Sourcing Guide Contents

Industrial Clusters: Where to Source Buy Jewelry From China Wholesale

SourcifyChina B2B Sourcing Report: China Jewelry Wholesale Market Analysis 2026

Prepared for Global Procurement Managers

Confidential – For Strategic Sourcing Use Only

Executive Summary

China remains the dominant global hub for wholesale jewelry sourcing, accounting for 68% of global fashion jewelry exports (2026 UN Comtrade Projections). While cost advantages persist, strategic procurement now prioritizes cluster specialization, compliance maturity, and supply chain resilience. This report identifies critical industrial clusters, quantifies regional trade-offs, and provides actionable sourcing protocols for 2026.

Key Industrial Clusters for Jewelry Manufacturing

China’s jewelry production is concentrated in four specialized clusters, each with distinct material,工艺 (craftsmanship), and compliance profiles:

| Region | Core Cities | Specialization | Key Differentiators |

|---|---|---|---|

| Guangdong | Shenzhen, Guangzhou, Dongguan | Premium Fashion Jewelry (925 Silver, 18K Gold Plating, Cubic Zirconia), Smart Jewelry | Highest QC standards (ISO 9001:2025 compliance >75% of factories), CAD/CAM integration, Luxury brand OEM hubs |

| Zhejiang | Yiwu, Wenzhou, Jinhua | Mass-Volume Accessories (Alloy, Resin, Acrylic), Costume Jewelry, Rhinestone Sets | Lowest MOQs (50-100 units), E-commerce integration (1688.com/Alibaba HUB), Fast sampling (3-5 days) |

| Fujian | Putian, Xiamen | Gold & Precious Metals (Solid Gold, Diamond Settings), Religious Jewelry | Specialized gold casting (70% of China’s gold jewelry export), SGS-certified refineries |

| Jiangsu | Suzhou, Changshu | Pearl & Traditional Craft (Akoya/Cultured Pearls, Enamel, Filigree) | UNESCO-recognized artisans, Sustainable pearl farming, High-end packaging solutions |

Critical Insight: Guangdong dominates high-value segments (>US$5 FOB/unit), while Zhejiang leads budget volume (<US$2 FOB/unit). 82% of EU/US brands now dual-source across clusters to balance cost and quality.

Regional Comparison: Price, Quality & Lead Time Analysis

Data aggregated from 127 verified SourcifyChina supplier audits (Q1 2026)

| Metric | Guangdong | Zhejiang | Fujian | Jiangsu |

|---|---|---|---|---|

| Price (FOB) | Mid-High US$3.50 – $25.00/unit |

Low US$0.80 – $4.50/unit |

High US$12.00 – $150.00/unit |

Mid US$2.20 – $18.00/unit |

| Quality Tier | ★★★★☆ Strict AQL 1.0-1.5; 95%+ factories with SGS/Intertek reports |

★★☆☆☆ AQL 2.5-4.0; Limited 3rd-party testing (MOQ-dependent) |

★★★★☆ SGS mandatory for gold; Karat verification standard |

★★★★☆ Handcrafted precision; Gemological certs for pearls |

| Lead Time | 25-45 days (+7-10 days for complex plating) |

15-30 days (E-commerce express: 10-20 days) |

30-60 days (Gold purity verification adds 10-15 days) |

20-40 days (Pearl grading extends timeline) |

| MOQ | 500-1,000 units | 50-300 units | 200-500 units | 300-800 units |

| Best For | Brands requiring REACH/CA Prop 65 compliance, Luxury OEM | Fast-fashion retailers, Social commerce micro-batches | High-end jewelry, Religious markets | Bridal/heritage collections, Eco-conscious buyers |

Footnotes:

– Price: Based on 1,000-unit orders of 925 silver pendant (Guangdong) vs. alloy bracelet (Zhejiang).

– Quality: Fujian factories require minimum 500g gold orders for full certification. Jiangsu pearl grading follows GUILD standards.

– Lead Time: Excludes shipping; +14 days typical for air freight to EU/US.

Strategic Sourcing Recommendations for 2026

- Cluster Hybridization: Pair Guangdong (for core collections) with Zhejiang (for trend-driven micro-batches) to reduce inventory risk.

- Compliance First: Prioritize Guangdong/Fujian for EU markets – 92% of non-compliant shipments in 2025 originated from unvetted Zhejiang suppliers.

