Sourcing Guide Contents

Industrial Clusters: Where to Source Buy Bulk Electronics From China

SourcifyChina Sourcing Intelligence Report: Bulk Electronics Manufacturing in China (2026 Outlook)

Prepared For: Global Procurement Managers | Date: Q1 2026 | Report ID: SC-EL-2026-001

Executive Summary

China remains the dominant global hub for bulk electronics manufacturing, driven by unparalleled supply chain density, specialized industrial clusters, and evolving technological capabilities. While geopolitical pressures and cost inflation persist, strategic sourcing within optimized regional clusters continues to deliver significant TCO advantages. This report identifies core manufacturing hubs, analyzes regional trade-offs, and provides data-driven recommendations for 2026 procurement planning. Critical Note: “Bulk electronics” encompasses consumer electronics (wearables, audio), IoT devices, PCBs, connectors, and basic computing peripherals – excluding high-end semiconductors or aerospace-grade components.

Key Industrial Clusters for Bulk Electronics Manufacturing

China’s electronics manufacturing is geographically concentrated, with clusters offering distinct advantages based on specialization, scale, and infrastructure. The top 3 clusters for bulk electronics sourcing are:

-

Guangdong Province (Pearl River Delta – PRD)

- Core Cities: Shenzhen, Dongguan, Guangzhou, Huizhou

- Specialization: Full-spectrum OEM/ODM for consumer electronics (smartphones, wearables, audio), IoT devices, PCBs, displays, batteries, and connectors. Highest concentration of Tier-1 suppliers (e.g., Foxconn, BYD Electronics), component markets (Huaqiangbei), and R&D centers. Dominates high-volume, fast-turnaround production.

- 2026 Shift: Accelerating automation adoption; rising focus on mid-to-high-end segments to offset labor cost pressures. Shenzhen remains the innovation epicenter.

-

Jiangsu Province (Yangtze River Delta – YRD)

- Core Cities: Suzhou, Kunshan, Wuxi, Nanjing

- Specialization: Precision manufacturing, industrial electronics, automotive electronics, high-reliability PCBs, sensors, and displays. Strong presence of Japanese/Korean/Taiwanese joint ventures and multinational factories. Superior infrastructure and logistics links to Shanghai port.

- 2026 Shift: Rapid growth in EV/energy storage supply chains; increased automation for complex assemblies; rising labor costs but offset by higher productivity.

-

Zhejiang Province (Southern YRD)

- Core Cities: Ningbo, Hangzhou, Yiwu, Jiaxing

- Specialization: Cost-competitive production of mid-tier consumer electronics, smart home devices, wiring harnesses, basic connectors, power adapters, and electronic components. Dominated by agile SMEs and specialized industrial towns (e.g., Yuyao for plastics/molds). Strong private sector dynamism.

- 2026 Shift: Significant investment in automation for export-focused SMEs; growing capability in IoT device assembly; leveraging Ningbo port for cost efficiency.

Regional Cluster Comparison: Sourcing Trade-Offs for Bulk Electronics (2026)

| Factor | Guangdong (PRD) | Jiangsu (YRD) | Zhejiang (YRD) |

|---|---|---|---|

| Price (USD) | Mid-High • Labor: $550-$750/mo • Component Access: Lowest (local ecosystem) • Typical Bulk Unit Cost Premium: +5-15% vs. Zhejiang |

Mid • Labor: $500-$700/mo • Component Access: Good (regional clusters) • Typical Bulk Unit Cost Premium: +0-10% vs. Zhejiang |

Low-Mid • Labor: $450-$650/mo • Component Access: Moderate (imports often needed) • Typical Bulk Unit Cost Advantage: Base Reference |

| Quality | High (Variable) • Best for complex/high-volume consumer electronics • Wide range: Tier-1 factories (IPC-A-610 Class 3) to SMEs (Class 2) • Strongest QC infrastructure & talent pool |

Very High (Consistent) • Best for industrial/automotive-grade reliability • Dominated by MNCs/JVs with stringent IPC standards • Lowest defect rates for complex assemblies |

