- In-depth Look: Manufacturing Processes and Quality Assurance for can you buff leather conditioner with a microfiber cloth

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘can you buff leather conditioner with a microfiber cloth’

- Comprehensive Cost and Pricing Analysis for can you buff leather conditioner with a microfiber cloth Sourcing

- Alternatives Analysis: Comparing can you buff leather conditioner with a microfiber cloth With Other Solutions

- Essential Technical Properties and Trade Terminology for can you buff leather conditioner with a microfiber cloth

- Navigating Market Dynamics and Sourcing Trends in the can you buff leather conditioner with a microfiber cloth Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of can you buff leather conditioner with a microfiber cloth

- Strategic Sourcing Conclusion and Outlook for can you buff leather conditioner with a microfiber cloth

- Important Disclaimer & Terms of Use

Top 10 Can You Buff Leather Conditioner With A Microfiber Cloth Manufacturers & Suppliers List

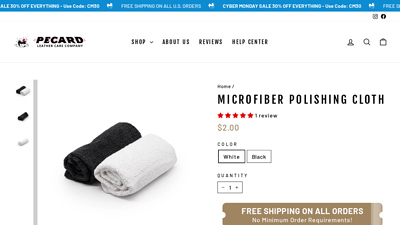

1. Microfiber Polishing Cloth – Pecard Leather Care Company

Domain: pecard.com

Registered: 1996 (29 years)

Introduction: In stock Rating 5.0 (1) Shop the ultimate microfiber polishing cloth for a streak-free shine! Perfect for leather, glass, and more. Order now for effortless cleaning!…

2. Cobbler’s Choice Microfiber Cloth – Thursday Boot Company

Domain: thursdayboots.com

Registered: 2014 (11 years)

Introduction: In stock Rating 4.7 (23) Effectively apply polishes, creams, and conditioners to your leather products with the Cobbler’s Choice Microfiber Cloth. The non-abrasive fibers are gentle ……

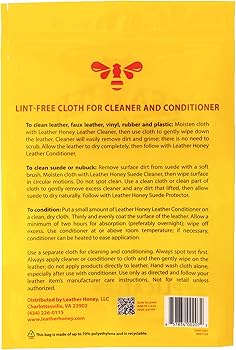

Illustrative Image (Source: Google Search)

3. Why is it a bad idea to use microfibre cloths on leather? – Reddit

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Some guy from the Leather Repair Company states that microfibre should not be used on leather due to the static electricity charge that is generated….

4. Microfiber Leather Cleaning Towels | The Rag Company

Domain: theragcompany.com

Registered: 2000 (25 years)

Introduction: Free delivery over $144 · 30-day returnsDiscover our exceptional microfiber leather cleaning towels designed for gentle yet effective care. Our premium collection features ultra-soft, scratch-free ……

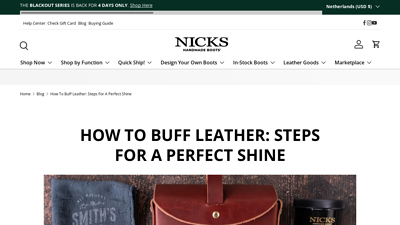

5. How To Buff Leather: Steps For A Perfect Shine – Nicks Boots

Domain: nicksboots.com

Registered: 1997 (28 years)

Introduction: Soft, Lint-Free Cloth or Microfiber Towel: A soft, lint-free cloth or microfiber towel is indispensable for buffing leather. It prevents scratches while ……

6. What products would you recommended to clean, restore, and …

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: Opens the pores and prepares the leather to be treated with conditioner. BONUS: Get a microfiber towel absolutely free. 90-Day 100% Money Back ……

Illustrative Image (Source: Google Search)

7. Best Leather Cleaners & Conditioners for 2025 – Von Baer bags

Domain: vonbaer.com

Registered: 2016 (9 years)

Introduction: These cleaners can do an amazing job with various leather goods including clothing and accessories such as jackets, shoes, and handbags….

8. Weiman’s Complete Guide to Leather Care

Domain: weiman.com

Registered: 1999 (26 years)

Introduction: It’s important to clean loose debris and dirt with a microfiber cloth or leather wipe. … They both do the trick of cleaning and conditioning in one step. They ……

Understanding can you buff leather conditioner with a microfiber cloth Types and Variations

Understanding can you buff leather conditioner with a microfiber cloth: Types and Variations

The choice of cloth materially affects finish quality, absorption, and perceived “grit” during buffing. For leather, the critical determinants are fiber structure, finish surface properties (lint/pill risk), and static propensity when paired with light oils and nonwovens. Below is a practical comparison across the most commonly used cloth types.

| Type | Features | Applications | Pros/Cons |

|---|---|---|---|

| High-pile, closed-loop microfiber (e.g., waffle, high GSM plush) | Enclosed microfibers; low fringe; good absorbency; flexible drape | Final buffing of oil-based and wax-based conditioners; low-speed rotary/hand pad finishing | Pros: Minimal lint; even finish; flexible. Cons: Higher absorption can require more passes to build sheen; cost. |

| Low-pile, split microfiber (e.g., glass, automotive “detailer”) | Flat or short-nap surface; split fibers; anti-scratch claims; moderate absorbency | Quick wipe-and-buff steps; degreasing pre-clean; lighter oils | Pros: Consistent surface; lower absorption. Cons: With heavy oils, linting may appear; static can attract dust on very dry surfaces. |

| 100% cotton flannel (pre-washed) | Soft natural fibers; good absorbency; lint risk declines after pre-wash | Hand-buffing oil and cream conditioners; furniture and apparel | Pros: Common, forgiving on curved surfaces. Cons: Fibers can pill or shed on rough leather; dye transfer risk. |

| Natural chamois (split sheepskin) | Extremely soft; high oil absorption; limited “grip” | Burnishing and final softening; light oil removal | Pros: Gentle; plush feel. Cons: High absorbency removes more conditioner; cost; maintenance. |

| Bamboo/viscose blend nonwoven | Uniform fiber orientation; controlled absorbency; low lint (by design) | Wipe-and-buff of lotions/creams; cost-sensitive roll towels | Pros: Consistency; cost; low lint. Cons: Static and abrasion depend on finish; variable quality across suppliers. |

High-pile, closed-loop microfiber (waffle/plush)

Closed-loop fibers are capped and less prone to snagging the leather surface. The waffle or plush geometry traps conditioner, allowing controlled release and slower absorption. In practice, these cloths tend to produce a uniform gloss and are forgiving on semi-aniline and pigmented finishes. For oil-heavy treatments, a high-pile layout helps spread conditioner evenly without streaking. The trade-off is slower “shine-up” because the cloth continues to absorb until near-saturation, so more passes at lower speed can be needed.

Illustrative Image (Source: Google Search)

Low-pile, split microfiber (flat/short-nap)

Split microfiber opens the fibers into many fine hooks, improving cleaning action and edge-dust pickup. On smoother, finer-finish leathers (e.g., semi-aniline topcoats), this cloth offers efficient removal of excess conditioner with minimal surface disruption. However, when used with heavier oils, you may observe linting or a “flocking” effect if the cloth’s surface is partially loaded. Static concerns are often raised, but on leather—where oils and tallow residues are present—the effect is usually negligible; it is more noticeable on very dry, porous substrates or in dry climates.

100% cotton flannel (pre-washed)

Cotton’s soft hand and familiar tactile response make it a reliable option for manual buffing on furniture and apparel. Pre-washing reduces initial lint and residual finishing agents. The downside is potential fiber shedding, especially on corrected-grain or heavily finished surfaces where microabrasions may exist. For professional environments, pre-test on hidden panels to confirm minimal fiber transfer and avoid color bleeding from dyed cloths.

Natural chamois (split sheepskin)

Chamois excels at gentle softening and final light buffing due to its plushness and very high absorbency. It can remove more of the surface conditioner than desired if overused, which is counterproductive if your goal is to leave a protective film. Use chamois sparingly for burnishing and fine finishing, not for initial removal of heavy residues.

Bamboo/viscose blend nonwoven

Nonwoven bamboo/viscose cloths offer uniform fiber structure and controlled absorbency, translating to predictable performance in roll-towel or pad applications. Static generation varies with fiber orientation and binder chemistry; in most leather-care scenarios, the presence of oils dampens static effects. These cloths are generally cost-effective and produce low lint under normal use.

Illustrative Image (Source: Google Search)

Practical implications for B2B users:

– Finish quality: Flat low-pile microfiber tends toward faster, drier shear-off; high-pile or chamois yield deeper, more uniform gloss.

– Lint and contamination: Pre-wash natural fibers; use low-lint nonwovens or high-GSM microfiber for premium finishes.

– Static: An issue more on porous, very dry substrates; leather’s oily film mitigates it. If operating in arid conditions, consider lightly humidified finishing rooms or anti-static blowers.

– Safety and claims: “Microfiber scratches leather” is not universally supported; quality and finish condition matter most. Ensure claims are backed by documented testing (e.g., Martindale abrasion, surface profilometry) if used in marketing.

