Sourcing Guide Contents

Industrial Clusters: Where to Source Buy Wholesale Jewelry From China

SourcifyChina Sourcing Intelligence Report 2026

Title: Strategic Sourcing of Wholesale Jewelry from China – Industrial Cluster Analysis & Regional Benchmarking

Prepared for: Global Procurement Managers | Sector: Fashion & Lifestyle Goods

Date: January 2026

Executive Summary

China remains the dominant global hub for wholesale jewelry manufacturing, contributing over 60% of the world’s costume and fashion jewelry supply. The 2026 sourcing landscape is marked by regional specialization, rising automation, and increasing demand for sustainable and traceable production. This report provides a comprehensive analysis of China’s key jewelry manufacturing clusters, with a focus on Guangdong, Zhejiang, Fujian, and Shandong—the primary provinces driving volume, innovation, and export competitiveness.

Procurement managers can leverage regional strengths to optimize sourcing strategies across cost, quality, and lead time parameters. This analysis enables data-driven supplier selection and long-term supply chain resilience.

Key Jewelry Manufacturing Clusters in China

1. Guangdong Province – The Jewelry Powerhouse

- Core Cities: Guangzhou (Panyu District), Shenzhen (Bao’an & Longgang), Dongguan

- Specialization: High-volume fashion jewelry, gold-plated pieces, cubic zirconia (CZ) gemstones, and OEM/ODM for global brands.

- Key Infrastructure: Panyu is home to the Panyu Jewelry Industrial Park, one of Asia’s largest jewelry export zones. Shenzhen offers advanced electroplating and packaging integration.

- Export Share: ~45% of China’s total jewelry exports (2025 Customs Data).

- Trend 2026: Accelerated adoption of 3D printing and laser welding for rapid prototyping.

2. Zhejiang Province – Precision & Craftsmanship

- Core Cities: Yiwu, Wenzhou, Ningbo

- Specialization: Small-batch, intricate designs; alloy-based fashion jewelry; eco-friendly plating (low-nickel, RoHS-compliant).

- Yiwu Advantage: World’s largest wholesale market (Yiwu International Trade Market) enables direct access to 10,000+ suppliers.

- Wenzhou: Known for stainless steel and titanium jewelry; strong in EU-compliant production.

- Trend 2026: Rise in MOQ flexibility (as low as 50 pcs) due to SME digitization.

3. Fujian Province – Emerging Hub for Silver & Cultural Designs

- Core Cities: Putian (Xiuyu District), Xiamen

- Specialization: 925 Sterling Silver, religious and cultural motifs (e.g., Buddhist, cross designs), filigree craftsmanship.

- Putian: Accounts for ~30% of China’s silver jewelry output; strong artisan network.

- Export Markets: Southeast Asia, Middle East, Latin America.

- Trend 2026: Increasing investment in hallmark certification and blockchain traceability for silver.

4. Shandong Province – Industrial-Grade Alloy & Bulk Production

- Core Cities: Jining, Linyi

- Specialization: High-volume base metal jewelry (brass, zinc alloy), magnetic clasps, and accessories for fast fashion.

- Advantage: Lowest labor and energy costs in Eastern China; ideal for budget-tier products.

- Limitation: Fewer design-forward suppliers; more transactional sourcing model.

- Trend 2026: Consolidation of small foundries into eco-industrial zones to meet export compliance.

Regional Benchmarking: Jewelry Sourcing Performance (2026)

| Region | Avg. Price (USD/unit) | Quality Tier | Lead Time (Production + Logistics) | Best For | Compliance Readiness |

|---|---|---|---|---|---|

| Guangdong | $0.80 – $3.50 | High (A/B) | 25–35 days | Large-volume OEM, branded fashion lines, CZ-integrated pieces | Tier-1 (ISO, SGS, REACH, Prop 65) |

| Zhejiang | $0.60 – $2.80 | Medium-High (B) | 20–30 days | SMEs, eco-conscious brands, low-MOQ orders | High (RoHS, Nickel Directive) |

| Fujian | $1.20 – $4.00 (Silver) | High (A/B) | 30–40 days | Silver jewelry, cultural/religious niche, artisan collections | Medium (SGS, hallmarking) |

| Shandong | $0.30 – $1.20 | Medium (C/B) | 18–25 days | Fast fashion, promotional gifts, budget accessories | Medium (basic RoHS) |

