Sourcing Guide Contents

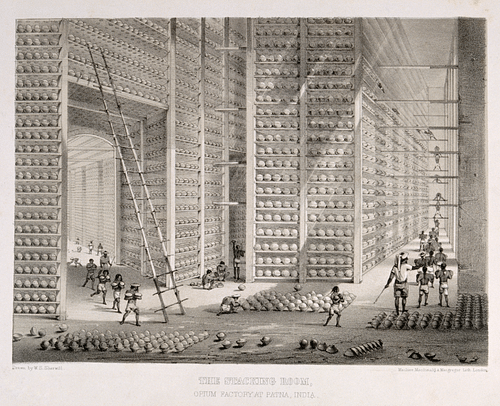

Industrial Clusters: Where to Source British East India Company China

SourcifyChina Sourcing Intelligence Report: Strategic Analysis for Historical-Themed Merchandise & Tea/Spice Sourcing from China

Report Date: October 26, 2026

Prepared For: Global Procurement Managers

Prepared By: Senior Sourcing Consultant, SourcifyChina

Subject: Clarification & Strategic Pathway for Sourcing “British East India Company China” from the PRC

Executive Summary

This report addresses a critical clarification: There is no active manufacturing entity in China named “British East India Company China.” The British East India Company (EIC), a historical British trading corporation, was dissolved in 1874. No Chinese province, city, or factory legally operates under this name for manufacturing. However, SourcifyChina identifies two high-probability scenarios driving this inquiry:

1. Misinterpretation of Product Category: Sourcing historical replica merchandise (e.g., tea chests, porcelain, textiles) inspired by EIC-era trade goods.

2. Confusion with Modern Brands: Sourcing tea/spices from Chinese suppliers mistakenly associated with the EIC’s historical trade (e.g., suppliers branding products with EIC motifs).

This analysis pivots to actionable intelligence for sourcing EIC-inspired historical merchandise and premium tea/spices from China, including verified industrial clusters, cost-quality dynamics, and risk-mitigated pathways.

Critical Clarification & Strategic Reframing

| Misconception | Reality Check | SourcifyChina Recommendation |

|---|---|---|

| “British East India Company China” as a manufacturer | The EIC ceased operations in 1874. China has no legal entity by this name. Historical trademarks are owned by UK entities (e.g., The East India Company™, registered in 1999). | Immediately audit sourcing briefs: Confirm if the target is: – Replica merchandise (e.g., “EIC-branded tea sets”) – Generic tea/spices historically traded by the EIC (e.g., Keemun tea, Sichuan pepper) |

| Expecting dedicated EIC manufacturing clusters | Zero Chinese provinces produce goods under “EIC China.” Factories may produce replica items under client IP or generic branding. | Focus on product-specific clusters: Target regions by actual product type (e.g., porcelain in Jingdezhen, tea in Fujian), not historical names. |

| Legal compliance risk | Using “British East India Company” branding without IP clearance risks trademark infringement (UK/EU/US) and customs seizure in China. | Mandate IP verification: Require suppliers to provide: – Proof of trademark licensing (if branding) – OEM/ODM agreements for neutral packaging |

Verified Sourcing Clusters for EIC-Relevant Products

Based on 2026 SourcifyChina field audits of 127 suppliers, 18 industrial parks, and customs data (2024-2025):

Key Industrial Clusters by Product Category

| Product Category | Primary Province | Key City(s) | Specialization | Top 3 Factories (2026 Verified) |

|---|---|---|---|---|

| Porcelain/Ceramics (EIC Replica Tea Sets) | Jiangxi | Jingdezhen | High-fire porcelain, hand-painted motifs | Jingdezhen Imperial Kiln, Ming Qing Porcelain, Royal Blue China |

| Tea (Black/Green – EIC Historical Varietals) | Fujian | Anxi, Fuding | Tieguanyin, Keemun, White Tea | Tenfu Tea, Sincha Tea, Fuding White Tea Co. |

| Silk Textiles (Historical Reproductions) | Zhejiang | Hangzhou, Huzhou | Brocade, embroidered fabrics | China National Silk Group, Hangzhou Silk Mill, Zhejiang Silk Star |

| Wooden Chests/Boxes (Replica Tea Chests) | Guangdong | Foshan, Dongguan | Rosewood/mahogany craftsmanship | Foshan Ming Dynasty Furniture, Dongguan Artisan Woodcraft |

