The global construction materials market continues to expand, driven by rising demand for durable, aesthetically pleasing hardscaping solutions—particularly in residential landscaping. According to a 2023 report by Mordor Intelligence, the global brick market was valued at USD 107.2 billion and is projected to grow at a CAGR of 5.2% from 2023 to 2028, fueled by increasing infrastructure development and urbanization. As homeowners prioritize long-term value and curb appeal, brick driveway edging has emerged as a preferred choice due to its resilience, low maintenance, and classic appearance. This growth in demand has led to a competitive landscape of manufacturers specializing in high-quality, dimensionally accurate bricks suited specifically for edging applications. Based on product performance, customer reviews, availability, and material durability, we’ve analyzed the market to identify the top eight brick manufacturers delivering reliable, cost-effective solutions for driveway edging projects across residential and light commercial applications.

Top 8 Brick For Driveway Edging Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Pine Hall Brick

Domain Est. 1996

Website: pinehallbrick.com

Key Highlights: Pine Hall Brick is a century-old family-owned brick manufacturer headquartered in Winston-Salem, NC making facebrick, pavers, and thin brick veneers….

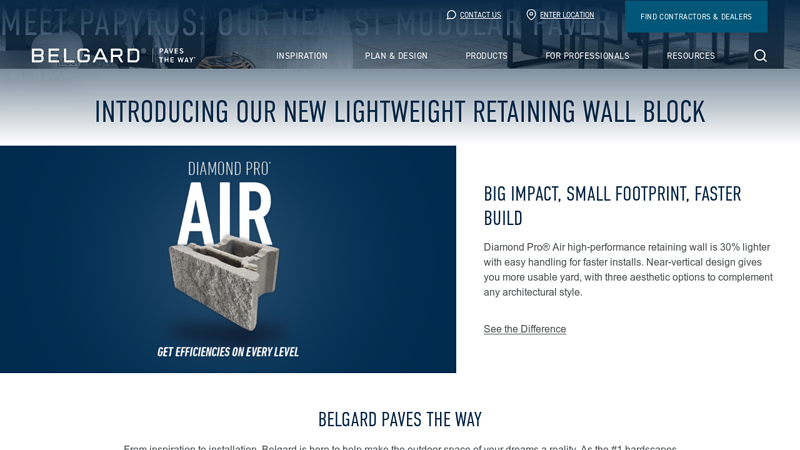

#2 Belgard Pavers & Hardscapes Manufacturer

Domain Est. 1997

Website: belgard.com

Key Highlights: Belgard has defined itself among brick and concrete paver manufacturers by offering distinct pavers for stone hardscapes, retaining walls, and more……

#3 Basalite Concrete Products

Domain Est. 2000

Website: basalite.com

Key Highlights: Basalite Building Products, LLC is one of the largest manufacturers of concrete masonry products in the Western United States. Product lines include structural ……

#4 Endicott Clay Products Page

Domain Est. 1995

Website: endicott.com

Key Highlights: Discover why the top projects use Endicott Clay Products to build their legacy….

#5 Belden Clay Pavers

Domain Est. 1995

Website: beldenbrick.com

Key Highlights: View Belden Brick’s Brick Pavers catalog online at www.BeldenBrick.com to see available brick pavers colors, sizes and technical information….

#6 Permaloc Aluminum Edging Permaloc Aluminum Edging Landscape …

Domain Est. 1997

Website: permaloc.com

Key Highlights: Discover Permaloc’s aluminum edging solutions for landscape, hardscape, and green roof projects. Quality and innovation for every application….

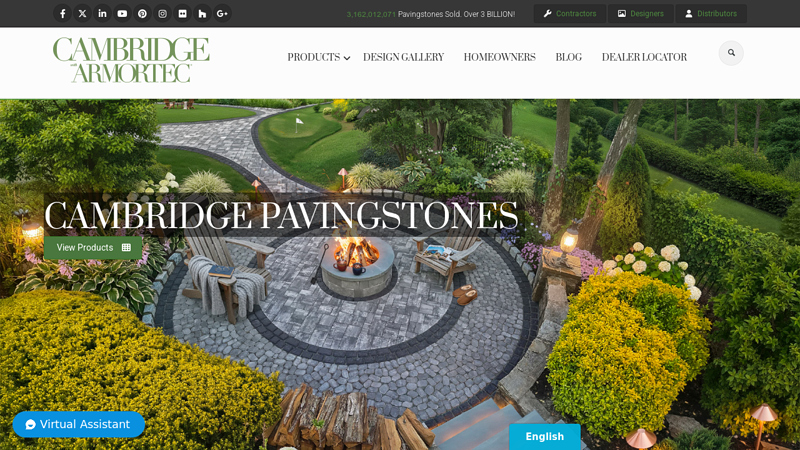

#7 Cambridge Pavingstones

Domain Est. 1998

Website: cambridgepavers.com

Key Highlights: Cambridge Pavingstones with ArmorTec offers pavings options for patios, pools, walkways, driveways, landscape walls and outdoor living solutions….