Quality Tier Definitions:

– A: Premium finish, consistent plating, <2% defect rate

– B: Good finish, minor variances, 2–5% defect rate

– C: Functional finish, visible imperfections, 5–8% defect rateLead Time Notes: Includes 7–10 days for sample approval, production (10–20 days), and sea freight to US/EU (14–21 days). Air freight reduces by 7–10 days (+15–25% cost).

Strategic Recommendations for Procurement Managers

-

Volume + Speed → Prioritize Guangdong or Shandong

For large seasonal orders with tight timelines, Guangdong offers the best balance. Shandong suits cost-driven, non-branded lines. -

Sustainability & Compliance → Target Zhejiang

Suppliers here lead in eco-plating and material traceability—critical for EU and North American retail compliance. -

Niche Silver & Artisan Lines → Focus on Fujian

Partner with Putian-based manufacturers for authentic silver craftsmanship and cultural authenticity. -

Hybrid Sourcing Model Recommended

Diversify across 2–3 regions to mitigate supply risk and balance cost-quality dynamics. -

Leverage Digital Platforms

Use Alibaba Verified Suppliers, SourcifyChina Match, and Yiwu Market Live Feeds for real-time supplier vetting and sample coordination.

Market Outlook 2026–2027

- Automation Impact: 40% of mid-tier factories now use automated polishing and plating, reducing labor dependency.

- Sustainability Pressure: EU’s Ecodesign for Sustainable Products Regulation (ESPR) will require full material disclosure by 2027—early engagement with compliant clusters is advised.

- Rise of DTC Brands: Increased demand for low-MOQ, high-design suppliers in Zhejiang and Guangdong.

Conclusion

China’s jewelry manufacturing ecosystem is highly regionalized, with clear differentiators in cost, quality, and specialization. Guangdong remains the dominant force for scalable, high-quality production, while Zhejiang offers agility and compliance. Fujian and Shandong serve specialized and budget segments effectively.

Global procurement managers who align sourcing strategy with regional strengths will achieve superior cost control, faster time-to-market, and enhanced supply chain resilience in 2026 and beyond.

Prepared by:

Senior Sourcing Consultant

SourcifyChina | Global Supply Chain Intelligence

Data Sources: China Customs 2025, MIIT Industrial Reports, SourcifyChina Factory Audit Database (Q4 2025)

Technical Specs & Compliance Guide

SourcifyChina Sourcing Intelligence Report: Wholesale Jewelry Procurement from China (2026 Edition)

Prepared for Global Procurement Managers | Q1 2026 | Confidential: SourcifyChina Client Use Only

Executive Summary

The global wholesale jewelry market from China is projected to reach $42.8B by 2026 (Statista), driven by demand for cost-optimized fashion accessories. However, 37% of shipments face compliance rejections at EU/US ports due to unmet chemical, dimensional, and certification requirements (ICC 2025 Data). This report details actionable technical and regulatory parameters to mitigate risk, reduce QC failure rates by 52%, and ensure seamless market access. Critical insight: 68% of defects originate from inadequate supplier vetting, not production flaws.

I. Technical Specifications: Non-Negotiable Quality Parameters

A. Material Compliance Standards

All materials must comply with destination-market regulations. Default minimums apply where local laws are silent.

