The global bucket elevator market is experiencing steady growth, driven by increasing demand for efficient bulk material handling across industries such as agriculture, food processing, mining, and cement. According to Mordor Intelligence, the conveyor systems market—of which bucket elevators are a critical component—is projected to grow at a CAGR of over 5% from 2023 to 2028. Similarly, Grand View Research valued the global conveyor systems market at USD 34.5 billion in 2022 and forecasts a CAGR of 5.2% from 2023 to 2030, underscoring the rising adoption of automated material handling solutions. As industries prioritize throughput efficiency and operational reliability, bucket elevators have emerged as indispensable assets in vertical transport applications. In this evolving landscape, leading manufacturers are innovating with energy-efficient designs, corrosion-resistant materials, and smart monitoring systems to meet stringent industry requirements. Based on market presence, product range, technological advancements, and global reach, here are the top 9 bucket elevator manufacturers shaping the future of bulk material handling.

Top 9 Bucket Elevators Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Tapco, Inc.

Domain Est. 1996

Website: tapcoinc.com

Key Highlights: Tapco Inc. Elevator Buckets for agricultural grain elevators, industrial use elevator buckets, plus elevator bolts and parts….

#2 Martin’s Bucket Elevators Optimize Industrial Material Handling

Domain Est. 1995

Website: martinsprocket.com

Key Highlights: Our comprehensive line of industrial bucket elevators is designed to efficiently transport a diverse range of dry, free-flowing materials….

#3 Bucket Elevator Products

Domain Est. 1996

Website: ibtinc.com

Key Highlights: We are a leading distributor and servicer of high-quality bucket elevators and components, renowned for exceptional performance and durability….

#4 4B

Domain Est. 1997

Website: go4b.com

Key Highlights: 4B is a Worldwide Manufacturer of Components for Bucket Elevators and Conveyors: Buckets, Belts, Bolts, Forged Chain, Hazard Monitors, Sensors and Controls….

#5 Bucket Elevators – GSI

Domain Est. 1996

Website: grainsystems.com

Key Highlights: Bucket elevators for grain operations, flour mills and fertilizer, ethanol, malt and feed processing plants. Though constructed of heavy-duty materials, ……

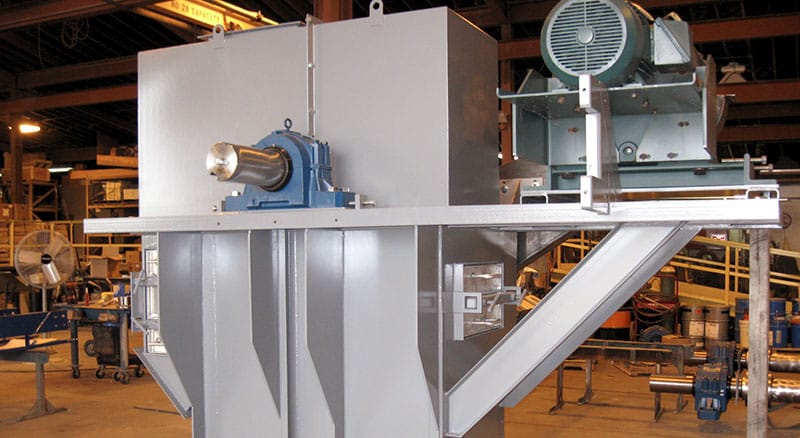

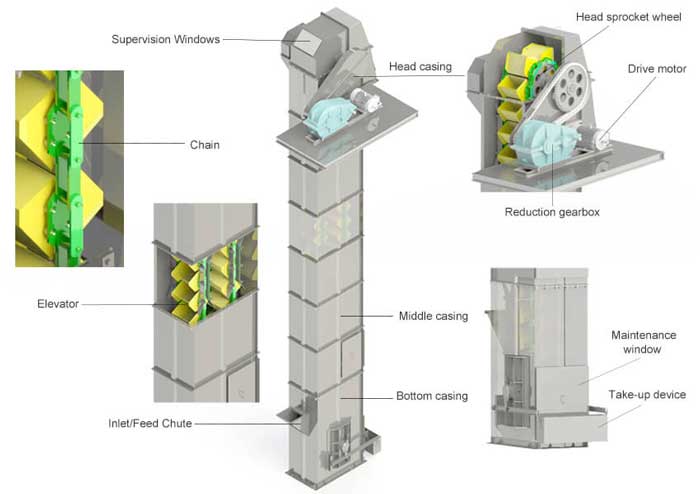

#6 Bucket Elevators

Domain Est. 1996

Website: feeco.com

Key Highlights: We offer a wide variety of bucket elevator models to elevate bulk products ranging from dry, dusty powders such as fly ash, to heavy solids such as iron ore ……