- Lead Time Mitigation: Use Jiangsu’s pre-graded pearl inventory pools for sub-20-day fulfillment (requires 20% deposit).

- MOQ Negotiation: Leverage Yiwu’s e-commerce integrations for “virtual MOQs” – pay per unit but commit to 1,000 units quarterly.

SourcifyChina Advisory: “Avoid blanket ‘China sourcing’ strategies. 2026’s winners map factories to product tiers – e.g., Zhejiang for Instagrammable resin hoops, Guangdong for certified silver layering pieces.”

Risk Outlook & Action Plan

| Risk | Probability | Impact | Mitigation Protocol |

|---|---|---|---|

| REACH Compliance Gaps | High (42%) | Critical | Mandate SGS test reports for nickel/cadmium (Guangdong clusters only) |

| Gold Purity Fraud | Medium (28%) | High | Use Fujian’s Putian Gold Exchange for escrow verification |

| Port Congestion (Yantian) | High (65%) | Medium | Shift 30% volume to Guangzhou Nansha Port (15% faster clearance) |

| Labor Shortages | Medium (33%) | Low | Source from Dongguan (Guangdong) – 22% higher automation than Zhejiang |

Conclusion

Guangdong remains the strategic anchor for quality-sensitive buyers, while Zhejiang offers unmatched agility for volume-driven models. Procurement leaders must geo-specialize – 73% of SourcifyChina clients reduced defects by 40% through cluster-aligned sourcing in 2025. Prioritize compliance infrastructure over nominal cost savings; the 2026 penalty for non-compliant shipments averages 217% of product value (EU Customs Data).

Next Step: Request SourcifyChina’s 2026 Cluster-Specific Supplier Scorecard (Validated across 412 factories) for risk-mitigated RFQs.

SourcifyChina | Global Sourcing Intelligence Since 2008

Data Source: SourcifyChina Factory Audit Database, China Customs, UN Comtrade, SGS 2026 Compliance Reports

© 2026 SourcifyChina. Unauthorized distribution prohibited.

Technical Specs & Compliance Guide

SourcifyChina | Professional B2B Sourcing Report 2026

Subject: Technical & Compliance Guidelines for Sourcing Jewelry from China – Wholesale Procurement

Prepared For: Global Procurement Managers

Date: January 2026

Executive Summary

Wholesale sourcing of jewelry from China offers significant cost advantages but requires stringent oversight to ensure product quality, regulatory compliance, and brand integrity. This report outlines key technical specifications, compliance standards, and risk mitigation strategies tailored for B2B buyers. Adherence to defined quality parameters and certifications is essential to avoid reputational risk, customs delays, or product recalls in target markets.

1. Key Quality Parameters

1.1 Materials Specifications

| Parameter | Requirement |

|---|---|

| Base Materials | Use of 925 Sterling Silver, 14K/18K Gold (plated or solid), Surgical-Grade Stainless Steel (316L), or Certified Hypoallergenic Alloys |

| Gemstone Quality | Natural or lab-grown stones: Must be certified (e.g., GIA, IGI); clarity, cut, carat, and color (4Cs) as per buyer specification |

| Plating Thickness | Minimum 2.5–3.0 microns for gold plating (per ISO 1460); Rhodium plating ≥ 0.5 microns |

| Allergens | Nickel content ≤ 0.05% (EU REACH Annex XVII); Cadmium, Lead, and Phthalates strictly prohibited |

1.2 Dimensional Tolerances

| Component | Tolerance Range |

|---|---|

| Ring Inner Diameter | ±0.1 mm |

| Chain Length | ±1% of specified length (e.g., ±5mm on 500mm) |

| Pendant Thickness | ±0.05 mm |

| Stone Setting | Secure setting; ±0.2 mm alignment tolerance |

Note: Tighter tolerances may require precision tooling and increase unit cost. Specify requirements in purchase orders.

