The global cake printing machine market has experienced significant growth, driven by rising demand for personalized baked goods and advancements in digital food printing technology. According to Mordor Intelligence, the cake printer machine market is projected to grow at a CAGR of over 7.2% during the forecast period 2023–2028, fueled by increasing consumer preference for customized desserts in both retail and commercial bakeries. Additionally, the broader edible printing market, which includes cake printers, was valued at USD 1.2 billion in 2022 and is expected to expand at a CAGR of 7.8% from 2023 to 2030, as reported by Grand View Research. This expansion is supported by innovations in inkjet-based food printing, the rising popularity of online cake customization platforms, and the integration of AI and automation in bakery equipment. As the industry evolves, a select group of manufacturers has emerged as leaders, combining precision engineering, food-safe technology, and user-friendly design to meet growing global demand. The following list highlights the top 9 cake printer machine manufacturers leading this transformation.

Top 9 Cake Printer Machine Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Edible Ink Printer

Domain Est. 2013

Website: cake-stock.com

Key Highlights: Cake Stock Edible Printers are perfect for creating custom edible decorations for cakes, cookies, macarons, and other baked goods.Missing: machine manufacturer…

#2 Edible Printer Cake Printing Machine

Domain Est. 2023

Website: hentofoodmachine.com

Key Highlights: We’re well-known as one of the leading edible printer cake printing machine manufacturers and suppliers in China. Please feel free to buy customized edible ……

#3 3D Systems

Domain Est. 1996

Website: 3dsystems.com

Key Highlights: 3D Systems provides comprehensive products and services, including 3D printers, print materials, software, on-demand manufacturing services, and healthcare ……

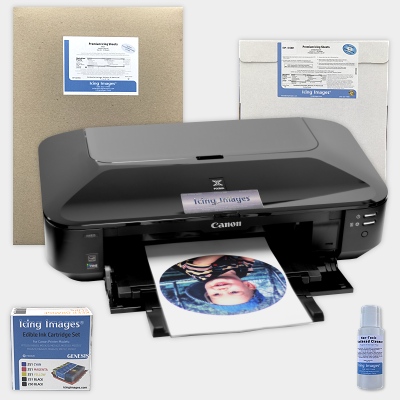

#4 Genesis Professional Wide Format Edible Printer System

Domain Est. 1999

#5 Inkedibles.com

Domain Est. 2011

Website: inkedibles.com

Key Highlights: Personalize your cakes with Direct to Food Printers. Go ahead, Print Incredible Cakes! It’s easy to do! Shop Now…

#6 Professional Direct to Food Edible Printers

Domain Est. 2016

Website: icinginks.com

Key Highlights: Free delivery 30-day returnsDirect to Food edible printers are equipped with edible cartridges that print directly on cakes, cookies and other baked confectionaries. Best food prin…

#7 Edible Ink Food Printer Art Prints For Cake, Macaron, Chocolate …

Domain Est. 2016

Website: ant-print.com

Key Highlights: Edible food inkjet printer is a specialized printer that is designed to print edible designs or graphics onto food items, such as cake, chocolate, macaron, ……

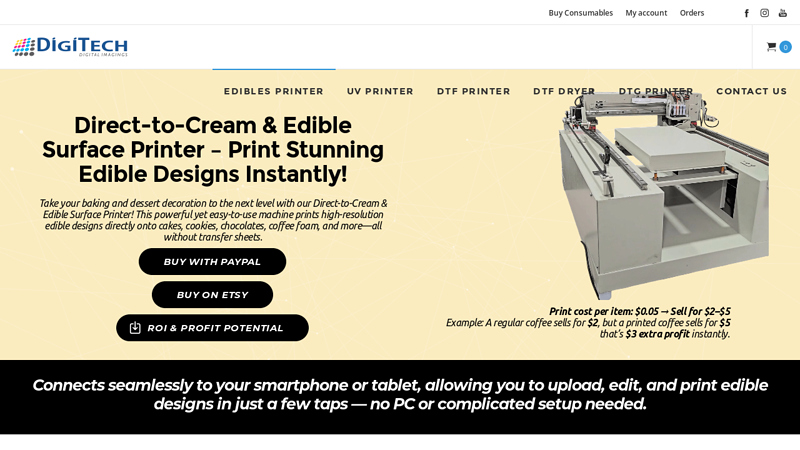

#8 Edible Cake Printer

Domain Est. 2017

Website: digitechuvprinter.com

Key Highlights: Unlike resellers, we manufacture our edible printers, ensuring top-notch quality and affordable pricing. Complete Technical Support If Your Machine Goes Down….