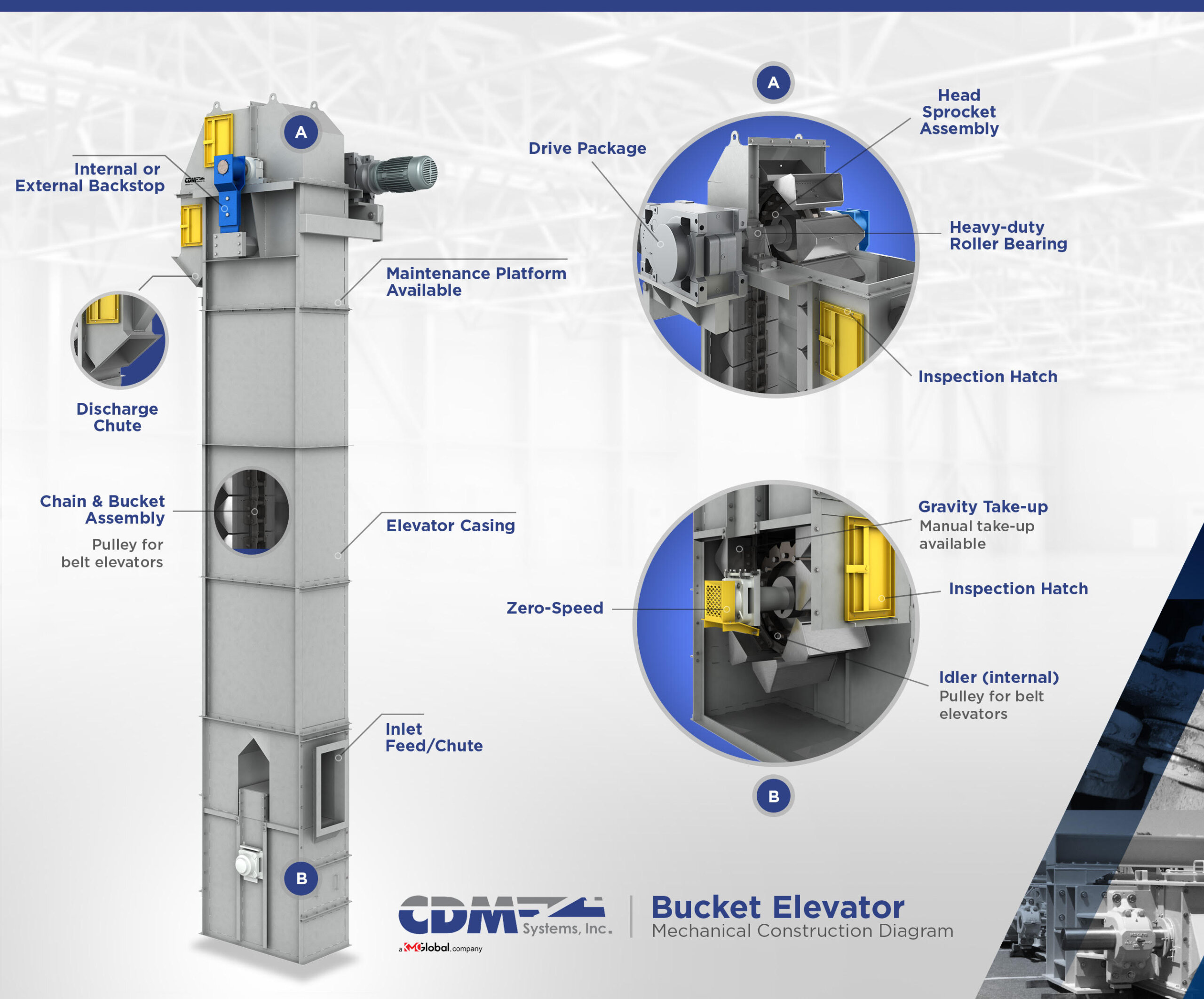

#7 Bucket Elevators

Domain Est. 1997

Website: universalindustries.com

Key Highlights: Universal Industries designs and manufactures bucket elevators / grain & seed legs, slider belt conveyors, idler bed conveyors, continuous cup elevators, ……

