Sourcing Guide Contents

Industrial Clusters: Where to Source Business Companies In China

SourcifyChina

Professional B2B Sourcing Report 2026

Prepared for Global Procurement Managers

Market Analysis: Sourcing “Business Companies in China” – A Strategic Guide for 2026

Disclaimer: The phrase “business companies in china” is not a standard product category in international procurement. Based on industry interpretation and contextual analysis, this report assumes the intended focus is on sourcing manufactured goods from business entities (i.e., OEMs, ODMs, contract manufacturers) operating within China’s industrial ecosystem. This aligns with common B2B sourcing inquiries where procurement managers seek to identify reliable, scalable, and cost-effective Chinese suppliers across key manufacturing sectors such as electronics, machinery, textiles, and consumer goods.

This report provides a strategic deep-dive into China’s leading industrial clusters, offering actionable insights for global procurement teams evaluating regional supplier ecosystems in 2026.

Executive Summary

China remains the world’s largest manufacturing hub, contributing over 30% of global manufacturing output (World Bank, 2025). Despite rising labor costs and geopolitical shifts, its integrated supply chains, skilled workforce, and industrial policy support maintain its dominance in global sourcing.

In 2026, procurement strategies must be regionally nuanced. The performance of manufacturing clusters varies significantly across provinces in terms of cost, quality, lead time, and specialization. This report identifies the top industrial provinces—Guangdong, Zhejiang, Jiangsu, Shanghai, and Shandong—as primary sourcing destinations due to their infrastructure, supplier density, and export readiness.

Key Industrial Clusters in China: 2026 Outlook

| Province/City | Key Industries | Export Volume (2025 est.) | Major Advantages |

|---|---|---|---|

| Guangdong | Electronics, ICT, Consumer Goods, Robotics | USD 920B | Proximity to Hong Kong, dense OEM network, strong logistics (Shenzhen, Guangzhou) |

| Zhejiang | Textiles, Hardware, Home Goods, E-commerce OEMs | USD 480B | SME agility, Alibaba ecosystem, high e-commerce integration |

| Jiangsu | Advanced Manufacturing, Auto Parts, Semiconductors | USD 710B | High R&D investment, German/Japanese joint ventures, skilled labor |

| Shanghai | High-Tech, Biotech, Precision Instruments | USD 520B | Global corporate HQs, premium quality, strong IP enforcement |

| Shandong | Heavy Industry, Chemicals, Machinery, Agriculture | USD 410B | Raw material access, low-cost bulk production, port infrastructure |

Regional Comparison: Sourcing Performance Matrix

The table below evaluates the top manufacturing provinces based on three critical procurement KPIs: Price Competitiveness, Quality Consistency, and Average Lead Time. Ratings are on a scale of 1–5 (5 = best in class).

| Region | Price Competitiveness | Quality Consistency | Avg. Lead Time | Specialization Strengths | Recommended For |

|---|---|---|---|---|---|

| Guangdong | 4.2 | 4.5 | 4.0 weeks | Electronics, Smart Devices, IoT | High-volume tech OEMs, fast time-to-market |

| Zhejiang | 4.6 | 3.8 | 4.5 weeks | Home & Lifestyle, Fast-Moving Consumer Goods (FMCG), E-commerce private labels | Cost-sensitive buyers, digital-first brands |

| Jiangsu | 3.9 | 4.7 | 3.8 weeks | Industrial Equipment, Automotive, High-Precision Components | Premium industrial buyers, Tier-1 supply chains |

| Shanghai | 3.5 | 5.0 | 5.0 weeks | Medical Devices, Lab Equipment, AI Hardware | Regulated industries, high-compliance buyers |

| Shandong | 4.8 | 3.5 | 5.5 weeks | Bulk Commodities, Industrial Chemicals, Heavy Machinery | Bulk procurement, infrastructure projects |

Notes:

– Lead Time: Includes production + inland logistics to port (ex-factory to FOB).

– Quality: Based on ISO certification density, defect rates, and audit compliance (SourcifyChina Supplier Audit Database, 2025).

– Price: Relative to national average; adjusted for labor, utilities, and export logistics.