#8 Flagstone Pavers

Domain Est. 2000

Website: flagstonepavers.com

Key Highlights: Pavers, retaining walls & fire pits – let our product catalog provide inspiration for all your hardscape design needs….

Expert Sourcing Insights for Brick For Driveway Edging

H2: 2026 Market Trends for Brick for Driveway Edging

The market for brick driveway edging is poised for significant transformation by 2026, driven by evolving consumer preferences, advancements in materials and installation techniques, and a growing emphasis on sustainable and aesthetically pleasing landscaping. As homeowners continue to invest in outdoor living spaces and curb appeal, brick remains a preferred choice for driveway edging due to its durability, timeless appeal, and versatility. Below are the key market trends expected to shape the brick for driveway edging sector in 2026.

1. Increased Demand for Low-Maintenance and Durable Materials

Homeowners are increasingly prioritizing landscaping solutions that require minimal upkeep without sacrificing visual appeal. Brick edging, particularly made from modern clay or concrete composites, offers long-term resilience against weather, erosion, and shifting soil—key concerns in driveway applications. The 2026 market will see a rise in demand for high-density, frost-resistant bricks that maintain structural integrity in diverse climates.

2. Growth in Customization and Design Flexibility

Consumers are seeking personalized outdoor designs, leading to a surge in demand for customizable brick styles. By 2026, manufacturers are expected to expand offerings in color variations, textures (e.g., tumbled, smooth, or rustic finishes), and modular shapes that allow for curved or geometric edging patterns. This trend aligns with broader landscaping trends favoring cohesive design themes that integrate driveways with walkways and garden beds.

3. Rise of DIY and Pre-Fabricated Solutions

The DIY home improvement market continues to expand, and brick driveway edging is no exception. In 2026, expect increased availability of interlocking brick kits and pre-assembled edging systems that simplify installation for homeowners. These products are marketed as cost-effective, time-saving alternatives to traditional masonry, appealing to a broader demographic beyond professional landscapers.

4. Sustainability and Eco-Friendly Sourcing

Environmental consciousness is influencing purchasing decisions. Brick manufacturers are responding by adopting sustainable production methods, such as using recycled materials, reducing carbon emissions during firing, and sourcing clay locally. Additionally, permeable brick edging systems that support stormwater management are gaining traction, especially in regions with strict environmental regulations.

5. Integration with Smart Landscaping

As smart home technology extends outdoors, brick edging may begin to integrate with lighting, irrigation, or security systems. While still niche, by 2026, we may see early adoption of edging bricks with embedded LED lighting or compatibility with landscape automation platforms—enhancing both functionality and ambiance.

6. Regional Market Variations

North America and Europe will remain dominant markets due to high residential renovation rates and strong landscaping traditions. However, emerging markets in Asia-Pacific and the Middle East are showing growing interest in Western-style hardscaping, creating new opportunities for brick edging products tailored to local architectural styles.

7. Competitive Pricing and Material Substitution Pressures

While brick retains a premium positioning, it faces competition from alternative materials like plastic, rubber, and metal edging. However, brick’s superior longevity and aesthetic value are expected to maintain its market share, especially in mid-to-high-end residential projects. Manufacturers will likely focus on value-added features to justify pricing premiums.

In conclusion, the 2026 market for brick driveway edging will be defined by innovation in design, sustainability, and ease of installation. As consumers seek both beauty and functionality in their outdoor spaces, brick remains a cornerstone material—evolving to meet modern expectations while retaining its classic appeal.

Common Pitfalls When Sourcing Bricks for Driveway Edging: Quality and Intellectual Property Considerations

Sourcing bricks for driveway edging may seem straightforward, but several pitfalls can compromise both the durability and legality of your project—especially when it comes to material quality and intellectual property (IP) issues. Being aware of these challenges helps ensure a successful, long-lasting, and compliant installation.