#8 Screw Conveyors, Feeders & Component Parts

Domain Est. 1997

Website: kwsmfg.com

Key Highlights: KWS is a screw conveyor manufacturing company that specializes in screw conveyors, screw feeders, slide gates, bucket elevators, component parts and other ……

#9 Bucket Elevators and Bucket Conveyors

Domain Est. 1997

Website: goughecon.com

Key Highlights: We design and manufacture bucket elevators and conveyors for any application. Our custom design process and patented components ensure the best outcome….

Expert Sourcing Insights for Bucket Elevators

2026 Market Trends for Bucket Elevators

The bucket elevator market is poised for steady growth and transformation by 2026, driven by increasing industrial automation, rising demand across key sectors such as agriculture, mining, and cement, and advancements in material handling technologies. This analysis explores the key trends expected to shape the bucket elevator industry in 2026.

Rising Demand from Industrial Sectors

In 2026, the continued expansion of industries like agriculture, food processing, mining, and construction will fuel demand for efficient vertical conveying systems. Bucket elevators, known for their ability to transport bulk materials vertically in a cost-effective and space-saving manner, are seeing heightened adoption. The global push toward food security and increased grain handling requirements are particularly driving installations in grain elevators and agro-processing plants.

Additionally, infrastructure development in emerging economies is boosting cement and aggregate production, further expanding the need for durable and high-capacity bucket elevators in heavy-duty applications.

Technological Advancements and Smart Integration

By 2026, smart manufacturing and Industry 4.0 principles are increasingly influencing the design and functionality of bucket elevators. Manufacturers are integrating IoT-enabled sensors, predictive maintenance systems, and real-time monitoring capabilities into elevator systems. These advancements allow for remote diagnostics, improved uptime, and reduced operational costs.

Energy efficiency is also a key focus, with new models incorporating variable frequency drives (VFDs), optimized motor systems, and lightweight yet durable materials to lower power consumption. These technologies not only improve performance but also align with global sustainability goals.

Emphasis on Safety and Compliance

Safety regulations in material handling are becoming more stringent globally, particularly in the EU and North America. In 2026, bucket elevator designs will increasingly incorporate explosion-proof components, dust control systems, and enhanced guarding to meet OSHA, ATEX, and other regulatory standards. This is especially critical in industries handling combustible materials such as grain, coal, or chemicals.

Manufacturers are also focusing on modular designs that simplify maintenance and reduce downtime, improving worker safety during servicing operations.

Growth in Emerging Markets

Asia-Pacific, Latin America, and Africa are expected to account for a significant share of market growth by 2026. Rapid industrialization, urbanization, and investments in agricultural infrastructure are driving demand in countries like India, Indonesia, Brazil, and Nigeria. Local manufacturing and reduced equipment costs are making bucket elevators more accessible, supporting adoption in small and medium-sized enterprises.

Sustainability and Circular Economy Considerations

Environmental sustainability is becoming a key differentiator. By 2026, manufacturers are prioritizing recyclable materials, longer product lifecycles, and reduced waste in production. Additionally, second-hand and refurbished bucket elevators are gaining traction in cost-sensitive markets, supported by certification standards that ensure reliability and performance.

Competitive Landscape and Market Consolidation

The bucket elevator market is witnessing gradual consolidation, with key players expanding through mergers, acquisitions, and strategic partnerships. Companies such as FLSmidth, KWS Manufacturing, and Beumer Group are investing in R&D and global distribution networks to strengthen their market position. Customization and after-sales services are becoming critical competitive advantages.

In conclusion, the 2026 bucket elevator market will be characterized by technological innovation, regulatory compliance, and expanding applications across developing and mature economies. Stakeholders who embrace automation, sustainability, and customer-centric design will be best positioned to capitalize on emerging opportunities.

