The global market for pipe fittings, including British Standard Pipe (BSP) thread fittings, has witnessed steady expansion driven by rising demand across industries such as oil and gas, water treatment, construction, and manufacturing. According to a report by Mordor Intelligence, the global pipe fittings market was valued at USD 34.8 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 5.2% from 2024 to 2029. This growth is fueled by infrastructure development, increased industrialization in emerging economies, and stringent regulations mandating reliable and standardized piping systems. BSP thread fittings, conforming to internationally recognized British Standard Pipe specifications (BS 21 and ISO 7), remain a preferred choice in regions including Europe, Asia-Pacific, and parts of the Middle East due to their reliability in high-pressure and high-temperature applications. As demand for standardized, leak-proof connections intensifies, a select group of manufacturers have emerged as leaders in producing high-quality BSP thread fittings, combining precision engineering, material durability, and compliance with international standards. The following analysis highlights the top nine manufacturers leading innovation and market share in the British Standard Pipe thread fittings space.

Top 9 British Standard Pipe Thread Fittings Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Bonney Forge

Domain Est. 1996

Website: bonneyforge.com

Key Highlights: Bonney Forge is a leading manufacturer of Forged and Cast Steel Valves,Olets*/Pipets*, Forged Steel Fittings and Unions, and Specialty Products….

#2 ASC Engineered Solutions

Domain Est. 2020

Website: asc-es.com

Key Highlights: Manufacturer and solutions provider of precision-engineered pipe joining products, valves, and related services for the entire construction project ……

#3

Domain Est. 1995

Website: parker.com

Key Highlights: As the global leader in motion and control technologies, Parker Hannifin plays a pivotal role in applications that have a positive impact on the world….

#4 British Metrics

Domain Est. 1996

Website: britishmetrics.com

Key Highlights: At British Metrics, we carry a variety of metric fittings, valves, washers and more. Search our pneumatic accessories and hydraulic fittings for sale now….

#5 to Alemite

Domain Est. 1996

Website: skf.com

Key Highlights: Threaded. Metric Fittings. Metric Zerk Fittings (DIN71412). Relief Fittings. British Standard Pipe Thread · Drive Relief Fittings · Threaded Relief Fittings….

#6 Tenaris

Domain Est. 2000

Website: tenaris.com

Key Highlights: We supply the most extensive portfolio of high-quality casing and tubing, drill pipe, premium connections, and pipe accessories, for all types of oil and gas ……

#7 BSPP, BSPT, British Fittings

Domain Est. 2014

Website: titanfittings.com

Key Highlights: Free delivery over $10K · 30-day returnsBritish Fittings · British Std Pipe Parallel (BSPP) · British Strd Pipe Tapered (BSPT) · Stainless BSP Fittings · Japanese Cone Seat (JIS 3…

#8 Explanation of common threads including BSP & NPT

Website: valvesonline.com.au

Key Highlights: BSP thread form stands for British Standard Pipe and is common in Australia and the commonwealth countries. It is based on trade size rather than actual ……

#9 What is a BSPT fitting?

Domain Est. 2023

Website: fluidtechpiping.com

Key Highlights: A British Standard Pipe Taper (BSPT) fitting is a type of threaded connector used extensively in plumbing and pipework, particularly in ……

Expert Sourcing Insights for British Standard Pipe Thread Fittings

H2: Market Trends for British Standard Pipe Thread (BSPT) Fittings in 2026

By 2026, the global market for British Standard Pipe Thread (BSPT) fittings is expected to experience steady growth, driven by continued demand in industrial, oil and gas, water treatment, and construction sectors—particularly in regions with established engineering standards and legacy infrastructure. While there is a gradual shift toward metric and international standards, BSPT fittings maintain strong relevance due to compatibility with existing systems and regulatory acceptance in key markets.