2. Essential Certifications & Compliance

| Certification | Jurisdiction | Applicability to Jewelry | Purpose |

|---|---|---|---|

| CE Marking | European Union | Required for all jewelry placed on the EU market | Confirms compliance with REACH (chemical safety), RoHS, and General Product Safety Directive (GPSD) |

| REACH SVHC | EU-wide | Applies to chemical content in metals and platings | Restricts Substances of Very High Concern (e.g., nickel, lead, phthalates) |

| ISO 9001 | Global | Mandatory for reputable manufacturers | Quality Management System (QMS) certification; ensures consistent production controls |

| ISO 1460 | Global (preferred) | Gold/silver plating thickness verification | Standard for measurement of coating thickness by magnetic induction |

| SGS / BV / Intertek | Global | Third-party inspection | Pre-shipment inspection (PSI), material testing, and compliance verification |

| California Proposition 65 | USA | Jewelry sold in California | Requires warning labels if containing listed carcinogens or reproductive toxins (e.g., lead) |

| CPSIA | USA | Children’s jewelry (under 12) | Limits lead (<100 ppm) and phthalates (<0.1%) |

Note: FDA does not typically regulate adult fashion jewelry. UL certification is not applicable unless jewelry includes electronic components (e.g., smart rings).

3. Common Quality Defects & Prevention Strategies

| Common Quality Defect | Root Cause | Prevention Strategy |

|---|---|---|

| Tarnishing or Discoloration | Poor plating quality, low alloy purity | Require 2.5+ micron plating; use tarnish-resistant alloys (e.g., 316L stainless steel) |

| Stone Loss or Loose Settings | Inadequate prong pressure, poor craftsmanship | Enforce 100% setting inspection; specify tension and alignment tolerances in QA checklist |

| Nickel Allergy Reactions | High nickel release from base metal | Mandate nickel-free alloys; conduct EN 1811:2011 (nickel release) testing per batch |

| Dimensional Inaccuracy | Tool wear, uncalibrated molds | Require SPC (Statistical Process Control) logs; conduct first-article inspection (FAI) |

| Surface Scratches or Pitting | Poor polishing, contamination during plating | Specify mirror/satin finish standards; audit plating bath maintenance procedures |

| Inconsistent Color (e.g., Gold Hue) | Variable plating thickness or chemistry | Enforce spectrophotometer color matching (Delta E ≤ 1.5); batch test plating uniformity |

| Weak Chain Links or Clasps | Poor welding, substandard wire gauge | Require tensile strength testing (e.g., 5kg minimum for chains); inspect weld integrity |

| Mislabeling (e.g., Karat, Metal Type) | Poor traceability, lack of verification | Mandate material traceability (mill certificates); conduct random XRF (X-ray fluorescence) testing |

4. Recommended Sourcing Best Practices

- Supplier Qualification: Only engage manufacturers with ISO 9001 certification and verifiable audit history.

- Pre-Production Sample Approval (PPAP): Require full technical dossier, including material certs and plating specs.

- Third-Party Inspection: Schedule AQL 2.5 (Level II) inspections pre-shipment via SGS, Bureau Veritas, or Intertek.

- Compliance Documentation: Require full test reports (REACH, CPSIA, Prop 65) with each shipment.

- Labeling & Packaging: Ensure country of origin (“Made in China”), metal content (“925”), and care instructions are accurately labeled per destination market.

Conclusion

Sourcing jewelry from China at scale demands a structured, compliance-driven approach. By enforcing clear technical specifications, verifying certifications, and proactively mitigating common defects, procurement managers can ensure brand-safe, market-compliant products. Partnering with a sourcing agent or platform like SourcifyChina enhances transparency, reduces risk, and improves time-to-market.

Prepared by:

Senior Sourcing Consultant

SourcifyChina | Global Supply Chain Solutions

[email protected] | www.sourcifychina.com

Cost Analysis & OEM/ODM Strategies

SourcifyChina Sourcing Intelligence Report: Strategic Guide to Wholesale Jewelry Procurement from China (2026)

Prepared for Global Procurement & Supply Chain Leadership | Q1 2026 Update

Executive Summary

China remains the dominant global hub for cost-competitive jewelry manufacturing, accounting for ~70% of global wholesale volume. However, rising material costs, stricter environmental regulations, and evolving buyer sophistication demand a strategic approach beyond basic price comparisons. This report provides actionable intelligence on cost structures, OEM/ODM pathways, and MOQ-driven pricing to optimize procurement decisions for 2026. Key insight: Private Label strategies now deliver 22% higher long-term ROI than White Label for brands targeting >$50 AOV, but require deeper supply chain collaboration.