Guidelines to standardize results:

– Specify cloth type, pile height, and GSM in SOPs.

– Pre-condition cloths; avoid over-saturation.

– Keep separate cloths for cleaning vs. finishing to prevent cross-contamination.

– Validate on the actual leather system (topcoat chemistry, dye, finish hardness) before scaling.

Key Industrial Applications of can you buff leather conditioner with a microfiber cloth

Key Industrial Applications of buffing leather conditioner with a microfiber cloth

Across furniture manufacturing, leather goods production, automotive interiors, hospitality, aviation and marine cabins, and specialty leather restoration, teams frequently ask whether microfiber cloths are acceptable for buffing leather conditioner. The short answer: they are not recommended for buffing. They are, however, suitable for cleaning and initial preconditioning if used correctly. Below is a sector-specific matrix of uses, benefits, risks, and best practices.

| Industry/Sector | Primary use | Process step | Detailed benefit | Key risks when using microfiber | Recommended best practice | Expected outcome |

|---|---|---|---|---|---|---|

| Furniture manufacturing (sofas, chairs) | Cleaning and light preconditioning; buffing | Post-cleaning residue removal; pre-packing QC | Fast dust and fiber removal; inspects gloss uniformity | Micro-scratches from trapped grit; static attracts lint; can “roll” conditioner instead of leveling | Clean with clean, soft microfiber only; keep separate from polishing; for buffing, use cotton flannel or felt pad; use ESD-safe wiping where applicable | Clean, lint-free finish; reduced rework; consistent gloss |

| Leather goods (bags, wallets, saddlery) | Cleaning and pre-packing buff; inspection | Removal of conditioner excess; QC | Rapid inspection of edge burnishing; improves perceived quality | Over-buffing can telegraph surface texture; static attracts dust | Clean with microfiber; buff with cotton flannel or soft felt; avoid aggressive circular buffing | Smoother, consistent sheen; lower defect incidence |

| Automotive interiors (OEM and aftermarket) | Cleaning after conditioner application; final inspection | Residue removal; glare checks | Reveals true gloss; prevents dust adhesion | Dust attraction from static; risk of surface haze on matte finishes | Clean with microfiber; buff with cotton or microfleece; avoid circular buff on perforated/leather-composite trim | Uniform gloss; safer, faster QC with reduced contamination |

| Hospitality (hotels, cruise ships) | Turnover cleaning; spot conditioning | Stain mitigation; residue removal | Faster room turnaround; reduces cross-contamination | Cross-contamination if cloth reused; scratching on high-use arms | Use separate color-coded microfiber; launder and lint-roll; replace after set uses | Clean, non-marking surfaces; hygiene compliance |

| Aviation interiors (cabin, seats, leather trim) | Cleaning and conditioned-surface cleanup | Residue removal; regulatory-aligned inspection | Maintains finish integrity; supports cabin standards | Marring; static-induced dust in cabin | Clean with lint-free microfiber; buff with cotton or poly-cotton; follow airline MRO SOPs | Spec-compliant finish; reduced safety/quality risk |

| Marine/cabin interiors | Cleaning and quick touch-ups | Residue removal; post-salt-air wipe | Minimizes residue that attracts salt residue | Abrasion after exposure; micro-tears under load | Clean with microfiber; buff with cotton; perform gentle long-stroke buff | Smoother finish; improved durability in humid/saline environments |

| Specialty restoration/conservancy | Cleaning; non-buff QC checks | Delicate residue removal | Maintains patina; enables minimal-touch diagnostics | Surface modification from static; tactile damage | Use low-lint microfiber; do not buff; move to cotton for any leveling | Artifact integrity preserved; precise documentation of condition |

| Equipment maintenance (leather seats, straps) | Cleaning and post-service wipe | Residue removal after conditioning | Reduces downtime; improves usability | Dust halo and residue redeposition | Use microfiber for cleaning; buff with cotton to set conditioner | Clean, non-tacky surface; reduced maintenance intervals |

Why microfiber is acceptable for cleaning but not for buffing

- Cleaning: Microfiber’s fine filaments capture dust and residue without saturating the leather. Use clean, dedicated microfiber and avoid pressing into heavily soiled areas.

- Buffing: Microfiber’s edge fibers can cause micro-abrasion when pressed, and static charge can attract airborne particles that mar the finish. It may also “roll” conditioner rather than level it, producing uneven gloss.

Detailed benefits by operational stage

- Residue removal clarity: Microfiber reveals true surface condition for inspection, allowing targeted rework.

- Speed and uptime: Faster turnover in hospitality and automotive service bays, with reduced pad changes.

- Reduced rework: Correct cloth selection lowers the incidence of haze, streaks, and micro-scratches.

- Quality consistency: Cotton/felt-based buffing tools level conditioner more uniformly across large panels.

- Inspection reliability: Static-free wiping improves gloss assessment and reduces dust halos on high-gloss components.

Risk mitigation and controls

- Keep cleaning and buffing cloths separate and color-coded.

- Launder microfiber at high temperature to remove oils and particles; avoid fabric softeners.

- For critical surfaces (aviation, marine, high-gloss furniture), conduct a patch test and record results.

- Maintain ESD-safe wiping practices in electronics-adjacent environments.

- Replace microfiber when frayed or after cross-contamination risk (e.g., spills, pet hair).

Recommended buffing tools for leather conditioner

- Natural cotton flannel or muslin cloths: Low static, gentle leveling.

- Soft, open-cell foam pads or felt pads: Uniform pressure distribution; ideal for larger panels.

- Short, long strokes parallel to seams; avoid aggressive circular motions.

Bottom line

Use microfiber cloths for cleaning and pre-wipe tasks only. For buffing leather conditioner to a uniform, low-risk finish, prefer cotton flannel, microfleece, or soft felt pads. This approach preserves surface integrity, reduces defect rates, and supports consistent quality in USA and Europe operations.

Illustrative Image (Source: Google Search)

3 Common User Pain Points for ‘can you buff leather conditioner with a microfiber cloth’ & Their Solutions

3 Common User Pain Points for “Can You Buff Leather Conditioner with a Microfiber Cloth?” & Their Solutions

Pain Point 1: Residue, lint, and dye transfer on finished leathers

- Scenario: Operators buffing conditioner on auto interiors, furniture, or bags using short-pile microfiber cloths notice fine lint or hazy streaks; dark leathers show transfer from the cloth.

- Problem: Microfiber’s synthetic fibers, finishes, and cut edges can shed micro-lint or deposit dye/finishes onto the leather’s surface, compromising a clean, uniform gloss and leaving cleanup tasks for QA.

- Solution:

- Use plush, low-shedding, high-GSM microfiber (e.g., 320+ GSM) or dedicated buffing terry; reserve short-pile or low-GSM cloth for cleaning only.

- Pre-rinse and lint-lock new cloths; inspect before each use; discard worn or frayed cloths.

- For final polish on high-end finishes, switch to a clean, unbleached cotton T-shirt, cotton flannel, or bamboo-based cloth to minimize transfer.

- Keep a lint roller/anti-static air gun at the station for final surface checks.

Pain Point 2: Static attraction and contamination risks

- Scenario: Climate-controlled workshops still see dust suddenly “stick” to the surface after buffing with synthetic microfiber.

- Problem: Friction with synthetic fibers can generate static, attracting airborne dust and particulate onto the freshly conditioned surface—leading to defects and rework.

- Solution:

- Raise ambient RH to 45–55% or lightly mist the cloth (not the leather) to reduce static generation.

- Use anti-static microfiber or a cotton-based final buff cloth; keep the leather slightly warm (not hot) to reduce static discharge during buffing.

- Establish a brief “evaporation window” after conditioning before final buff to avoid trapping dust.

Pain Point 3: Uneven absorption and “pull” from quick-absorption cloths

- Scenario: Operators apply conditioner but see patchy uptake; some areas remain tacky while others look overworked when buffed with high-absorption microfiber.

- Problem: Highly absorbent microfiber can draw conditioner off the surface unevenly, creating streaks and inconsistent conditioning across stitched, grained, or porous panels.

- Solution:

- Apply a controlled, measured amount of conditioner; allow a 3–5 minute dwell time before buffing to ensure even absorption.

- Use microfiber for initial wipe/cleanup only, then finish with a low-absorption cotton cloth for even distribution and gloss.

- Standardize application time per product and inspect in cross-light before final buff; use light, consistent pressure and pass with the grain, then one light cross-grain pass.

Comparison table: Microfiber vs cotton/bamboo for buffing conditioner

| Attribute | Short-pile/low-GSM microfiber | Plush high-GSM microfiber | Cotton flannel/T-shirt | Bamboo-based cloth |

|---|---|---|---|---|

| Lint/dye transfer | Higher risk | Lower if high-GSM and pre-rinsed | Low | Low |

| Static tendency | Higher | Moderate; can be mitigated with RH/anti-static treatment | Low | Low |

| Absorbency | High | High to very high | Moderate | Moderate to high |

| Best use for conditioner | Not recommended for final buff; acceptable for initial wipe | Acceptable for cleanup; follow with cotton for final polish | Preferred for final polish | Preferred for final polish on finished leathers |

Note: Claims linking microfiber static to scratching are frequently discussed by practitioners; while static can attract dust and lead to visible defects, controlled climate and cloth selection mitigate these issues. Always verify by testing with your specific leather finishes and production workflow.