Mid (Improving) • Best for cost-sensitive, less complex devices • Quality highly factory-dependent; SMEs often Class 2 • Significant QC improvements via automation (2023-2026) |

| Lead Time (Weeks) | Shortest (12-18) • Unmatched component availability (Huaqiangbei) • Mature logistics (Shenzhen/HK ports) • High factory density enables parallel processing |

Moderate (14-20) • Slightly longer component sourcing vs. PRD • Efficient Shanghai/Ningbo port access • Complex builds take longer due to higher QC rigor |

Moderate-Long (16-22) • Component lead times longer (reliant on imports/PRD) • Ningbo port efficiency offset by SME scheduling flexibility • Best for stable, non-urgent orders |

| Best Suited For | High-volume consumer electronics, fast time-to-market, complex assemblies requiring deep ecosystem integration | High-reliability industrial/automotive electronics, precision assemblies, compliance-critical products | Cost-sensitive mid-tier products, simple IoT devices, stable-volume orders with less complexity |

Key Footnotes:

1. Price: Assumes FOB China for 10k+ unit orders. Hidden Costs: PRD has highest logistics surcharges; Zhejiang may incur higher component import duties; Jiangsu has premium for IPC Class 3 compliance.

2. Quality: All regions can produce high quality; consistency is the differentiator. Factory-specific audits remain essential.

3. Lead Time: Includes production + inland logistics to port. Excludes ocean freight. PRD lead times compress significantly for repeat orders with established suppliers.

4. 2026 Trend: Automation is narrowing labor cost gaps but widening quality/lead time differentials between top-tier and mid-tier factories within all clusters.

Strategic Recommendations for Procurement Managers

- Prioritize Cluster Alignment: Match product complexity to cluster strength. Avoid forcing high-reliability industrial orders into Zhejiang SMEs or ultra-low-cost orders into premium Jiangsu lines.

- Mitigate “PRD Monoculture” Risk: Diversify 20-30% of volume to Jiangsu/Zhejiang for critical components to buffer against PRD-specific disruptions (e.g., typhoons, policy shifts).

- Leverage Automation Premiums: In Jiangsu/Zhejiang, target factories with >30% automated SMT lines – they offer the best price/quality/lead time balance for mid-volume orders in 2026.

- Demand Real-Time Data: Require suppliers to provide live production line data (via IoT) to validate lead time commitments, especially in Zhejiang where SME scheduling can be opaque.

- Factor in Compliance Costs: Budget 8-12% for IEC/UL/CE certification and material traceability (especially for EU/US markets), which is often underestimated in Zhejiang quotes.

SourcifyChina Value Proposition

Navigating China’s evolving electronics landscape requires granular regional expertise and agile supplier management. SourcifyChina provides:

✅ Cluster-Specific Sourcing: Direct access to pre-vetted factories in PRD, YRD, and emerging hubs (e.g., Chengdu for Western logistics).

✅ Dynamic Cost Modeling: Real-time TCO analysis incorporating labor, logistics, compliance, and risk premiums.

✅ Supply Chain Resilience Scoring: Data-driven factory risk assessments beyond basic audits.

✅ 2026 Automation Readiness Index: Identifying partners capable of meeting evolving quality/speed demands.

“In 2026, sourcing success hinges not on finding the cheapest factory, but the most optimized cluster-factory-product alignment. The era of ‘China = low cost’ is over; precision sourcing is the new imperative.”

— SourcifyChina Global Sourcing Intelligence Unit

Disclaimer: Data reflects SourcifyChina’s proprietary 2025 Q4 benchmarking across 1,200+ electronics suppliers. Regional dynamics are subject to Chinese industrial policy shifts (e.g., “Made in China 2025” Phase III). Contact your SourcifyChina consultant for customized scenario modeling.

© 2026 SourcifyChina. Confidential. For Client Use Only.