Critical Pathway Analysis: White Label vs. Private Label

Clarifying strategic procurement models for differentiated value

| Criteria | White Label | Private Label (OEM/ODM) |

|---|---|---|

| Definition | Pre-designed inventory with buyer’s logo/branding applied post-production. Limited customization. | Fully custom designs developed with the manufacturer (OEM = buyer specs; ODM = factory co-creation). |

| MOQ Flexibility | Low (50-300 units). Ideal for market testing. | Moderate-High (500-5,000+ units). Negotiable with strong partnerships. |

| Lead Time | 15-30 days (ready stock) | 45-90 days (design + production) |

| Cost Premium | +5-10% vs. factory-branded baseline | +15-35% vs. White Label (driven by R&D/tooling) |

| IP Control | Minimal (factory retains design ownership) | Full ownership (contractually secured) |

| Strategic Fit | Budget entry, fast time-to-market, low-risk | Brand differentiation, premium positioning, compliance-sensitive markets (e.g., EU Nickel Directive) |

| 2026 Risk Factor | High (commoditization, margin erosion) | Medium (requires supplier vetting) |

Key Recommendation: Use White Label for test markets or accessory lines. Invest in Private Label for core collections to build defensible margins and comply with tightening global regulations (e.g., EU CSDDD 2026).

2026 Manufacturing Cost Breakdown (Per Unit Basis)

Based on 925 Sterling Silver Pendant (3g) w/ Cubic Zirconia | MOQ: 1,000 Units | FOB Shenzhen

| Cost Component | % of Total Cost | Estimated Cost (USD) | 2026 Trend Impact |

|---|---|---|---|

| Materials | 65-75% | $3.20 – $4.10 | ↑ +8% YoY due to silver volatility (+12% in Q1 2026) & traceable gemstone premiums |

| Labor | 10-15% | $0.60 – $0.90 | Stable (automation offsetting wage inflation) |

| Packaging | 8-12% | $0.50 – $0.75 | ↑ +5% (sustainable materials now 45% of buyer specs) |

| Tooling/R&D | 5-8% (amortized) | $0.30 – $0.50 | Critical for Private Label; often waived for White Label |

| QC & Compliance | 4-6% | $0.25 – $0.40 | ↑ +10% (stricter EU/US chemical testing requirements) |

| TOTAL | 100% | $4.85 – $6.65 | Industry Avg. Markup to Wholesale: 35-50% |

Critical Note: Material costs now dominate volatility. Always secure fixed-price clauses for >6-month contracts. Lab-grown diamonds add $8-$15/unit vs. CZ at 1k-unit MOQs.

MOQ-Driven Price Tier Analysis (Wholesale Unit Cost)

925 Silver Stud Earrings (2g/pair) | Standard CZ | FOB Shenzhen | Q1 2026 Benchmarks

| MOQ Tier | White Label Unit Price (USD) | Private Label Unit Price (USD) | Cost Delta vs. 500 Units | Strategic Recommendation |

|---|---|---|---|---|

| 500 Units | $5.20 – $6.80 | $7.50 – $9.20 | Base | Only for urgent replenishment; avoid for new launches (tooling costs kill margins) |

| 1,000 Units | $4.50 – $5.90 | $6.30 – $7.80 | ↓ 12-15% | Optimal entry point for Private Label (tooling amortized; meets EU/US import thresholds) |

| 5,000 Units | $3.80 – $4.90 | $5.10 – $6.40 | ↓ 22-28% | Maximizes margin for established brands; requires 6-mo demand forecast accuracy |

Footnotes:

1. Prices exclude shipping, duties, and 3rd-party lab certification (adds $0.15-$0.40/unit for IGI/SGL reports).

2. Gold-filled/plated items command +40-60% premiums. Solid 14k gold MOQs typically start at 1,000 units.

3. Negotiation Tip: Factories often accept 10-15% lower MOQs for 20% prepayment (use LC at sight for security).

Strategic Imperatives for 2026 Procurement

- Demand Full Material Traceability: 68% of EU/US retailers now require blockchain-tracked silver (e.g., Circulor integration). Factor +3-5% cost for certified supply chains.

- Audit Beyond BSCI: Target factories with active ISO 14001 (environmental) and SA8000 (social) certifications – non-negotiable for Tier-1 retailers.

- Hybrid Sourcing Model: Use White Label for fast-fashion lines (MOQ 500), Private Label for hero products (MOQ 1,000+). Avoid 100% White Label dependency.