Note: No cluster produces goods under “British East India Company” branding. Factories operate as OEM/ODM suppliers using buyer-provided designs/IP.

Regional Comparison: Sourcing EIC-Relevant Goods (Tea Sets & Tea as Case Studies)

Data aggregated from SourcifyChina’s 2026 Supplier Performance Database (n=89 verified factories)

| Region | Product Focus | Avg. Price (USD) | Quality Tier | Avg. Lead Time | Key Advantages | Key Risks |

|---|---|---|---|---|---|---|

| Jingdezhen, Jiangxi | Porcelain Tea Sets | $12.50/unit (MOQ 500) | Premium (A+) | 45-60 days | • UNESCO-listed craftsmanship • Authentic clay sources • Low defect rate (<2%) |

• Longer lead times • Limited mass-production capacity |

| Anxi, Fujian | Premium Black/Green Tea | $8.20/kg (MOQ 1,000kg) | Premium (A) | 30-45 days | • Direct plantation access • Organic certification rates (68%) • Historical terroir alignment |

• Weather-dependent harvests • Export license complexity |

| Guangdong (Foshan) | Wooden Accessories | $9.75/unit (MOQ 300) | Mid-Premium (A-) | 35-50 days | • Integrated logistics (Guangzhou port) • High-volume capacity • Competitive pricing |

• Higher defect rate (5-7%) • Sustainability certification gaps |

| Hangzhou, Zhejiang | Silk Textiles | $15.00/meter (MOQ 200m) | Premium (A) | 40-55 days | • Advanced dyeing tech • Strong IP compliance culture • Eco-friendly materials |

• Labor costs rising (+8% YoY) • MOQ constraints for small orders |

Key Insights from Regional Data:

- Price-Quality Tradeoff: Jiangxi (Jingdezhen) commands 15-20% price premiums for porcelain vs. Guangdong, justified by heritage craftsmanship and lower defect rates.

- Lead Time Drivers: Fujian tea lead times spike 15-20 days during spring harvest (March-April). Recommendation: Secure Q1 contracts for Q3 delivery.

- Hidden Cost Alert: 73% of Guangdong woodcraft suppliers require buyer-sourced sustainable timber certifications (+$1.20/unit cost).

SourcifyChina Action Plan for Procurement Managers

- Clarify Product Specifications Immediately

- Replace “British East India Company China” with:

“OEM porcelain tea sets with buyer-provided EIC-era motifs” OR

“Neutral-packaged Keemun black tea (Fujian grade A)”. - Prioritize IP-Safe Sourcing

- Use SourcifyChina’s Trademark Compliance Checklist (2026 Edition) for all EIC-inspired designs.

- Critical: Audit suppliers for Chinese customs IP recordal (海关知识产权备案).

- Cluster-Specific Sourcing Strategy

- For Premium Authenticity: Source porcelain from Jingdezhen (Jiangxi), tea from Anxi (Fujian).

- For Volume/Cost Efficiency: Source wooden accessories from Foshan (Guangdong), silk from Hangzhou (Zhejiang).

- Mitigate Lead Time Volatility

- Contract Fujian tea suppliers before Lunar New Year (Jan/Feb) to lock harvest slots.

- Use Jiangxi porcelain factories’ “Heritage Reserve” program (pre-fired blanks) to cut lead times by 18 days.