-

Regional Demand and Industrial Applications

Europe, particularly the UK and parts of Eastern Europe, continues to be a core market for BSPT fittings, where they remain the standard in plumbing, hydraulics, and pneumatic systems. Additionally, demand persists in the Middle East and Asia-Pacific, especially in countries with British-influenced engineering practices such as India, Australia, and several Southeast Asian nations. In the oil and gas industry, BSPT fittings are frequently used in wellhead equipment, process piping, and offshore platforms due to their reliability and sealing performance in high-pressure environments. -

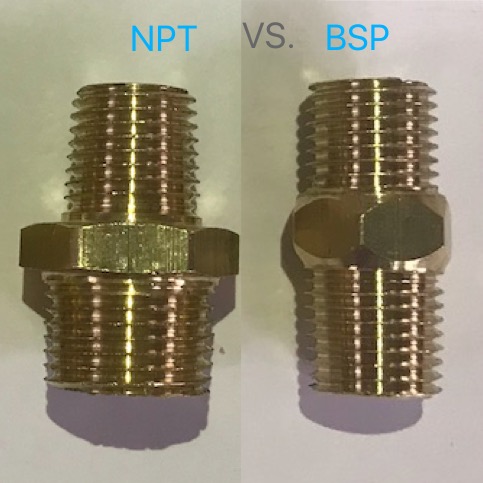

Competition from NPT and Metric Standards

BSPT fittings face ongoing competition from National Pipe Taper (NPT) threads in North America and metric ISO 7 and ISO 228 threads in Europe and emerging markets. However, BSPT’s conical thread design provides a reliable seal without requiring additional sealing materials, which sustains its preference in specific industrial applications. The 2026 market sees an increase in hybrid solutions—fittings designed to be compatible with both BSPT and ISO standards—supporting global supply chain flexibility. -

Material and Manufacturing Innovations

By 2026, manufacturers are increasingly adopting corrosion-resistant alloys, stainless steel grades (316/304), and advanced brass formulations to meet stricter environmental and safety regulations. Additive manufacturing and precision CNC machining are enhancing customization and reducing lead times, allowing for more complex BSPT configurations tailored to niche industrial needs. -

Sustainability and Regulatory Influences

Environmental regulations, particularly in the EU under REACH and the UKCA marking requirements, are pushing manufacturers to reduce lead content and ensure recyclability. This has led to growth in lead-free brass and eco-conscious production processes. Additionally, water efficiency standards in commercial and residential construction are increasing demand for leak-proof BSPT fittings in sustainable plumbing systems. -

Digitalization and Supply Chain Integration

Digital procurement platforms and B2B e-commerce are streamlining access to BSPT fittings, especially for SMEs and maintenance, repair, and operations (MRO) sectors. In 2026, many suppliers offer digital twins of fittings, 3D CAD models, and AR-assisted selection tools, improving integration into engineering workflows and reducing installation errors. -

Outlook and Growth Projections

The global BSPT fittings market is projected to grow at a CAGR of approximately 3.8% from 2023 to 2026, reaching an estimated value of USD 2.9 billion by 2026. While not expanding as rapidly as metric-based systems, BSPT maintains a resilient niche supported by retrofitting projects, maintenance of legacy systems, and regional standardization inertia.

In conclusion, the 2026 market for British Standard Pipe Thread fittings reflects a blend of tradition and innovation. Despite global standardization pressures, BSPT remains vital in specific sectors and geographies, with manufacturers adapting through material science, digital tools, and sustainable practices to ensure continued relevance.

Common Pitfalls When Sourcing British Standard Pipe Thread (BSP) Fittings: Quality and Intellectual Property Issues

Quality Inconsistencies

One of the most prevalent challenges when sourcing BSP thread fittings is inconsistent product quality. Many manufacturers, especially those outside the UK or in low-cost regions, may produce fittings that appear compliant but fail to meet the dimensional and material standards defined in BS EN ISO 7-1 and BS 21. These discrepancies can lead to leaks, improper sealing, or system failures. Buyers often encounter substandard materials—such as low-grade brass or improperly heat-treated steel—that compromise durability and pressure ratings. Additionally, poor thread accuracy, incorrect taper angles, or inadequate surface finish may not be immediately visible but can cause significant operational issues in the field.