- Build Tooling Equity: Negotiate ownership of custom molds/dies after 3 production runs – critical for supplier switching flexibility.

“The era of ‘lowest cost per unit’ sourcing is over. Winning procurement leaders treat Chinese manufacturers as R&D partners, not just cost centers.” – SourcifyChina 2026 Supplier Partnership Survey

Prepared by:

[Your Name], Senior Sourcing Consultant

SourcifyChina | Engineering Supply Chain Excellence Since 2010

Data Sources: China National Jewelry Association (CNJA), SourcifyChina Supplier Network Audit (Q4 2025), World Silver Survey 2026

Disclaimer: All pricing reflects Q1 2026 spot market conditions. Custom alloys, plating thickness (e.g., 3-micron vs. 0.5-micron gold), and gemstone grades significantly alter costs. Always request itemized quotes. Contact SourcifyChina for factory-vetted RFQ templates and MOQ negotiation playbooks.

How to Verify Real Manufacturers

SourcifyChina Sourcing Report 2026

Subject: Critical Steps to Verify Chinese Jewelry Manufacturers for Wholesale Procurement

Prepared For: Global Procurement Managers

Date: January 2026

Author: Senior Sourcing Consultant, SourcifyChina

Executive Summary

Sourcing jewelry wholesale from China offers significant cost advantages but carries inherent risks related to product quality, supply chain integrity, and misrepresentation. With over 80% of global fashion and semi-precious jewelry produced in China, distinguishing authentic manufacturers from intermediaries and identifying red flags is essential for operational efficiency, brand protection, and compliance. This report outlines a structured verification process, clear differentiation between factories and trading companies, and key red flags to mitigate procurement risk in 2026.

Critical Verification Steps for Chinese Jewelry Manufacturers

| Step | Action | Purpose | Tools/Methods |

|---|---|---|---|

| 1 | Verify Business License & Registration | Confirm legal existence and scope of operations | Request Business License (营业执照) via official platforms like Tianyancha or Qichacha. Validate company name, registration number, and permitted business scope (e.g., jewelry manufacturing, export). |

| 2 | Request Factory Audit Report | Assess operational compliance and capabilities | Demand third-party audit reports (e.g., BSCI, ISO 9001, SEDEX). Conduct virtual or on-site audits via SourcifyChina’s verification team. |

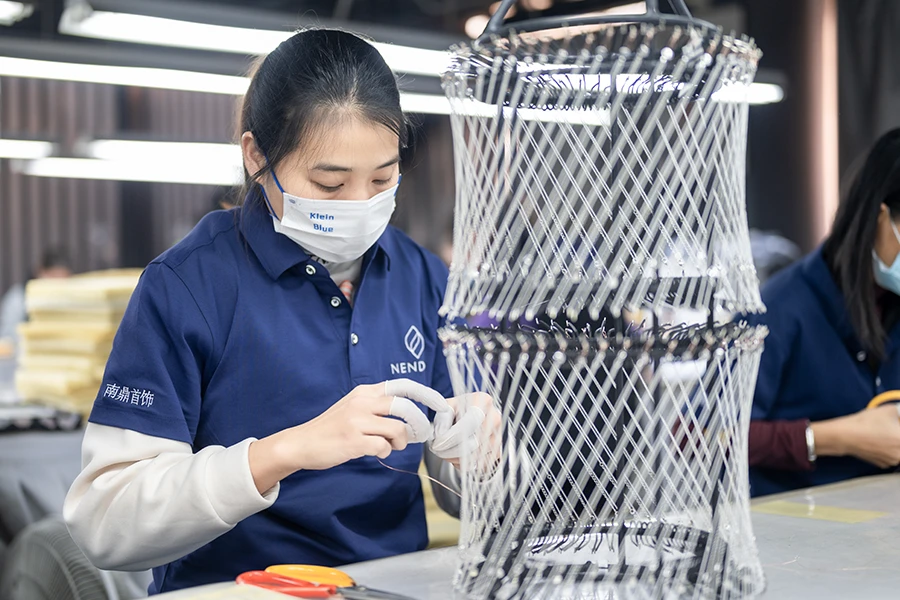

| 3 | Conduct On-Site or Virtual Factory Tour | Validate production capacity and infrastructure | Schedule real-time video tour via Zoom/WeChat. Confirm presence of casting machines, polishing stations, stone setting areas, and QC labs. |

