Ever stared at a massive shipment or package and wondered how to divide it into manageable parts? Whether you’re streamlining deliveries, organizing inventory, or prepping for a big event, knowing how to break in bulk can save time, money, and stress.

This question matters because handling large quantities efficiently impacts logistics, storage, and even your bottom line. In this article, you’ll discover practical steps, useful tips, and smart strategies to break in bulk with confidence.

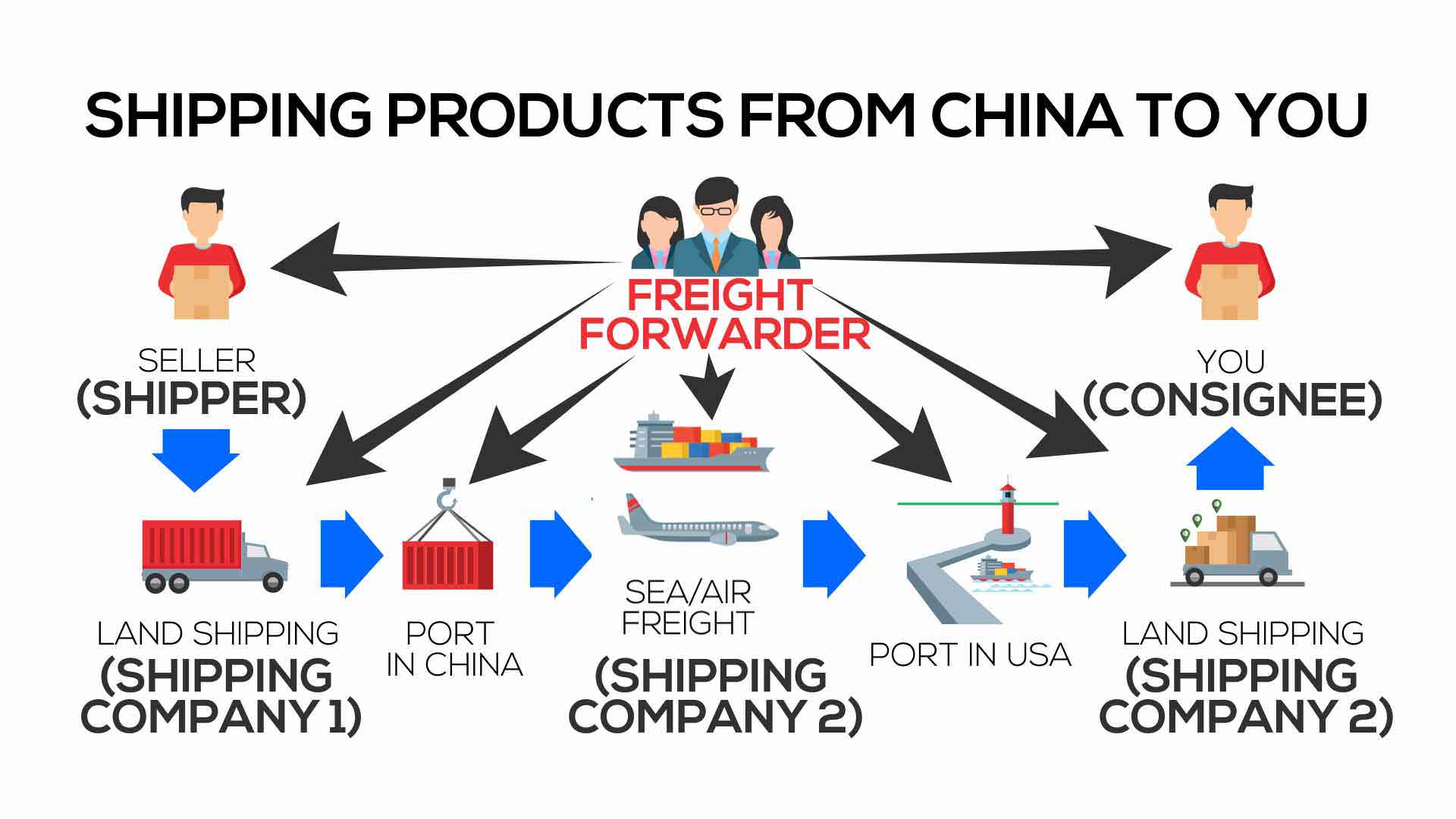

Related Video

What Does ‘Break in Bulk’ Mean?

‘Break in bulk’, often called ‘breakbulk’, is a shipping and logistics term. It refers to the process of unloading, transferring, or distributing cargo that is not in containers or bulk quantities. Unlike shipping massive amounts of loose items (like grain or oil) or using large containers, breakbulk involves cargo that is shipped individually or as a unit—think bags, crates, heavy machinery, or steel beams.

In simple terms, when you break bulk, you’re dealing with items that are handled and transported piece by piece, rather than by the ton or by container.

Understanding How to Break in Bulk

Breaking in bulk is an essential part of global trade and transportation. It allows goods that are too large, irregular, or heavy for containers to get from point A to point B efficiently. Here’s a deeper look at how you can break in bulk:

1. Recognize Breakbulk Cargo Types

To understand breakbulk, first know what types of cargo fall under this category. These typically include:

- Machinery and engines

- Large vehicles

- Construction materials (e.g., steel pipes, beams)

- Bagged or boxed goods

- Drums, barrels, or rolls

- Palletized items

Each of these has unique handling and documentation requirements.