#9 Food Printer Direct To Cakes cookies Macaron Chocolate etc.

Domain Est. 2023

Expert Sourcing Insights for Cake Printer Machine

2026 Market Trends for Cake Printer Machine

The cake printer machine market is poised for significant evolution by 2026, driven by technological advancements, shifting consumer preferences, and expanding commercial applications. Here’s an analysis of the key trends expected to shape the industry:

Rising Demand for Personalization and Customization

Consumers increasingly seek unique, personalized baked goods for celebrations, gifting, and social media appeal. Cake printer machines enable bakeries, cafes, and home users to effortlessly create custom designs, names, logos, and intricate artwork on cakes, cupcakes, and cookies. This trend is fueling demand for user-friendly, high-resolution printing solutions that offer creative flexibility.

Technological Advancements in Print Quality and Speed

By 2026, expect cake printers to feature enhanced print resolution, faster processing times, and improved color accuracy. Innovations in edible ink formulations and printhead technology will allow for crisper, more vibrant images. Integration with AI and automated design software will simplify the creation process, enabling even novice users to produce professional-quality results.

Expansion of E-Commerce and Direct-to-Consumer Models

The growth of online bakeries and direct-to-consumer cake delivery services is creating new opportunities for cake printer adoption. These businesses rely on automation and consistency to scale operations, and cake printers offer a cost-effective way to personalize products at volume. Cloud-based design platforms linked to printers will become more common, streamlining order fulfillment.

Increased Adoption in Commercial and Industrial Settings

Beyond small bakeries, large-scale food manufacturers and catering companies are investing in industrial-grade cake printers to meet mass customization demands. These high-throughput machines support brand marketing (e.g., logo printing on promotional desserts) and seasonal product lines, improving efficiency and reducing labor costs.

Focus on Food Safety and Regulatory Compliance

As edible printing gains traction, regulatory scrutiny around food-safe inks and machine hygiene will intensify. Leading manufacturers will prioritize compliance with FDA, EFSA, and other global food safety standards. Transparent sourcing of edible inks and easy-to-clean printer components will become key selling points.

Growth in Emerging Markets

Asia-Pacific, Latin America, and the Middle East are emerging as high-growth regions due to rising disposable incomes, urbanization, and the popularity of Western-style desserts. Localized marketing and affordable entry-level models will drive adoption in these markets, supported by expanding distribution networks.

Sustainability and Eco-Friendly Innovations

Environmental concerns will influence product development, with a push toward biodegradable ink cartridges, energy-efficient machines, and recyclable packaging. Brands emphasizing sustainable practices will gain a competitive edge among eco-conscious consumers and businesses.

Integration with Smart Kitchen Ecosystems

By 2026, cake printers may increasingly connect with broader smart kitchen systems via IoT. Features like remote operation, automatic ink level monitoring, and integration with recipe apps will enhance user convenience and operational efficiency, particularly in professional settings.

In summary, the 2026 cake printer machine market will be defined by innovation, personalization, and scalability. Companies that invest in advanced technology, user-centric design, and global compliance will be best positioned to capitalize on these growing opportunities.

Common Pitfalls When Sourcing a Cake Printer Machine (Quality and Intellectual Property)

Sourcing a cake printer machine can be a complex process, particularly when balancing cost, performance, and legal considerations. Below are key pitfalls related to quality and intellectual property (IP) that buyers should be aware of.

Poor Build Quality and Component Durability

Many low-cost cake printers, especially those from less reputable suppliers, use substandard materials and components. This can lead to frequent mechanical failures, clogged print heads, or inconsistent extrusion—resulting in wasted ingredients and downtime. Look out for machines with plastic gears or flimsy frames, as these are prone to wear and misalignment over time.

Inaccurate or Low-Resolution Printing

Some machines advertise high-resolution printing but fail to deliver in practice due to poor software integration or imprecise motion control systems. This results in blurry or distorted designs on cakes, undermining the product’s visual appeal. Always request live demonstrations or sample prints to verify actual print quality.

Lack of Calibration and Consistency

Even machines with good specs may suffer from inconsistent output due to poor factory calibration or inadequate maintenance protocols. Without proper calibration tools and documentation, maintaining print accuracy across multiple batches becomes difficult—especially in commercial environments.