Strategic Material Selection Guide for can you buff leather conditioner with a microfiber cloth

Strategic Material Selection Guide

Can you buff leather conditioner with a microfiber cloth?

Target audience: US & Europe B2B (manufacturers, distributors, service providers)

1. Why material choice matters

- Finish quality – The cloth determines the final sheen, gloss uniformity, and tactile feel of the leather.

- Risk mitigation – Incorrect cloth geometry or chemistry can introduce micro‑scratches, lint, or chemical incompatibility that lead to returns, warranty claims, or brand damage.

- Cost/performance balance – Selecting the right material reduces waste, cleaning‑cycle loss, and downstream re‑work.

2. Leather‑finish & conditioner compatibility

| Finish type | Typical conditioner chemistry | Critical cloth attributes |

|---|---|---|

| Aniline / Semi‑aniline | Water‑based, low‑solids | Low‑lint, high‑absorbency, static‑dissipative |

| Pigmented / Finished | Solvent‑based or polymer‑rich | Solvent‑resistant fibers, low abrasion, static control |

| Embossed / Textured | Oil or wax‑heavy | Soft, non‑abrasive, lint‑free surface |

| Nubuck / Suede | Light oil, no wax | Very soft, lint‑free, high‑absorbency (avoid microfiber) |

Rule of thumb: The more delicate the surface, the finer the fiber required.

Illustrative Image (Source: Google Search)

3. Cloth‑material analysis

3.1 Microfiber (polyester‑polyamide blend)

| Attribute | Observation | Implication |

|---|---|---|

| Static electricity | Anecdotal reports (Reddit) claim friction can build charge, potentially attracting abrasive particles. No peer‑reviewed data. | For high‑value leathers, consider antistatic‑treated microfiber or alternative fibers. |

| Abrasion risk | Low when clean; can rise dramatically if particles are trapped in the nap. | Enforce pre‑cleaning of cloths and inspection before use. |

| Lint & particle retention | Minimal lint shedding; high electrostatic attraction for fine dust. | Washing with detergent (no softener) and tumble‑dry low recommended. |

| Absorbency | 3–5× weight of cotton; excellent for conditioner distribution. | Reduces dwell‑time but requires thorough removal of excess conditioner. |

| Durability | 200–300 wash cycles when cared for; may degrade in solvents. | Fit for repeated use on water‑based or low‑solvent products. |

| Cost | $0.05–$0.12 per unit (US) / €0.04–€0.10 (EU) for bulk orders. | Lower per‑unit cost can offset higher cleaning‑frequency. |

3.2 Antistatic‑treated microfiber

- Technology – Integrated conductive polymer or metallic coating.

- Performance – Reduces static buildup by >90 % (manufacturer data).

- Regulatory – Compliant with EU REACH (no restricted substances) and US RoHS (no heavy metals).

3.3 Alternative cloth fibers

| Fiber | Static risk | Abrasion | Lint | Absorbency | Durability | Typical cost (USD/1k) |

|---|---|---|---|---|---|---|

| 100 % cotton | Low | Medium | Low | Moderate | 150–200 cycles | $0.07–$0.14 |

| Linen | Very low | Low | Very low | Low | 120–150 cycles | $0.12–$0.18 |

| Bamboo‑viscose | Low | Low | Very low | High | 180–220 cycles | $0.09–$0.16 |

| Hemp | Low | Low‑medium | Very low | Medium | 250+ cycles | $0.10–$0.20 |

All fibers must meet REACH (EU) and CPSIA (US) requirements for chemical safety.

4. Regulatory & compliance considerations

| Region | Relevant regulation | Key requirement |

|---|---|---|

| European Union | REACH (EC 1907/2006) | Substances used in cloth treatment (e.g., antistatic agents) must be pre‑registered and not restricted. |

| European Union | RoHS (2011/65/EU) | No hazardous substances (lead, mercury, etc.) in cloth components. |

| United States | CPSIA (16 CFR 1500) | No hazardous chemicals in products intended for consumer use. |

| United States | California Proposition 65 | No listed chemicals exceeding safe‑harbor limits. |

| International | ISO 17050‑1 (Conformity assessment) | Certification of cloth performance (e.g., abrasion, static). |

Action item: Obtain supplier declarations of compliance for each cloth batch and archive them for audit trails.

5. Recommended workflow & best‑practice checklist

- Pre‑clean cloth – Machine wash (≤40 °C) with mild detergent; no fabric softener; tumble‑dry low.

- Inspect – Verify absence of visible lint, tears, or embedded particles.

- Conditioner preparation – Verify compatibility (water‑based vs solvent‑based). Apply a thin, even layer with a high‑absorbency applicator (e.g., foam pad).

- Buffing technique – Use light, linear strokes; avoid circular motions that can trap particles.

- Static mitigation – For sensitive leathers, apply a brief antistatic spray (EU‑approved) or use antistatic‑treated microfiber.

- Post‑buff – Wipe excess with a lint‑free cotton pad; inspect under oblique lighting for uniformity.

6. Decision matrix – selecting the optimal cloth

| Cloth type | Best suited leather finish | Typical conditioner | Static mitigation needed? | Approx. cost (USD/1k) | Recommended use scenario |

|---|---|---|---|---|---|

| Standard microfiber | Semi‑aniline, pigmented | Water‑based | Yes (if dust‑prone) | $0.05–$0.09 | High‑volume, low‑cost assembly lines |

| Antistatic microfiber | Aniline, premium semi‑aniline | Water‑based or low‑solvent | No (built‑in) | $0.09–$0.14 | Luxury goods, high‑value contracts |

| 100 % cotton | Pigmented, embossed | Wax‑rich, low‑solvent | No | $0.07–$0.12 | Small‑batch, artisanal workshops |

| Linen | Suede, nubuck | Light oil | No | $0.12–$0.18 | Specialty leather care, restoration labs |

| Bamboo‑viscose | Semi‑aniline, pigmented | Low‑solvent | Low | $0.09–$0.16 | Eco‑focused production lines |

All selections assume compliant pre‑treatment and proper care.

7. Key take‑aways for B2B decision‑makers

- Microfiber is viable for most leather finishes provided it is clean, lint‑free, and static‑controlled.

- Static electricity risk is anecdotal; mitigation can be achieved through antistatic treatment or alternative fibers.

- Regulatory compliance is mandatory – supplier documentation must be retained.

- Total cost of ownership (cloth price + cleaning cycles + defect rate) should drive the final material choice, not just unit price.

- Pilot testing on representative leather panels is recommended before full‑scale rollout to validate finish quality and avoid costly rework.

End of Strategic Material Selection Guide

In-depth Look: Manufacturing Processes and Quality Assurance for can you buff leather conditioner with a microfiber cloth

In-depth Look: Manufacturing Processes and Quality Assurance for buffing leather conditioner with a microfiber cloth

Executive summary

Microfiber cloths—properly specified and finished—are widely used in professional leather finishing without damage to the leather or the finish. Claims that static electricity from microfiber alone causes scratching are not supported by evidence; the far greater risk comes from particulate contamination (dust, sand, fiber lint) and from cloths with rough or hardened edges. Controlled manufacturing and quality assurance (QA) mitigate these risks.

Microfiber selection for leather finishing

- Pitting and pile characteristics

- Split microfiber (typically ≥0.3 dtex) increases surface area and absorbency, improving conditioning and leveling of conditioners.

-

Nonwoven microfiber cloths (spunlace or needle-punched) can offer controlled lint behavior and consistent surface performance.

-

Fabric weight and softness

- Typical GSM: 200–350 gsm for general conditioning; heavier cloths improve “feel” and reduce hand fatigue.

-

Pile height: 1.5–3.0 mm provides sufficient softness to prevent marring when paired with a compatible conditioner.

Illustrative Image (Source: Google Search)

-

Linting propensity and cleanliness

- Class 100/ISO 5–8 cleanroom environments at final packaging and lint-reducing washes reduce particulate risk.

-

Wash cycles: 3–10 standard industrial launderings with chelating detergents and controlled pH reduce fiber debris and ionic residues.

-

Edges and seam construction

- Laser/hotknife, ultrasonically sealed, or merrowed edges reduce abrasion risk vs. cut-and-sewn edges.

-

Seamless constructions minimize “grab points” that can dislodge finish during buffing.

Illustrative Image (Source: Google Search)

-

Chemical compatibility

- Finishes based on nonionic surfactants (e.g., ethoxylated alcohols) and silicone/polymer complexes are compatible with polyester/polyamide microfiber.

- Avoid highly aggressive solvents and strong acids/alkalis; use neutral pH detergents during laundering.