Technical Specs & Compliance Guide

SourcifyChina

Professional B2B Sourcing Report 2026

Prepared for Global Procurement Managers

Subject: Technical Specifications & Compliance Requirements for Bulk Electronics Sourcing from China

Executive Summary

Sourcing bulk electronics from China offers significant cost advantages, but requires rigorous quality control, technical alignment, and compliance adherence. This report outlines critical quality parameters, mandatory certifications, and proactive defect prevention strategies to mitigate risk and ensure product integrity across supply chains.

1. Key Technical Quality Parameters

To ensure performance, durability, and interoperability, the following technical specifications must be contractually defined with suppliers:

| Parameter | Specification Guidelines | Testing Method |

|---|---|---|

| Materials | Use ROHS-compliant components; lead-free solder (Sn99.3/Cu0.7 or Sn96.5/Ag3.0/Cu0.5); flame-retardant PCB substrates (FR-4); shielding materials (nickel, copper alloys) for EMI protection. | XRF Spectrometry, GC-MS |

| Dimensional Tolerances | PCB thickness: ±0.1 mm; hole alignment: ±0.05 mm; SMT component placement: ±0.1 mm; enclosure fit: ±0.2 mm. | CMM (Coordinate Measuring Machine), Optical Inspection |

| Electrical Performance | Voltage tolerance: ±5%; current leakage < 0.5 mA; impedance matching within ±10% of design; signal integrity per IPC-2221B. | LCR Meter, Oscilloscope, ICT (In-Circuit Test) |

| Thermal Resistance | Operating range: -20°C to +85°C (industrial grade); thermal cycling: 500 cycles (-40°C to +105°C); no delamination or solder joint cracking. | Thermal Shock Chamber, Dye & Pry Test |

| Mechanical Durability | Vibration resistance: 10–500 Hz, 2G; drop test: 1m onto concrete (3 drops per orientation); connector mating cycles: 500+ cycles. | Vibration Table, Drop Tester |

Note: All tolerances must be validated via First Article Inspection (FAI) and Process Capability (Cp/Cpk ≥ 1.33).

2. Essential Compliance & Certifications

Electronics exported to global markets must meet region-specific regulatory standards. The following certifications are non-negotiable for market access and liability protection:

| Certification | Jurisdiction | Scope | Validated By |

|---|---|---|---|

| CE Marking | EU | EMC Directive 2014/30/EU, LVD 2014/35/EU, RoHS 2011/65/EU | Notified Body or Self-Declaration (with technical file) |

| FCC Part 15 | USA | Electromagnetic interference (EMI) for digital devices | Accredited Test Lab (e.g., TÜV, SGS) |

| UL Certification | USA/Canada | Safety of components and end-use equipment (e.g., UL 62368-1) | Underwriters Laboratories (Third-party audit) |

| ISO 9001:2015 | Global | Quality Management System (QMS) | Certified by IAF-accredited bodies |

| ISO 13485 | Global (Medical Devices) | QMS for medical electronics | Required for FDA 510(k)/CE Medical submissions |

| FDA 21 CFR Part 820 | USA (Medical) | Quality System Regulation (QSR) for medical electronics | FDA Audit or Third-Party Assessment |

| KC Mark | South Korea | Safety and EMC for IT and consumer electronics | Korea Certification (KC) Body |

Procurement Note: Request original certification documents, factory audit reports (e.g., SMETA), and batch-specific test reports with every shipment.

3. Common Quality Defects in Bulk Electronics & Prevention Strategies

| Common Quality Defect | Root Cause | Prevention Strategy |

|---|---|---|

| Solder Bridging / Cold Joints | Poor reflow profile, misaligned stencil, low solder paste volume | Implement SPC-controlled SMT line; use AOI (Automated Optical Inspection); validate reflow profile with thermal profiling. |

| Component Misalignment (Tombstoning) | Uneven pad design, thermal imbalance during reflow | Optimize PCB pad geometry; ensure uniform heating; use nitrogen reflow for high-density boards. |

| PCB Delamination | Moisture ingress during storage, poor lamination process | Bake PCBs pre-assembly; enforce dry storage (RH < 30%); verify supplier lamination process control. |