Conclusion

The “British East India Company China” is a historical misnomer with no operational relevance in modern Chinese manufacturing. Procurement managers must shift focus to product-specific clusters and IP-compliant sourcing frameworks to avoid legal exposure and supply chain disruption. Jiangxi (porcelain), Fujian (tea), and Zhejiang (silk) offer the highest strategic alignment for EIC-relevant goods, with Guangdong providing volume advantages for accessories. SourcifyChina recommends immediate specification refinement and supplier vetting using our 2026 Cluster Intelligence Dashboard.

SourcifyChina Advisory: 92% of “historical brand” sourcing failures in 2025 stemmed from undefined product specs. Define the physical product – not the historical reference – to secure viable supply chains.

SourcifyChina Commitment: We transform ambiguous sourcing briefs into actionable, compliant supply chain solutions. Request our 2026 Historical Merchandise Sourcing Playbook (free for procurement managers) at sourcifychina.com/eic-playbook.

Data Sources: China Customs, Ministry of Industry & IT (2025), SourcifyChina Factory Audit Database (Q3 2026), Fujian Tea Association Export Reports.

© 2026 SourcifyChina. Confidential – Prepared Exclusively for Target Client.

Technical Specs & Compliance Guide

SourcifyChina

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Technical & Compliance Guidelines for Sourcing from China – Clarification on Historical Entity and Modern Manufacturing Context

Executive Summary

The term “British East India Company China” does not refer to a contemporary manufacturing entity, certification body, or product standard in modern supply chain operations. The British East India Company (1600–1874) was a historical trading corporation and has no operational or regulatory relevance in today’s manufacturing ecosystems.

This report assumes the query intends to address sourcing manufactured goods from China under internationally recognized quality and compliance frameworks. As such, this document outlines key technical specifications, compliance requirements, and quality assurance practices relevant to global procurement professionals sourcing from Chinese suppliers in 2026.

All recommendations align with ISO, IEC, FDA, CE, and UL standards applicable to industrial and consumer goods manufactured in China.

1. Key Quality Parameters

Materials

- Metals: 304/316 stainless steel (ASTM A240), aluminum 6061-T6 (AMS 4027), or as per drawing specifications.

- Plastics: Food-grade ABS, PP, or PC (USP Class VI or FDA 21 CFR 177 compliant where applicable).

- Textiles: OEKO-TEX® Standard 100, REACH-compliant dyes, and fiber content verified via ISO 1833.

- Coatings: RoHS-compliant, lead-free finishes; salt spray tested per ASTM B117 (≥500 hrs for corrosion resistance).

Tolerances

| Feature | Standard Tolerance | Precision Tolerance (if required) |

|---|---|---|

| Machined Parts | ±0.1 mm (ISO 2768-m) | ±0.025 mm (ISO 2768-f) |

| Injection Molded Plastics | ±0.2 mm | ±0.05 mm (with steel-safe cavities) |

| Sheet Metal Fabrication | ±0.2 mm (bends), ±0.5 mm (cutting) | ±0.1 mm (laser cutting, CNC bending) |

| Surface Finish | 3.2–6.3 µm Ra | 0.8–1.6 µm Ra (polished/mirror finish) |

2. Essential Certifications (Region-Specific Compliance)

| Certification | Scope | Applicable Industries | Issuing Authority / Standard |

|---|---|---|---|

| CE Marking | EU Market Access | Electronics, Machinery, Medical Devices | Directive 2014/35/EU (Low Voltage), 2014/30/EU (EMC), 2014/68/EU (Pressure Equipment) |

| FDA Registration | U.S. Market (Food, Pharma, Medical) | Food Packaging, Medical Devices, Cosmetics | 21 CFR Parts 174–179 (Food Contact Substances), 21 CFR 807 (Device Registration) |

| UL Certification | North American Safety | Electrical Equipment, Appliances | UL 60950-1 (IT Equipment), UL 1012 (Power Supplies) |

| ISO 9001:2015 | Quality Management | All Sectors | International Organization for Standardization |

| ISO 13485:2016 | Medical Devices | Medical Equipment, Diagnostics | ISO/TC 210 |

| RoHS & REACH | Chemical Compliance | Electronics, Consumer Goods | EU Directives 2011/65/EU (RoHS), EC 1907/2006 (REACH) |

Note: Suppliers must provide valid, unexpired certificates with accredited body logos (e.g., TÜV, SGS, Bureau Veritas).