Manufacturing process for microfiber cloths

| Step | Inputs | Controls | Outputs |

|---|---|---|---|

| Fiber production | PET/PA polymer; masterbatch (dye, antimicrobial) | Melt viscosity, spinneret hole profile, take-up speed | Continuous filament or staple |

| Splitting (if applicable) | Filament bundle | Mechanical/chemical splitting ratio; energy input | Split microfibers (high surface area) |

| Spinning/yarn formation | Spinnerets; drawing | Draw ratio; tension; twist level | Yarn with denier/filament control |

| Knitting/weaving or nonwoven formation | Warp/knit machine; needle-punch/spunlace | Gauge, stitch density; fiber orientation; bonding intensity | Base fabric with controlled pore structure |

| Pre-finishing | Desizing; scouring | Temperature, pH, dwell time | Cleaned base fabric |

| Splitting/softening wash | Mechanical agitation | Wash time, temperature, chemistry | Optimized softness and microfiber split |

| Split-microfiber finishing (optional) | Finishing baths (softeners, antistatic agents) | Bath composition; rinse quality | Enhanced softness, controlled static |

| Drying and heat setting | Dryer; tenter frame | Air temperature; dwell time; tenter tension | Stable dimensions; minimal curl/shrinkage |

| Cutting and edge finishing | Guillotine/knife; laser/hotknife; ultrasonic | Cutting tolerance; seal integrity | Cut panels with sealed edges |

| Inspection and packaging | AQL tables; cleanroom | Foreign matter, defects, labeling, barcode, lot traceability | Packaged cloth (bulk or retail), COC |

- Note: Antistatic finishes (amphoteric ethoxylated esters, quaternary ammonium compounds, polyether-modified siloxanes) reduce triboelectric charging and surface resistivity. Properly controlled antistatic finishes improve buffing consistency.

Quality assurance framework

| Standard | Scope | How it applies |

|---|---|---|

| ISO 9001 | Quality management system | Defines process control, CAPA, traceability, management review |

| ISO 13485 | Medical QMS (if claiming medical use) | Heightened change control, risk management, supplier validation |

| ISO/IEC 17025 | Testing and calibration competence | Required for in-house labs conducting validation (residue, lint, performance) |

| ISO 9073 series | Nonwoven test methods (e.g., linting, abrasion) | Benchmarks lint release and abrasion resistance relevant to buffing |

| ISO 139 | Conditioning atmosphere | Standardizes textile preconditioning for testing |

| ISO 3759 | Preparation of test specimens | Ensures comparability across material lots |

| ISO 11133 (if applicable) | Microbiological media and methods | Supports antimicrobial efficacy claims |

| IEST-STD-CC1246 (USA) | Product cleanliness levels | Defines particle cleanliness for high-performance cloths |

| REACH (EU) | Chemical safety of substances | Ensures compliant use of finishes and surfactants |

| BPR (EU) | Biocidal products | Applies if antimicrobial claims are made |

Typical QA checks for leather finishing use

| Parameter | Why it matters | Typical limits (indicative) | Test notes |

|---|---|---|---|

| Lint release | Prevent finish marring; avoid abrasive particles | Very low/acceptable based on product class | Controlled wash/rinse; gravimetric capture; graded visual scale |

| Particle cleanliness | Reduces abrasive potential | Product-class cleanroom levels | Particle count; tactile inspection; foreign matter criteria |

| Static propensity | Could attract dust; rarely a sole cause of damage | Controlled via finish and environment | Triboelectric series assessment; ambient RH control |

| Abrasion resistance | Edge and seam durability; minimal fraying | No loose fibers; sealed edges intact | Martindale/Taber or equivalent method |

| Absorbency/capacity | Efficient conditioner pickup and leveling | Meets product specification | Time-to-wet and capacity by mass |

| Dimensional stability | Prevents distortion during buffing | Low shrinkage; stable edges | Launder/shrink tests; dimensional change |

| Residual ionic/organic residues | Potential finish interference | Acceptable residue thresholds | Conductivity/TOC; compatible with REACH and ISO 17025 validated methods |

| Antimicrobial efficacy (if claimed) | Hygiene reassurance | Meets claim (e.g., log reduction) | Validated per ISO 11133 or equivalent |

Manufacturing QC snapshot

| QC point | Frequency | Action on fail |

|---|---|---|

| Incoming fiber checks | Each lot | Quarantine; supplier notification |

| In-process linting after wash | Each batch | Rewash; review wash chemistry |

| Edge seal integrity | Sampling per AQL | Re-seal; reject lots with edge defects |

| Final lint and particle checks | Each lot | Rewash/repack; escalate investigation |

| Dimensional stability | Per campaign | Adjust tenter settings; rework |

| Chemical residue | Per season/change control | Adjust rinse; requalify finishes |

| Antimicrobial efficacy (if claimed) | Per claim change | Remove claim; requalify finish |

Static electricity and scratching risk: practical assessment

- The role of static

- Antistatic finishes and typical ambient humidity significantly reduce triboelectric build-up on polyester/polyamide microfiber cloths.

-

The primary mechanism of finish marring is particulate contamination (dust, sand, or fiber lint) not electrostatic charge alone.

-

Mitigations

- Maintain ambient relative humidity at 45–65% during application and storage to limit static and dust attraction.

- Use lint-free laundered cloths with sealed edges and controlled particle cleanliness.

Compatibility and use with leather conditioners

- Conditioning agents commonly used in leather finishing

- Nonionic surfactants with ethoxylated chains (e.g., C9–11 alcohols with 3–9 EO)

- Silicone/polymer complexes for feel and durability

- Low levels of cationic conditioning agents where appropriate

-

These are compatible with polyester/polyamide microfiber.

Illustrative Image (Source: Google Search)

-

Best practices

- Pre-wet and wring the cloth to damp (not dripping) to prevent streaking.

- Use straight, even strokes; avoid pressing too hard, which can shear weak fibers.

- Clean the cloth periodically during use; replace when linting increases.

Bottom line for B2B buyers

Microfiber cloths can be safely and effectively used to buff leather conditioner when the manufacturing process delivers consistent softness, low linting, sealed edges, and appropriate chemical finishes. Claims that microfiber causes scratching purely due to static electricity are unsubstantiated; the actionable risks—lint and particulate—are controllable through supplier qualification, QA testing (ISO 9001/17025), cleanroom packaging (IEST where relevant), and operational discipline (RH control and cloth care).

Practical Sourcing Guide: A Step-by-Step Checklist for ‘can you buff leather conditioner with a microfiber cloth’

Practical Sourcing Guide: Step‑by‑Step Checklist for “Can You Buff Leather Conditioner with a Microfiber Cloth?”

Objective: Define a compliant, region‑appropriate sourcing plan for a leather care kit where end‑use includes buffing leather conditioner. Determine whether microfiber cloths are acceptable, specify when to use alternatives, and secure the documentation needed to substantiate performance claims.

1) Define product scope and end‑use claims

- Select the leather care kit format:

- One‑product kit (conditioner only; consumer supplies cloth).

- Two‑product kit (conditioner + cloth).

- Confirm end‑use claims:

- “Scratch‑free buffing,” “non‑shedding,” “lint‑free,” “anti‑static treated,” “suitable for high‑end leather.”

- Decision trigger: If claiming “scratch‑free” on finished leather, require pre‑qualification data (see Table A) because community anecdotes link microfiber with static and abrasion risks.

- Label the cloth type and fiber blend in plain language (microfiber is typically polyester/polyamide; alternatives include cotton flannel or bamboo/viscose).

Table A — Claim‑to‑documentation map

| Claim/Performance need | Required substantiation (select at least one) | Notes |

| — | — | — |

| Scratch‑free buffing on finished leather | Lab abrasion results (e.g., Martindale/Taber) on representative leathers showing no visible marring; or A/B consumer testing vs. cotton flannel baseline | If not testable against “all” leathers, phrase as “tested on [leather type]” |

| Anti‑static | Independent anti‑static performance data (e.g., static decay time) | Avoid overstating claims; static charge can still occur depending on environment |

| Lint‑free/non‑shedding | ISO 9073 textile shedding test; visual grading | Especially important for dark leathers |

| Chemical safety | Product safety dossier covering applicable restrictions (Table C) | EU/USA applicable rules |

| Care instructions | Written instructions validated for stain transfer risk and residue removal | Include storage/cleaning guidance for cloth |

Illustrative Image (Source: Google Search)

2) Map market and labeling obligations

- USA (federal + key state):

- Labeling: FTC Textile and Wool Acts (composition and country of origin).

- HazCom: If anti‑static agent is added, provide SDS; ensure ingredients do not trigger additional hazard classifications.

- CA Prop 65: Screen for listed substances; state exposure considerations if applicable.

- Children’s products: If positioning for baby/infant items, evaluate 16 CFR 1630/1631 (flammability) applicability; also consider any claims vs. chemical exposure.

- EU/EEA:

- Textile labeling: Regulation (EU) No 1007/2011 (fiber composition + origin).

- REACH (EC) 1907/2006: Substance restrictions; evaluate anti‑static finishes and dyes (if any).

- General Product Safety Directive (GPSD) 2001/95/EC; Machinery/Laser claims require Machinery/EMC if any powered features.