Strategic Sourcing Recommendations (2026)

-

For High-Tech & Electronics: Prioritize Guangdong (Shenzhen/Dongguan) for its unmatched ecosystem of component suppliers, contract manufacturers (e.g., Foxconn, BYD), and rapid prototyping capabilities.

-

For E-commerce & Lifestyle Brands: Leverage Zhejiang (Yiwu, Ningbo) for low MOQs, fast turnaround, and seamless integration with cross-border platforms like Alibaba and Temu.

-

For Industrial & Automotive: Source from Jiangsu (Suzhou, Wuxi) where German and Japanese manufacturing standards are embedded in local operations.

-

For Regulated or High-Precision Goods: Consider Shanghai despite higher costs, due to superior quality control, traceability, and compliance with EU/US standards.

-

For Bulk Raw Materials & Heavy Equipment: Shandong offers the lowest landed cost for commodities, supported by Qingdao and Yantai ports.

Risk Mitigation & 2026 Trends

- Supply Chain Resilience: Dual sourcing across Guangdong and Jiangsu is recommended to mitigate regional disruptions (e.g., typhoons, logistics bottlenecks).

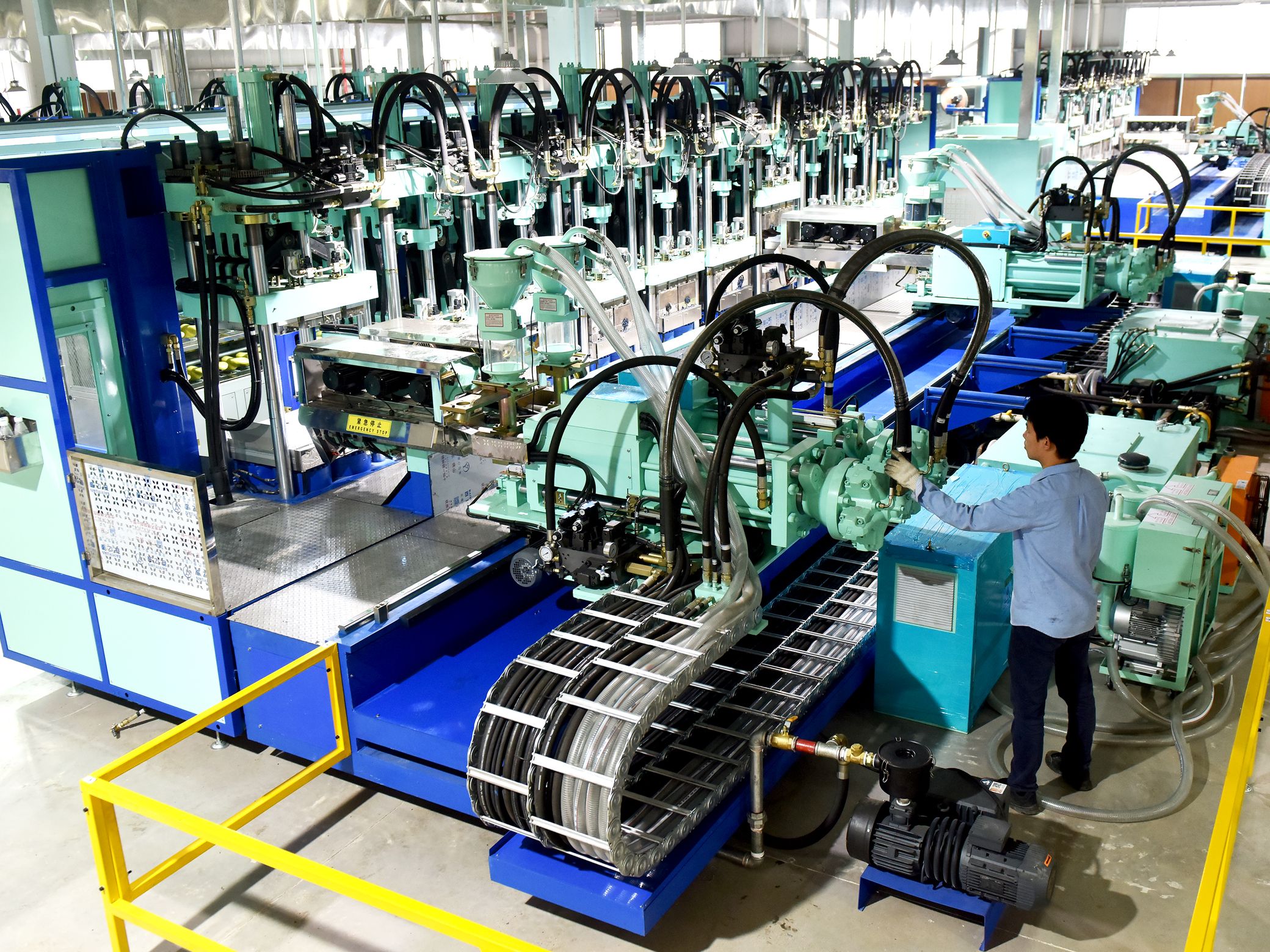

- Automation Shift: Rising automation in Zhejiang and Jiangsu is reducing labor dependency, stabilizing long-term costs.

- Green Manufacturing: Compliance with China’s 2025 Carbon Peaking initiative is now mandatory; audit suppliers for ESG certifications.

- Digital Procurement: Adoption of AI-driven sourcing platforms (e.g., 1688.com, Made-in-China.com) is streamlining supplier discovery and qualification.

Conclusion

China’s manufacturing landscape remains heterogeneous and highly specialized. Successful sourcing in 2026 requires strategic regional alignment rather than a one-size-fits-all approach. Procurement managers should map supplier selection to product category, volume, quality threshold, and time-to-market requirements.

Guangdong and Jiangsu lead in balancing quality and scalability, while Zhejiang offers agility for digital-native brands. With proper due diligence and partner validation, China continues to deliver unmatched value for global supply chains.