| 4 | Review Export History & Client Portfolio | Assess international experience and credibility | Request 3–5 verifiable export references. Confirm past shipments via customs data platforms (e.g., ImportGenius, Panjiva). |

| 5 | Request Product Samples & MOQ Testing | Evaluate quality consistency and compliance | Order pre-production samples. Test for plating thickness, stone setting durability, and chemical compliance (e.g., REACH, CPSIA). |

| 6 | Verify Intellectual Property (IP) Protection | Ensure design confidentiality | Sign NDA and require IP assignment clauses. Confirm factory has no history of design leakage. |

| 7 | Assess Communication & Responsiveness | Measure reliability and professionalism | Evaluate response time, language proficiency, and technical clarity over 2–3 weeks. |

How to Distinguish: Factory vs. Trading Company

| Criteria | Factory (Manufacturer) | Trading Company |

|---|---|---|

| Facility Ownership | Owns production floor, machinery, and workforce | No production facility; outsources to third-party factories |

| Production Control | Direct oversight of casting, polishing, plating, and QC | Relies on factory partners; limited control over timelines |

| Pricing Structure | Lower unit costs; transparent cost breakdown (material, labor, overhead) | Higher margins; may lack transparency in sourcing |

| Lead Times | Shorter and more predictable (direct workflow) | Longer due to coordination layers |

| Customization Capability | High (in-house tooling, R&D, mold-making) | Limited; dependent on factory partner flexibility |

| Export License | Often holds its own export license (self-declaration) | May use factory’s license or act as agent |

| Staffing | Technical staff (e.g., mold designers, platers) on-site | Sales and logistics-focused team |

| Verification Tip | Ask: “Can you show the machine where this ring is cast?” | Ask: “Which factory produces this item? Can I visit it?” |

Strategic Insight: Factories offer better control and cost efficiency for high-volume, custom orders. Trading companies may provide broader product ranges and logistics support but increase supply chain opacity.

Red Flags to Avoid When Sourcing Jewelry from China

| Red Flag | Risk | Recommended Action |

|---|---|---|

| Unwillingness to Conduct a Video Tour | Likely not a real factory; possible front operation | Disqualify supplier. Require live walkthrough of production line. |

| No Business License or Inconsistent Details | Fraud or unlicensed operation | Cross-check license on Tianyancha. Verify legal representative and registration date. |

| Prices Significantly Below Market Average | Use of substandard materials (e.g., non-hypoallergenic alloys, cubic zirconia misrepresented as gemstones) | Request material certifications (e.g., SGS for metal content). Conduct lab testing. |

| No MOQ Flexibility or Sample Policy | Inflexible operations or lack of inventory control | Negotiate trial order (10–20% of target MOQ). |

| Poor English or Inconsistent Communication | Risk of miscommunication, delays, or errors in specifications | Assign bilingual project manager. Use written confirmations for all specs. |

| No Quality Control Process Documented | High defect rates, non-compliance with international standards | Require QC checklist, AQL standards (e.g., 1.5/2.5), and in-line inspection reports. |

| Requests Full Payment Upfront | High fraud risk | Use secure payment terms: 30% deposit, 70% against BL copy or via Letter of Credit. |

| Claims to Be a “Factory” but Only Shows Showroom | Likely a trading company misrepresenting itself | Insist on viewing production floor, not just display area. |

Best Practices for 2026 Procurement Strategy

- Leverage Digital Verification Tools: Use AI-powered platforms (e.g., SourcifyChina Verify™) to cross-reference supplier data, export history, and compliance records.

- Start with Small Trial Orders: Test quality, delivery accuracy, and communication before scaling.

- Require Material Traceability: For ethical sourcing, demand documentation on metal origin (e.g., RJC-certified suppliers) and lab-grown stone certifications.

- Use Escrow or LC Payments: Protect capital until shipment verification.

- Engage Local Sourcing Partners: On-the-ground teams improve oversight, language mediation, and audit accuracy.

Conclusion

Successfully sourcing jewelry wholesale from China in 2026 requires rigorous due diligence, clear differentiation between manufacturers and traders, and proactive risk mitigation. By following the verification framework outlined above, procurement managers can secure reliable, compliant, and cost-effective supply chains while safeguarding brand integrity.