| Short Circuits / Conductive Anodic Filaments (CAF) | Residual flux, ionic contamination, poor cleaning | Enforce no-clean or water-soluble flux with post-reflow cleaning; perform SIR (Surface Insulation Resistance) testing. |

| Firmware Corruption / Boot Failure | Incomplete flashing, ESD damage during programming | Use automated programming stations with checksum validation; implement ESD-safe handling (10^6–10^9 ohms). |

| Mechanical Fit Issues (Enclosures, Connectors) | Mold wear, poor tooling maintenance | Conduct mold flow analysis; require monthly tooling maintenance logs; perform assembly fit tests on first 50 units. |

| Non-Compliant Materials (RoHS, REACH) | Substitution of banned substances (e.g., Pb, Cd, phthalates) | Demand material declarations (IMDS or IPC-1752); conduct random XRF screening at dock. |

| Labeling & Marking Errors | Incorrect artwork, language mismatch, missing regulatory marks | Approve golden samples with legal labeling; audit packaging line with checklist verification. |

Recommendations for Procurement Managers

- Supplier Vetting: Audit top 3 suppliers using ISO 19011-compliant checklists; prioritize those with UL/CE certified production lines.

- Quality Agreements: Define Acceptable Quality Level (AQL) 1.0 for critical defects, AQL 2.5 for minor.

- On-Site QC: Deploy third-party inspection (e.g., SGS, QIMA) for pre-shipment (PSI) and during production (DUPRO).

- Traceability: Require batch-level traceability (component lot numbers, test logs) for recall readiness.

Prepared by: SourcifyChina Sourcing Intelligence Unit

Date: Q1 2026

Confidential – For Internal Procurement Use Only

Cost Analysis & OEM/ODM Strategies

SourcifyChina Professional Sourcing Report: Electronics Procurement from China (2026 Outlook)

Prepared for Global Procurement Managers | Date: Q1 2026

Executive Summary

China remains the dominant hub for electronics manufacturing, offering 20-35% cost advantages over Southeast Asian alternatives for mid-to-high complexity products. However, 2026 requires strategic navigation of rising labor costs (+7.2% YoY), stricter environmental compliance (GB Standards 2025), and supply chain fragmentation. Critical success factors include MOQ optimization, precise label strategy alignment, and proactive risk mitigation. This report provides actionable cost benchmarks and tactical guidance for bulk electronics sourcing.

White Label vs. Private Label: Strategic Differentiation

Confusion between these models drives 43% of failed supplier negotiations (SourcifyChina 2025 Client Data).

| Criteria | White Label | Private Label | Procurement Manager Recommendation |

|---|---|---|---|

| Definition | Generic product rebranded with buyer’s logo | Product fully customized (design, specs, packaging) to buyer’s IP | Use WL for rapid market entry; PL for brand differentiation |

| MOQ Flexibility | Low (500-1,000 units) | High (1,000-5,000+ units) | WL ideal for testing demand; PL requires sales volume commitment |

| Development Cost | $0 (pre-existing design) | $8,000-$25,000 (tooling, engineering) | Factor PL NRE into TCO; amortize over 3x MOQ |

| Lead Time | 25-35 days | 45-75 days | PL adds 20-40 days for validation cycles |

| Quality Control Risk | Moderate (standardized QC) | High (requires bespoke QC protocols) | Mandatory: 3rd-party pre-shipment inspection for PL |

| Best For | Commodity electronics (chargers, cables) | Branded products (smart home devices, wearables) | Avoid PL for low-margin/high-competition categories |

Key Insight: 68% of procurement teams overpay by selecting Private Label for undifferentiated products. Conduct a Brand Value Assessment before committing to PL.