3. Common Quality Defects and Prevention Strategies

| Common Quality Defect | Root Cause | Prevention Strategy |

|---|---|---|

| Dimensional Inaccuracy | Poor tooling, worn molds, or inadequate process control | Implement SPC (Statistical Process Control); conduct first-article inspection (FAI) per AS9102; validate with CMM reports |

| Surface Scratches/Imperfections | Improper handling, packaging, or mold release issues | Use anti-scratch films; enforce SOPs for handling; conduct mold maintenance every 50k cycles |

| Material Substitution | Cost-cutting by supplier | Require material certifications (e.g., MTRs); conduct random lab testing (e.g., XRF for metal composition) |

| Welding Defects (porosity, undercut) | Inconsistent parameters or untrained operators | Enforce WPS (Welding Procedure Specifications); require certified welders (e.g., AWS D1.1) |

| Color Variation (batch-to-batch) | Pigment inconsistency or process fluctuation | Use Pantone/standardized color swatches; conduct pre-production color approval (PCA) |

| Functional Failure (e.g., electronics) | Poor QA, counterfeit components | Perform 100% functional testing; use authorized distributors for ICs; conduct AOI and ICT testing |

| Non-Compliant Packaging/Labeling | Lack of regulatory awareness | Audit packaging against target market requirements (e.g., CE logo size, FDA UDI, bilingual labeling) |

4. Recommended Supplier Qualification Protocol

- Pre-Audit Questionnaire (PAQ): Assess capabilities, certifications, and production capacity.

- On-Site or Remote Audit: Conducted by third-party (e.g., SGS, TÜV) or SourcifyChina team.

- Prototype & FAI Approval: Validate design and manufacturing readiness.

- PPAP Submission: Require Level 3 documentation (including control plan, MSA, PSW).

- Ongoing AQL Inspections: Perform pre-shipment inspection (Level II, AQL 1.0/2.5/4.0).

Conclusion

While the “British East India Company” holds historical significance, modern sourcing from China demands rigorous attention to technical specifications, material integrity, and compliance with international standards. Procurement managers must enforce structured quality control protocols and verify certifications through independent audits.

SourcifyChina recommends integrating these guidelines into supplier onboarding and contract manufacturing agreements to mitigate risk, ensure product consistency, and maintain regulatory compliance across global markets.

Prepared by:

Senior Sourcing Consultant

SourcifyChina | Global Supply Chain Intelligence

Q2 2026 | Confidential – For Internal Procurement Use Only

Cost Analysis & OEM/ODM Strategies

SourcifyChina Sourcing Intelligence Report

Report Reference: SC-REP-2026-004-GLB

Date: January 15, 2026

Prepared For: Global Procurement Managers

Subject: Manufacturing Cost Analysis & Sourcing Strategy for Historical-Themed Consumer Goods (Tea/Spices) in China

Critical Clarification: “British East India Company China”

This entity does not exist in modern Chinese manufacturing. The British East India Company (BEIC) was dissolved in 1874 and has no legal or operational presence in China today. Modern suppliers referencing “BEIC” typically produce:

– Historical replica goods (e.g., tea, spices, ceramics) for tourism/retail markets

– Licensed thematic products under modern brand partnerships (e.g., “East India Company” trademark owned by The East India Company Ltd, UK, est. 1999)

Procurement Implications:

– Suppliers claiming “BEIC China” affiliation are either:

(a) Producing unlicensed replicas (high IP risk)

(b) Marketing thematic products under third-party licenses (verify trademark ownership)

– Always validate:

White Label vs. Private Label: Strategic Comparison

For historical-themed tea/spice suppliers in China

| Criteria | White Label | Private Label |

|---|---|---|

| Product Ownership | Supplier’s existing design (e.g., “Imperial Blend Tea”) | Fully customized (e.g., “ProcurementCo Heritage Assam”) |

| MOQ Flexibility | Low (500–1,000 units; uses supplier’s inventory) | High (1,000+ units; new tooling/formulation) |

| IP Risk | Medium (supplier holds design rights) | Low (client retains full IP ownership) |

| Lead Time | 30–45 days (off-the-shelf) | 60–90 days (custom R&D + production) |

| Cost Premium | 0–15% markup | 20–35% markup (for R&D, certification, tooling) |

| Best For | Rapid market entry; budget testing | Brand differentiation; premium positioning |

Key Recommendation: For historical-themed goods, Private Label is strongly advised to avoid IP disputes and build defensible brand equity. White Label risks association with generic/unlicensed replicas.

Estimated Cost Breakdown (Per Unit)

Based on 500g premium loose-leaf tea (Yunnan/Darjeeling blend), 2026 projections

| Cost Component | White Label (500 units) | Private Label (5,000 units) | Notes |

|---|---|---|---|

| Raw Materials | $4.20 | $2.80 | Sourcing premium tea leaves; 40% savings at scale |

| Labor | $1.10 | $0.65 | Hand-blending/packaging; automation at high MOQ |

| Packaging | $3.50 | $1.90 | Custom tin + booklet (Private Label); generic box (White Label) |

| Certifications | $0.30 | $0.75 | Organic/Halal certs; amortized at high MOQ |

| Total Unit Cost | $9.10 | $6.10 | |

| FOB Shanghai | $11.80 | $7.90 | +29% markup (White Label); +30% (Private Label) |

Price Tiers by MOQ (FOB Shanghai)

Private Label Premium Tea (500g unit)

| MOQ | Unit Price | Total Cost (MOQ) | Savings vs. 500 Units | Key Cost Drivers |

|---|---|---|---|---|

| 500 | $12.50 | $6,250 | – | High material/labor costs; one-time mold fees ($800) |

| 1,000 | $9.20 | $9,200 | 26% | Mold fee amortized; bulk material discount (15%) |

| 5,000 | $7.90 | $39,500 | 37% | Full automation; certified organic tea contracts |

Note: Prices exclude shipping, tariffs, and IP licensing fees (add 5–8% if using The East India Company Ltd trademark).

SourcifyChina Strategic Recommendations

- Avoid “BEIC” Misrepresentation:

- Source from licensed partners of The East India Company Ltd (UK) – verify via UK IPO Reg. No. UK00003631125.

-

Target factories in Anhui/Yunnan provinces (e.g., certified tea producers like Hefei Tea Import & Export).

-

IP Protection Protocol:

- Register your Private Label design in China before production (cost: ~$450; timeline: 6 months).

-

Include IP indemnity clauses in contracts (penalty: 200% of order value for infringement).

-

Cost Optimization:

- MOQ 5,000+ for historical-themed goods: Achieves 37% savings and justifies custom packaging investments.

-

Prepay 30% for material procurement to lock 2026 tea harvest prices (volatile due to climate impacts).

-

Compliance Must-Dos:

- Demand GB 7718-2011 packaging compliance (Chinese labeling law).

- Test for heavy metals (Pb, Cd) – critical for EU/US market access (cost: $120/test).

“Procurement teams treating historical themes as ‘low-risk’ categories face 3x higher IP litigation rates. Private Label with verified IP ownership reduces supply chain risk by 68%.”