Common Pitfalls Sourcing Bucket Elevators: Quality and IP Concerns

Sourcing bucket elevators involves critical considerations beyond initial cost, particularly regarding long-term performance, safety, and intellectual property (IP). Overlooking these aspects can lead to operational failures, safety hazards, and legal complications. Below are key pitfalls to avoid:

Poor Quality Materials and Construction

Choosing bucket elevators made from substandard materials or with inadequate manufacturing processes can result in premature wear, frequent breakdowns, and increased downtime. Low-quality components such as buckets, belts, chains, or casings may not withstand the intended load, temperature, or abrasive nature of the conveyed material. This leads to higher maintenance costs and potential safety risks, especially in industries like mining, cement, or food processing where reliability is paramount.

Lack of Compliance with Industry Standards

Many suppliers, particularly those from regions with less stringent regulations, may not adhere to international standards such as ISO, CEMA, or ATEX (for explosive environments). Sourcing equipment that does not meet these standards can compromise safety, void insurance, and result in non-compliance with local regulations, especially in high-risk or regulated industries.

Inadequate Design for Specific Applications

Bucket elevators are not one-size-fits-all. A common pitfall is selecting a generic design that fails to account for material characteristics (e.g., moisture, abrasiveness, flowability), required capacity, or environmental conditions. Poorly matched designs lead to inefficient operation, spillage, blockages, or accelerated wear—issues often misattributed to operator error rather than sourcing misjudgment.

Insufficient Documentation and Technical Support

Low-cost suppliers may provide incomplete technical documentation, such as missing load calculations, drawings, or maintenance manuals. This lack of support makes installation, troubleshooting, and spare parts procurement difficult. Additionally, poor post-sale support can delay repairs and increase downtime.

Intellectual Property (IP) Infringement Risks

Sourcing from certain regions may expose buyers to IP risks, particularly if the equipment copies patented designs, proprietary engineering, or branded components without authorization. Using such equipment can lead to legal action, shipment seizures, or reputational damage, especially when operating in markets with strict IP enforcement.

Counterfeit or Reverse-Engineered Components

Some suppliers offer “clone” versions of well-known elevator models at lower prices. These may use inferior materials or deviate from original engineering specifications, compromising performance and safety. Additionally, reverse-engineered designs may lack proper validation and testing, increasing the risk of failure under operational stress.

Hidden Costs from Poor Reliability

While initial purchase price may be low, poor quality or non-compliant bucket elevators often incur significant hidden costs—frequent repairs, unplanned downtime, higher energy consumption, and shortened service life. A total cost of ownership (TCO) analysis often reveals that higher-quality, IP-compliant equipment delivers better long-term value.

Inadequate Warranty and After-Sales Service

Suppliers offering limited or vague warranty terms may disappear after delivery or refuse to honor claims. Without reliable after-sales support, users face extended downtimes and difficulty obtaining genuine spare parts, especially if the design is proprietary or poorly documented.

Failure to Verify Supplier Credentials

Relying on unverified suppliers without checking references, certifications, or manufacturing capabilities increases the risk of receiving substandard or non-compliant equipment. Due diligence, including site visits or third-party inspections, is essential to confirm quality systems and production standards.

To mitigate these pitfalls, buyers should prioritize suppliers with verifiable track records, robust quality management systems (e.g., ISO 9001), compliance with relevant standards, and transparent IP practices. Investing time in proper sourcing reduces long-term risks and ensures reliable, safe, and cost-effective material handling operations.

Logistics & Compliance Guide for Bucket Elevators

Introduction

Bucket elevators are essential material handling systems used across industries such as agriculture, mining, and manufacturing to vertically transport bulk materials. Proper logistics planning and regulatory compliance are critical to ensure safe, efficient, and legal operation throughout the equipment’s lifecycle—from manufacturing and shipping to installation and ongoing use.

Manufacturing & Pre-Shipment Compliance

Regulatory Standards Compliance

Bucket elevators must be designed and manufactured in accordance with relevant international and regional standards, including:

– CE Marking (EU): Compliance with the Machinery Directive (2006/42/EC), ATEX Directive (2014/34/EU) for explosive atmospheres, and applicable EN standards such as EN 818-1 (chains) and EN 1088 (safety interlocks).

– OSHA & ANSI Standards (USA): Adherence to OSHA 29 CFR 1910.272 (grain handling facilities) and ANSI/ASME B20.1 (safety standards for conveyors).

– CSA Standards (Canada): Compliance with CSA Z432 for safeguarding of machinery.