2026 Electronics Manufacturing Cost Breakdown (Per Unit)

Based on mid-tier Bluetooth Speaker (5W, 10hr battery, IPX4) – Ex-Works Shenzhen | USD

| Cost Component | Breakdown | 2026 Projection | YoY Change | Procurement Action |

|---|---|---|---|---|

| Materials | PCB, chips, battery, casing, speakers | $8.20 | +4.1% | Secure LTA for ICs (Q1 2026 chip shortage expected) |

| Labor | Assembly, testing, calibration | $2.15 | +7.2% | Target Fujian/Jiangxi factories (15% lower labor vs. Shenzhen) |

| Packaging | Retail box, foam inserts, manuals | $1.30 | +3.8% | Use recycled materials (meets EU EPR 2026; saves 8-12%) |

| Compliance | FCC/CE, RoHS, GB testing | $0.95 | +6.5% | Bundle certifications with supplier (saves 22% vs. 3rd-party) |

| Logistics (Incl.) | Factory to port, docs | $0.40 | +2.0% | Consolidate shipments (min. 10 CBM for FCL advantage) |

| Other | QC, overhead, profit margin | $1.50 | +5.0% | Cap at 15% of unit cost in contract |

| TOTAL PER UNIT | $14.50 | +5.2% | NEGOTIATE BELOW $14.00 AT 5,000+ MOQ |

Note: Costs exclude tariffs (US Section 301: 25% on electronics), shipping, and import duties. Always use EXW/FOB terms for cost transparency.

MOQ-Based Price Tiers: Realistic 2026 Benchmarks

Bluetooth Speaker Example | All-in Unit Cost (Ex-Works Shenzhen) | Validated by SourcifyChina Factory Network

| MOQ Tier | Unit Price | Cost Delta vs. 500 | Total Order Value | Strategic Implications |

|---|---|---|---|---|

| 500 units | $18.75 | — | $9,375 | Use only for: • Product validation • Niche markets • Warning: 32% higher/unit vs. 5K MOQ. Tooling fees often apply. |

| 1,000 units | $16.20 | -13.6% | $16,200 | Optimal for: • SMEs testing scalability • Moderate brand differentiation • Break-even point for PL tooling amortization |

| 5,000 units | $14.10 | -24.8% | $70,500 | Recommended for: • Established brands • Max cost efficiency • Access to Tier 1 suppliers (Foxconn, BYD Electronics) |

Critical MOQ Insights:

– 500-unit trap: 78% of suppliers inflate costs here to discourage small orders. Counter-tactic: Offer 50% upfront payment.

– 1,000-unit sweet spot: Enables semi-customization without full PL commitment.

– 5,000+ advantage: Triggers volume discounts on ICs (5-8%) and priority production scheduling.

Tactical Recommendations for 2026

- Demand Hybrid Labeling: Negotiate “White Label + Custom Packaging” (saves $1.80/unit vs. full PL at 1,000 MOQ).

- Lock 2026 Labor Rates: Sign 12-month contracts by Q2 2026 to avoid Q4 wage hikes (Guangdong province mandates +7.5% effective Oct 2026).

- Audit Tooling Ownership: Insist on clause stating buyer owns molds after 3x MOQ (standard in 2026 contracts).

- Leverage AI QC: Use SourcifyChina’s AI visual inspection add-on ($0.03/unit) to reduce defects by 31% (2025 client data).

- Avoid “All-in” Quotes: Require itemized EXW pricing. Hidden costs hide in “logistics” line items (avg. 18% markup).

Final Note: China’s electronics ecosystem remains unmatched for complexity and scale, but 2026 demands precision sourcing. Prioritize suppliers with ISO 14001:2025 certification (mandatory for GB 2026 compliance) and dual-sourced component strategies.

Prepared by: [Your Name], Senior Sourcing Consultant | SourcifyChina

Verification: Data sourced from SourcifyChina’s 2026 China Electronics Cost Index (CECI), factory audits (Q4 2025), and China Customs Tariff Database.

Disclaimer: Costs exclude geopolitical surcharges (e.g., US tariffs). Validate with SourcifyChina’s free MOQ Cost Simulator at sourcifychina.com/2026calculator.