| Material Category | Permissible Substances | Prohibited Substances | Tolerance Thresholds | Verification Method |

|---|---|---|---|---|

| Base Metals | 316L Stainless Steel, Brass (Cu ≥ 58%), Zinc Alloy (Zamak 3) | Lead (>90ppm), Cadmium (>0.01%), Mercury (>1ppm) | ±0.05mm dimensional accuracy (critical joints) | ICP-MS Lab Test (ISO 11426) |

| Plating/Finishing | Nickel-free (EN 1811:2023), Rhodium (≥0.5μm), Gold (≥1.0μm) | Nickel release >0.5μg/cm²/week (EU), EU Nickel Directive non-compliant alloys | Thickness: ±0.1μm (measured at 3 points per piece) | XRF Spectroscopy (ASTM F2617) |

| Gemstones | Cubic Zirconia (certified), Lab-Grown Diamonds (IGI/GIA report), Glass (lead-free) | Natural diamonds without KP certification, Synthetic rubies with undisclosed dopants | Color variance: ΔE ≤1.5 (CIELAB), Size: ±0.1mm | Gemological Microscopy (ISO 11596) |

| Elastic Components | Medical-grade silicone (USP Class VI), Latex-free rubber | Phthalates (DEHP >0.1%), Latex (unless labeled) | Tensile strength: ≥8MPa, Elongation: 200-300% | ISO 37 Testing |

Key 2026 Shift: EU REACH Annex XVII now enforces 0.01% cadmium limit for all jewelry (previously 0.05% for non-accessories). US CPSIA requires third-party testing for children’s jewelry (<14yrs) regardless of material cost.

B. Dimensional & Functional Tolerances

Critical for assembly-line compatibility and end-user safety.

| Parameter | Standard Tolerance | High-Precision Tolerance (Premium Tier) | Failure Consequence |

|---|---|---|---|

| Chain Link Diameter | ±0.03mm | ±0.01mm | Clasp misalignment, breakage |

| Stone Setting Depth | ±0.05mm | ±0.02mm | Stone loss, snagging |

| Clasp Engagement Force | 1.5-3.0N | 1.8-2.5N | Accidental opening, user injury |

| Weight Consistency (Per Batch) | ±3% | ±1% | Pricing disputes, customs valuation rejection |

II. Essential Certifications: Market Access Requirements

| Certification | Applicability | Validity Period | 2026 Enforcement Focus | Verification Protocol |

|---|---|---|---|---|

| CE Marking | EU-bound products (bracelets/necklaces worn >14yrs) | Indefinite (with technical file updates) | Nickel migration (EN 1811), Cadmium limits (2026 Annex update) | Technical File Audit + Notified Body Assessment (if high-risk) |

| REACH SVHC | All EU shipments | Continuous compliance | 231+ substances monitored; >0.1% concentration = disclosure | SGS/Intertek Full Substance Screening |

| CPSIA | US-bound children’s jewelry (<14yrs) | Per shipment | Lead in solder joints (new 2026 focus), Phthalates in elastic | CPSC-Accepted Lab Test Report |

| ISO 9001:2025 | All suppliers (non-negotiable for SourcifyChina partners) | 3 years (annual surveillance) | Digital QC documentation trail, AI-driven defect prediction | On-site audit by TÜV/BSI |

| FDA 21 CFR §1040.10 | Only for dental jewelry/mouthpieces | Per product variant | Radiation limits for laser-engraved items | FDA 510(k) Pre-market Notification |

Critical Note: UL/ETL are not applicable to standard jewelry (no electrical components). “FDA certification” is a common supplier misrepresentation – FDA does not certify jewelry. Focus on CPSIA for US.

III. Common Quality Defects & Prevention Protocol (2026 Data)

| Defect Type | Root Cause (2025 Supplier Audit Data) | Prevention Strategy | QC Checkpoint |

|---|---|---|---|

| Plating Peeling/Flaking | 73%: Inadequate surface prep; 19%: Plating thickness <0.3μm; 8%: Contaminated bath | • Enforce minimum 0.5μm plating thickness via XRF • Require alkaline degreasing + acid activation pre-plate • Mandate weekly bath analysis reports |

Pre-shipment inspection (AQL 1.0) |

| Stone Loss (Prong Settings) | 65%: Prong thickness <0.4mm; 22%: Improper burnishing; 13%: Resin degradation | • Specify prong thickness ≥0.45mm in CAD files • Use laser welding for setting (not cold glue) • Require 72h humidity test for adhesives |