Inadequate After-Sales Support and Spare Parts Availability

Many overseas suppliers do not offer reliable technical support or spare parts delivery. If a critical component fails, long wait times for replacements can halt production. Ensure the supplier provides clear service agreements, accessible customer support, and a documented supply chain for consumables and spare parts.

Use of Counterfeit or Unlicensed Software

Some cake printer manufacturers use pirated or reverse-engineered software to control their machines. This not only risks system instability but may also expose the buyer to legal liability. Always verify that the machine runs on legitimate, licensed software with proper documentation and updates.

Infringement of Patented Technologies

Certain cake printing mechanisms, nozzle designs, or software algorithms may be protected by patents. Sourcing a machine that incorporates patented technology without authorization can lead to intellectual property disputes, import bans, or forced product recalls—especially in markets like the U.S. or EU. Conduct due diligence on the manufacturer’s IP compliance and request proof of licensing where applicable.

Unclear Ownership of Design Files and Software

Some suppliers retain ownership of the design software or cloud platforms used to operate the printer. This can restrict your ability to modify, transfer, or scale operations. Clarify IP rights over software, firmware, and design libraries before purchase to avoid future limitations or licensing fees.

Hidden Costs from Non-Standard Consumables

Certain machines are designed to work only with proprietary icing cartridges or print materials. This creates vendor lock-in and inflates long-term operating costs. Evaluate whether consumables are standardized and widely available to ensure flexibility and cost efficiency.

Avoiding these pitfalls requires thorough supplier vetting, technical evaluation, and legal review—especially when sourcing from international markets. Prioritize transparency, proven performance, and IP compliance to ensure a reliable and legally sound investment.

Logistics & Compliance Guide for Cake Printer Machine

Product Classification & Documentation

Ensure the cake printer machine is classified correctly under the Harmonized System (HS) code, typically under heading 8443 (printing machinery). Maintain accurate product specifications, user manuals, CE/FCC certifications, and safety compliance documents. Include technical drawings and component lists for customs clearance.

International Shipping & Packaging

Use durable, shock-resistant packaging with protective foam inserts to prevent damage during transit. Clearly label packages with handling instructions (e.g., “Fragile,” “This Side Up”). Choose reputable freight forwarders experienced in handling precision equipment and opt for air or sea freight based on urgency and cost.

Import/Export Regulations

Verify export controls in the origin country and import requirements in the destination country. Some regions may require import licenses, customs duties, or value-added tax (VAT) payments. Confirm compliance with local electrical standards (e.g., voltage, plug type) and electromagnetic compatibility (EMC) regulations.

Safety & Regulatory Compliance

Ensure the machine meets regional safety standards such as CE (Europe), FCC (USA), or PSE (Japan). Include required warning labels, electrical safety certifications, and compliance with RoHS (Restriction of Hazardous Substances). Machines with laser components may require additional FDA or laser safety certifications.

Warranty & After-Sales Support Logistics

Provide clear warranty terms and arrange for spare parts inventory in key markets. Partner with local service providers for maintenance and repairs. Include multilingual support documentation and offer remote troubleshooting to minimize downtime.

Environmental & Disposal Compliance

Follow WEEE (Waste Electrical and Electronic Equipment) directives for end-of-life disposal in applicable regions. Design packaging using recyclable materials and provide disposal guidelines to customers. Maintain records for environmental compliance audits.

Conclusion on Sourcing a Cake Printer Machine

Sourcing a cake printer machine is a strategic investment that can significantly enhance the efficiency, customization, and professionalism of cake decorating operations—whether for a bakery, confectionery business, or catering service. After evaluating various models, suppliers, features, and price points, it is evident that selecting the right machine requires careful consideration of print quality, ease of use, maintenance requirements, compatibility with edible inks and icing sheets, and overall cost-effectiveness.

Key factors such as print resolution, software compatibility, customer support, and durability play a vital role in ensuring consistent and high-quality output. Additionally, purchasing from reputable suppliers with positive reviews and reliable after-sales service minimizes operational disruptions and supports long-term success.

Ultimately, a well-chosen cake printer machine not only streamlines production but also opens new avenues for creative designs and personalized cakes, helping businesses stand out in a competitive market. By aligning the machine’s capabilities with specific business needs and scaling potential, sourcing the right cake printer becomes a valuable step toward innovation, customer satisfaction, and business growth.