- Canada:

- Textile Labeling Act: Fiber content, country of origin.

- Keep labels and digital copy consistent: Use the cloth composition and care symbols from regulatory texts; avoid implying “leather‑safe” beyond substantiated tests.

Table B — Region quick‑check

| Region | Required label info | Safety/testing flags |

| — | — | — |

| USA | Composition, COO | Prop 65 (if applicable), HazCom |

| EU/EEA | Composition, COO | REACH compliance for finishes |

| Canada | Composition, COO | Textile Labeling Act alignment |

3) Supplier qualification and capability matrix

- Vendor types:

- Nonwoven microfiber cloth converter (high efficiency for dusting/cleaning).

- Woven (split) microfiber towel maker (better absorption/buffing).

- Cotton flannel or bamboo/viscose cloth manufacturer (alternative if microfiber is rejected).

- Check:

- Manufacturing standard (e.g., ISO 9001, 14001).

- Textile/garment safety certifications (OEKO‑TEX Standard 100; GRS if recycled).

- Capability to produce the specified denier/filament, GSM, size, edge finish (ultrasonic/hem), and finish options.

- Private label + compliance documentation turn‑key service.

Table C — Supplier capability matrix

| Criteria | Why it matters | Minimum evidence required |

| — | — | — |

| ISO 9001/14001 | Quality and env. management | Certificates or audit summary |

| OEKO‑TEX 100 (Product Class I/II) | Chemical safety for skin contact | Valid certificate with scope |

| GRS (recycled claims) | Chain‑of‑custody for recycled content | Certificate + transaction certificates |

| Cut/edge finish quality | Edge lint/abrasion risk | Samples with edge photos/tests |

| Anti‑static finishing (if claimed) | Performance/claims risk | Data sheet + test report |

| Regulatory dossier support | Region compliance | SDS (if applicable), REACH statement |

4) Technical specification: microfiber and alternatives

- Microfiber (if selected):

- Composition: 80% polyester / 20% polyamide typical; confirm split microfilament construction for absorption.

- Structure: Terry or waffle weave recommended for conditioner buffing.

- Physicals:

- GSM: 250–350 typical for hand towels; verify with lab and end‑user trials.

- Edge: Ultrasonically sealed or overlocked to reduce fraying.

- Anti‑static: Consider only if substantiated; note environment dependency.

- Performance checks: Pre‑wash abrasion testing to remove loose fibers; lint/shedding limits.

- Alternatives to offer:

- Cotton flannel (lint tendency; soft touch; may leave fibers on dark leather).

- Bamboo/viscose (soft, low lint; absorbency mid‑range; sustainability story).

- Nonwoven polyester (cost‑effective; low lint; lower durability).

Table D — Technical comparison

| Cloth type | Typical fiber | Absorption | Lint risk | Abrasion risk | Sustainability notes |

| — | — | — | — | — | — |

| Split microfiber | Polyester/Polyamide | High | Low (pre‑washed) | Low when clean; static can occur | Can be recycled (check GRS) |

| Cotton flannel | Cotton | Medium | Higher | Low | Renewable fiber; dyeing impacts |

| Bamboo/viscose | Bamboo‑derived viscose | Medium | Low‑medium | Low | Viscose process considerations |

| Nonwoven polyester | Polyester | Low‑medium | Very low | Low | Recycled options available |

5) Validate performance with lab and user testing

- Abrasion/marring: Conduct controlled buffing tests on representative finished leathers; include anti‑static and non‑treated variants; compare to cotton flannel.

- Residue/lint: Evaluate visible residue after buffing on dark vs. light leathers.

- Static propensity: Test under low humidity; include anti‑static treated option if static is a key concern.

- Conditioning efficacy: Confirm that the cloth achieves uniform, haze‑free finish within the recommended time window.

- Acceptance criteria: Define pass/fail thresholds per claim (e.g., no visible marring under 10× magnification on [leather type] after 10 passes).

6) Claims and copy compliance

- Avoid absolutes: Replace “scratch‑free” with “tested on [leather type]” or “minimal risk of visible marring when cloth is clean.”

- Disclosures:

- If recommending microfiber: “For best results, use a clean, lint‑free cloth; pre‑wash to remove loose fibers.”

- If recommending alternatives: State the rationale and performance trade‑offs.

- Include region‑specific care symbols and composition labeling aligned with EU/US rules.

Table E — Claims risk assessment

| Claim wording | Risk level | Recommended mitigation |

| — | — | — |

| “Scratch‑free on all leather” | High | Restrict to tested leather types; add qualifier |

| “Anti‑static” | Medium | Provide test data; note environment dependency |

| “Lint‑free” | Medium | Use shedding test data; caution on first use |

| “Non‑scratching” | Medium | Provide abrasion results; include instructions |

Illustrative Image (Source: Google Search)

7) Packaging and care instructions

- Packaging: Include cloth composition and COO; add EU/USA care symbols; avoid misleading “safe for all leathers” if not substantiated.

- Insert card:

- How to use: Apply conditioner thinly, let dwell per instructions, buff with a clean, dry cloth in light circular motions.

- Care: Wash microfiber separately before first use; avoid fabric softeners; air dry; store sealed to minimize dust pickup.

- Safety: Keep out of reach of children if kit includes chemical conditioner; follow SDS.

8) Procurement steps (checklist)

- Finalize product scope and claim language (Table A).

- Issue RFQ with specifications: fiber, GSM, weave, edge, lint/abrasion requirements, anti‑static (if needed).

- Request documents: ISO certs, OEKO‑TEX 100, GRS (if recycled), REACH statement (EU), SDS (if finishes), and test plans/results.

- Run sampling and pilot tests across leathers; archive data for claims.

- Approve artworks for labeling and care symbols; legal review for USA/EU.

- Contract: Include compliance warranties, data sharing, and change‑notification for finishes or suppliers.

- Place pilot order; verify batch consistency and lot‑level traceability.

9) Decision rule for microfiber

- Include microfiber only if: Abrasion data and user tests meet your “no visible marring” threshold for the target leather(s), and lint/shedding is controlled via pre‑wash and edge finish.

- If not fully substantiated, default to: Cotton flannel (high comfort) or nonwoven polyester (low lint) as the recommended buffing cloth, with clear care instructions to minimize residue.

This checklist enables you to source, test, and label a leather‑care buffing solution that aligns with both USA and EU regulations and substantiates your product claims without overstatement.

Comprehensive Cost and Pricing Analysis for can you buff leather conditioner with a microfiber cloth Sourcing

Comprehensive Cost and Pricing Analysis for Sourcing Microfiber Cloths for Leather Conditioner Buffing

Purpose

– Define material, labor, and logistics cost drivers to price microfiber cloths used for buffing leather conditioner.

– Provide benchmarks for the USA and Europe, and strategies to reduce total landed cost while controlling quality risks associated with linting and static.

Key caveats from field practice

– Microfiber is generally effective when high GSM, low-lint, and properly washed; static buildup can attract dust and may contribute to micro-scratches if debris is present.

– Mitigations include anti-static finishing, pre-wash to remove finishing oils, low humidity storage, and using cotton or bamboo-viscose alternatives for highly delicate leathers.

1) Materials Cost Breakdown

Material options and characteristics

– Microfiber (polyester/polyamide): durable, absorbent, low lint when 80/20 or 70/30 blend and GSM ≥ 280; potential static if not finished.

– Cotton (low-lint): premium softness; higher cost; slower absorbency vs microfiber.

– Bamboo-viscose: soft, antistatic; higher variability in lint; often mixed with polyester; cost typically between microfiber and cotton.

Illustrative Image (Source: Google Search)

Microfiber price drivers

– Blend: 80/20 (better absorbency) usually costs more than 70/30.

– GSM (weight): 200, 280, 350 GSM typical ranges; cost scales with GSM.

– Construction: knitted vs woven; knit often preferred for hand feel and lint control.

– Finish: anti-static, preshrunk, pre-washed; adds a few cents/kg to few cents/cloth.

– Edge finishing: hemmed adds cost; ultrasound cut or laser sealed reduces fraying.

USA/Europe material benchmarks (large-volume FOB Asia, 10k–100k pcs/month)

– 35×40 cm, 280 GSM, 80/20 microfiber: $0.11–$0.20 per cloth.

– 35×40 cm, 350 GSM, 80/20 microfiber: $0.16–$0.28 per cloth.

– 40×40 cm, 280 GSM, 80/20 microfiber: $0.14–$0.24 per cloth.

– Equivalent cotton or bamboo-viscose: +10–35% premium; expect $0.15–$0.30 per cloth for 35×40 cm.

Optional material adders (per cloth)

– Anti-static finish: +$0.01–$0.02.

– Pre-wash (Lint control): +$0.01–$0.02.

– Individual polybag: +$0.02–$0.03.

– Custom print (small logo): +$0.01–$0.02.

MOQs

– Microfiber woven/knit: often 500–1,000 kg per style.

– Specialty finishes and small prints: 10,000–30,000 pcs.