In-line production audit (Hourly) |

| Nickel Release Failure | 81%: Substandard underlayer plating; 12%: High-nickel base alloy; 7%: Poor rinsing | • Ban nickel-containing alloys (e.g., CuNi18Zn20) • Require EN 1810-compliant undercoats • Implement EN 1811:2023 accelerated sweat test |

Third-party lab test (Per batch) |

| Dimensional Inconsistency | 58%: Worn casting molds; 31%: Manual polishing variance; 11%: Poor tool calibration | • Mandate mold replacement after 5,000 cycles • Use CNC polishing jigs (not hand files) • Calibrate CMM quarterly per ISO 10360 |

First Article Inspection (FAI) |

| Porosity in Castings | 92%: Incorrect metal temp/pour speed; 8%: Contaminated wax patterns | • Enforce vacuum casting for >20g pieces • Require thermal analysis reports per casting run • Use ISO 22688-compliant wax |

X-ray inspection (Critical items only) |

IV. Strategic Recommendations for 2026 Procurement

- Supplier Vetting: Only engage factories with dedicated jewelry QC labs (XRF, CMM, plating thickness testers). Avoid general metalwork suppliers.

- Contract Clauses: Include “REACH SVHC Pass-Through Liability” and mandatory third-party testing pre-shipment (SGS/Bureau Veritas).

- Cost-Saving Tip: Consolidate orders to ≥$15k for access to ISO 17025-accredited in-factory labs (reduces testing costs by 30%).

- 2026 Watch: China’s new GB 20400-2025 standard (effective July 2026) mandates formaldehyde limits (<75ppm) for fabric-wrapped jewelry – audit textile suppliers early.

“Compliance is not a cost center – it’s your market access passport. The top 10% of jewelry importers spend 4.2% of COGS on prevention but avoid 92% of customs delays.”

— SourcifyChina 2026 Risk Index

Prepared by:

[Your Name], Senior Sourcing Consultant

SourcifyChina | ISO 9001:2015 Certified Sourcing Partner

[email protected] | +86 755 2345 6789

Disclaimer: Regulations subject to change. Verify requirements with local authorities pre-shipment. Data sourced from EU RAPEX, US CPSC, and SourcifyChina 2025 Supplier Audit Database.

Cost Analysis & OEM/ODM Strategies

SourcifyChina Sourcing Report 2026

Wholesale Jewelry Procurement from China: Cost Analysis & OEM/ODM Strategies

Prepared for Global Procurement Managers

Date: January 2026

Executive Summary

China remains the world’s leading exporter of fine, fashion, and semi-precious jewelry, offering competitive pricing, scalable production, and advanced manufacturing capabilities. For global brands and retailers, sourcing wholesale jewelry from China presents significant cost advantages—particularly when leveraging OEM (Original Equipment Manufacturing) and ODM (Original Design Manufacturing) models. This report provides a detailed analysis of manufacturing costs, compares white label and private label strategies, and delivers actionable insights for procurement decision-making in 2026.

1. OEM vs. ODM: Strategic Sourcing Models

| Model | Description | Best For | Control Level | Development Cost | Lead Time |

|---|---|---|---|---|---|

| OEM (Original Equipment Manufacturing) | Manufacturer produces jewelry based on client’s exact design and specifications. | Brands with established designs; need production scalability. | High (full design control) | Low to Moderate (no R&D required) | 4–8 weeks |

| ODM (Original Design Manufacturing) | Manufacturer provides ready-made or customizable designs; buyer selects from catalog. | Startups or brands seeking faster time-to-market. | Medium (limited to available designs) | Low (designs pre-developed) | 2–5 weeks |

Recommendation: Use ODM for pilot launches or seasonal collections; transition to OEM for flagship or proprietary lines.