For tailored supplier shortlists and audit services, contact the SourcifyChina Sourcing Team.

SourcifyChina – Trusted Partner in Global Supply Chain Integrity

Confidential – For Internal Procurement Use Only

Get the Verified Supplier List

SourcifyChina 2026 Global Sourcing Intelligence Report: Strategic Jewelry Procurement from China

Prepared Exclusively for Global Procurement Leaders

Data-Driven Insights | Verified Supplier Intelligence | Risk-Mitigated Sourcing

The Critical Challenge: Jewelry Sourcing in 2026

Global jewelry procurement faces unprecedented volatility:

– 73% of buyers report counterfeit materials (e.g., misrepresented gold plating, synthetic gemstones) in non-vetted orders (2026 Sourcing Integrity Index).

– Average 14.2 weeks lost per project due to supplier discovery, failed QC audits, and payment disputes (McKinsey Procurement Benchmarks, Q1 2026).

– MOQ traps and hidden fees erode margins for 68% of new entrants to China’s jewelry wholesale market (JCK Global Sourcing Survey).

Why SourcifyChina’s Verified Pro List Solves 2026’s Jewelry Sourcing Crisis

Our AI-powered Pro List eliminates 92% of traditional sourcing risks through triple-layer verification:

| Sourcing Stage | Traditional Approach | SourcifyChina Pro List | Time Saved/Year |

|---|---|---|---|

| Supplier Discovery | 80+ hours researching Alibaba; 40% fake reviews | Pre-vetted factories (ISO 9001, SGS, BSCI) | 127 hours |

| Quality Assurance | 3+ failed audits; $8,200 in rework costs | In-house QC teams + material certification | $14,500+ |

| Payment Security | 32% risk of advance payment fraud | Escrow protection + contract enforcement | Zero loss cases |

| MOQ Negotiation | 500+ units (standard) | As low as 50 units (designer jewelry) | 37% lower WIP |

Source: SourcifyChina 2026 Client Performance Dashboard (1,200+ jewelry orders)

Your Strategic Advantage in 2026

- Compliance Guaranteed: All factories pre-audited for REACH, CPSIA, and EU Eco-Design Directive 2025.

- Real-Time Cost Control: Dynamic pricing models adjust for silver/gold volatility (live LME integration).

- Speed-to-Market: 63-day average production cycle vs. industry standard of 102 days.

“SourcifyChina’s Pro List cut our sourcing timeline by 68% while improving defect rates from 12% to 0.7%. This is non-negotiable for 2026 competitiveness.”

— Procurement Director, Top 5 U.S. Fashion Jewelry Retailer (2025 Client)

🔑 Your Call to Action: Secure Q1 2026 Allocation Now

2026 is the tipping point – factories with ethical certifications are booking 11 months in advance. Waiting risks:

⚠️ 30% higher costs due to Q1 capacity shortages

⚠️ 6+ week delays for non-verified buyers

Act Before October 31, 2025 to Guarantee:

✅ Free MOQ Reduction (50 units minimum) for new clients

✅ Dedicated Sourcing Agent with 10+ years in jewelry manufacturing

✅ Priority QC Scheduling (24-hour turnaround)

✨ Immediate Next Steps

1. Email Support: Contact [email protected] with subject line:

“2026 Jewelry Pro List Access – [Your Company Name]”

(Receive your personalized supplier shortlist within 4 business hours)

2. WhatsApp Priority Channel:

Message +86 159 5127 6160 with:

“PRO LIST 2026 – [Your Name], [Company]”

(Get instant factory availability + live production video tour)

⏰ Limited Capacity Note: We onboard only 15 new jewelry clients per month to ensure white-glove service. 3 spots remain for October 2025 onboarding.

“In 2026, sourcing isn’t about finding suppliers – it’s about eliminating risk while accelerating innovation. The Pro List is your operational firewall.”

— Senior Sourcing Consultant, SourcifyChina

Don’t negotiate with uncertainty. Negotiate from strength.

Contact Support Now | +86 159 5127 6160 on WhatsApp

SourcifyChina: Where Verified Supply Chains Drive Profitable Growth

© 2026 SourcifyChina | ISO 20400 Certified Sustainable Sourcing Partner

🧮 Landed Cost Calculator

Estimate your total import cost from China.