The global wool yarn market is experiencing steady expansion, driven by rising consumer demand for sustainable, natural fibers and the resurgence of interest in premium knitwear. According to a report by Mordor Intelligence, the global wool market was valued at USD 4.2 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 4.8% through 2029. Brazil, with its strong textile heritage and access to high-quality raw materials, has emerged as a key player in the Latin American wool yarn manufacturing sector. Bolstered by investments in sustainable production and innovation in blended yarns, Brazilian manufacturers are increasingly capturing attention in both regional and international markets. As the demand for ethically produced, fine wool yarns continues to rise—particularly merino and eco-friendly blends—the country’s top manufacturers are well-positioned to capitalize on this upward trend. Here’s a data-driven look at the top 9 Brazilian wool yarn manufacturers shaping the future of the industry.

Top 9 Brazilian Wool Yarn Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Sutlej Textiles

Domain Est. 2009

Website: sutlejtextiles.com

Key Highlights: A one-stop shop for all types of yarn and premium range of exclusives, innovative textiles crafted for home fabrics and and Green Fibre with marquee clients in ……

#2 Yarns manufacturing companies from Brazil

Domain Est. 2015

Website: textileinfomedia.com

Key Highlights: Looking for yarn manufacturers in Brazil? Just visit us and find yarns manufacturers, suppliers, exporters and wholesalers in Brazil. They all are yarn ……

#3 Salud Style

Domain Est. 2018

Website: saludstyle.com

Key Highlights: Salud Style is a yarn manufacturer and supplier. We produce high-quality yarn for global customers. Email: [email protected]….

#4 Woolmark Supplier Search

Domain Est. 1995

Website: woolmark.com

Key Highlights: The Woolmark Supplier Search features a diverse range of Woolmark-licensed suppliers – from spinners and weavers to trading houses and vertical operations….

#5 Katia Yarns – Wool – Fabrics…

Domain Est. 1997

Website: katia.com

Key Highlights: KATIA Official Website – Knitting yarns, fabrics, books and free patterns by Katia….

#6 Brazilian wool

Domain Est. 1999

Website: chinatexnet.com

Key Highlights: We,China Brazilian wool Supplier, offer Brazilian wool with competitive price to global textile industry users….

#7 Brazilian Wool Hair Acrylic Yarn for African Hair Braiding

Domain Est. 2001

Website: mh-chine.com

Key Highlights: Brazilian yarn for hair braidings are lightweight and easy to blends with human hair. Great for Jumbo Braid Senegalese twist, wraps, braids….

#8 LANGYARNS

Domain Est. 2002

Website: langyarns.com

Key Highlights: Since 1867 LANGYARNS has been developing and distributing high quality hand knitting yarns. Find classic as well as trend yarns with matching instructions….