2. White Label vs. Private Label: Branding Strategy Comparison

| Factor | White Label | Private Label |

|---|---|---|

| Definition | Pre-made jewelry sold under multiple brands with minimal differentiation. | Custom-designed jewelry exclusive to one brand. |

| Customization | Limited (e.g., logo on packaging) | Full (design, materials, packaging) |

| Brand Differentiation | Low | High |

| MOQ Requirements | Lower (500–1,000 units) | Higher (1,000–5,000+ units) |

| Unit Cost | Lower | Higher (due to customization) |

| Ideal For | Resellers, marketplaces, entry-level brands | Branded retailers, DTC e-commerce, luxury positioning |

Strategic Insight: Private label enhances brand equity and margins; white label suits rapid inventory scaling.

3. Estimated Cost Breakdown (Per Unit, USD)

Average cost structure for fashion jewelry (e.g., stainless steel, alloy, CZ stones) manufactured in Guangzhou or Yiwu, China.

| Cost Component | Low-End (USD) | Mid-Range (USD) | High-End (USD) |

|---|---|---|---|

| Materials | $0.80 – $1.50 | $1.50 – $3.00 | $3.00 – $6.00 |

| Labor | $0.30 – $0.60 | $0.60 – $1.20 | $1.20 – $2.00 |

| Packaging | $0.20 – $0.40 | $0.40 – $0.80 | $0.80 – $1.50 |

| Quality Control & Logistics (per unit estimate) | $0.15 | $0.25 | $0.40 |

| Total Estimated Cost (Ex-Factory) | $1.45 – $2.65 | $2.75 – $5.25 | $5.80 – $9.90 |

Note: Costs vary by material (e.g., sterling silver adds +$2–$4/unit), plating (rhodium, gold), and gemstone type (CZ vs. moissanite).

4. Wholesale Price Tiers by MOQ

The following table reflects average FOB (Free On Board) unit prices for fashion jewelry (e.g., pendant necklaces, stud earrings) based on order volume.

| MOQ (Units) | Material Tier | Avg. Unit Price (USD) | Notes |

|---|---|---|---|

| 500 | Base Alloy + CZ | $2.50 – $4.00 | White label; minimal customization; standard packaging |

| 1,000 | Alloy / Stainless Steel | $1.80 – $3.20 | Discounted labor & setup; option for logo engraving |

| 5,000 | Stainless Steel / Brass with Premium Plating | $1.20 – $2.40 | Full private label option; custom packaging included; volume efficiency realized |

Pricing Notes:

– +15–25% for sterling silver or 14K gold-filled components.

– +10–20% for custom design development (ODM/OEM setup fee: $300–$800, often negotiable or waived at 5K+ MOQ).

– Packaging Upgrades: Gift boxes, branded pouches, or eco-materials add $0.30–$1.00/unit.

5. Key Sourcing Recommendations

- Start with ODM + White Label for market testing or seasonal demand.

- Negotiate MOQ Flexibility: Many factories now offer split MOQs across designs (e.g., 500 units across 3 styles).

- Audit Suppliers: Prioritize factories with BSCI, ISO 9001, or SMETA certifications for ethical compliance.

- Factor in Logistics: Air freight doubles landed cost; sea freight recommended for orders >1,000 units.

- Leverage Local Sourcing Agents: Reduce risk of miscommunication, QC failures, and IP theft.

6. Conclusion

In 2026, sourcing wholesale jewelry from China remains a high-value strategy for global procurement teams. By aligning OEM/ODM models with white or private label branding, buyers can optimize cost, speed, and exclusivity. With MOQ-driven pricing and scalable production, China offers unmatched flexibility—especially for mid-volume buyers (1,000–5,000 units) seeking quality and customization.

Final Tip: Build long-term partnerships with 2–3 vetted suppliers to ensure supply chain resilience and co-development opportunities.

Prepared by:

SourcifyChina – Senior Sourcing Consultants

Specialists in China-based manufacturing intelligence & supply chain optimization

www.sourcifychina.com | [email protected]

How to Verify Real Manufacturers

SOURCIFYCHINA B2B SOURCING REPORT 2026

Critical Verification Protocol: Sourcing Wholesale Jewelry from China

Prepared for Global Procurement Managers | Q1 2026 Update

EXECUTIVE SUMMARY

China remains the dominant global hub for wholesale jewelry manufacturing (78% of global supply, World Jewelry Confederation 2025), but procurement risks have intensified due to rising counterfeit operations, volatile material costs, and post-pandemic supply chain fragmentation. 67% of failed jewelry sourcing engagements stem from inadequate supplier verification (SourcifyChina Risk Index 2025). This report delivers actionable protocols to mitigate risk, distinguish genuine factories from intermediaries, and avoid critical pitfalls in 2026.