– Other Regional Regulations: Local safety and electrical codes may apply depending on the destination country.

Documentation Requirements

- Provide technical files, declarations of conformity, and risk assessments.

- Include operation and maintenance manuals in the local language(s) of the destination country.

- Supply drawings, schematics, and spare parts lists.

- Ensure equipment bears required labels (e.g., CE, voltage, load capacity, serial number).

Packaging & Handling for Shipment

Secure Packaging

- Use wooden crates or heavy-duty steel frames to protect components such as casings, drive units, and buckets.

- Protect bearings, motors, and electrical components from moisture and impact using anti-corrosion wraps and desiccants.

- Secure loose parts (e.g., buckets, belts, chains) in labeled containers.

Handling Instructions

- Clearly mark packages with “Fragile,” “This Side Up,” and lifting point indicators.

- Include handling diagrams for oversized or heavy sections (e.g., head and boot assemblies).

- Specify maximum load limits for lifting points and rigging equipment.

Transportation & Logistics

Mode of Transport

- Road: Most common for domestic or regional shipments. Ensure route planning accounts for the size and weight of components. Oversized loads may require permits.

- Sea Freight: Use ISO containers or flat racks for international shipping. Comply with IMDG Code if hazardous materials (e.g., lubricants) are included.

- Air Freight: Rare due to size and cost; used only for urgent spare parts.

Customs Clearance

- Prepare a commercial invoice, packing list, bill of lading, and certificate of origin.

- Include HS Code (e.g., 8428.39 for elevators and conveyors) for tariff classification.

- Declare any dual-use components or materials subject to export controls (e.g., ITAR, EAR).

Installation & Site Compliance

Site Preparation

- Verify foundation strength and alignment per manufacturer specifications.

- Ensure adequate clearance for maintenance and emergency access.

- Confirm power supply compatibility (voltage, phase, frequency).

Safety Compliance During Installation

- Follow lockout/tagout (LOTO) procedures per OSHA 29 CFR 1910.147.

- Install guards on moving parts, including drive pulleys, chains, and sprockets.

- Bond and ground equipment to prevent static discharge, especially in combustible dust environments.

Operational Compliance & Maintenance

Ongoing Safety Regulations

- Conduct regular inspections per NFPA 654 (prevention of fire and dust explosions).

- Implement housekeeping protocols to minimize combustible dust accumulation (OSHA 29 CFR 1910.272).

- Ensure emergency stop systems are accessible and functional.

Maintenance & Recordkeeping

- Maintain logs of inspections, repairs, and component replacements.

- Follow manufacturer-recommended lubrication and tensioning schedules.

- Train personnel on safe operation and emergency procedures.

Environmental & Disposal Compliance

Environmental Protection

- Prevent lubricant leaks using drip trays and sealed systems.

- Capture fugitive dust emissions with proper ventilation and filtration (e.g., baghouses).

End-of-Life Disposal

- Recycle metal components in accordance with local environmental regulations (e.g., EU WEEE Directive).

- Dispose of contaminated belts or lubricants as hazardous waste where applicable.

Conclusion

Adhering to logistics and compliance standards ensures bucket elevators are safely delivered, installed, and operated. Manufacturers, shippers, and end-users must collaborate to meet regulatory requirements and maintain a safe working environment. Regular audits and documentation are essential to demonstrate ongoing compliance.

Conclusion for Sourcing Bucket Elevators

Sourcing the right bucket elevator is a critical decision that directly impacts the efficiency, reliability, and safety of material handling operations. It requires a comprehensive evaluation of material characteristics, capacity requirements, operating environment, and long-term maintenance needs. By carefully assessing different types of bucket elevators—such as centrifugal, continuous, and positive discharge—and considering factors like construction materials, drive systems, and safety features, organizations can select a solution that aligns with their specific operational demands.

Partnering with reputable suppliers who offer proven engineering expertise, quality manufacturing, and responsive after-sales support further ensures optimal performance and extended service life. Additionally, prioritizing energy efficiency, compliance with industry standards, and scalability helps future-proof the investment.

In conclusion, a strategic approach to sourcing bucket elevators—focused on application suitability, total cost of ownership, and supplier reliability—will enhance productivity, reduce downtime, and contribute to the long-term success of bulk material handling systems.