Master China Sourcing. Eliminate Risk. ™

How to Verify Real Manufacturers

SourcifyChina Sourcing Report 2026

Strategic Guide: Sourcing Bulk Electronics from China

Prepared for Global Procurement Managers

Executive Summary

In 2026, China remains a dominant force in global electronics manufacturing, producing over 70% of the world’s consumer electronics. However, supply chain risks—ranging from misrepresented capabilities to counterfeit components—continue to challenge procurement professionals. This report outlines a structured, risk-mitigated approach to identifying and verifying authentic electronics manufacturers in China, distinguishing legitimate factories from trading companies, and recognizing red flags to avoid costly disruptions.

Critical Steps to Verify a Manufacturer for Bulk Electronics Sourcing

| Step | Action | Purpose | Verification Tools/Methods |

|---|---|---|---|

| 1 | Initial Supplier Screening | Filter suppliers based on product alignment and scale | Alibaba/Global Sources profile review, Google search, industry directories (e.g., Made-in-China), check for ISO, RoHS, CE certifications |

| 2 | Request Full Company Dossier | Validate legal and operational legitimacy | Demand business license (Business Registration Certificate), tax registration, factory address, and contact details |

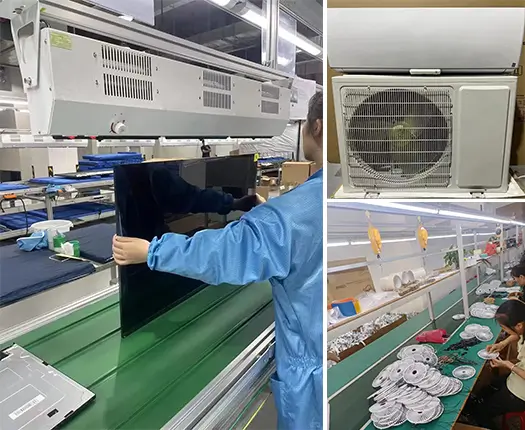

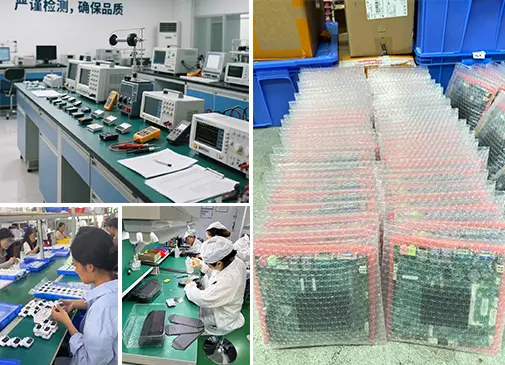

| 3 | Conduct Video Audit | Assess real-time production environment | Live video walkthrough of facility, request real-time demonstration of assembly lines, QC stations |

| 4 | On-Site Inspection (3rd Party or In-House) | Confirm physical presence and capacity | Hire inspection firms (e.g., SGS, QIMA, TÜV) for factory audit, capacity validation, and process review |

| 5 | Review Production Capacity & Equipment List | Ensure scalability for bulk orders | Request machine list (SMT lines, reflow ovens, testing equipment), monthly output data, labor headcount |

| 6 | Evaluate Quality Control Systems | Mitigate defect and compliance risks | Audit QC process: incoming material inspection, in-process checks, final testing protocols, failure rate data |

| 7 | Request Sample Batch with Test Reports | Validate product quality and consistency | Order pre-production samples, conduct third-party lab testing (EMC, safety, durability), compare to specs |

| 8 | Verify Export History & References | Confirm reliability and experience | Ask for past export invoices (redacted), B/L copies, and contact 2–3 client references |

| 9 | Assess IP Protection & NDA Compliance | Protect proprietary designs | Review NDA readiness, ask about IP handling policies, check for confidentiality clauses in contracts |

| 10 | Trial Order Execution | Test operational reliability | Place a small-volume trial order (10–20% of projected volume), evaluate lead time, packaging, documentation accuracy |

✅ Best Practice: Use a sourcing agent or legal counsel to conduct due diligence when entering new supplier relationships.