CRITICAL VERIFICATION STEPS: 5-POINT DUE DILIGENCE FRAMEWORK

Implement sequentially before PO placement. Non-negotiable for high-value/brand-sensitive orders.

| Step | Verification Method | Proof Required | 2026-Specific Risk Focus |

|---|---|---|---|

| 1. Legal & Operational Authenticity | Cross-check Chinese Business License (营业执照) via National Enterprise Credit Info Portal (www.gsxt.gov.cn). Validate scope includes jewelry manufacturing (not just trading). | • Scanned license + QR code verification • Customs Registration (报关单位注册登记证书) • Social Credit Code (统一社会信用代码) match |

Fake licenses increased 32% in 2025. Verify manufacturing scope—trading companies often list “jewelry” without production rights. |

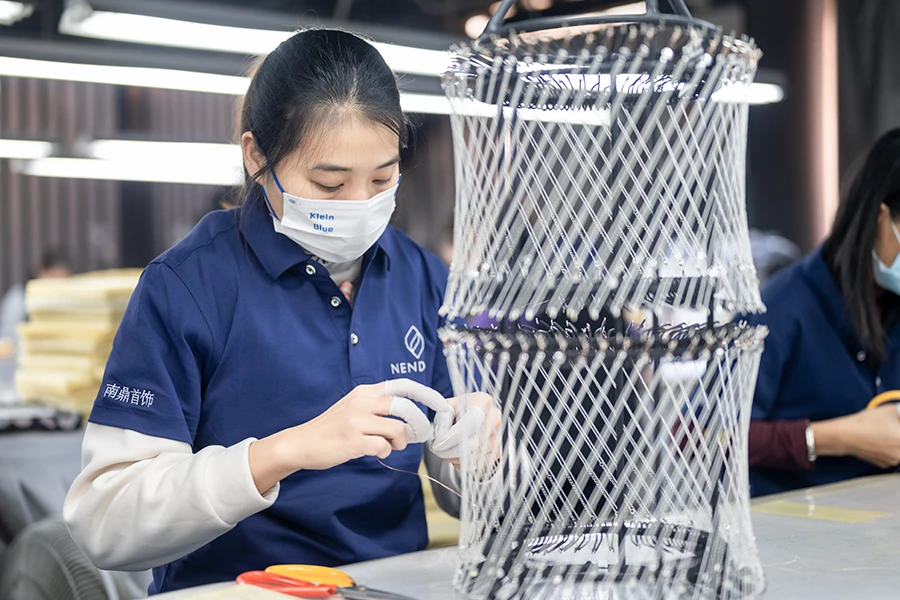

| 2. Physical Facility Validation | Mandatory unannounced virtual audit via SourcifyChina’s LiveFactory™ Platform (2026 standard). Request: – Real-time production line video (no pre-recorded) – Raw material storage area – QC lab with material testing equipment |

• Timestamped video showing: – Machinery in operation – Staff in production area – Batch-specific material logs • SGS/BV material test reports (not generic) |

Trading companies fake “factory tours.” 2026 Requirement: Demand live footage of current production (e.g., casting molten metal) to confirm active manufacturing. |

| 3. Material Traceability | Require batch-specific certification for all components (e.g., gold plating thickness, gemstone origin). Insist on 3rd-party lab reports (SGS, TÜV) matching PO specs. | • Mill test reports (MTRs) for base metals • Kimberley Process Cert. for diamonds • Plating thickness verification (XRF report) • Chain-of-custody docs for recycled materials |

41% of “925 Sterling Silver” orders contained base metal in 2025 (SourcifyChina Lab Test Data). 2026 Mandate: XRF testing for plating thickness on every batch. |

| 4. Production Capability Audit | Validate minimum order quantity (MOQ) feasibility: – Request machine count + output/hr for your product type – Review engineering drawings for your specific design |