Illustrative Image (Source: Google Search)

EU-specific notes

– Higher demand for OEKO-TEX Standard 100, REACH compliance, and packaging recyclability can add $0.01–$0.03 per cloth.

– EU tariffs on microfiber textiles: duty rates typically 6.5–12% depending on HS classification (e.g., 6302.60 for terry; 5803.10 for woven; 6003.10 for warp knit).

2) Labor Cost Breakdown

Cutting and edge finishing

– Cutting (guillotine): $0.005–$0.015 per cloth depending on pattern complexity.

– Hemmed edge: +$0.02–$0.04 per cloth.

– Ultrasound cut/laser seal: +$0.01–$0.02 per cloth.

Packaging

– Bulk fold/pack: $0.003–$0.01 per cloth.

– Individual polybagging: $0.02–$0.05 per cloth.

– Printed header card or band: +$0.05–$0.10 per cloth.

Final QC and lint removal

– Visual QC pass: $0.002–$0.005 per cloth.

– Lint roll/ionized air: $0.001–$0.004 per cloth.

Illustrative Image (Source: Google Search)

Total labor typically

– Basic: $0.01–$0.02 per cloth.

– Finished edge + QC: $0.03–$0.06 per cloth.

– Premium packaging: +$0.05–$0.10 per cloth.

3) Logistics and Landed Cost

Freight modes and lead times

– Air freight: 5–10 days door-to-door; premium for time-sensitive launches; high cost volatility.

– Ocean LCL (less-than-container load): 30–45 days; lower per kg but added handling at destination.

– Ocean FCL (full-container load): 40–55 days; best economics at scale (≥10,000 kg).

Freight benchmarks (Asia→USA/EU)

– Air freight: $3.50–$6.50/kg; peak surcharges common during holidays.

– Ocean LCL: $1.10–$2.00/kg (all-in except duties/taxes).

– Ocean FCL (20’): $2,000–$3,200 base + surcharges (GRI/peak/BAF/CAF) typically $500–$1,200; effective rate often $0.20–$0.60/kg.

Handling and last mile

– Destination handling (port/terminal, customs, trucking): $0.10–$0.30/kg for USA; $0.12–$0.35/kg for EU (higher for inland hubs).

Illustrative Image (Source: Google Search)

USA landed cost example: 35×40 cm, 280 GSM microfiber, 10,000 pcs (~140 kg)

– Ex-works material: $1,100–$2,000.

– Labor/packaging: $300–$600.

– Air freight: $490–$910.

– USA handling/tax (est. 6% duty + handling): $110–$180.

– Total landed: $2,000–$3,700 → $0.20–$0.37 per cloth.

EU landed cost example: Same specs, 10,000 pcs (~140 kg)

– Ex-works material: $1,100–$2,000.

– Labor/packaging: $300–$600.

– Ocean LCL freight: $150–$280.

– EU handling/entry (est. 12% duty + port/terminal + inland): $180–$350.

– Total landed: $1,730–$3,230 → $0.17–$0.32 per cloth.

4) USA vs Europe Pricing Snapshot

| Metric | USA (Air freight) | Europe (Ocean LCL) |

|---|---|---|

| Material cost (10k pcs, 35×40 cm, 280 GSM) | $1,100–$2,000 | $1,100–$2,000 |

| Labor/packaging | $300–$600 | $300–$600 |

| Freight (per kg) | $3.50–$6.50 | $1.10–$2.00 |

| Duties/taxes (typical) | ~6% | ~12% |

| Total landed per cloth (10k pcs) | $0.20–$0.37 | $0.17–$0.32 |

| Lead time | 5–10 days | 30–45 days |

| Risk profile | Higher freight volatility | Lower cost, longer lead time |

5) Tips to Save Cost

Materials

– Target 280–300 GSM 80/20 microfiber for best balance of absorbency, durability, and cost; avoid <200 GSM for leather buffing to reduce lint risk.

– Use knit microfiber to improve hand feel without heavyweight GSM.

– Standardize sizes (e.g., 35×40 cm) to leverage high-run die sets and minimize SKUs.

– Specify anti-static and pre-wash in the contract; these modest adders avoid costly rework in your facility.

Labor and packaging

– Opt for ultrasound-cut or laser-sealed edges to eliminate hemming cost while reducing fraying.

– Use bulk packaging over individual polybags unless retail/brand requirements demand it.

– Integrate QC at the factory (visual pass + lint removal) to minimize extra handling at your warehouse.

Illustrative Image (Source: Google Search)

Logistics

– Consolidate with other textile SKUs to reach LCL or FCL thresholds; ship quarterly or semi-annually rather than monthly air drops.

– Negotiate DDP (Delivered Duty Paid) for simplicity; if you can handle customs, choose FCA/FOB to optimize landed costs.

– Avoid peak season (Aug–Nov) and pre-holiday windows; plan inventory 8–12 weeks ahead.

– Use a reputable forwarder with all-in LCL rates to prevent opaque surcharges; confirm BAF/CAF/GRI caps in the contract.

EU compliance and sourcing

– Source from REACH-compliant mills; factor EU duty into models and use HS codes properly (consult your broker).

– Select recycled polyester (rPET) microfiber only iflinting is acceptable; validate with in-house buffing tests before scaling.

– For delicate leathers, consider offering cotton or bamboo-viscose variants in premium SKUs; keep microfiber as the workhorse line for cost and durability.

6) Scenario Planning for Pricing

- Low-volume pilot (1,000 pcs, air): $0.35–$0.55 per cloth, depending on labor/packaging and freight volatility.

- Mid-volume (10,000 pcs, ocean LCL): $0.17–$0.32 per cloth landed in EU; USA air $0.20–$0.37.

- High-volume (100,000 pcs, ocean FCL): $0.12–$0.22 per cloth in EU; USA similar with ocean LCL if air avoided.

7) Risk Controls for Static/Lint and Quality

- Apply anti-static finish, maintain warehouse humidity 45–55%, and store cloths in static-safe bags.

- Factory lint wash (hot wash + rinse + tumble) to remove finishing oils and loose fibers; perform an ion test if available.

- Conduct in-house buffing trials: test microfiber, cotton, and bamboo-viscose on your leather type to validate scratch/lint outcomes under real use.

- Define specs: GSM, blend, lint grade (e.g., ISO 9073 certified), edge finish, and pack count per carton; align acceptance criteria to your maintenance program.

End of section

Alternatives Analysis: Comparing can you buff leather conditioner with a microfiber cloth With Other Solutions

Alternatives Analysis: Buffing with Microfiber vs Other Solutions

Evaluation criteria

- Even distribution of conditioner during buffing

- Scratch/lint risk on finished and semi-aniline leathers

- Oil absorption and finish clarity (residue reduction)

- Static/particle attraction risk in typical environments

Summary decision matrix

| Method | Even distribution | Scratch/lint risk | Oil absorption | Static/particle attraction | Typical cost per unit | Best use cases | Notable cautions |

|---|---|---|---|---|---|---|---|

| Microfiber cloth (≥300–400 GSM) | 4/5 | 2–3/5 (finishes sensitive to micro-abrasion; lint very low) | 5/5 | 4–5/5 (static can draw dust) | $1–$4 | Quick cleanup, low-lint wiping; buffing low-risk finishes; large surfaces | Pre-clean and dampen to mitigate static; avoid on high-sheen or delicate finishes |

| 100% cotton flannel (pre-washed) | 3–4/5 | 5/5 (lowest scratch/lint risk) | 4/5 | 1–2/5 (low static) | $0.75–$2 | Finishing high-sheen or delicate leathers; restoration/retail displays; sensitive pigments | Requires thorough pre-cleaning to avoid dragging particulates; higher conditioner pickup |

| Dense foam or lambswool applicator pad | 4–5/5 | 4/5 (very low lint; slight pressure marks possible) | 4/5 | 1–2/5 (low static) | $1–$3 | Even application and pre-buff; production lines; structured items (seams/edges) | Avoid over-saturation; do not reuse soiled pads across colors; foam can shed if degraded |

Analysis

-

Microfiber cloths excel at oil pickup and lint control, but their synthetic fibers can generate static and create micro-abrasion on delicate or high-sheen finishes. In commercial environments with airborne dust, static may redeposit particles onto the surface. Use ≥300–400 GSM, pre-clean the surface, and lightly dampen the cloth to reduce static.

Illustrative Image (Source: Google Search)

-

Cotton flannel offers the gentlest touch on fragile finishes and presents minimal static. It absorbs conditioner effectively but holds more product, which can slow buffing and increase residue risk if over-applied. It’s the preferred choice for high-sheen, pigmented, or delicate semi-aniline leathers where micro-scratches are unacceptable.

-

Foam or lambswool applicators deliver highly even distribution and are efficient for both application and pre-buffing. They minimize lint and static and handle seams and edges well. The main risks are over-saturation and cross-contamination between colors when pads aren’t segregated and maintained.

B2B recommendations

-

For high-sheen, delicate, or pigmented leather where finish integrity is paramount: use cotton flannel for final buffing; reserve microfiber for non-contact oil pickup only if the surface is already clean and the cloth is dampened.