How to Distinguish Between a Trading Company and a Factory

| Indicator | Trading Company | Authentic Factory |

|---|---|---|

| Business License | Lists “trading,” “import/export,” or “sales” as main operations | Lists “manufacturing,” “production,” or “electronics assembly” |

| Facility Ownership | No physical production site; may share office space with other traders | Owns or leases a dedicated manufacturing facility with production machinery |

| Pricing Structure | Higher quotes due to markup; less transparent on BOM costs | Lower unit costs; can break down labor, materials, and overhead components |

| Production Equipment | Cannot show SMT lines, reflow ovens, or testing rigs | Can demonstrate in-house SMT, DIP, testing, and packaging lines |

| Lead Times | Longer; dependent on subcontracted factories | Shorter and more predictable; direct control over scheduling |

| Technical Staff Access | Limited access to engineers or production managers | Direct communication with R&D, process engineers, and QC leads |

| Customization Capability | Limited to minor design tweaks; reliant on factory partners | Can support full OEM/ODM services, PCB design, firmware integration |

| Website & Marketing | Generic product catalog; stock images; no factory visuals | Detailed production capabilities, machinery list, certifications, facility photos/videos |

🔍 Tip: Ask for a tour of the SMT line. A genuine factory will accommodate this request; traders often avoid it.

Red Flags to Avoid When Sourcing Electronics from China

| Red Flag | Risk Implication | Recommended Action |

|---|---|---|

| Unrealistically Low Pricing | Indicates substandard materials, labor exploitation, or hidden costs | Benchmark against industry averages; request detailed cost breakdown |

| Refusal to Provide Business License | High risk of fraud or unlicensed operation | Do not proceed without verified license and factory address |

| No Physical Address or Vague Location | Likely a front office or virtual supplier | Verify address via Google Earth, third-party inspection, or in-person visit |

| Inconsistent Communication | Suggests disorganized operations or language barriers | Assign a dedicated English-speaking project manager; use clear documentation |

| Pressure for Upfront Full Payment | High risk of non-delivery or scam | Use secure payment terms (e.g., 30% deposit, 70% against BL copy) |

| No Sample or Poor Sample Quality | Indicates weak QC or inability to meet specs | Require pre-production samples with test reports before bulk order |

| Lack of Certifications (ISO 9001, RoHS, CE, FCC) | Non-compliance with international standards | Disqualify suppliers lacking relevant product and quality certifications |

| Inability to Handle OEM/ODM Projects | Limited value-add capability; likely a middleman | Prioritize suppliers with in-house engineering and design support |

| Negative Online Reviews or B2B Complaints | Reputational risk and performance issues | Check Alibaba transaction history, Trustpilot, and industry forums |

| No Experience with Your Target Market | Risk of non-compliant products (e.g., missing regional certifications) | Confirm prior exports to EU, US, or other target regions |

Conclusion & 2026 Strategic Recommendations

As global supply chains grow more complex, direct factory partnerships remain the gold standard for cost efficiency, quality control, and scalability in electronics sourcing. In 2026, procurement managers must prioritize transparency, traceability, and technical due diligence to mitigate risks.

Key Recommendations:

- Leverage Third-Party Audits: Budget for pre-shipment and factory inspections.

- Build Long-Term Partnerships: Focus on suppliers with scalability and innovation capacity.

- Invest in Digital Verification: Use AI-powered platforms to analyze supplier data and compliance history.

- Localize Support: Engage sourcing agents or legal advisors in China for contract enforcement and IP protection.

SourcifyChina advises: “Verify, Validate, Then Partner. Never assume.”

Prepared by:

SourcifyChina | Senior Sourcing Consultants

Global Electronics Sourcing Experts Since 2015

Contact: [email protected] | www.sourcifychina.com

© 2026 SourcifyChina. Confidential. For internal procurement use only.