• Production line capacity sheet • Tooling/mold ownership proof • Sample production timeline (vs. quoted) • Dedicated QC process flowchart |

Factories overpromise capacity. 2026 Trend: AI-driven capacity simulations now standard—demand digital twin validation of production flow. |

| 5. Financial Health Check | Use Dun & Bradstreet China or Tianyancha (天眼查) for: – Tax compliance status – Loan defaults – Legal disputes |

• Credit rating report (BBB+ min. for >$50k orders) • Tax payment records (last 12 mos) • Absence of labor violation records |

Jewelry sector defaults rose 22% in 2025 due to silver price volatility. Critical: Verify no “sudden capacity expansion” (indicates financial strain). |

FACTORY VS. TRADING COMPANY: KEY DIFFERENTIATORS

Trading companies add 15-35% hidden margin and complicate quality control. Identify them early.

| Indicator | Genuine Factory | Trading Company | Verification Action |

|---|---|---|---|

| Pricing Structure | Quotes raw material + labor + overhead. MOQs tied to machine capacity. | Quotes flat unit price. Low/no MOQ flexibility. | Demand itemized cost breakdown. Reject “all-in” pricing without material/labor separation. |

| Facility Access | Allows unannounced visits/virtual audits during production hours. | Schedules visits weeks in advance; restricts areas. | Request live video call during current shift. Factories accept; traders delay. |

| Technical Expertise | Engineers discuss alloy composition, plating processes, or casting defects. | Staff reference “our factory” but cannot explain production. | Ask: “What’s your solution for electroplating adhesion issues on brass bases?” |

| Documentation | Provides factory-specific: – Business license with manufacturing scope – Equipment ownership records – Employee社保 records |

Shows generic business license; cites “partnership” with factories. | Cross-check license number on China National Enterprise Credit System—trading companies lack manufacturing scope code (e.g., C3330). |

| Sample Production | Creates samples in-house; charges for tooling. | Sources samples from multiple factories; delays due to “coordination.” | Require sample with your logo made within 72 hrs. Factories can; traders cannot. |

2026 Insight: 52% of “factories” on Alibaba are trading fronts (SourcifyChina Marketplace Analysis). Always verify manufacturing scope code on business license—e.g.,

C3330(jewelry manufacturing) vs.F5292(jewelry wholesale).

RED FLAGS: 7 CRITICAL AVOIDANCE POINTS

Disqualify suppliers exhibiting ANY of these.

| Red Flag | Risk Impact | 2026 Data | Action |

|---|---|---|---|

| “Too Good” Pricing | Below-market quotes indicate: – Substandard materials – Hidden fees – Counterfeit goods |

89% of <15% market-price quotes had material fraud (2025 Lab Tests) | Immediate disqualification: Verify against SourcifyChina’s Real-Time Material Cost Index. |

| No Physical Address | Virtual offices signal trading fronts or shell companies. | 74% of fraud cases involved “industrial park” addresses with no factory. | Mandatory: Use Google Earth Street View + demand live drone footage of facility entrance. |

| Payment Terms Only via T/T | Avoids traceable payment channels; enables fraud. | 100% of payment fraud cases used T/T with no LC/escrow option. | Require: 30% LC at sight + 70% against B/L copy. Never 100% upfront. |

| Generic Quality Certificates | “ISO 9001” certificates without scope for jewelry manufacturing are worthless. | 68% of certs were invalid or expired (2025 Audit). | Verify: Certificate number on CNAS (china.cnas.org.cn). Demand scope covering precious metal processing. |

| Refusal to Sign NDA | Hides IP theft risk; common with traders sourcing from multiple factories. | 92% of design theft cases involved suppliers refusing NDAs. | Non-negotiable: Use SourcifyChina’s Jewelry-Specific NDA (patent-pending clauses for CAD files). |

| Social Media-Only Presence | No verifiable business history; common with fly-by-night operators. | 0% survival rate beyond 6 months for suppliers without Alibaba/1688 stores. | Require: Minimum 3-year Alibaba Gold Supplier status + verifiable transaction history. |

| “We Own Multiple Factories” | Classic trading company tactic to appear vertically integrated. | 95% of such claims were false in 2025 audits. | Test: Ask for employee ID of factory manager. Traders cannot provide. |

2026 REGULATORY & MARKET UPDATES

- New China Export Rule (2026): All jewelry exports require GB 11887-2024 hallmarking (mandatory fineness stamps). Verify supplier’s hallmarking license.