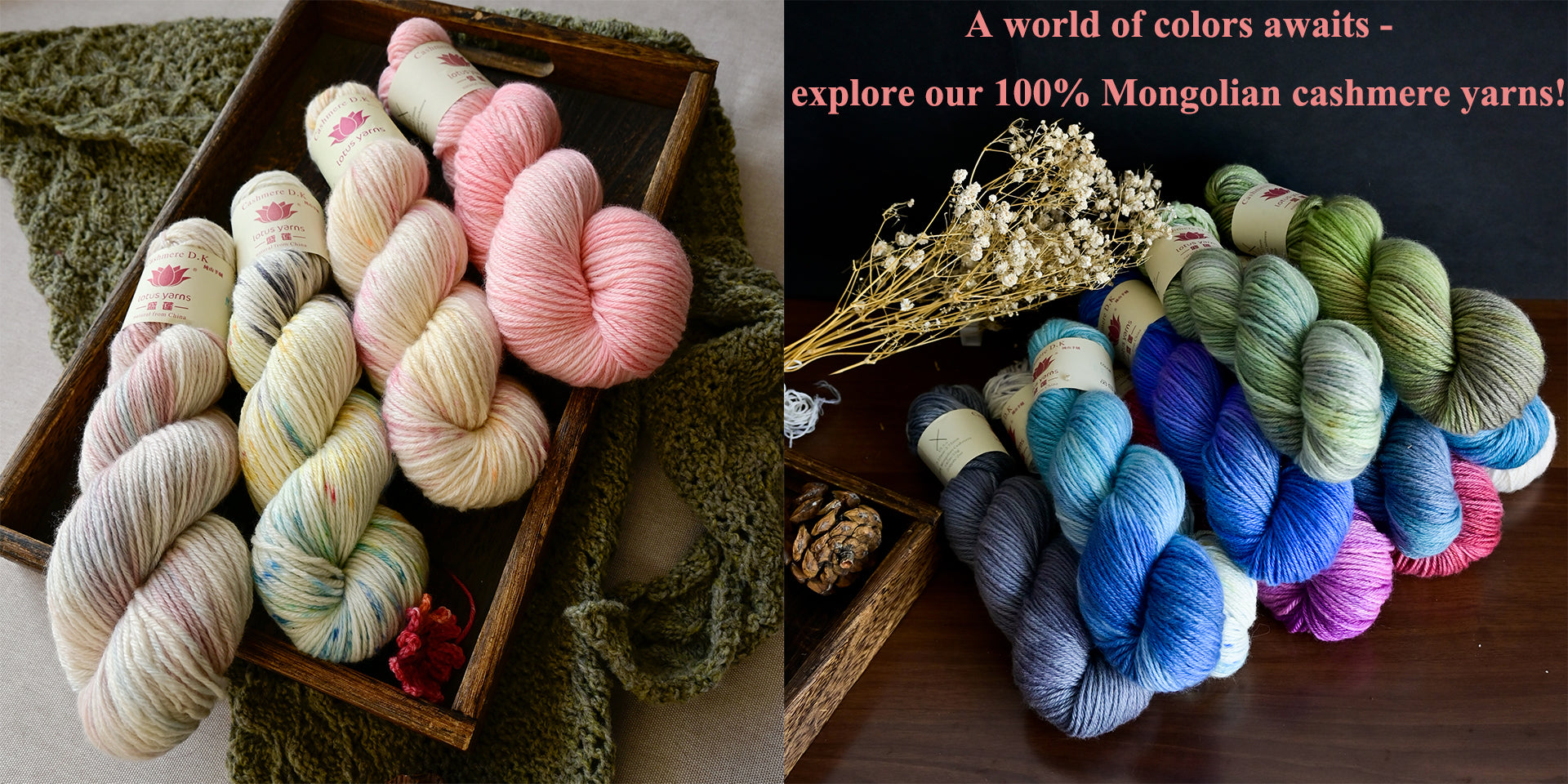

#9 Lotus Yarns

Domain Est. 2007

Website: lotusyarns.com

Key Highlights: Lotus Cashmere Co.,Ltd specializes in spinning and dyeing natural luxury fibers for global markets, including woven yarns, hand knitting yarns, hand-dyeing, and ……

Expert Sourcing Insights for Brazilian Wool Yarn

H2: 2026 Market Trends for Brazilian Wool Yarn

The Brazilian wool yarn market in 2026 is expected to reflect a complex interplay of domestic challenges, global shifts, and evolving consumer preferences. While not a dominant global player in raw wool production, Brazil’s textile sector, particularly in value-added yarns, will navigate key trends shaping its trajectory.

1. Domestic Production Constraints and Import Reliance:

Brazil’s domestic sheep farming is limited and primarily focused on meat (notably Churrasco breeds), resulting in minimal fine wool (like Merino) output. Consequently, the Brazilian wool yarn industry remains heavily dependent on imported raw wool—mainly from Australia, New Zealand, and Argentina. In 2026, this dependency will persist, making yarn producers vulnerable to international price volatility, supply chain disruptions, and exchange rate fluctuations of the Real. Local efforts to improve wool quality and volume (e.g., in Rio Grande do Sul) are nascent and unlikely to significantly alter import dependence by 2026.

2. Growth in Sustainable and Eco-Conscious Textiles:

A major trend driving the 2026 market is the rising demand for sustainable, natural fibers. Wool—being biodegradable, renewable, and low-impact compared to synthetics—is gaining favor among environmentally conscious consumers and brands. Brazilian yarn spinners are increasingly marketing wool blends (e.g., wool/organic cotton, wool/linen, wool/recycled fibers) with sustainability certifications (e.g., RWS, GOTS). This shift is supported by growing domestic and international interest in ethical fashion and circular economy principles.

3. Niche Market Positioning and Premiumization:

Brazilian wool yarn producers are focusing on niche, high-value segments rather than competing on volume. Hand-knitting yarns for the artisan and craft market—especially those emphasizing natural dyes, regional identity, and small-batch production—are seeing growth. Brands like Tricô Arte and Circulo S.A. are leveraging digital platforms to reach both domestic and export markets with premium, design-focused wool and wool-blend offerings. The “Made in Brazil” label, associated with creativity and craftsmanship, adds value in export markets like the U.S. and Europe.

4. Influence of Global Fashion Cycles and Economic Conditions:

The 2026 outlook is sensitive to global economic health. Recessionary pressures in major economies could dampen demand for luxury and fashion wool garments, impacting Brazilian exporters. Conversely, a rebound in consumer spending—especially in North America and Europe—could boost orders for Brazilian-produced yarns used in high-end knitwear. Fashion trends favoring natural textures, slow fashion, and winter wear will positively influence wool yarn demand.