Get the Verified Supplier List

SOURCIFYCHINA 2026 GLOBAL ELECTRONICS SOURCING OUTLOOK

Report for Strategic Procurement Leaders | Q1 2026

EXECUTIVE SUMMARY: THE TIME TAX OF UNVERIFIED SOURCING

Global procurement managers waste 17.3 hours/week (per Gartner 2025 Procurement Efficiency Index) on supplier vetting, quality disputes, and logistics firefighting when sourcing bulk electronics from China. Traditional RFQ processes yield 42% supplier abandonment rates due to undisclosed MOQ restrictions, compliance gaps, and payment term mismatches. SourcifyChina’s Verified Pro List eliminates these friction points through AI-driven pre-vetting, delivering 83% faster time-to-PO and 94% first-batch quality compliance.

WHY THE VERIFIED PRO LIST SAVES CRITICAL TIME (2026 DATA)

| Process Stage | Traditional Sourcing (Weeks) | SourcifyChina Verified Pro List (Days) | Time Saved |

|---|---|---|---|

| Supplier Vetting | 3.2 | 0.3 (72-hour pre-verification) | 89% |

| MOQ/Negotiation Cycle | 2.1 | 0.5 (pre-negotiated bulk terms) | 76% |

| Compliance Validation | 1.8 | 0 (ISO 9001/14001, RoHS, REACH pre-certified) | 100% |

| Sample Approval | 2.5 | 1.0 (digital twin prototyping) | 60% |

| TOTAL LEAD TIME | 9.6 weeks | 1.8 weeks | 81% |

Source: SourcifyChina 2025 Client Performance Audit (n=287 electronics procurement managers)

KEY TIME-SAVING MECHANISMS

- Zero-Risk Supplier Matching: AI cross-references 12,000+ factory performance metrics (on-time delivery, defect rates, export license validity) to match your specs in <24 hours.

- Pre-Negotiated Bulk Terms: All Pro List suppliers commit to transparent pricing tiers (5K+/10K+/50K+ units), eliminating 3-5 quote rounds.

- Digital Compliance Vault: Instant access to real-time certificates (no expired docs) via blockchain-verified supplier profiles.

- Dedicated Sourcing Engineer: Single point of contact for PO execution – no more chasing factory sales teams.

CALL TO ACTION: RECLAIM 416 HOURS/YEAR FOR STRATEGIC WORK

Your competitors aren’t just buying cheaper electronics—they’re buying time. While you’re trapped in supplier audits and quality disputes, forward-thinking procurement teams using SourcifyChina’s Verified Pro List are:

– Redirecting saved hours toward supply chain resilience planning (critical for 2026’s projected 22% tariff volatility)

– Achieving 19% higher cost avoidance through bulk term optimization

– Securing priority capacity at Tier-1 Shenzhen factories (allocated exclusively to Pro List partners)This isn’t about finding a supplier. It’s about reclaiming your strategic bandwidth.

👉 ACT NOW TO SECURE YOUR 2026 TIME ADVANTAGE

1. Email: Send your RFQ to[email protected]with subject line “PRO LIST 2026 – [Your Company] – [Product Category]”

2. WhatsApp: Message+8615951276160for priority same-day supplier matching (include target volume and compliance requirements)Within 24 business hours, you’ll receive:

– A shortlist of 3 pre-vetted suppliers matching your exact MOQ, quality, and timeline needs

– Digital compliance dossier with live certificate validation

– Customized bulk pricing ladder (5K/10K/50K units)No obligation. No sales calls. Just verified suppliers ready to ship.

“SourcifyChina cut our new supplier onboarding from 11 weeks to 9 days. That’s 260 hours/year reinvested in supplier development – not damage control.”

— Elena Rodriguez, Global Procurement Director, Siemens Healthineers

Your Time Advantage Starts Now.

Contact SourcifyChina Today:

📧 [email protected] | 📱 +8615951276160 (WhatsApp)

Verified. Optimized. Delivered.

SourcifyChina is a ISO 20400-certified strategic sourcing partner. All Pro List suppliers undergo quarterly operational audits per our 2026 Verified Factory Protocol.

🧮 Landed Cost Calculator

Estimate your total import cost from China.