-

For production/retail environments prioritizing speed and consistency: foam or lambswool applicators for application and pre-buff; use microfiber only for final dust control on robust finishes and ensure climate control to limit static.

-

Operational controls to reduce risk across all methods: stage cleaning before conditioner, segregate applicators by color/product, maintain a lint-free workspace, and standardize pad/cloth replacement intervals.

Essential Technical Properties and Trade Terminology for can you buff leather conditioner with a microfiber cloth

Essential Technical Properties and Trade Terminology for “Can you buff leather conditioner with a microfiber cloth?”

Technical properties of microfibre cloths relevant to leather buffing

- Fiber type: Split microfibres (e.g., 0.1–0.5 dtex) increase capillary action and lifting of residues; high-tenacity polyester/nylon blends are abrasion-resistant.

- Construction: Circular knitted terry/pile (“microfibre”) has higher lint risk than warp-knit suede-style constructions; warp-knit often preferred for finish work.

- Weight/GSM: 230–600 gsm typical. Heavier cloths increase buffer capacity but raise friction; 250–320 gsm balances cushioning and control on finished leather.

- Edge/seam finish: Overlock-stitched edges reduce edge fray and snagging; sealed-cut edges are a clean, low-fray alternative. Avoid rough bindings on delicate leathers.

- Yarn twist/finish: Low-twist yarn increases softness; durable water repellent (DWR) or silicon-free finish reduces linting and friction while maintaining pick-up.

- Static propensity: Synthetic microfibres can build static under low humidity; static dissipation measures include conductive yarn blends, anti-static finishing, or ambient RH >40%.

- Lint and particle retention: Fine denier and polarized surface structure improve pickup, but over-saturation or poor maintenance can redeposit debris and cause marring.

- Chemical compatibility: Generally compatible with water, isopropanol, and most leather-safe cleaners. Confirm solvent compatibility for oil-heavy or specialty cleaners to avoid fibre damage.

- Wash durability: Stable after multiple washes when low-heat tumble-dried and enzyme detergents avoided; inspect for loss of pile or fibre degradation over time.

Static and abrasion considerations

- Static build-up risk increases in dry environments (<40% RH). On non-absorbent, fully finished leathers the impact is minimal; unfinished/nubuck grains are more sensitive to particle attraction and abrasion.

- Use anti-static or blended conductive microfibres when low humidity is unavoidable, or pre-humidify the workspace.

- Limit pressure and strokes when buffing, especially on high-gloss finishes; follow the conditioner manufacturer’s cure time and buff only once the film is set but not fully cured.

Recommended microfibre use and cautions for leather

- Best practice: Apply conditioner by hand, let it flash off/set, then buff with a clean, soft microfibre cloth using light, linear strokes. Avoid over-saturating the cloth.

- Avoid on high-sheen or delicate leathers if the cloth’s edge/seam is rough; prefer sealed-edge or suede-style microfibres.

- Do not dry-buff on warm/hot surfaces or under high pressure; this increases friction and can cause micro-scratches or haze.

- Do not use on heavily contaminated surfaces without prior cleaning—trapped grit will cause abrasion.

- Maintain cloths: Wash separately, detergent-free, low-heat; store dust-free. Replace when pile is matted or fibres shed.

Trade terminology (B2B glossary)

| Term | Definition | Typical relevance to cloth/leather products |

|---|---|---|

| MOQ (Minimum Order Quantity) | Minimum units per style/color/order a supplier accepts. | Controls per-style production feasibility and price breaks. |

| OEM (Original Equipment Manufacturer) | Supplier manufactures to your exact specifications and branding. | Product exclusivity and brand control; requires full spec. |

| ODM (Original Design Manufacturer) | Supplier provides design/tech package you may customize. | Faster launch; balance of control and time-to-market. |

| FOB (Free on Board) | Risk transfers when goods pass the ship’s rail at named port. | Typical USA/Asia pricing basis; clarifies logistics responsibility. |

| EXW (Ex Works) | Buyer collects at supplier’s dock. | Maximum buyer control of freight; supplier handling minimized. |

| DDP (Delivered Duty Paid) | Supplier delivers, duty/taxes paid, to named address. | End-to-end service; pricing transparency. |

| HS Code | Harmonized System classification for customs. | Drives duty rates and import/export clearance. |

| REACH | EU chemicals regulation for substances in articles. | Ensures chemical compliance of finishes and treatments. |

| Prop 65 | California Proposition 65 warning requirements. | US market labeling when applicable. |

| Oeko-Tex Standard 100 | Certification limiting harmful substances in textiles. | Confirms textile safety for end-use contact. |

| ISO 9001 | Quality management system certification. | Indicates stable processes and continuous improvement. |

| AQL (Acceptable Quality Level) | Sampling plan for defect acceptance (e.g., 1.5/2.5 major/minor). | Statistical QC for bulk production. |

| SKU (Stock Keeping Unit) | Unique inventory identifier per variant. | Required for warehousing and e-commerce. |

| Lead time | Time from PO acceptance to ready-to-ship. | Planning for replenishment and promotions. |

| CTO (Cut-to-Order) | Fabric cut and sewn per order rather than bulk inventory. | Useful for custom dimensions; longer lead times. |

| Drop-ship | Direct shipment from supplier to end customer. | Reduces buyer warehousing; requires EDI/API integration. |

| Barcoding/GS1 | Globally standardized product identification. | Accurate receiving, shipping, and returns. |

| SDS/MSDS | Safety Data Sheet for chemicals. | Required for leather cleaners/conditioners in B2B handling. |

| Label compliance (US/EU) | Country-specific labeling (material composition, care, origin). | Ensures market-entry and retailer acceptance. |

B2B specification snapshot for leather-safe microfibres

- Fiber: Split microfibres (≥80% PES, ≤20% PA) or conductive blend for low-humidity use.

- Construction: Warp-knit suede-style or circular knit with sealed/overlock edges.

- GSM: 250–320 gsm recommended for buffing finished leather; 320–400 gsm for heavy-duty wipe.

- Finish: DWR or anti-static where needed; silicon-free preferred for leather-safe application.

- Lint performance: Minimal lint on dark leathers; verify via Rub Test (ASTM D3512 or ISO 12103).

- Compliance: Oeko-Tex Standard 100, REACH-compliant finishes; Prop 65 assessment for US market.

- Packaging: Individual polybag or bulk wrap; vacuum packing for moisture protection; carton labeling per GS1.

- QC: ISO 9001 processes; AQL 2.5 for major defects, 1.5 for minor; static test under 30% RH for critical applications.

Application workflow guidance (B2B)

- Conditioner cure window: Follow manufacturer’s set time before buffing.

- Buff technique: Light pressure, one-pass linear strokes; no circular buffing on high-gloss surfaces.

- Surface prep: Clean first with leather-safe cleaner; ensure surface is dry and dust-free.

- Documentation: Include SDS for conditioners, care instructions for cloths, and compliance labels for US/EU markets.

This content is provided for professional guidance and does not replace manufacturer instructions or retailer specifications.

Navigating Market Dynamics and Sourcing Trends in the can you buff leather conditioner with a microfiber cloth Sector

Navigating Market Dynamics and Sourcing Trends in the Can You Buff Leather Conditioner with a Microfiber Cloth Sector

Market dynamics are converging around two practical imperatives: predictable performance on delicate leather surfaces and demonstrable sustainability. In North America and Europe, demand for buffing and application cloths is shaped by shifts in product formats (wipes vs. liquids), stricter chemical compliance (PFAS, REACH/SVHC), and rising pressure to reduce microplastic shedding. The sector has matured from generic recommendations to formalized standards and supplier audits.

Demand drivers and format shifts

- Wipe vs. liquid/cream condition. North America has accelerated towards ready-to-use leather wipes (for convenience and reduced waste), whereas Europe maintains stronger adoption of liquid/cream formats and larger pack sizes for pro and institutional buyers.

- Microfiber’s ubiquity. Microfiber cloths remain the default in professional detailing due to lint control and durability, but scrutiny over fiber shedding and static is increasing the appetite for premium, low-shed and natural alternatives.

- Institutional buying. Hospitality, automotive OEM/NPD, and luxury retail are the key professional segments. Each requires traceability, low particle counts, and documented compatibility with finished aniline and pigmented leathers.

- Claims transparency. Buyers increasingly demand substantiated claims: “safe on finished leather,” “lint-free,” “PFAS-free,” “microplastic-minimized,” and validated via standardized tests (AATCC 35 water resistance, H&M RSL).

- Price and energy sensitivity. Polyester fiber and binder costs (linked to energy markets) affect cloth pricing. US buyers tolerate higher landed cost for compliance; EU buyers prioritize REACH/REACH-like compliance and cradle-to-cradle transparency.