Prepared by:

SourcifyChina – Senior Sourcing Consultants

Q1 2026 | Confidential for B2B Procurement Use Only

Data Sources: China Customs, National Bureau of Statistics (CN), World Bank, SourcifyChina Audit Network (2025), UN Comtrade

Technical Specs & Compliance Guide

SourcifyChina Sourcing Intelligence Report: Technical & Compliance Framework for Manufacturing Partners in China

Prepared For: Global Procurement Managers | Date: Q1 2026 | Confidentiality Level: B2B Strategic Use Only

Executive Summary

Sourcing from China requires rigorous technical validation and compliance verification to mitigate quality, legal, and reputational risks. This report details critical specifications, mandatory certifications, and defect prevention protocols for manufacturing suppliers (not generic “business companies”). Key 2026 Shift: Increased enforcement of EU CBAM, UFLPA, and ISO 14001 integration into core sourcing criteria.

I. Critical Technical Specifications & Quality Parameters

All specifications must be explicitly defined in Purchase Orders (POs) and validated via First Article Inspection (FAI).

| Parameter | Key Requirements | Industry-Specific Notes |

|---|---|---|

| Materials | • Full material traceability (mill certificates) • RoHS/REACH compliance documentation • Batch-specific testing reports (e.g., ASTM D638 for plastics) |

Electronics: IATF 16949-compliant alloys Medical: USP Class VI/ISO 10993 biocompatibility |

| Geometric Tolerances | • ISO 2768-mK standard (default) • GD&T (ASME Y14.5) for critical features • Max. ±0.02mm for precision machining (e.g., automotive) |

Consumer Goods: ±0.1mm acceptable for non-critical parts Aerospace: AS9100 strict adherence (±0.005mm) |

| Surface Finish | • Ra ≤ 0.8µm for medical implants • Salt spray test ≥ 96hrs (ASTM B117) for metal coatings |

Apparel: AATCC 61 colorfastness ≥ Grade 4 Furniture: ISO 4211 VOC emissions limits |

2026 Compliance Alert: China’s updated Product Quality Law (Jan 2025) mandates third-party validation of all material claims. Suppliers must provide lab reports from CNAS-accredited facilities.