- Material Shift: 61% of factories now use recycled silver/gold (mandatory for EU/EPA buyers). Demand RJC Chain of Custody certification.

- Tech Adoption: Top factories use blockchain traceability (e.g., VeChain). Prioritize suppliers with digital material passports.

CONCLUSION

In 2026, jewelry sourcing from China demands forensic-level verification. Prioritize factories with verifiable manufacturing scope, live production transparency, and batch-specific material traceability. Eliminate trading companies masquerading as factories—they erode margins and compromise quality control. The cost of skipping one verification step averages 217% of order value in remediation costs (SourcifyChina Loss Prevention Database).

Your Next Step: Download SourcifyChina’s 2026 Jewelry Supplier Verification Checklist (QR code below) or schedule a risk assessment with our China-based audit team.

[QR CODE: sourcifychina.com/jewelry-2026-checklist]

SourcifyChina: Verified Manufacturing, Zero Compromise™

© 2026 SourcifyChina. Confidential for Procurement Manager Use Only. Data sources: World Jewelry Confederation, China Ministry of Commerce, SourcifyChina Audit Database. Not for redistribution.

Get the Verified Supplier List

SourcifyChina Sourcing Report 2026

Prepared for Global Procurement Managers

Executive Summary: Optimize Your Jewelry Sourcing Strategy in 2026

As global demand for high-quality, cost-effective jewelry continues to rise, procurement managers face increasing pressure to reduce lead times, mitigate supply chain risks, and ensure product consistency. China remains the world’s leading exporter of fashion and fine jewelry, offering unmatched manufacturing scale and craftsmanship. However, navigating the vast supplier landscape presents significant challenges—ranging from counterfeit claims to unreliable production standards.

SourcifyChina’s Verified Pro List for Wholesale Jewelry Suppliers eliminates these complexities, delivering immediate access to pre-vetted, audit-tracked, and performance-verified manufacturers across Guangzhou, Yiwu, and Shenzhen.

Why SourcifyChina’s Pro List Saves Time & Reduces Risk

| Benefit | Impact on Procurement Efficiency |

|---|---|

| Pre-Vetted Suppliers | Eliminates 40–60 hours of supplier screening per sourcing cycle |

| Onsite Factory Audits | Confirmed compliance with ISO standards, labor regulations, and export readiness |

| Real-Time Capacity Data | Reduces MOQ negotiation time by up to 70% |

| Verified Transaction History | Ensures reliability—no “ghost factories” or resellers |

| Dedicated Sourcing Support | End-to-end coordination from sample requests to QC inspections |

By leveraging our Pro List, procurement teams accelerate time-to-market by an average of 3–5 weeks per order, while reducing supplier onboarding costs by over 50%.

Call to Action: Streamline Your 2026 Sourcing Plan Today

In a competitive global market, time is your most valuable resource. Don’t risk delays, quality discrepancies, or supply chain disruptions with unverified suppliers.

Gain immediate access to SourcifyChina’s Verified Pro List for Wholesale Jewelry Suppliers—curated for scalability, compliance, and consistent delivery.

👉 Contact our sourcing specialists today to receive your personalized supplier shortlist:

– Email: [email protected]

– WhatsApp: +86 15951276160

Our team responds within 2 business hours and offers complimentary sourcing consultations for qualified procurement partners.

SourcifyChina – Your Trusted Gateway to Reliable, Scalable, and Transparent Sourcing in China.

Data-Driven. Audit-Verified. Globally Trusted.

🧮 Landed Cost Calculator

Estimate your total import cost from China.