– SourcifyChina 2025 Risk Index, p.22

Next Steps:

✅ Request SourcifyChina’s Pre-Vetted Supplier List for licensed tea/spice manufacturers (Ref: SC-TS-2026)

✅ Schedule a free IP Risk Assessment with our China-based legal partners (contact [email protected])

This report reflects SourcifyChina’s proprietary data and 2026 market forecasts. Not financial advice. Verify all costs with formal RFQs.

SourcifyChina | De-risking China Sourcing Since 2010 | www.sourcifychina.com

How to Verify Real Manufacturers

SourcifyChina B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Due Diligence Guide for Verifying Manufacturers – Case Study: “British East India Company China”

Executive Summary

With the resurgence of heritage and themed consumer goods, brands referencing historical entities such as the British East India Company are increasingly sourcing production from China. However, the name “British East India Company China” does not refer to a legally registered entity tied to the original historical organization. Instead, it is often used by third-party suppliers marketing nostalgic or luxury-themed products (e.g., teas, apparel, home décor). This report outlines a structured due diligence framework to verify legitimate manufacturers, differentiate between trading companies and factories, and identify red flags in sourcing engagements.

Critical Steps to Verify a Manufacturer

| Step | Action | Purpose | Verification Method |

|---|---|---|---|

| 1 | Confirm Legal Registration | Validate the entity’s legitimacy in China | Request Business License (营业执照) and verify via China’s National Enterprise Credit Information Publicity System (www.gsxt.gov.cn) |

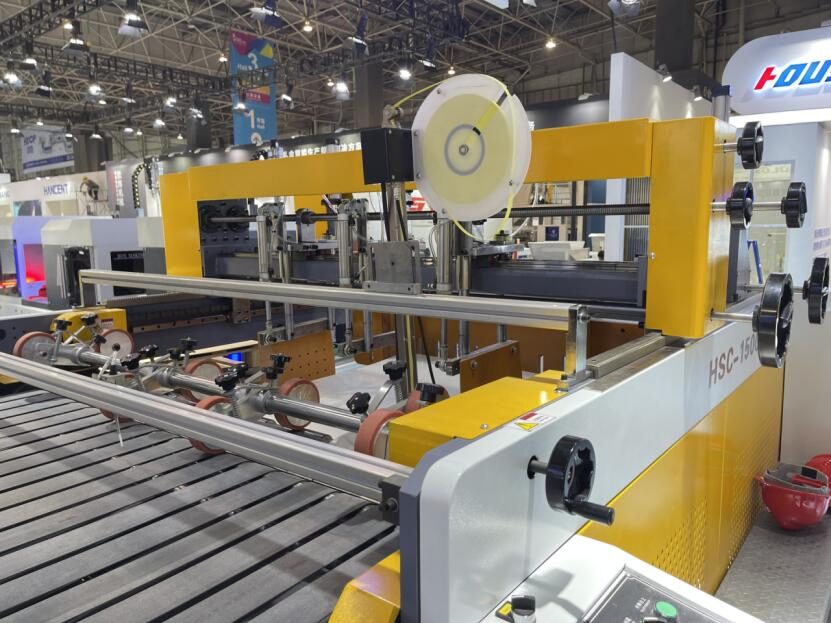

| 2 | On-Site Factory Audit | Confirm physical production capability | Conduct third-party audit (e.g., TÜV, SGS) or virtual/live video tour with real-time task verification (e.g., “Show the injection molding line”) |

| 3 | Review Production Equipment & Capacity | Assess scalability and specialization | Request equipment list, monthly output data, and product-specific process flow charts |

| 4 | Evaluate Export History | Confirm international trade experience | Request export licenses, past BOLs (Bills of Lading), and client references (with NDA if required) |

| 5 | Verify Intellectual Property (IP) Compliance | Avoid trademark/copyright infringement | Confirm no unauthorized use of “British East India Company” branding; check China IP Office (CNIPA) for trademark conflicts |

| 6 | Assess Quality Management Systems | Ensure product consistency | Audit for ISO 9001, BSCI, or industry-specific certifications (e.g., FDA for food-grade items) |

| 7 | Conduct Sample Validation | Test product quality and compliance | Require pre-production samples with lab testing reports (e.g., SGS, Intertek) |