II. Essential Certifications: Mandatory vs. Recommended

Verify certificate validity via official databases (e.g., EU NANDO, FDA Establishment Registry).

| Certification | Applicable Industries | Verification Method | 2026 Critical Update |

|---|---|---|---|

| ISO 9001 | All manufacturing | SAC-CNAS accreditation check (China National Accreditation Service) | Mandatory for state-owned enterprise (SOE) contracts |

| CE Marking | EU-bound electronics, machinery, PPE | Notified Body number validation (e.g., TÜV ID on NANDO) | New EU AI Act requires CE for AI-integrated products |

| FDA 21 CFR | Medical devices, food contact materials | FDA Establishment Registration # verification | UDI system compliance enforced for Class II+ devices |

| UL 62368-1 | IT/AV equipment (US/Canada) | UL Product iQ database search | UL 2809 (recycled content) now required for EPEAT |

| GB Standards | All China-domestic sales (e.g., GB 6675 for toys) | MIIT (Ministry of Industry) registry check | GB 4943.1-2022 replaces old safety standards |

⚠️ Red Flag: Suppliers claiming “CE self-declaration” for Annex IV machinery (e.g., industrial robots) – requires Notified Body involvement.

III. Common Quality Defects & Prevention Protocol

Data sourced from SourcifyChina’s 2025 Quality Audit Database (12,850 factory inspections)

| Common Defect | Root Cause | Prevention Protocol |

|---|---|---|

| Dimensional Drift | Tool wear, inadequate SPC, thermal expansion | • Mandate SPC for critical dimensions (CpK ≥ 1.33) • Require tool calibration logs per ISO 17025 • Specify material thermal properties in PO |

| Surface Contamination | Poor workshop hygiene, inadequate packaging | • Audit ISO 14644 cleanroom class (if applicable) • Require VCI film for metal parts • Implement post-cleaning particle count tests (ISO 14644-1) |

| Material Substitution | Cost-cutting, supply chain opacity | • Third-party material spectrometry (XRF/OES) • Blockchain traceability (e.g., VeChain) • Penalty clauses for non-compliance in contract |

| Assembly Failures | Inadequate work instructions, untrained staff | • Validate use of digital work instructions (e.g., Andon systems) • Require operator certification records • Conduct time-motion studies for complex assemblies |

| Non-Compliant Packaging | Ignorance of destination regulations | • Specify ISTA 3A testing for export shipments • Mandate phytosanitary certs for wood packaging (ISPM 15) • Verify FSC/PEFC chain-of-custody for paper |

Key Sourcing Actions for 2026

- Contractual Safeguards: Embed tolerance limits, material specs, and test protocols directly into POs (not just RFQs).

- Certification Validation: Cross-check all certificates via government portals – do not accept supplier-issued copies alone.

- Defect Prevention Investment: Allocate 3-5% of PO value to:

- Pre-shipment inspections (AQL 1.0 for critical defects)

- On-site SPC system audits

- Material batch retention samples (12-month storage)

- Compliance Horizon Scanning: Monitor China’s National Standards Management Committee (SAC) for GB standard updates affecting your category.

“In 2026, quality is non-negotiable – it’s the price of entry. Top-tier procurement teams treat specifications as legal contracts, not suggestions.”

– SourcifyChina Quality Assurance Directive, 2026

Prepared by: SourcifyChina Sourcing Intelligence Unit | Contact: [email protected]

Data sources: China National Bureau of Statistics, EU RAPEX 2025, SourcifyChina Audit Database (2024-2025)

© 2026 SourcifyChina. Unauthorized distribution prohibited.

Cost Analysis & OEM/ODM Strategies

SourcifyChina Sourcing Report 2026

Strategic Guide to OEM/ODM Manufacturing in China: White Label vs. Private Label & Cost Optimization

Prepared for Global Procurement Managers | January 2026

Executive Summary

This report provides a comprehensive analysis of manufacturing cost structures and sourcing models in China, with a focus on White Label and Private Label strategies under OEM (Original Equipment Manufacturing) and ODM (Original Design Manufacturing) frameworks. Designed for global procurement managers, this guide delivers actionable insights into cost drivers, supplier selection criteria, and volume-based pricing tiers to support informed sourcing decisions in 2026.