Counterfeit and Misrepresented Products

Another major pitfall involves counterfeit or mislabeled BSP fittings. Some suppliers falsely claim compliance with British Standards or use fake certification marks (such as the UKCA or old BS Kitemark) to appear legitimate. These products may mimic genuine fittings in packaging and labeling but lack the required testing and traceability. This misrepresentation not only risks system integrity but can also expose procurement teams to legal and safety liabilities, particularly in regulated industries like oil and gas, water treatment, or pharmaceuticals.

Intellectual Property (IP) Infringement Risks

Sourcing BSP fittings from unauthorized or third-party manufacturers can lead to intellectual property concerns. Certain designs, proprietary coatings, or patented connection technologies used in high-performance BSP fittings may be protected under IP law. When suppliers replicate these features without licensing, buyers may unknowingly purchase infringing products. This can result in supply chain disruptions, legal action, or the need to replace non-compliant components—especially in international markets with strict IP enforcement.

Lack of Traceability and Certification

Many low-cost suppliers fail to provide proper material test certificates (e.g., ISO 17025), mill certificates, or traceable batch information. Without these documents, it becomes difficult to verify compliance or investigate failures. The absence of traceability increases the risk of receiving fittings made from recycled or unverified materials, which may not perform as expected under pressure or in corrosive environments.

Inadequate Supplier Vetting

A common oversight is failing to conduct thorough due diligence on suppliers. Some vendors may list BSP fittings in their catalogs without actually manufacturing to standard, relying instead on inconsistent subcontractors. Without on-site audits, sample testing, or third-party inspection, buyers cannot ensure ongoing compliance. This is particularly risky when dealing with online marketplaces or new suppliers offering unusually low prices.

Conclusion

To mitigate these risks, buyers should prioritize suppliers with proven certifications (e.g., ISO 9001), request full technical documentation, and conduct regular quality audits. Engaging with reputable, UK-recognized manufacturers or authorized distributors can help ensure both quality and compliance with British Standards, safeguarding system performance and minimizing IP exposure.

Logistics & Compliance Guide for British Standard Pipe Thread (BSP) Fittings

This guide outlines essential logistics and compliance considerations when sourcing, handling, shipping, and using British Standard Pipe Thread (BSP) fittings. Adherence to standards and best practices ensures operational efficiency, safety, and regulatory conformity.

Understanding BSP Fittings and Applicable Standards

BSP fittings are widely used in plumbing and industrial applications, conforming to British Standard specifications. Key standards include:

– BS 21 / ISO 7: Defines dimensions, tolerances, and design requirements for pipe threads where the thread form seals on the threads themselves (tapered threads).

– BS EN 10255: Specifies requirements for non-alloy steel tubes suitable for screwing to BSP fittings.

– ISO 228: Covers parallel (straight) pipe threads for joints where sealing is achieved via a washer or O-ring, not the threads.

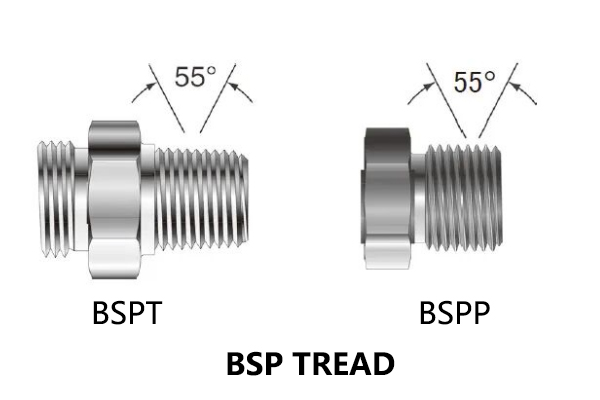

Understanding whether a fitting is BSPT (British Standard Pipe Taper) or BSPP (British Standard Pipe Parallel) is critical for compatibility and leak prevention.

Material and Manufacturing Compliance

Ensure BSP fittings meet recognized material and quality standards:

– Material Specifications: Common materials include brass, stainless steel, carbon steel, and plastic. Verify compliance with ASTM, ISO, or EN material standards (e.g., ASTM B61 for bronze, EN 12164 for brass).

– Certification Requirements: Suppliers should provide Mill Test Certificates (MTCs) or Material Test Reports (MTRs) confirming chemical composition and mechanical properties.