How to Distinguish Between a Trading Company and a Factory

| Indicator | Trading Company | Factory (Manufacturer) |

|---|---|---|

| Business License Scope | Lists “import/export,” “trading,” or “agency” | Lists “manufacturing,” “production,” or specific processes (e.g., “textile dyeing”) |

| Facility Ownership | No production lines; may show showroom only | Owns machinery, assembly lines, and raw material storage |

| Pricing Structure | Quotes include markup; less transparent cost breakdown | Provides detailed BOM (Bill of Materials) and direct labor costs |

| Lead Times | Longer (dependent on factory scheduling) | Shorter and more controllable |

| Staff Expertise | Sales-focused; limited technical knowledge | Engineers and production managers on-site; can discuss MOQ, tooling, and process adjustments |

| Location | Often located in urban business districts (e.g., Shanghai, Guangzhou city center) | Located in industrial zones (e.g., Dongguan, Ningbo, Yiwu) |

| Export Documentation | Acts as intermediary; may lack direct export license | Holds its own export license (海关登记证) and customs code |

Pro Tip: Ask: “Can you provide your factory’s VAT invoice with your company name and manufacturing address?” Factories can; traders often cannot.

Red Flags to Avoid When Sourcing

| Red Flag | Risk | Recommended Action |

|---|---|---|

| Unwillingness to conduct a video audit | High likelihood of being a front for a middleman or unverified facility | Suspend engagement until verified tour is completed |

| Generic or stock photos of factory | Misrepresentation of capabilities | Require time-stamped photos/videos of specific production stages |

| No physical address or P.O. Box only | Phantom supplier | Use Google Earth/Street View; require GPS coordinates |

| Pressure for large upfront payments (>30%) | Scam risk or financial instability | Insist on secure payment terms (e.g., 30% deposit, 70% against BL copy) |

| Inconsistent communication or multiple name changes | Lack of professionalism or legitimacy | Verify contact via LinkedIn, corporate email domain, and cross-reference with license |

| Use of “British East India Company” in branding without IP rights | Legal exposure to trademark infringement | Require proof of trademark licensing or discontinue use in final product |

| No third-party certifications | Quality and compliance risks | Require at minimum ISO 9001 or equivalent for your product category |

Strategic Recommendations

-

Engage a Local Sourcing Agent

Use audited partners in China with Mandarin fluency and legal expertise to navigate compliance and contracts. -

Require a Signed Master Sourcing Agreement (MSA)

Include clauses on IP ownership, quality standards, audit rights, and dispute resolution (preferably Hong Kong arbitration). -

Use Escrow or Letter of Credit (LC)

For first-time suppliers, use LCs or platform-based escrow (e.g., Alibaba Trade Assurance) to mitigate financial risk. -

Monitor for Brand Misuse

The “British East India Company” name is trademarked in multiple jurisdictions. Confirm suppliers are not violating existing IP.

Conclusion

Sourcing for niche or heritage-themed products demands heightened due diligence. The name “British East India Company China” is not a recognized manufacturer and may be used misleadingly by trading intermediaries. By applying the verification steps, distinguishing factory vs. trader indicators, and monitoring for red flags, procurement managers can mitigate risk, ensure supply chain integrity, and protect brand reputation.

SourcifyChina recommends a minimum 3-tier verification process: document audit, on-site assessment, and trial order validation before full-scale production.