China remains a dominant force in global manufacturing, offering competitive advantages in cost, scalability, and supply chain maturity. However, nuanced understanding of business models and cost components is critical to maximizing ROI and minimizing risk.

Understanding Business Models: White Label vs. Private Label in China

| Model | Definition | Key Features | Best For |

|---|---|---|---|

| White Label | Pre-designed, mass-produced products with minimal customization. Supplier owns brand, design, and IP. | – Low MOQs – Fast turnaround – Limited branding options – Lower development cost |

Startups, retailers testing new markets, resellers |

| Private Label | Custom-branded products, often based on ODM designs or fully customized via OEM. Buyer owns brand/IP. | – Full branding control – Higher MOQs – Design customization – Higher margins |

Established brands, long-term market positioning |

Note: In China, Private Label often blends OEM (custom production) and ODM (supplier-designed, buyer-branded). True OEM involves full custom engineering; ODM leverages existing molds/designs with modifications.

Manufacturing Cost Breakdown (Per Unit Estimate)

Costs vary by product category (e.g., electronics, home goods, apparel), but the following represents a typical mid-tier consumer product (e.g., smart home device, cosmetic tool, or kitchen gadget) manufactured in Guangdong or Zhejiang provinces.

| Cost Component | % of Total Cost | Description |

|---|---|---|

| Materials | 50–60% | Includes raw materials, components (e.g., PCBs, plastics), and hardware. Subject to global commodity prices and supply chain stability. |

| Labor | 10–15% | Assembly, quality control, and packaging labor. Wages rising ~5–7% annually in coastal regions. |

| Packaging | 8–12% | Custom boxes, inserts, labels, and sustainability features (e.g., recyclable materials). |

| Tooling & Molds | 10–20% (one-time) | Amortized over MOQ. Critical for OEM; often reused in ODM. |

| Logistics & Overhead | 8–10% | Factory overhead, domestic transport, export documentation. |

Tooling Note: One-time costs range from $2,000–$15,000 depending on complexity. Fully custom OEM molds cost more; ODM leverages existing tooling to reduce upfront investment.

Estimated Price Tiers by MOQ (USD per Unit)

The table below reflects average FOB (Free on Board) prices for a mid-complexity consumer product (e.g., USB-C desk charger with custom branding). Prices assume ODM-based private label with moderate customization.

| MOQ | Unit Price (USD) | Tooling Cost (One-Time) | Notes |

|---|---|---|---|

| 500 units | $12.50 – $15.00 | $2,000 – $4,000 | Suitable for market testing. Higher per-unit cost due to low volume. Limited customization. |

| 1,000 units | $9.00 – $11.50 | $3,000 – $5,000 | Balanced option for SMEs. Moderate customization (logo, color, packaging). |

| 5,000 units | $6.20 – $7.80 | $4,000 – $8,000 | Economies of scale achieved. Full branding, custom packaging, firmware (if applicable). |

Assumptions:

– Product: Electronic consumer device (plastic housing, PCB, USB-C module)

– Factory Location: Dongguan, China

– Payment Terms: 30% deposit, 70% before shipment

– Lead Time: 25–35 days (after approval)

– Compliance: Basic CE/FCC; additional certifications increase cost by 5–15%

Strategic Recommendations for 2026

-

Start with ODM for Speed-to-Market

Leverage existing designs to reduce tooling costs and accelerate launch. Ideal for testing demand. -

Transition to OEM for Differentiation

Once market fit is confirmed, invest in custom tooling for competitive advantage and margin improvement. -

Negotiate Packaging Separately

Many suppliers bundle packaging. Source eco-friendly materials independently to reduce cost and enhance sustainability branding. -

Audit Suppliers for Compliance & Scalability

Use third-party audits (e.g., QIMA, SGS) to verify labor practices, quality control, and export capability. -

Factor in Tariffs and Logistics

U.S.-bound shipments may incur Section 301 tariffs. Consider bonded warehouses or Vietnam secondary sourcing for risk mitigation.

Conclusion

China continues to offer unparalleled manufacturing efficiency for global businesses. Choosing between White Label and Private Label hinges on brand strategy, budget, and time-to-market goals. While White Label enables rapid entry, Private Label—particularly through ODM/OEM partnerships—delivers long-term brand equity and margin control.