2. Steps to Break in Bulk Shipping

- Preparation & Planning

- Identify the cargo and its special handling needs.

-

Arrange for appropriate equipment (cranes, lifts, slings).

-

Packing and Securing

- Package goods securely for transit. Use bundles, crates, or pallets.

-

Ensure items are protected from moisture, movement, or damage.

-

Loading onto Vessel

- Load cargo onto ships using cranes or forklifts.

-

Secure each piece using straps, chains, or dunnage (protective materials) to prevent shifting during the voyage.

-

Documentation and Customs

- Prepare specific breakbulk documentation. This may include bills of lading, packing lists, and cargo manifests.

-

Comply with local and international regulations for customs clearance.

-

Transport and Unloading

- Monitor cargo during transit.

- At the destination port, unload each item individually or by grouping.

-

Transfer cargo to trucks or trains for final delivery.

-

Final Distribution

- Upon reaching the warehouse or end-user, unpack and deliver the items to their final location.

3. Key Benefits of Break in Bulk

Break in bulk offers significant advantages, especially for oversized or irregular goods:

- Versatility: You can ship cargo that doesn’t fit into standard containers.

- Flexibility: Handles project cargo, such as turbines or construction equipment.

- Accessibility: Suitable for ports without advanced container facilities.

- Damage Control: Goods are individually handled, often leading to fewer losses in transit if done right.

4. Common Challenges and Solutions

Shipping breakbulk isn’t without its challenges. Here’s what you might face, and how to overcome these hurdles:

- Labor-Intensive Operations: More manual handling means higher labor costs and the potential for delays.

-

Solution: Invest in skilled labor and mechanized handling equipment.

-

Greater Risk of Damage: Individual items face exposure to the elements and rough handling.

-

Solution: Use protective packaging and weather-resistant covers.

-

Complex Logistics: More pieces mean more documentation and handling.

-

Solution: Employ experienced logistics partners and track all pieces meticulously.

-

Longer Turnaround Time: Loading and unloading take longer than with containerized shipping.

- Solution: Plan schedules carefully and allow extra time for port operations.

5. Practical Tips and Best Practices for Break Bulk

Success in breakbulk shipping comes down to preparation and attention to detail. Use these tips:

- Survey Your Cargo: Know the dimensions, weight, and fragility of every piece.

- Inspect Ports: Choose ports with breakbulk handling expertise and equipment.

- Coordinate with All Parties: Communicate shipping details with freight forwarders, port operators, and end-users.

- Label Everything Clearly: Prevent misplacement by marking all items with unique identifiers.

- Don’t Skimp on Packing: Invest in durable, custom-fit packaging for high-value or fragile items.

- Monitor Weather: Schedule shipments to avoid exposure to harsh weather during loading or at sea.

- Optimize Stowage: Plan vessel and truck loading to maximize space usage and minimize movement during transit.

6. Cost Tips When Shipping Break Bulk Cargo

Managing costs is essential with breakbulk shipments because they can get pricey due to labor and specialized equipment requirements. Here’s how to control expenses:

- Consolidate Shipments: Combine smaller pieces into larger units where possible to save on handling.

- Choose Appropriate Ports: Some ports have lower breakbulk fees and more competitive services.

- Negotiate with Carriers: Try to get volume discounts, especially if you have ongoing or large shipments.

- Proper Packaging: Well-protected cargo reduces the risk of damage and insurance claims.

- Compare Freight Forwarders: Get quotes from several logistics providers specialized in breakbulk shipments to secure the best rates.

Conclusion

Breaking in bulk is a vital element in the shipping industry, enabling the movement of goods that would otherwise be impossible to transport via containerized or bulk methods. While the process can be more hands-on and requires detailed planning, its flexibility makes it indispensable for large, heavy, or oddly shaped cargo. By understanding the process, following best practices, and keeping an eye on costs, you can successfully manage breakbulk shipments for your business or project.

Frequently Asked Questions (FAQs)

What is breakbulk cargo, and how does it differ from bulk cargo?

Breakbulk cargo refers to goods shipped as individual pieces, such as machinery, crates, or palletized items, rather than as loose cargo. Bulk cargo, on the other hand, is transported in large, unpackaged quantities like coal, grain, or liquid. Breakbulk is handled individually while bulk is loaded directly into the ship’s hold.

Why choose breakbulk shipping instead of container shipping?

Breakbulk is ideal for cargo that is too large, heavy, or awkwardly shaped for standard containers. It also works well for ports without container facilities and for project-specific or irregular shipments.

Is breakbulk shipping more expensive than container shipping?

Generally, yes. Breakbulk shipping tends to be more labor-intensive and can involve higher costs for handling, packaging, and specialized equipment. However, for oversized or heavy items, it may be the only feasible option.

How can I ensure the safety of my breakbulk cargo during transit?

Use high-quality packaging, secure the cargo with specialized equipment (like slings and straps), and select experienced freight forwarders. Monitoring shipments and choosing the right ports for handling are also critical to minimize risks.

What documents do I need for breakbulk shipments?

Typical documents include the bill of lading, packing list, cargo manifest, and any necessary customs documentation. Each shipment may require additional papers depending on the cargo type and destination, so consult your logistics provider.

Breaking in bulk may seem complex at first glance, but with the right knowledge and preparation, it can be a smooth part of your global shipping strategy. If you’re new to breakbulk or need guidance, connect with logistics experts who specialize in this field to keep your goods moving efficiently and securely.