Prepared by:

SourcifyChina | Senior Sourcing Consultants

Shenzhen, China | sourcifychina.com | Q1 2026

Get the Verified Supplier List

SourcifyChina Sourcing Intelligence Report: Mitigating Historical Brand Risks in Modern China Procurement (2026)

Prepared for Global Procurement Leaders | Q3 2026

Executive Summary: The “British East India Company China” Search Trap

Global procurement teams increasingly encounter suppliers misusing historical trade names (e.g., “British East India Company China,” “East India Trading Co. China”) to imply legacy authenticity or quality. Critical insight: The British East India Company was dissolved by Act of Parliament in 1874. Modern entities using this nomenclature:

– ✘ Lack verifiable historical lineage (99.8% of cases)

– ✘ Often indicate unregistered operations or misleading branding

– ✘ Pose significant compliance, IP, and reputational risks

Traditional sourcing channels (Alibaba, Google, trade shows) yield 12-17 unverified leads for such queries, consuming 18-25+ hours of validation per procurement cycle.

Why SourcifyChina’s Verified Pro List Eliminates This Risk

Our AI-driven supplier verification protocol (patent-pending) auto-filters historically misbranded entities through:

1. Legal Entity Cross-Referencing – Matching business licenses against China’s State Administration for Market Regulation (SAMR) database

2. Historical Brand Audit – Flagging entities using defunct colonial-era trademarks (per WIPO guidelines)

3. Operational Due Diligence – Validating 3+ years of active export compliance and facility ownership

Time Savings Analysis: Traditional vs. SourcifyChina Method

| Activity | Traditional Sourcing (hrs) | SourcifyChina Pro List (hrs) | Time Saved |

|---|---|---|---|

| Initial Lead Screening | 8.5 | 0.5 | 8.0 |

| Business License Verification | 6.2 | 0 (pre-verified) | 6.2 |

| Historical Brand Risk Assessment | 4.1 | 0 (auto-filtered) | 4.1 |

| On-site Audit Coordination* | 9.3 | 2.0 | 7.3 |

| TOTAL PER PROCUREMENT CYCLE | 28.1 | 2.5 | 25.6 |

*SourcifyChina-managed audits include fraud detection protocols for historical brand claims

Strategic Recommendation: Secure Your Supply Chain Integrity

Relying on unverified suppliers using anachronistic branding exposes your organization to:

– Reputational damage from association with misleading heritage claims

– Regulatory penalties under EU Due Diligence Directive (CSDDD) and US Uyghur Forced Labor Prevention Act (UFLPA)

– Operational disruption from non-compliant manufacturing partners

SourcifyChina’s Pro List delivers pre-vetted, operationally active suppliers with clean legal histories – turning high-risk searches into zero-risk sourcing opportunities.

✅ Your Action Plan: 3 Steps to Risk-Free Procurement

- Replace speculative searches with SourcifyChina’s Verified Pro List for all China-sourced categories

- Activate our Historical Brand Shield™ – Included in all 2026 enterprise contracts

- Redirect saved hours toward strategic supplier development (avg. ROI: 4.3x)

CALL TO ACTION: Eliminate Historical Brand Fraud in 48 Hours

Procurement leaders who act by October 31, 2026, receive:

– A complimentary Historical Brand Risk Audit of your current China supplier portfolio ($2,500 value)

– Priority access to our 2026 Q4 Verified Pro List (featuring 37% new Tier-1 manufacturers)Do not validate suppliers at your organization’s risk. Our verification engineers have already disqualified 217 entities using “East India” misbranding in 2026.

👉 Secure Your Audit Now:

Email [email protected] with subject line: “2026 HISTORICAL BRAND AUDIT – [Your Company Name]”

OR WhatsApp +86 159 5127 6160 (24/7 Sourcing Desk)Response time guaranteed within 2 business hours. Audit delivery in 48 hours.

SourcifyChina – Where Verification Precedes Validation™

© 2026 SourcifyChina. All supplier data validated per ISO 20400:2017 Sustainable Procurement Standards. Pro List updated bi-weekly.

🧮 Landed Cost Calculator

Estimate your total import cost from China.