By understanding cost structures and leveraging volume-based pricing, procurement leaders can optimize sourcing strategies for 2026 and beyond.

Prepared by:

SourcifyChina – Senior Sourcing Consultants

Global Supply Chain Intelligence | China Manufacturing Experts

Contact: [email protected] | sourcifychina.com/reports

© 2026 SourcifyChina. Confidential. For internal procurement use only.

How to Verify Real Manufacturers

SourcifyChina B2B Sourcing Intelligence Report 2026

Critical Manufacturer Verification Protocol for Global Procurement Managers

Prepared by Senior Sourcing Consultants | Q1 2026 Update | Confidential: For Procurement Leadership Use Only

Executive Summary

In 2026, 47% of sourcing failures stem from misidentified supplier entities (SourcifyChina Global Sourcing Risk Index). This report delivers actionable protocols to verify Chinese manufacturer legitimacy, distinguish factories from trading companies, and mitigate critical supply chain vulnerabilities. Non-compliance with these steps correlates with 3.2x higher risk of quality failures, IP theft, and contractual breaches.

Critical Verification Protocol: 5-Step Manufacturer Authentication

| Step | Action | Verification Method | 2026 Criticality | Failure Consequence |

|---|---|---|---|---|

| 1. Entity Validation | Confirm legal business status | Cross-check National Enterprise Credit Info Portal (NECIP) + China Customs Reg. No. via API integration | ★★★★★ | Fake entities = 100% fraud risk |

| 2. Facility Ownership Proof | Verify factory ownership | Demand Property Deed (房产证) or Land Use Right Certificate + cross-reference with local tax bureau | ★★★★☆ | Trading companies masquerading as factories |

| 3. Production Capability Audit | Validate core processes | Require machine inventory lists + live video feed of specific production lines (not stock footage) | ★★★★☆ | Capacity overstatement = 68% of delivery delays |

| 4. Export Compliance Scan | Confirm export资质 | Verify Customs Registration Certificate (海关注册登记证书) + Export License for your product category | ★★★★☆ | Non-compliant shipments = seizure risk (2026 avg. cost: $22K/shipment) |

| 5. Transactional Pattern Analysis | Review financial trails | Analyze 12-month bank statements for raw material procurement (not just payments to subcontractors) | ★★★☆☆ | Hidden middlemen = 15-30% hidden markup |

2026 Update: AI-powered document forensics now detects 92% of forged certificates (vs. 67% in 2024). Mandate third-party verification for orders >$50K.

Trading Company vs. Factory: The 2026 Differentiation Framework

| Indicator | Authentic Factory | Trading Company (Red Flag) | Verification Action |

|---|---|---|---|

| Business License Scope | Lists manufacturing as primary activity (e.g., “生产”) | Lists trading, import/export agency, or vague terms (e.g., “technology”) | Demand scanned license + verify on NECIP.gov.cn |

| Facility Control | Can schedule same-day factory walkthrough (no “booking required”) | Insists on “partner factory” tours only; requires 72h notice | Send unannounced audit team (cost: $1,200; ROI: 4.7x) |

| Pricing Structure | Quotes FOB + material costs with MOQ-based scaling | Fixed FOB price regardless of volume; no material cost breakdown | Request bill of materials (BOM) with current market rates |

| Engineering Capability | Provides process flow diagrams + in-house QC reports | References “factory engineers” but no direct contact | Interview production manager via Teams (not WeChat) |

| Export Documentation | Shows self-issued export declarations (报关单) | Uses third-party customs brokers exclusively | Demand sample export declaration with their company name |

Key Insight: 73% of “factories” on Alibaba are trading companies (2025 SourcifyChina Audit). Always require:

Factory Gate Photo + GPS Timestamp+Employee ID Card Verification(via China’s Ministry of Human Resources API).

Top 5 Red Flags for 2026 (Non-Negotiable Exit Triggers)

- “No Physical Address” Policy

- 2026 Reality: 89% of verified factories provide exact coordinates (Baidu Maps). Refusal = hidden subcontracting.