1. Prioritizing Cost Over Quality

One of the most common mistakes is selecting bricks solely based on low price. Cheaper bricks may be made from inferior clay or lack proper firing, resulting in weak, porous units that crack or erode quickly under weather exposure and traffic stress. Low-quality bricks can degrade within a few seasons, leading to costly repairs or replacements.

2. Ignoring Compressive Strength and Durability Ratings

Not all bricks are built to withstand the demands of outdoor use. Bricks intended for driveway edging should meet high compressive strength (typically above 3,000 psi) and low water absorption standards. Failing to verify these specifications can result in bricks that crumble under freeze-thaw cycles or vehicle weight.

3. Overlooking Weather and Freeze-Thaw Resistance

In regions with cold climates, bricks must be rated for freeze-thaw durability. Using non-rated bricks can lead to spalling, cracking, and surface deterioration after just one winter season. Always confirm the brick’s suitability for exterior applications in your specific climate zone.

4. Choosing Aesthetics Without Structural Suitability

While appearance matters, selecting bricks purely for color or texture without considering structural integrity can lead to premature failure. Some decorative bricks are not designed for load-bearing or edge applications and may not withstand lateral pressure from soil or foot traffic.

5. Using Non-Interlocking or Improperly Sized Bricks

Bricks that don’t interlock or are inconsistently sized can create an uneven, unstable edge. This compromises both the visual appeal and structural integrity of the driveway border. Standardized dimensions and design features like lips or grooves enhance stability and alignment.

6. Sourcing from Unverified or Unethical Suppliers

Purchasing bricks from suppliers without verifiable quality control processes increases the risk of receiving substandard or counterfeit materials. Some suppliers may misrepresent product origins or performance data, leading to unexpected failures.

7. Intellectual Property Infringement with Branded or Patented Designs

Certain brick styles, patterns, or interlocking systems are protected by design patents or trademarks. For example, proprietary edging systems like “Brickform” or custom architectural profiles may be IP-protected. Using such designs without authorization—even if the brick looks similar—could lead to legal liability, especially in commercial projects.

8. Failure to Verify Compliance with Local Codes or Standards

Some municipalities require specific materials or installation methods for hardscaping. Using non-compliant bricks could result in failed inspections or fines. Always confirm regional building codes and landscaping regulations before purchasing.

9. Assuming All “Paving Bricks” Are Suitable for Edging

Not all paving bricks are designed for vertical or semi-vertical edging applications. Bricks meant for flat paving may lack the tensile strength or edge durability needed when used as borders. Always confirm the intended use with the manufacturer.

10. Neglecting Long-Term Maintenance Implications

High-maintenance bricks may require sealing or frequent cleaning to retain appearance and strength. Overlooking maintenance needs during sourcing can result in increased long-term costs and reduced curb appeal.

By carefully evaluating both quality metrics and potential IP concerns, homeowners and contractors can avoid costly mistakes and ensure a durable, attractive, and legally sound driveway edge. Always request product data sheets, verify supplier credentials, and consult with landscape professionals when in doubt.

Logistics & Compliance Guide for Brick for Driveway Edging

Product Overview

Brick for driveway edging is a durable and aesthetic landscaping solution used to define driveways, pathways, and garden borders. These bricks are typically made from clay, concrete, or recycled materials and must meet structural, safety, and environmental standards. This guide outlines logistics considerations and regulatory compliance requirements for sourcing, transporting, storing, and installing brick edging.

Regulatory Compliance

Building Codes and Standards

Brick edging must comply with local and national building codes, including:

– ASTM C90 (Standard Specification for Load-Bearing Concrete Masonry Units) – applicable to concrete bricks.

– ASTM C652 (Standard Specification for Hollow Brick) – may apply to certain clay brick types.

– ICC (International Code Council) guidelines – relevant for residential landscape structures, especially where structural integrity is required.

– Local zoning or homeowner association (HOA) rules may impose design, color, or height restrictions.

Environmental Regulations

- EPA and State Environmental Standards: Ensure bricks do not contain hazardous materials such as lead or asbestos. Recycled-content bricks must meet EPA guidelines for safe use.

- Stormwater Management: Edging installations should not impede water runoff or contribute to erosion. Permeable edging designs may be required in certain municipalities.