– Pressure and Temperature Ratings: Confirm that fittings are rated for intended service conditions. Compliance with PED (Pressure Equipment Directive 2014/68/EU) may be required for use in the European Economic Area.

– Traceability: Maintain full traceability from supplier to end-use, including heat numbers and batch identification.

Packaging and Handling Logistics

Proper handling and packaging prevent damage and contamination:

– Protective Packaging: Use sealed plastic bags, cardboard boxes, or wooden crates with cushioning to prevent thread damage. For bulk shipments, use pallets with edge protectors.

– Labeling: Each package must be clearly labeled with:

– Fitting type (BSPT or BSPP)

– Size (nominal bore and thread size)

– Material grade

– Standard designation (e.g., BS EN 10255)

– Manufacturer’s name or mark

– Batch/lot number

– Storage Conditions: Store in a dry, climate-controlled environment to prevent corrosion, especially for ferrous materials. Avoid exposure to chemicals, moisture, or direct sunlight.

Shipping and Transportation Compliance

Ensure safe and compliant transportation:

– Hazard Classification: Most BSP fittings are non-hazardous, but verify if coatings or materials (e.g., lead content in brass) require special handling under regulations like REACH or RoHS.

– International Shipping: Comply with import/export regulations. Provide accurate Harmonized System (HS) codes (e.g., 7412.10 for copper pipe fittings).

– Documentation: Include commercial invoice, packing list, certificate of conformity, and any required export licenses.

– Freight Considerations: Use appropriate freight modes (air, sea, ground) based on urgency and cost. Secure heavy loads to prevent shifting.

Regulatory and Certification Requirements

Compliance varies by region and application:

– European Union: BSP fittings used in pressurized systems may require CE marking under the Pressure Equipment Directive (PED). Compliance with REACH (chemical safety) and RoHS (restriction of hazardous substances) is mandatory.

– United States: While NPT is more common, BSP fittings must meet ANSI/ASME standards if used in regulated systems. Verify compliance with local plumbing codes (e.g., IPC, UPC).

– UKCA Marking: For products placed on the UK market post-Brexit, UKCA marking may be required, depending on the product category and use.

– Industry-Specific Standards: Oil & gas, water treatment, or food-grade applications may require additional certifications (e.g., WRAS approval for potable water, NSF/ANSI 61).

Quality Assurance and Inspection

Implement a robust QA process:

– Incoming Inspection: Verify thread dimensions using ring or plug gauges per ISO 7-2 or BS 21.

– Visual Inspection: Check for cracks, burrs, corrosion, or deformation.

– Dimensional Tolerances: Confirm adherence to specified tolerances for pitch diameter, thread angle, and length.

– Leak Testing: Conduct pressure tests as required by system specifications.

Supplier and Supply Chain Due Diligence

- Approved Vendor List (AVL): Source fittings only from qualified suppliers with proven compliance track records.

- Audits: Conduct periodic supplier audits to verify quality management systems (e.g., ISO 9001 certification).

- Counterfeit Prevention: Implement traceability and verification protocols to avoid substandard or counterfeit products.

Conclusion

Proper logistics and compliance management for BSP fittings ensures reliability, safety, and legal conformity across global supply chains. By adhering to international standards, maintaining documentation, and conducting rigorous quality checks, organizations can mitigate risks and ensure seamless integration of BSP components in critical systems.

Conclusion:

Sourcing British Standard Pipe (BSP) thread fittings requires careful consideration of technical specifications, supplier reliability, and compliance with relevant standards to ensure compatibility, safety, and performance in fluid system applications. As BSP threads remain widely used across industries—particularly in Europe, Asia, and other regions outside North America—it is essential to verify thread type (parallel BSPP or tapered BSPT), size, material, pressure ratings, and adherence to standards such as ISO 7-1 or BS EN 10226.

Working with reputable suppliers who provide certification, traceability, and technical support helps mitigate risks related to counterfeit or substandard components. Additionally, understanding regional regulatory requirements and ensuring compatibility with existing systems prevents operational failures and reduces maintenance costs. By prioritizing quality, standardization, and supplier vetting, organizations can effectively source BSP fittings that meet both performance expectations and long-term reliability needs.