5. Technological Advancements and Blending Innovation:

To remain competitive, Brazilian spinners are investing in technology to improve yarn consistency, softness, and dye uptake. There is increasing innovation in blending wool with technical fibers (e.g., TENCEL™, recycled polyester) to enhance performance (moisture-wicking, durability) while maintaining wool’s natural benefits. Digitalization in supply chain management and e-commerce platforms will also streamline distribution and connect producers directly with end-users.

6. Challenges: Cost Pressures and Competition:

High production costs in Brazil—driven by energy prices, logistics inefficiencies, and labor—continue to challenge competitiveness. Brazilian wool yarns often face stiff competition from lower-cost producers in China, Turkey, and India. Additionally, inflation and interest rate pressures within Brazil may constrain domestic consumer spending on non-essentials, including premium yarns.

Conclusion:

By 2026, the Brazilian wool yarn market will likely remain a specialized, import-dependent sector focused on sustainability, craftsmanship, and premium product differentiation. Success will hinge on the industry’s ability to leverage its creative strengths, embrace eco-certifications, expand digital outreach, and adapt to global fiber trends—while managing structural cost and supply vulnerabilities. Growth is expected in niche and export-oriented segments, rather than broad market expansion.

Common Pitfalls When Sourcing Brazilian Wool Yarn (Quality and Intellectual Property)

Sourcing Brazilian wool yarn can offer unique benefits, such as access to regional fiber characteristics and sustainable practices. However, importers and manufacturers often encounter several pitfalls related to quality consistency and intellectual property (IP) concerns. Being aware of these challenges can help mitigate risks and ensure a reliable supply chain.

Inconsistent Fiber Quality and Specifications

One of the most frequent issues when sourcing Brazilian wool yarn is variability in fiber quality. Brazilian wool, often sourced from crossbred sheep in the southern states like Rio Grande do Sul, can vary significantly in micron count, staple length, and cleanliness. Without strict quality control protocols, suppliers may deliver batches that differ in fineness, strength, or color, leading to production disruptions and inconsistent end-product performance. Buyers should demand detailed technical specifications and third-party lab testing (e.g., SGS or Intertek) to verify fiber attributes.

Lack of Traceability and Transparency

Many Brazilian wool suppliers operate within fragmented supply chains, making it difficult to trace the origin of the wool. This lack of traceability raises concerns about animal welfare practices, sustainability claims, and the use of chemicals during processing. Without clear documentation, brands risk reputational damage or non-compliance with international regulations (e.g., REACH, Oeko-Tex). Ensure suppliers provide full chain-of-custody documentation and consider partnering with certified farms or mills.

Misrepresentation of Fiber Content and Blends

Some suppliers may mislabel wool blends or exaggerate the percentage of pure wool versus synthetic fibers. This constitutes both a quality and a legal issue, potentially violating consumer protection laws in importing countries. Always request a fiber content certificate and conduct random batch testing to confirm claims. Clear contracts with penalties for misrepresentation are essential.

Intellectual Property Risks in Yarn Design and Branding

When sourcing custom or specialty yarns, there is a risk of intellectual property (IP) infringement, especially if the supplier replicates proprietary blends, textures, or colorways for other clients. Brazilian IP laws protect designs and trademarks, but enforcement can be inconsistent. To protect your IP:

– Sign a robust Non-Disclosure Agreement (NDA) and Manufacturing Agreement specifying IP ownership.

– Register trademarks and design patents in Brazil if planning long-term collaborations.

– Avoid sharing sensitive technical data unless legally protected.

Limited Standardization in Processing Methods

Brazilian wool often undergoes varied processing techniques—scouring, carding, spinning—that affect the final yarn’s hand feel, durability, and dye uptake. Without adherence to international standards (e.g., ISO or AWTA protocols), results can be unpredictable. Request samples processed under consistent conditions and insist on process documentation.

Currency and Contractual Instability

While not directly a quality or IP issue, economic volatility in Brazil (e.g., BRL fluctuations, import/export regulations) can indirectly impact yarn quality. Suppliers under financial pressure may cut corners on fiber selection or processing. Use fixed-price contracts with quality clauses and consider escrow arrangements to ensure performance.

Conclusion

Successfully sourcing Brazilian wool yarn requires due diligence in vetting suppliers, enforcing quality standards, and protecting intellectual property. Partnering with reputable, certified suppliers and investing in clear legal frameworks can help avoid common pitfalls and build a sustainable, ethical supply chain.

Logistics & Compliance Guide for Brazilian Wool Yarn

Overview of Brazilian Wool Yarn Exports

Brazil is a notable producer of high-quality wool yarn, primarily derived from Merino and Corriedale sheep breeds. The country’s wool industry emphasizes sustainable farming and processing, making its yarn desirable in international markets. Export logistics and compliance are critical to maintaining market access and ensuring smooth customs clearance in destination countries.