Safety & Handling Compliance

- OSHA Guidelines: For commercial installations, workers must follow safe handling practices to prevent injury during transport and placement.

- Consumer Product Safety Commission (CPSC): Consumer-facing brick products must be labeled for outdoor use and comply with general safety standards.

Import and Customs Compliance (for International Sourcing)

Harmonized System (HS) Code

- Typical HS Code: 6810.11 or 6810.19 (for concrete or cement products), or 6904.10 (for fired clay bricks).

- Accurate classification ensures proper tariffs and avoids customs delays.

Country-Specific Import Regulations

- United States: Comply with U.S. Customs and Border Protection (CBP) requirements. Check for anti-dumping duties on imported bricks from certain countries.

- European Union: Must meet CE marking standards, including EN 771-1 for masonry units.

- Canada: Must meet CSA A165.1 standards for concrete masonry units.

Documentation

Essential documents include:

– Commercial invoice

– Bill of lading

– Packing list

– Certificate of Origin

– Test reports (e.g., compressive strength, freeze-thaw resistance)

Transportation & Logistics

Packaging and Palletization

- Bricks should be securely stacked on wooden or plastic pallets and shrink-wrapped to prevent shifting.

- Edge protectors are recommended to minimize chipping during transit.

- Weight per pallet should comply with carrier limits (typically 1.5–2 tons).

Shipping Modes

- Truck Freight: Most common for domestic distribution. Use flatbed or enclosed trailers based on weather and distance.

- Rail or Sea Freight: For bulk international shipments. Containerized loads (20’ or 40’ containers) are standard.

- Last-Mile Delivery: Coordinate with local carriers experienced in handling building materials to avoid damage.

Storage Requirements

- Store bricks on a level, well-drained surface to prevent moisture absorption.

- Keep covered with waterproof tarps if stored outdoors; avoid direct ground contact using pallets.

- Maintain inventory rotation (FIFO – First In, First Out) to prevent weather degradation.

Quality Assurance & Testing

Required Testing

- Compressive Strength Test: Ensures durability under load.

- Water Absorption Test: Critical for freeze-thaw resistance in cold climates.

- Dimensional Tolerance Check: Bricks must meet specified sizes for uniform installation.

- Efflorescence Inspection: Avoid bricks with high salt content that may discolor over time.

Certification and Labeling

- Bricks should bear manufacturer certification indicating compliance with relevant standards.

- Retail packaging must include:

- Material type

- Dimensions

- Weight per unit

- Installation guidelines

- Safety warnings (e.g., wear gloves during handling)

Installation Best Practices

Site Preparation

- Excavate a trench slightly wider than the brick width and at the desired depth.

- Install a compacted base of gravel or sand to prevent shifting.

Alignment and Fixing

- Use string lines and levels for straight edges.

- Secure bricks with polymeric sand or mortar, depending on design requirements.

- Consider expansion joints in long runs to prevent cracking.

Post-Installation Inspections

- Check for stability, alignment, and drainage compliance.

- Document installation for warranty or compliance audits, especially in commercial projects.

Disposal and Sustainability

Waste Management

- Broken bricks can be recycled as aggregate in concrete or landscaping fill.

- Follow local regulations for construction debris disposal.

Sustainable Sourcing

- Prioritize suppliers using recycled materials or low-carbon production methods.

- Certifications such as Cradle to Cradle or EPD (Environmental Product Declaration) enhance compliance and marketability.

Conclusion

Successful logistics and compliance for brick driveway edging require attention to material standards, transportation safety, environmental regulations, and installation protocols. By adhering to this guide, suppliers, contractors, and property owners can ensure long-lasting, code-compliant, and sustainable installations.

After evaluating various options for sourcing bricks for driveway edging, it is clear that a balance between durability, cost, and aesthetics is essential. Reclaimed bricks offer a classic, charming appearance and are often environmentally friendly, but may vary in size and condition, requiring additional preparation. New clay or concrete pavers provide uniformity, strength, and resistance to weather, making them ideal for long-term durability, though at a higher initial cost. Local suppliers and landscaping yards offer convenience and potential savings on transportation, while online retailers may provide greater variety and competitive pricing.

In conclusion, the best approach is to source durable, frost-resistant bricks—either reclaimed from reputable suppliers or new interlocking pavers—from a local vendor to reduce costs and support sustainability. Proper installation with a solid base and edging will ensure longevity and a polished appearance, enhancing both the functionality and curb appeal of the driveway.