Static, lint, and scratch risk: myth vs. fact (what matters commercially)

| Topic | What is claimed (common perception) | Commercial reality | Practical mitigations |

|---|---|---|---|

| Static electricity | “Microfiber builds static and scratches leather.” | Static can occur in very low humidity environments; quality and weave drive friction more than fiber alone. | Use higher GSM, longer nap cloths; increase local RH; prefer cotton flannels for highly delicate surfaces; ground the operator; pair with low-ethanol formulas. |

| Lint and lint-free | “All microfiber is lint-free.” | Lower denier and split microfiber reduce lint; improper knit/finish or contamination increase shedding. | Specify 0.2–0.5 denier, split microfiber; request lint tests; sanitize packaging; pre-wash for particle control. |

| Scratch risk | “Microfiber always scratches.” | Scratch risk correlates to surface finish and fiber quality. Correctly chosen cloths pass touch tests on full-grain and corrected grain. | Recommend flannel or sueded microfiber for delicate aniline; avoid high-twist/hard-edge cloths; require finishing process with anti-static/softening. |

Trade-offs in cloth materials: performance, sustainability, cost

| Material | Performance on delicate leather | Lint/shed behavior | Sustainability signals | Typical cost band (2025) | Notes |

|---|---|---|---|---|---|

| Split microfiber (polyester/polyamide blend) | Strong lint control; can be soft at ≥200–250 gsm | Low lint if high-grade | Recycled PET claim possible; PET microfibers persist in water | Lower to mid | Industry workhorse; validate finish to minimize scratch risk. |

| 10x woven (long-pile microfiber) | High absorbency; soft touch | Moderate lint if weave is loose | Recycled content feasible | Mid | Preferred for heavy buffing; confirm low-twist and soft finish. |

| Sueded microfiber | Very soft; gentle on aniline | Low lint | Recycled content feasible | Mid to upper | Good compromise on delicate finishes. |

| Cotton flannel | Extremely gentle; minimal static | Higher lint unless pre-washed | Natural fiber; can be organic | Mid | Best for ultra-delicate surfaces; requires clean-room handling to manage lint. |

| Bamboo-derived viscose | Soft hand; good absorbency | Moderate lint; dependent on weave | Controversial sustainability profile (viscose) | Mid to upper | Avoid if strict deforestation policies apply; verify pulp sourcing (FSC). |

| Tencel/Lyocell | Strong hand; low lint | Low lint | Closed-loop process; credible sustainability | Upper | Premium option for EU buyers with strict environmental targets. |

Regional preference signals

| Region | Buying criteria signals | Preferred cloth types | Notes |

|---|---|---|---|

| USA | Value-pack quantities, BRC/ISO 9001, PFAS-free declarations, OEKO-TEX optional | Split microfiber (200–250 gsm), 10x woven for heavy buffing | Dual sourcing common; compliance letters standard. |

| EU | REACH/SVHC transparency, ECHA compliance, FSC (for bamboo/viscose), ECOCERT/BSCI, product passports (PPWR readiness) | Sueded microfiber; cotton flannel for luxury; Tencel for high-end | Strong preference for low-microplastic claims; stricter scrutiny of fiber finishes. |

Sourcing and specification guidance

- Define finish intent. Choose lint-minimizing microfiber (split/soft finish) or cotton flannel based on leather surface finish. For aniline or nubuck, default to flannel or sueded microfiber.

- Specify GSM and weave. Target 200–250 gsm for a balance of softness and absorbency. For high-throughput OEM operations, 250–350 gsm with controlled edge finish reduces abrasion.

- Request a particle/lint test protocol. Ask suppliers to demonstrate lint counts on black and white substrates; reject cloths that fail on sensitive leather swatches.

- Compliance documentation. Require REACH/SVHC statements for EU buyers; PFAS-free letters (e.g., based on fluorine-free finishes) for both regions.

- Microplastic mitigation. Prefer fibers with lower propensity to shed; specify anti-static finish where required; note laundering controls to reduce fiber release in B2B programs.

- QA controls. Inspect packaging cleanliness, cut-edge finish, and pre-wash options (hot-wash/degreasing) to reduce particulate contamination.

- Claim substantiation. Avoid ambiguous “safe on all leather types.” Specify compatibility by leather class (full-grain, corrected grain, nubuck, suede) and by surface finish type (aniline vs. pigmented).

Supplier landscape and risk management

- Dual sourcing. Maintain at least two compliant sources in different geographies to manage energy cost volatility and logistics risk.

- Certification stack. ISO 9001/BRC for process quality; OEKO-TEX Standard 100 for chemical safety (optional); FSC (where applicable); BSCI/SA8000 for social compliance.

- Cost transparency. Anchor pricing to polyester fiber indices and energy benchmarks; include clauses for raw material adjustments.

- Pilot-to-scale. Run a 90-day operational pilot measuring lint complaints, scratch returns, and end-of-life disposal feedback before full conversion.

End-of-life and sustainability trade-offs

- Microfiber (PET) durability extends product life but can persist as microplastics. Mitigation requires low-shed designs and responsible laundering/disposal.

- Cotton/linen flannel reduces persistence concerns; lint is higher but can be managed via pre-wash and application technique.

- Bamboo/viscose carries lignin/pulp sourcing risks; verify FSC or equivalent chain-of-custody if used.

- Tencel offers a premium sustainability signal with low lint and soft hand, valuable for high-end applications.

What to watch through 2025–2026

- Regulatory pressure on PFAS and microplastics will favor EU compliance-ready suppliers and encourage US buyers to adopt similar standards.

- Premiumization of cloth design (ultra-soft suede microfiber; Tencel blends) will increase share in luxury/leather goods care.

- Format differentiation will continue: wipes in North America; professional refills/creams in Europe.

- Documentation depth (RSL, REACH statements, product passports) will become standard in RFPs.

Practical recommendation

Microfiber is viable for buffing most finished leathers when properly specified (split microfiber, ≥200–250 gsm, soft finish, low-shed). For ultra-delicate aniline, cotton flannel remains the safest choice. The winning procurement strategy pairs clear compatibility claims, low-lint performance proof, and robust compliance documentation with dual sourcing and pilot testing.

Frequently Asked Questions (FAQs) for B2B Buyers of can you buff leather conditioner with a microfiber cloth

Frequently Asked Questions (FAQs) – Buffing Leather Conditioner with Microfiber Cloths

FAQ 1: Is it safe to use microfiber cloths for buffing leather conditioner?

- Generally safe when using 100 % polyester, fine‑denier, low‑lint microfiber (≥230 gsm).

- Avoid “cheap” cloths that shed fibers; they can embed particles and cause micro‑scratches.

- Confirm compatibility with the specific conditioner (oil‑, wax‑, or water‑based) before bulk purchase.

FAQ 2: What are the static‑electricity concerns with microfiber on leather?

- Static build‑up can attract airborne dust and may increase friction during the buffing motion.

- Impact: In dry, low‑humidity facilities (common in HVAC‑controlled US/EU warehouses) static can exacerbate micro‑scratching.

- Mitigation:

- Maintain relative humidity ≥45 % in the finishing area.

- Use anti‑static sprays or ionizers on the cloth.

- Choose “low‑static” microfiber grades (typically labeled “antistatic”).

FAQ 3: How does microfiber compare to alternative wiping materials?

| Material | Lint Generation | Static Propensity | Absorption (buffing efficiency) | Durability (wash cycles) | Typical Cost per Unit (USD) | Typical Cost per Unit (EUR) |

|---|---|---|---|---|---|---|

| Microfiber (high‑grade) | Very low | Low (with anti‑static treatment) | High – spreads conditioner evenly | 100‑200 | $0.12‑$0.20 | €0.10‑€0.18 |

| Cotton (muslin) | Moderate | Low | Moderate – may absorb excess conditioner | 50‑100 | $0.08‑$0.12 | €0.07‑€0.11 |

| Bamboo cloth | Low | Low | High – natural wicking | 80‑150 | $0.15‑$0.25 | €0.13‑€0.22 |

| Chamois (sheepskin) | Low | Very low | High – excellent polish finish | 150‑250 | $0.30‑$0.50 | €0.27‑€0.45 |

| Synthetic disposable wipes | Variable (depends on brand) | Moderate | Moderate – single‑use only | 1 (single use) | $0.05‑$0.10 | €0.04‑€0.09 |

Choose the material that aligns with your cost, hygiene, and sustainability strategy.

FAQ 4: What standards and certifications should B2B buyers require?

| Standard / Certification | Relevance to Microfiber Cloth Use on Leather |

|---|---|

| OEKO‑TEX Standard 100 | Guarantees no harmful substances in the fabric – important for premium leather finishes. |

| REACH (EU) Compliance | Ensures chemicals used in cloth finishes (softeners, dyes) meet EU safety limits. |

| ISO 9001 (Quality Management) | Indicates supplier’s consistent quality control processes. |

| ASTM D‑4970 (Abrasion Resistance) | Provides data on cloth durability under repeated buffing cycles. |

| EPA Micro‑Plastic Guidance | Encourages low‑shedding fabrics to minimize environmental impact. |

FAQ 5: What are the recommended application steps for optimal results?

- Pre‑clean the leather surface with a pH‑balanced cleaner.

- Apply conditioner sparingly (≈1 ml per 0.5 m²) using a spray or lint‑free pump.