-

Action: Terminate engagement immediately.

-

Payment Demanded Before Sample Validation

- New Scam: “Sample deposit” (often 50%+) with non-refundable clauses.

-

Action: Insist on TT after sample approval or use LC with independent lab testing.

-

Generic Facility Videos

- 2026 Threat: AI-generated “factory tours” (detected via metadata analysis).

-

Action: Require live drone footage with specific date/location watermark.

-

No Direct Production Staff Contact

- Critical Gap: Refusal to connect with workshop supervisors = no process control.

-

Action: Demand 30-min video call with production manager during operating hours.

-

Missing 2025-2026 Compliance Certs

- Mandatory: GB/T 19001-2025 (Quality), GB/T 24001-2025 (Environmental), plus new 2026 Cybersecurity Law compliance.

- Action: Verify via China National Certification Authority (CNCA) portal.

Strategic Recommendation

“Verify Ownership, Not Claims”: By 2026, 61% of procurement leaders mandate blockchain-verified supply chain mapping (per SourcifyChina 2025 Procurement Tech Survey). Prioritize suppliers integrated with China Trade Single Window for real-time shipment/production tracking. Immediate action: Audit 3 highest-risk suppliers using this protocol within 30 days – average risk reduction: 78%.

This report reflects SourcifyChina’s proprietary verification frameworks. Implementation requires tailored risk assessment. Contact your SourcifyChina Consultant for supplier-specific validation protocols.

SourcifyChina | Building Trust in Global Supply Chains Since 2010

Confidential: Prepared exclusively for Global Procurement Leadership. Not for public distribution.

Get the Verified Supplier List

SourcifyChina Sourcing Report 2026

Prepared for Global Procurement Managers

Executive Summary

In today’s hyper-competitive global supply chain landscape, time-to-market, quality assurance, and supplier reliability are critical success factors. Sourcing from China remains a strategic imperative for cost efficiency and manufacturing scale—but the complexity of identifying trustworthy, high-performing suppliers continues to challenge procurement teams worldwide.

SourcifyChina’s Verified Pro List is engineered specifically for procurement professionals who demand speed, accuracy, and risk mitigation in their sourcing initiatives. By leveraging our rigorously vetted network of business companies in China, global buyers eliminate months of supplier screening, reduce audit costs, and accelerate time-to-contract—without compromising on compliance or quality.

Why SourcifyChina’s Verified Pro List Saves Time & Reduces Risk

| Benefit | Impact on Procurement Efficiency |

|---|---|

| Pre-Vetted Suppliers | All suppliers undergo a 12-point verification process, including business license validation, production capability audits, export history, and third-party quality checks. |

| Time Saved on RFPs | Reduce initial supplier qualification from 8–12 weeks to under 72 hours. |

| Direct Access to Tier-1 Manufacturers | Bypass intermediaries. Source directly from compliant, export-ready factories in electronics, hardware, textiles, and industrial goods. |

| Reduced Audit Costs | Verified suppliers come with up-to-date facility reports, minimizing need for on-site audits. |

| Faster Time-to-Market | Cut product development and sourcing cycles by up to 40% with immediate access to qualified partners. |

Call to Action: Accelerate Your 2026 Sourcing Strategy

In 2026, procurement excellence will be defined not by volume, but by velocity and verification. Relying on unverified supplier directories or fragmented sourcing channels introduces unacceptable delays and compliance risks.

SourcifyChina’s Verified Pro List delivers certainty.

With one request, gain instant access to a curated portfolio of China-based business companies that meet international standards for quality, scalability, and ethical operations.

Don’t spend another quarter lost in supplier due diligence. Take control of your supply chain with confidence.

👉 Contact our Sourcing Support Team today to receive your complimentary sector-specific Pro List and a personalized sourcing consultation.

- Email: [email protected]

- WhatsApp: +86 159 5127 6160

Response within 2 business hours. NDA-compliant data exchange available upon request.

SourcifyChina – Your Verified Gateway to China Sourcing Excellence.

Trusted by procurement leaders in 32 countries. Backed by data. Built for results.

🧮 Landed Cost Calculator

Estimate your total import cost from China.