Export Classification and Tariff Codes

Identify the correct Harmonized System (HS) code for wool yarn to ensure accurate customs declarations. For Brazilian wool yarn:

– HS Code: Typically 5109.11 (combed wool yarn) or 5109.19 (other wool yarn), depending on processing and fiber characteristics.

– Accuracy in classification affects tariffs, quotas, and eligibility for trade agreements. Always verify with Brazil’s Secretariat of Foreign Trade (SECEX) or a customs broker.

Brazilian Export Regulations

All exporters must comply with national regulations administered by the Ministry of Development, Industry, Trade, and Services (MDIC):

– RADAR Registration: Exporters must be registered in the RADAR system, part of the Integrated Foreign Trade System (SISCOMEX).

– Export Declaration (DE): File a DE through SISCOMEX, detailing product specifications, value, origin, and destination.

– Phytosanitary and Health Certification: While wool is animal-origin, it may require a Veterinary Health Certificate issued by the Ministry of Agriculture, Livestock, and Supply (MAPA), especially if processed with additives or blended with regulated fibers.

Labeling and Packaging Requirements

Ensure packaging and labeling meet both Brazilian and destination country standards:

– Labeling: Include fiber content (e.g., 100% wool), weight, color, lot number, manufacturer details, and care instructions. Labels must be in Portuguese for domestic handling; English or local language may be required for export.

– Packaging: Use moisture-resistant, durable materials suitable for maritime or air transport. Properly secured spools or cones prevent damage during transit.

Transportation and Logistics

Choose the appropriate logistics method based on cost, delivery speed, and destination:

– Sea Freight: Most cost-effective for large volumes; common ports include Santos, Rio de Janeiro, and Paranaguá. Use FCL (Full Container Load) or LCL (Less than Container Load).

– Air Freight: Faster but more expensive; suitable for urgent or high-value orders.

– Incoterms: Clearly define responsibilities using standard Incoterms (e.g., FOB, CIF, DAP). Most wool yarn exports use FOB Santos or CIF destination.

Documentation for Export

Prepare a complete export dossier:

– Commercial Invoice

– Packing List

– Bill of Lading (B/L) or Air Waybill (AWB)

– Export Declaration (DE)

– Certificate of Origin (often required for preferential tariffs under trade agreements)

– Veterinary Health Certificate (if applicable)

– Any additional certifications requested by the importer (e.g., OEKO-TEX®, RWS)

Import Compliance in Target Markets

Understand the regulatory environment of the destination country:

– United States: Comply with U.S. Customs and Border Protection (CBP) and FTC labeling rules (e.g., fiber content, country of origin).

– European Union: Meet REACH and Ecolabel standards; ensure compliance with chemical restrictions and sustainable sourcing.

– Canada: Adhere to Textile Labeling Act requirements and CBSA import procedures.

Sustainability and Certification

Increasingly, buyers demand proof of ethical and environmental compliance:

– Responsible Wool Standard (RWS): Certification verifies animal welfare and land management practices.

– OEKO-TEX® Standard 100: Ensures yarn is free from harmful substances.

– Carbon Neutrality Claims: May require third-party verification if promoted.

Risk Management and Insurance

- Cargo Insurance: Protect against loss or damage during transit (e.g., marine insurance).

- Political and Currency Risk: Monitor exchange rates and consider hedging strategies.

- Supply Chain Transparency: Maintain records from farm to shipment for audit readiness.

Conclusion

Exporting Brazilian wool yarn requires careful coordination of logistics, accurate documentation, and strict adherence to both domestic and international regulations. By following this guide and partnering with experienced freight forwarders and compliance consultants, exporters can ensure timely delivery and maintain a strong reputation in global textile markets.

Conclusion for Sourcing Brazilian Wool Yarn

Sourcing Brazilian wool yarn presents a unique opportunity for businesses seeking high-quality, sustainable, and ethically produced textile materials. Brazil’s favorable climate and established livestock farming practices contribute to the production of fine, resilient wool, particularly from Merino and other adapted breeds. Additionally, the country’s growing emphasis on responsible farming, animal welfare, and environmental stewardship enhances the appeal of its wool on the global market.

While challenges such as higher production costs, logistical considerations, and smaller-scale output compared to traditional wool-producing nations exist, the advantages—such as traceability, innovation in processing, and alignment with eco-conscious consumer demands—make Brazilian wool yarn a competitive and valuable option. Building strong partnerships with local cooperatives and certified suppliers can further ensure consistency, quality, and ethical compliance.

In conclusion, sourcing Brazilian wool yarn supports sustainability goals, promotes ethical sourcing practices, and offers access to a distinctive, high-performance fiber. For brands focused on quality and responsibility, integrating Brazilian wool into their supply chain represents a strategic and forward-thinking decision in the global textile industry.